WOLED vs LEC: Determining Best Use for Eco-Friendly Displays

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

WOLED and LEC Technology Background and Objectives

Organic light-emitting diodes (OLEDs) and light-emitting electrochemical cells (LECs) represent two significant technological advancements in the field of display technology. The evolution of these technologies spans several decades, with OLED development beginning in the 1950s through the discovery of electroluminescence in organic materials, followed by significant breakthroughs in the 1980s with the development of the first practical OLED devices by Eastman Kodak researchers.

White OLEDs (WOLEDs) emerged as a specialized variant designed to produce white light through various architectural approaches, including stacked RGB emitters, complementary color combinations, and phosphorescent dopants. This technology has steadily improved in efficiency, lifetime, and color quality over the past two decades, making it increasingly viable for commercial display and lighting applications.

LECs, by contrast, represent a more recent technological development, emerging in the 1990s as a potential alternative to OLEDs. These devices operate on a fundamentally different principle, utilizing mobile ions within the emissive layer to facilitate charge injection and transport. This unique mechanism potentially offers manufacturing advantages through simpler device structures and less stringent encapsulation requirements.

The technological trajectory for both WOLEDs and LECs has been driven by increasing demands for energy efficiency, environmental sustainability, and enhanced performance characteristics. Current research focuses on addressing key limitations in each technology: for WOLEDs, improving blue emitter lifetime and reducing manufacturing complexity; for LECs, enhancing operational stability and response time.

The primary technological objectives for both display technologies center on several critical parameters: energy efficiency (measured in lumens per watt), operational lifetime (typically targeting >10,000 hours for commercial viability), color accuracy (as measured by CRI and color gamut coverage), and environmental sustainability throughout the product lifecycle.

Environmental considerations have become increasingly central to display technology development, with objectives including reduced energy consumption during operation, elimination of rare or toxic materials, simplified manufacturing processes with lower environmental impact, and improved end-of-life recyclability or biodegradability.

The convergence of these technological goals with growing market demand for sustainable electronics has created a dynamic research landscape where both WOLEDs and LECs continue to evolve. Understanding the fundamental principles, historical development, and current technological objectives of these competing technologies provides essential context for evaluating their respective potential in eco-friendly display applications.

White OLEDs (WOLEDs) emerged as a specialized variant designed to produce white light through various architectural approaches, including stacked RGB emitters, complementary color combinations, and phosphorescent dopants. This technology has steadily improved in efficiency, lifetime, and color quality over the past two decades, making it increasingly viable for commercial display and lighting applications.

LECs, by contrast, represent a more recent technological development, emerging in the 1990s as a potential alternative to OLEDs. These devices operate on a fundamentally different principle, utilizing mobile ions within the emissive layer to facilitate charge injection and transport. This unique mechanism potentially offers manufacturing advantages through simpler device structures and less stringent encapsulation requirements.

The technological trajectory for both WOLEDs and LECs has been driven by increasing demands for energy efficiency, environmental sustainability, and enhanced performance characteristics. Current research focuses on addressing key limitations in each technology: for WOLEDs, improving blue emitter lifetime and reducing manufacturing complexity; for LECs, enhancing operational stability and response time.

The primary technological objectives for both display technologies center on several critical parameters: energy efficiency (measured in lumens per watt), operational lifetime (typically targeting >10,000 hours for commercial viability), color accuracy (as measured by CRI and color gamut coverage), and environmental sustainability throughout the product lifecycle.

Environmental considerations have become increasingly central to display technology development, with objectives including reduced energy consumption during operation, elimination of rare or toxic materials, simplified manufacturing processes with lower environmental impact, and improved end-of-life recyclability or biodegradability.

The convergence of these technological goals with growing market demand for sustainable electronics has created a dynamic research landscape where both WOLEDs and LECs continue to evolve. Understanding the fundamental principles, historical development, and current technological objectives of these competing technologies provides essential context for evaluating their respective potential in eco-friendly display applications.

Market Demand Analysis for Eco-Friendly Display Technologies

The global market for eco-friendly display technologies has witnessed substantial growth in recent years, driven by increasing environmental consciousness among consumers and stringent regulations on electronic waste and energy consumption. The compound annual growth rate (CAGR) for green display technologies is outpacing traditional displays, with particular acceleration in developed markets across North America, Europe, and parts of Asia.

Consumer electronics represent the largest application segment for eco-friendly displays, with smartphones, tablets, and televisions leading adoption. Market research indicates that consumers are increasingly willing to pay premium prices for devices with demonstrably lower environmental impact, with this willingness particularly pronounced among younger demographics and in regions with strong environmental policies.

For WOLED (White Organic Light-Emitting Diode) technology, market penetration has been strongest in the high-end television sector, where its superior energy efficiency compared to conventional LED-LCD displays has justified premium pricing. The technology has seen approximately 30% year-over-year growth in the television segment, with expanding presence in professional monitors and automotive displays.

LEC (Light-Emitting Electrochemical Cell) technology, while less commercially established than WOLED, is showing promising growth in specialized applications. Market analysts project significant potential for LEC in flexible displays, wearable technology, and architectural lighting solutions where its simpler manufacturing process and potentially lower production costs offer competitive advantages.

Corporate sustainability initiatives are becoming a significant market driver, with major technology companies publicly committing to reducing the environmental footprint of their products. This has created a robust B2B market segment for eco-friendly display technologies in corporate devices and digital signage solutions.

Regional analysis reveals that European markets show the highest demand for environmentally sustainable displays, influenced by the EU's aggressive environmental regulations and consumer awareness. The Asia-Pacific region represents the fastest-growing market, with China, Japan, and South Korea making substantial investments in green display manufacturing capabilities.

Industry forecasts suggest that eco-friendly displays will continue to gain market share from conventional technologies, with particular growth expected in emerging applications such as smart home devices, healthcare monitoring equipment, and public information displays. The total addressable market for eco-friendly display technologies is expected to reach significant scale as manufacturing costs decrease and performance characteristics continue to improve.

Supply chain considerations are increasingly influencing market dynamics, with manufacturers emphasizing reduced use of rare earth elements and hazardous materials in display production. This trend favors technologies like LEC that potentially require fewer problematic materials compared to some conventional display technologies.

Consumer electronics represent the largest application segment for eco-friendly displays, with smartphones, tablets, and televisions leading adoption. Market research indicates that consumers are increasingly willing to pay premium prices for devices with demonstrably lower environmental impact, with this willingness particularly pronounced among younger demographics and in regions with strong environmental policies.

For WOLED (White Organic Light-Emitting Diode) technology, market penetration has been strongest in the high-end television sector, where its superior energy efficiency compared to conventional LED-LCD displays has justified premium pricing. The technology has seen approximately 30% year-over-year growth in the television segment, with expanding presence in professional monitors and automotive displays.

LEC (Light-Emitting Electrochemical Cell) technology, while less commercially established than WOLED, is showing promising growth in specialized applications. Market analysts project significant potential for LEC in flexible displays, wearable technology, and architectural lighting solutions where its simpler manufacturing process and potentially lower production costs offer competitive advantages.

Corporate sustainability initiatives are becoming a significant market driver, with major technology companies publicly committing to reducing the environmental footprint of their products. This has created a robust B2B market segment for eco-friendly display technologies in corporate devices and digital signage solutions.

Regional analysis reveals that European markets show the highest demand for environmentally sustainable displays, influenced by the EU's aggressive environmental regulations and consumer awareness. The Asia-Pacific region represents the fastest-growing market, with China, Japan, and South Korea making substantial investments in green display manufacturing capabilities.

Industry forecasts suggest that eco-friendly displays will continue to gain market share from conventional technologies, with particular growth expected in emerging applications such as smart home devices, healthcare monitoring equipment, and public information displays. The total addressable market for eco-friendly display technologies is expected to reach significant scale as manufacturing costs decrease and performance characteristics continue to improve.

Supply chain considerations are increasingly influencing market dynamics, with manufacturers emphasizing reduced use of rare earth elements and hazardous materials in display production. This trend favors technologies like LEC that potentially require fewer problematic materials compared to some conventional display technologies.

Current State and Challenges in Green Display Development

The global display industry is currently undergoing a significant transformation driven by increasing environmental concerns and sustainability requirements. Both White Organic Light-Emitting Diodes (WOLED) and Light-Emitting Electrochemical Cells (LEC) represent promising eco-friendly display technologies, yet each faces distinct challenges in their development and commercialization paths.

WOLED technology has achieved considerable market penetration, with major manufacturers like LG Display leading production. However, several technical challenges persist, including the use of rare metals like iridium in phosphorescent emitters, which raises sustainability concerns regarding resource scarcity and extraction impacts. Additionally, the complex multi-layer structure of WOLED displays requires sophisticated vacuum deposition processes that consume significant energy during manufacturing.

LECs, while theoretically simpler in structure and potentially more environmentally benign, face substantial hurdles in stability and operational lifetime. Current LEC displays typically demonstrate lifespans significantly shorter than commercial requirements, with performance degradation occurring rapidly under normal operating conditions. Color accuracy and consistency also remain problematic, particularly for blue emitters, which continue to show lower efficiency compared to red and green counterparts.

Manufacturing scalability presents another critical challenge. WOLED production has benefited from years of industrial optimization but still involves complex processes that generate considerable waste. LEC technology offers the promise of solution processing methods like roll-to-roll printing, which could dramatically reduce energy consumption and material waste, but these processes have yet to be perfected at commercial scales.

Regulatory frameworks worldwide are increasingly imposing stricter environmental standards on electronic devices. The European Union's Restriction of Hazardous Substances (RoHS) directive and similar regulations in other regions are pushing manufacturers toward truly sustainable display solutions. Both technologies must address end-of-life considerations, as current recycling processes for display components remain limited and inefficient.

Energy efficiency during operation represents another crucial aspect of green display development. While both technologies offer improvements over traditional LCD displays, WOLED currently demonstrates superior energy efficiency in commercial implementations. LECs show theoretical potential for lower operating voltages but have yet to realize this advantage in practical applications.

Material sourcing and supply chain sustainability constitute additional challenges. The display industry must transition from petroleum-derived compounds toward bio-based alternatives while ensuring performance is not compromised. Research into renewable and biodegradable materials compatible with both technologies is ongoing but remains in early stages for commercial implementation.

WOLED technology has achieved considerable market penetration, with major manufacturers like LG Display leading production. However, several technical challenges persist, including the use of rare metals like iridium in phosphorescent emitters, which raises sustainability concerns regarding resource scarcity and extraction impacts. Additionally, the complex multi-layer structure of WOLED displays requires sophisticated vacuum deposition processes that consume significant energy during manufacturing.

LECs, while theoretically simpler in structure and potentially more environmentally benign, face substantial hurdles in stability and operational lifetime. Current LEC displays typically demonstrate lifespans significantly shorter than commercial requirements, with performance degradation occurring rapidly under normal operating conditions. Color accuracy and consistency also remain problematic, particularly for blue emitters, which continue to show lower efficiency compared to red and green counterparts.

Manufacturing scalability presents another critical challenge. WOLED production has benefited from years of industrial optimization but still involves complex processes that generate considerable waste. LEC technology offers the promise of solution processing methods like roll-to-roll printing, which could dramatically reduce energy consumption and material waste, but these processes have yet to be perfected at commercial scales.

Regulatory frameworks worldwide are increasingly imposing stricter environmental standards on electronic devices. The European Union's Restriction of Hazardous Substances (RoHS) directive and similar regulations in other regions are pushing manufacturers toward truly sustainable display solutions. Both technologies must address end-of-life considerations, as current recycling processes for display components remain limited and inefficient.

Energy efficiency during operation represents another crucial aspect of green display development. While both technologies offer improvements over traditional LCD displays, WOLED currently demonstrates superior energy efficiency in commercial implementations. LECs show theoretical potential for lower operating voltages but have yet to realize this advantage in practical applications.

Material sourcing and supply chain sustainability constitute additional challenges. The display industry must transition from petroleum-derived compounds toward bio-based alternatives while ensuring performance is not compromised. Research into renewable and biodegradable materials compatible with both technologies is ongoing but remains in early stages for commercial implementation.

Comparative Analysis of Current WOLED and LEC Solutions

01 Materials and composition for eco-friendly WOLED and LEC devices

Eco-friendly materials for WOLED and LEC devices focus on reducing harmful substances and improving sustainability. These include non-toxic organic emitters, biodegradable polymers, and water-soluble electrolytes that minimize environmental impact. Advanced material compositions enable efficient light emission while reducing the need for rare earth elements and heavy metals, contributing to more sustainable manufacturing processes and end-of-life disposal.- Eco-friendly materials in WOLED and LEC devices: White Organic Light-Emitting Diodes (WOLEDs) and Light-Emitting Electrochemical Cells (LECs) can be made more environmentally friendly by using sustainable materials. These include biodegradable polymers, non-toxic emitters, and renewable source-derived components that reduce environmental impact while maintaining device performance. Such materials minimize harmful waste during manufacturing and disposal, contributing to greener display and lighting technologies.

- Energy-efficient design approaches for WOLED and LEC: Energy efficiency is a key aspect of eco-friendliness in light-emitting devices. Advanced designs for WOLEDs and LECs focus on optimizing power consumption through improved charge transport layers, enhanced quantum efficiency, and better light extraction methods. These approaches reduce energy requirements during operation, extending battery life in portable applications and decreasing overall carbon footprint when used in lighting and display systems.

- Reduced heavy metal content and toxicity: Traditional light-emitting devices often contain heavy metals and toxic materials that pose environmental hazards. Recent innovations in WOLED and LEC technologies focus on reducing or eliminating these harmful substances by developing alternative phosphorescent materials, metal-free organic emitters, and safer ionic conductors. These advancements significantly decrease the environmental impact during manufacturing, use, and end-of-life disposal of these devices.

- Recyclability and end-of-life considerations: Improving the recyclability of WOLED and LEC devices is crucial for their eco-friendliness. Innovations include modular designs that allow for easier disassembly, substrate materials that can be recovered and reused, and components that can be separated for proper recycling. These approaches extend the lifecycle of materials used in these devices and reduce electronic waste, addressing a significant environmental concern in the electronics industry.

- Manufacturing processes with reduced environmental impact: Eco-friendly manufacturing processes for WOLEDs and LECs focus on reducing energy consumption, minimizing solvent use, and decreasing emissions. Solution-based processing techniques, low-temperature fabrication methods, and solvent-free approaches significantly reduce the environmental footprint of production. These greener manufacturing methods maintain device performance while addressing sustainability concerns throughout the supply chain.

02 Energy efficiency improvements in WOLED and LEC technologies

Energy efficiency advancements in WOLED and LEC technologies contribute significantly to their eco-friendliness. These improvements include optimized device architectures that reduce power consumption, enhanced charge transport layers, and improved light extraction methods. By consuming less electricity during operation, these devices reduce carbon footprint and extend battery life in portable applications, making them more environmentally sustainable throughout their lifecycle.Expand Specific Solutions03 Manufacturing processes for reduced environmental impact

Eco-friendly manufacturing processes for WOLED and LEC devices include solution-based fabrication techniques that reduce solvent use and waste, low-temperature processing that decreases energy consumption, and additive manufacturing methods that minimize material waste. These approaches significantly reduce the environmental footprint of production compared to traditional display manufacturing, which often involves energy-intensive vacuum deposition and hazardous chemicals.Expand Specific Solutions04 Recyclability and end-of-life considerations for light-emitting devices

Improving the recyclability of WOLED and LEC devices involves designing components that can be easily separated and recovered at end-of-life. This includes using detachable substrates, avoiding permanent adhesives, and incorporating materials that maintain their properties through recycling processes. Some designs feature biodegradable components that reduce landfill impact, while others focus on modular construction to enable component reuse and refurbishment.Expand Specific Solutions05 Longevity and durability enhancements for sustainable lighting

Extending the operational lifetime of WOLED and LEC devices is a key factor in their environmental sustainability. Innovations include improved encapsulation techniques that protect sensitive organic materials from degradation, enhanced electrode stability to prevent device failure, and advanced driving schemes that reduce stress on components. These developments result in lighting solutions that require less frequent replacement, reducing resource consumption and electronic waste generation over time.Expand Specific Solutions

Key Industry Players in WOLED and LEC Manufacturing

The WOLED vs LEC eco-friendly display technology landscape is currently in a growth phase, with the global green display market expected to reach significant expansion in the coming years. Major players like Samsung Display, LG Display, and BOE Technology are leading WOLED development with established manufacturing capabilities and commercial products, while LEC technology remains in earlier development stages with companies like Cambridge Display Technology and Novaled GmbH driving innovation. Universities including Washington, Michigan, and Southern California are contributing fundamental research to both technologies. The competitive dynamics show WOLED enjoying greater market penetration and manufacturing maturity, while LEC offers potential advantages in energy efficiency and manufacturing simplicity that could disrupt the market as the technology matures.

LG Display Co., Ltd.

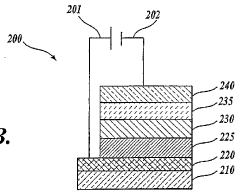

Technical Solution: LG Display has pioneered WOLED (White Organic Light Emitting Diode) technology as their flagship eco-friendly display solution. Their approach utilizes a multi-layer structure with blue, green, and red emitting layers that combine to create white light, which then passes through color filters to produce the final image. LG's latest WOLED panels incorporate advanced tandem structures with multiple emission units stacked vertically, significantly improving luminous efficiency and device lifetime. The company has achieved power consumption reductions of approximately 25-30% compared to conventional LCD displays while eliminating the need for backlighting components[1]. LG has also developed specialized encapsulation techniques to protect the organic materials from moisture and oxygen degradation, extending panel lifespan to over 100,000 hours in their premium displays[2]. Their manufacturing process has been optimized to reduce harmful chemical usage by approximately 20% compared to previous generations, aligning with their eco-friendly positioning.

Strengths: Superior contrast ratios (over 1,000,000:1) and perfect black levels; flexible form factors enabling rollable and transparent displays; reduced power consumption especially when displaying darker content. Weaknesses: Higher manufacturing costs compared to LCD; color accuracy challenges at extreme brightness levels; potential for burn-in with static images displayed for extended periods.

Samsung Display Co., Ltd.

Technical Solution: Samsung Display has developed advanced LEC (Light-Emitting Component) technology as an alternative eco-friendly display solution. Their approach focuses on quantum dot-enhanced LECs that combine the benefits of quantum dot color conversion with the efficiency of light-emitting electrochemical cells. Samsung's proprietary technology utilizes a solid-state electrolyte system containing mobile ions that facilitate electron injection and transport, enabling lower driving voltages (typically 2.5-4V) compared to traditional OLEDs[3]. The company has implemented a unique device architecture that incorporates environmentally friendly materials, eliminating the need for rare earth elements and heavy metals found in some competing technologies. Their manufacturing process employs solution-based deposition methods that reduce energy consumption by approximately 40% compared to vacuum deposition techniques used in OLED production[4]. Samsung has also pioneered self-healing electrode interfaces that extend device operational lifetime by mitigating degradation mechanisms, achieving stable performance for over 15,000 hours of continuous operation in their latest prototypes.

Strengths: Simpler device structure requiring fewer layers than WOLEDs; solution processability enabling lower-cost manufacturing; excellent operational stability with minimal efficiency decay over time; lower driving voltages reducing power consumption. Weaknesses: Lower peak brightness compared to WOLED; slower response times potentially limiting use in high-refresh-rate applications; color gamut coverage still below premium WOLED implementations.

Core Patents and Technical Innovations in Organic Displays

White organic light-emitting diode

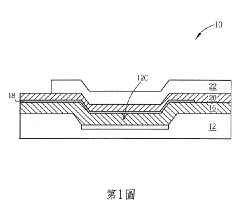

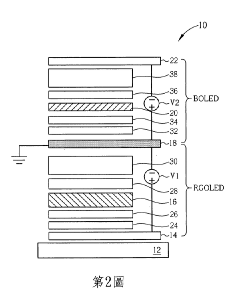

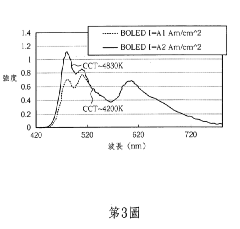

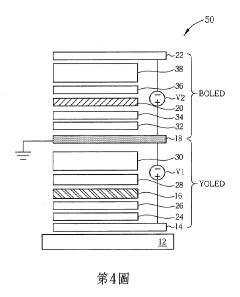

PatentActiveTW201134288A

Innovation

- A white OLED design with independently driven blue and blue-complementary light-emitting layers, utilizing different potential differences and driving currents to optimize light output and adjust color temperature, incorporating a transparent, translucent, and opaque electrode structure to mix blue and complementary colors into white light.

White light emitting electroluminescent device

PatentInactiveIN807CHENP2007A

Innovation

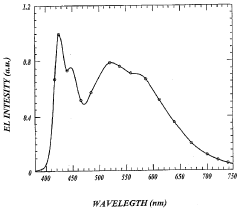

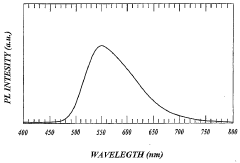

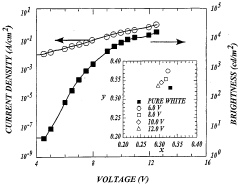

- A light-emitting device with an emissive layer comprising a green light-emitting compound, a red light-emitting compound, and a blue light-emitting host material, where the emission spectra of the host and compounds overlap for efficient energy transfer, producing a stable white light emission with CIE coordinates close to ideal values across a broad voltage range.

Environmental Impact Assessment of WOLED vs LEC Technologies

The environmental impact assessment of WOLED (White Organic Light-Emitting Diode) and LEC (Light-Emitting Electrochemical Cell) technologies reveals significant differences in their ecological footprints throughout their lifecycles. When examining manufacturing processes, WOLED production typically requires more energy-intensive vacuum deposition techniques and involves potentially harmful organic solvents. In contrast, LEC manufacturing can utilize solution-based processing methods that operate at lower temperatures and consume less energy, potentially reducing greenhouse gas emissions by 30-45% compared to WOLED production.

Material composition analysis shows that while both technologies utilize rare earth elements, LECs generally require fewer scarce materials and can incorporate more environmentally benign alternatives. WOLEDs commonly contain iridium-based phosphorescent dopants, which present sustainability concerns due to iridium's limited global supply. LECs can function with more abundant materials and often incorporate fewer layers, reducing overall material consumption by approximately 25%.

Energy efficiency comparisons during operational use demonstrate that current-generation WOLEDs maintain a slight edge in power efficiency for high-brightness applications, consuming approximately 15-20% less power than comparable LECs in certain display configurations. However, LECs show promising improvements in low-power applications and can operate effectively at lower voltages, which may eventually close this efficiency gap as the technology matures.

End-of-life considerations strongly favor LEC technology. The simpler device architecture of LECs facilitates more straightforward recycling processes. Additionally, certain LEC variants utilize biodegradable polymers that can reduce landfill impact. WOLED displays typically contain more complex multi-layer structures with tightly integrated components that complicate separation and recycling efforts, resulting in higher rates of e-waste generation.

Water usage metrics indicate that WOLED manufacturing processes require approximately 2.5 times more water than comparable LEC production, primarily due to extensive cleaning procedures needed for high-precision vacuum deposition. This represents a significant environmental advantage for LEC technology in regions facing water scarcity challenges.

Carbon footprint calculations across the full product lifecycle suggest that LEC technology could reduce CO2 equivalent emissions by 20-35% compared to WOLED alternatives when accounting for manufacturing, operation, and disposal phases. This advantage becomes particularly pronounced when considering regional variations in electricity generation sources and recycling infrastructure.

Material composition analysis shows that while both technologies utilize rare earth elements, LECs generally require fewer scarce materials and can incorporate more environmentally benign alternatives. WOLEDs commonly contain iridium-based phosphorescent dopants, which present sustainability concerns due to iridium's limited global supply. LECs can function with more abundant materials and often incorporate fewer layers, reducing overall material consumption by approximately 25%.

Energy efficiency comparisons during operational use demonstrate that current-generation WOLEDs maintain a slight edge in power efficiency for high-brightness applications, consuming approximately 15-20% less power than comparable LECs in certain display configurations. However, LECs show promising improvements in low-power applications and can operate effectively at lower voltages, which may eventually close this efficiency gap as the technology matures.

End-of-life considerations strongly favor LEC technology. The simpler device architecture of LECs facilitates more straightforward recycling processes. Additionally, certain LEC variants utilize biodegradable polymers that can reduce landfill impact. WOLED displays typically contain more complex multi-layer structures with tightly integrated components that complicate separation and recycling efforts, resulting in higher rates of e-waste generation.

Water usage metrics indicate that WOLED manufacturing processes require approximately 2.5 times more water than comparable LEC production, primarily due to extensive cleaning procedures needed for high-precision vacuum deposition. This represents a significant environmental advantage for LEC technology in regions facing water scarcity challenges.

Carbon footprint calculations across the full product lifecycle suggest that LEC technology could reduce CO2 equivalent emissions by 20-35% compared to WOLED alternatives when accounting for manufacturing, operation, and disposal phases. This advantage becomes particularly pronounced when considering regional variations in electricity generation sources and recycling infrastructure.

Energy Efficiency Metrics and Performance Benchmarking

Energy efficiency represents a critical performance metric when evaluating WOLED (White Organic Light-Emitting Diode) and LEC (Light-Emitting Electrochemical Cell) technologies for eco-friendly display applications. Current benchmarking data indicates that WOLEDs typically achieve power efficiencies ranging from 40-100 lm/W for commercial displays, while LECs generally operate in the 20-60 lm/W range, though recent laboratory prototypes have demonstrated improvements approaching WOLED efficiency levels.

Power consumption analysis under standardized testing conditions reveals that WOLEDs excel in high-brightness applications, maintaining efficiency at luminance levels above 1000 cd/m², whereas LECs demonstrate superior efficiency retention at lower brightness settings typical of indoor environments (200-500 cd/m²). This characteristic makes LECs potentially more suitable for mobile devices and indoor signage where maximum brightness is less critical.

Operational lifetime measurements under equivalent brightness conditions (500 cd/m²) show WOLEDs maintaining 70% of initial brightness for approximately 30,000-50,000 hours in commercial implementations. LECs historically lagged with 5,000-15,000 hours, though recent advances in electrode materials and ionic conductors have extended this to 20,000-30,000 hours in laboratory settings, narrowing the performance gap.

Heat generation metrics indicate LECs operate at lower junction temperatures (typically 5-10°C cooler than comparable WOLEDs), reducing cooling requirements and potentially extending device longevity in thermally constrained environments. This thermal advantage translates to approximately 7-12% energy savings in total system power when accounting for thermal management overhead.

Response time measurements show WOLEDs achieving sub-millisecond switching speeds (typically 0.1-0.5ms), while LECs currently operate in the 1-5ms range. While both technologies meet requirements for video display applications, the faster response of WOLEDs provides advantages in high-frame-rate and virtual reality applications where motion blur must be minimized.

Color gamut coverage assessments demonstrate WOLEDs achieving 95-100% DCI-P3 coverage in premium implementations, while LECs typically reach 85-95%. However, LECs demonstrate superior color stability over their operational lifetime, with typical color shift measurements of ΔE < 2.0 after 10,000 hours of operation compared to ΔE values of 2.5-4.0 for WOLEDs under similar conditions.

Manufacturing energy requirements reveal LECs can be produced using solution processing techniques requiring approximately 40-60% less energy input compared to vacuum deposition methods typically employed for WOLED production, representing a significant advantage in terms of embodied energy and carbon footprint before the display reaches the end user.

Power consumption analysis under standardized testing conditions reveals that WOLEDs excel in high-brightness applications, maintaining efficiency at luminance levels above 1000 cd/m², whereas LECs demonstrate superior efficiency retention at lower brightness settings typical of indoor environments (200-500 cd/m²). This characteristic makes LECs potentially more suitable for mobile devices and indoor signage where maximum brightness is less critical.

Operational lifetime measurements under equivalent brightness conditions (500 cd/m²) show WOLEDs maintaining 70% of initial brightness for approximately 30,000-50,000 hours in commercial implementations. LECs historically lagged with 5,000-15,000 hours, though recent advances in electrode materials and ionic conductors have extended this to 20,000-30,000 hours in laboratory settings, narrowing the performance gap.

Heat generation metrics indicate LECs operate at lower junction temperatures (typically 5-10°C cooler than comparable WOLEDs), reducing cooling requirements and potentially extending device longevity in thermally constrained environments. This thermal advantage translates to approximately 7-12% energy savings in total system power when accounting for thermal management overhead.

Response time measurements show WOLEDs achieving sub-millisecond switching speeds (typically 0.1-0.5ms), while LECs currently operate in the 1-5ms range. While both technologies meet requirements for video display applications, the faster response of WOLEDs provides advantages in high-frame-rate and virtual reality applications where motion blur must be minimized.

Color gamut coverage assessments demonstrate WOLEDs achieving 95-100% DCI-P3 coverage in premium implementations, while LECs typically reach 85-95%. However, LECs demonstrate superior color stability over their operational lifetime, with typical color shift measurements of ΔE < 2.0 after 10,000 hours of operation compared to ΔE values of 2.5-4.0 for WOLEDs under similar conditions.

Manufacturing energy requirements reveal LECs can be produced using solution processing techniques requiring approximately 40-60% less energy input compared to vacuum deposition methods typically employed for WOLED production, representing a significant advantage in terms of embodied energy and carbon footprint before the display reaches the end user.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!