How To Advance Additive Manufacturing With Tungsten?

Tungsten AM Background

Additive manufacturing (AM) with tungsten has emerged as a promising frontier in advanced manufacturing technologies. Tungsten, known for its exceptional properties such as high melting point, excellent thermal conductivity, and superior radiation shielding capabilities, has long been a material of interest in various high-performance applications. However, traditional manufacturing methods have often struggled to fully harness tungsten's potential due to its inherent challenges in processing.

The journey of tungsten in AM began in the early 2000s, with initial experiments focusing on powder bed fusion techniques. These early attempts faced significant hurdles, primarily due to tungsten's high melting point and tendency to oxidize rapidly at elevated temperatures. Despite these challenges, researchers persevered, driven by the potential benefits of creating complex tungsten components with unprecedented geometries and internal structures.

As AM technologies evolved, so did the approaches to working with tungsten. The development of high-power lasers and electron beam systems in the 2010s marked a turning point, enabling more effective melting and consolidation of tungsten powders. This progress opened up new possibilities in fields such as nuclear fusion research, aerospace, and medical imaging, where tungsten's unique properties could be leveraged to create innovative solutions.

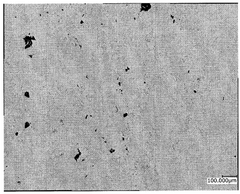

The technical evolution of tungsten AM has been characterized by a continuous refinement of process parameters, powder characteristics, and post-processing techniques. Researchers have explored various strategies to mitigate common issues such as cracking, porosity, and residual stresses in tungsten AM parts. These efforts have led to significant improvements in part density, surface finish, and mechanical properties.

In recent years, the focus has shifted towards expanding the range of tungsten-based materials suitable for AM. This includes the development of tungsten alloys and composites that offer enhanced processability while maintaining the desirable properties of pure tungsten. Additionally, hybrid manufacturing approaches combining AM with traditional machining techniques have shown promise in overcoming some of the limitations associated with pure AM processes for tungsten.

The current state of tungsten AM represents a convergence of materials science, advanced manufacturing technologies, and computational modeling. While significant progress has been made, there remain several challenges to be addressed before tungsten AM can be widely adopted in industrial applications. These include improving process reliability, enhancing material properties, and developing standardized procedures for quality control and certification of tungsten AM parts.

Market Demand Analysis

The market demand for additive manufacturing with tungsten is experiencing significant growth, driven by several key factors. The aerospace and defense industries are at the forefront of this demand, seeking high-performance materials for critical components that can withstand extreme temperatures and harsh environments. Tungsten's exceptional properties, including its high melting point and excellent thermal conductivity, make it an ideal candidate for these applications.

In the medical sector, there is a growing need for customized implants and prosthetics. Additive manufacturing with tungsten allows for the creation of complex, patient-specific designs that offer improved biocompatibility and functionality. This personalized approach to medical devices is expected to drive substantial market growth in the coming years.

The nuclear industry is another significant driver of demand for tungsten additive manufacturing. As nuclear power plants seek to improve efficiency and safety, there is an increasing need for radiation shielding components that can be precisely engineered. Tungsten's high density and radiation absorption properties make it an excellent material for these applications.

The automotive sector is also showing interest in tungsten additive manufacturing, particularly for high-performance racing applications and specialized components in electric vehicles. The ability to create lightweight yet strong parts with complex geometries is attracting attention from automotive engineers looking to optimize vehicle performance.

Market analysts predict that the global market for additive manufacturing with refractory metals, including tungsten, will see substantial growth over the next decade. This growth is expected to be fueled by advancements in 3D printing technologies that can handle high-temperature materials, as well as the development of new tungsten-based alloys specifically designed for additive manufacturing processes.

However, challenges remain in terms of material costs and processing difficulties. Tungsten's high melting point, while advantageous for many applications, presents challenges in the additive manufacturing process. Overcoming these technical hurdles is crucial for wider market adoption and will likely be a focus of research and development efforts in the near future.

As industries continue to push the boundaries of material performance, the demand for additive manufacturing with tungsten is expected to expand into new sectors. Emerging applications in energy storage, advanced electronics, and space exploration are likely to contribute to market growth. The ability to create complex, high-performance components with tungsten will enable innovations that were previously impossible or economically unfeasible with traditional manufacturing methods.

Technical Challenges

Additive manufacturing with tungsten presents several significant technical challenges that hinder its widespread adoption and advancement. One of the primary obstacles is the high melting point of tungsten, which exceeds 3400°C. This extreme temperature requirement poses difficulties in achieving consistent and controlled melting during the additive manufacturing process, leading to potential defects and inconsistencies in the final product.

The high density of tungsten, approximately 19.3 g/cm³, also contributes to challenges in powder handling and spreading. The material's weight makes it difficult to achieve uniform powder distribution, which is crucial for producing high-quality, defect-free parts. This issue is particularly pronounced in powder bed fusion processes, where even powder layers are essential for successful builds.

Tungsten's inherent brittleness and low ductility at room temperature present additional complications. These properties make the material prone to cracking during the rapid heating and cooling cycles typical in additive manufacturing processes. The thermal stresses induced during fabrication can lead to the formation of micro-cracks, compromising the structural integrity and mechanical properties of the printed components.

The high thermal conductivity of tungsten, while beneficial in some applications, poses challenges in maintaining precise temperature control during the additive manufacturing process. Rapid heat dissipation can lead to uneven cooling rates across the build, potentially resulting in warping, residual stresses, and dimensional inaccuracies in the final parts.

Another significant hurdle is the oxidation susceptibility of tungsten at elevated temperatures. When exposed to oxygen during the high-temperature additive manufacturing process, tungsten can form volatile oxides, leading to material loss and degradation of mechanical properties. This necessitates the use of stringent atmospheric controls, such as inert gas environments or vacuum chambers, which add complexity and cost to the manufacturing process.

The limited availability of high-quality tungsten powders specifically designed for additive manufacturing processes presents a further challenge. The powder characteristics, including particle size distribution, morphology, and flowability, significantly impact the quality of the final product. Developing and producing tungsten powders that meet the exacting requirements of additive manufacturing techniques remains an ongoing challenge for material suppliers.

Lastly, the post-processing of additively manufactured tungsten parts poses unique difficulties. The material's hardness and brittleness make traditional machining and finishing operations challenging and time-consuming. Developing effective post-processing techniques that can refine the surface finish, remove support structures, and achieve desired tolerances without compromising the part's integrity is a critical area requiring further research and development.

Current AM Solutions

01 Powder preparation for tungsten additive manufacturing

Specialized techniques for preparing tungsten powder suitable for additive manufacturing processes. This includes methods for producing fine, spherical tungsten particles with controlled size distribution and purity, which are critical for achieving high-quality 3D printed tungsten parts.- Powder preparation for tungsten additive manufacturing: Specialized powder preparation techniques are crucial for tungsten additive manufacturing. This includes methods for producing spherical tungsten powders with controlled particle size distribution, which are essential for achieving high-quality 3D printed tungsten parts. The preparation process may involve plasma spheroidization or other advanced techniques to ensure optimal flowability and packing density of the powder.

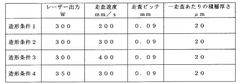

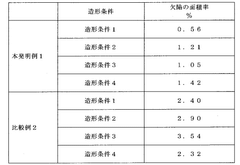

- Laser-based additive manufacturing of tungsten: Laser-based additive manufacturing techniques, such as selective laser melting (SLM) or laser powder bed fusion (LPBF), are commonly used for tungsten 3D printing. These methods involve layer-by-layer melting of tungsten powder using high-power lasers. Specific process parameters, including laser power, scan speed, and layer thickness, need to be optimized to address challenges associated with tungsten's high melting point and thermal properties.

- Post-processing of additively manufactured tungsten parts: Post-processing techniques are essential for improving the properties of 3D printed tungsten components. This may include heat treatment to reduce residual stresses, hot isostatic pressing (HIP) to increase density, and surface finishing methods to enhance surface quality. These processes aim to optimize the mechanical properties, density, and performance of the final tungsten parts.

- Tungsten alloys and composites for additive manufacturing: Development of tungsten alloys and composites specifically designed for additive manufacturing processes. These materials aim to improve printability, reduce cracking, and enhance the overall performance of 3D printed tungsten parts. Alloying elements or reinforcing phases may be added to tungsten to tailor its properties for specific applications while maintaining compatibility with additive manufacturing techniques.

- Applications of additively manufactured tungsten components: Exploration of various applications for 3D printed tungsten parts, leveraging the unique properties of tungsten and the design freedom offered by additive manufacturing. This includes applications in aerospace, nuclear industry, medical devices, and high-temperature environments. The ability to create complex geometries and internal structures enables the development of innovative tungsten components with enhanced performance characteristics.

02 Laser-based additive manufacturing of tungsten

Utilization of laser-based additive manufacturing techniques, such as selective laser melting (SLM) or laser powder bed fusion (LPBF), for processing tungsten. This involves optimizing laser parameters, scanning strategies, and process conditions to overcome challenges associated with tungsten's high melting point and thermal properties.Expand Specific Solutions03 Post-processing of additively manufactured tungsten parts

Methods for post-processing 3D printed tungsten components to improve their properties and performance. This includes heat treatment, surface finishing, and densification techniques to address issues such as porosity, residual stress, and surface roughness inherent in additively manufactured tungsten parts.Expand Specific Solutions04 Tungsten alloys and composites for additive manufacturing

Development of tungsten alloys and composite materials specifically designed for additive manufacturing processes. These materials aim to enhance printability, reduce cracking, and improve the mechanical and thermal properties of the final parts compared to pure tungsten.Expand Specific Solutions05 Applications of additively manufactured tungsten components

Exploration of various applications for 3D printed tungsten parts, leveraging the material's unique properties such as high density, excellent thermal conductivity, and radiation shielding capabilities. This includes applications in aerospace, nuclear, medical, and high-energy physics sectors.Expand Specific Solutions

Key Industry Players

The additive manufacturing landscape for tungsten is in a growth phase, with increasing market size driven by aerospace, defense, and medical applications. The technology's maturity is advancing, but challenges remain in process optimization and material properties. Key players like Plansee SE, Xiamen Tungsten Co., Ltd., and Toshiba Corp. are leading research efforts, while academic institutions such as MIT and Central South University contribute to fundamental advancements. Collaborations between industry leaders and research institutions, exemplified by partnerships involving companies like Applied Materials, Inc. and Lockheed Martin Corp., are accelerating innovation in this field. The competitive landscape is characterized by a mix of established materials companies and specialized additive manufacturing firms, each leveraging their unique expertise to overcome technical hurdles and expand market applications.

Plansee SE

Xiamen Tungsten Co., Ltd.

Tungsten AM Innovations

- Incorporating particulates with a melting point above the matrix phase to achieve a fine-grained microstructure, reducing oxygen precipitation at grain boundaries and enhancing grain boundary strength, and using precursor substances that react with process gases to form these particulates during layerwise fusion.

- A tungsten powder with controlled impurity levels of Mo (1% by mass or less) and Na (0.1 to 300.0 mass ppm) and a median diameter of 10 to 200 μm, along with high circularity and fluidity, is developed to minimize internal defects and enhance the manufacturing process, including the use of spheroidization and classification processes to improve powder quality.

Material Properties

Tungsten, with its unique material properties, plays a crucial role in advancing additive manufacturing (AM) technologies. The high melting point of tungsten, approximately 3422°C, makes it an ideal candidate for high-temperature applications in aerospace, nuclear, and defense industries. This refractory metal exhibits exceptional strength and hardness, maintaining its structural integrity even under extreme conditions.

The density of tungsten, at 19.3 g/cm³, is another significant property that contributes to its importance in AM. This high density allows for the creation of compact, yet heavy components, which is particularly valuable in applications requiring radiation shielding or ballistic protection. The material's excellent thermal and electrical conductivity further expands its potential uses in electronic and heat management systems.

However, the very properties that make tungsten attractive for AM also present challenges in processing. Its high melting point necessitates specialized equipment capable of reaching and maintaining extreme temperatures during the printing process. The material's hardness and brittleness can lead to difficulties in post-processing and may result in increased wear on manufacturing equipment.

Tungsten's low coefficient of thermal expansion is advantageous for dimensional stability in printed parts but can lead to residual stresses and potential cracking during the rapid heating and cooling cycles typical in AM processes. The material's tendency to oxidize at elevated temperatures requires careful control of the printing environment, often necessitating inert gas atmospheres or vacuum conditions.

The powder characteristics of tungsten also play a crucial role in AM processes. The high density of the material can lead to challenges in powder flowability and spreadability, which are essential for consistent layer formation in powder bed fusion techniques. Optimizing powder morphology, size distribution, and surface properties is critical for achieving high-quality prints with tungsten.

Alloying tungsten with other elements or creating tungsten-based composites offers potential solutions to some of these challenges. These modifications can improve ductility, reduce brittleness, and enhance processability while maintaining many of tungsten's desirable properties. Understanding and leveraging these material properties are key to advancing AM techniques for tungsten and expanding its applications in various high-performance sectors.

Sustainability Aspects

Additive manufacturing with tungsten presents unique sustainability challenges and opportunities. The high melting point and density of tungsten make it energy-intensive to process, requiring careful consideration of resource efficiency. However, the precision of additive manufacturing can significantly reduce material waste compared to traditional subtractive methods, particularly important for a rare metal like tungsten.

The longevity and recyclability of tungsten products contribute to their sustainability profile. Tungsten's durability allows for extended product lifecycles, reducing the need for frequent replacements. At the end of life, tungsten components can be recycled with high efficiency, conserving this valuable resource and reducing the environmental impact of mining.

Energy consumption remains a critical sustainability concern in tungsten additive manufacturing. The process typically requires high-powered lasers or electron beams, consuming substantial electricity. Improving energy efficiency through optimized process parameters and equipment design is crucial for enhancing sustainability. Additionally, the integration of renewable energy sources in manufacturing facilities can further mitigate the carbon footprint.

The localization of production enabled by additive manufacturing offers sustainability benefits by reducing transportation-related emissions. This is particularly relevant for tungsten products, which are often specialized and produced in limited quantities. On-demand, localized production can minimize inventory waste and optimize supply chains.

Advancing the sustainability of tungsten additive manufacturing also involves addressing powder production and handling. Developing more efficient methods for producing fine tungsten powders suitable for additive processes can reduce energy consumption and material waste. Implementing closed-loop systems for powder recycling and reuse within the manufacturing process further enhances resource efficiency.

Safety considerations in tungsten additive manufacturing contribute to its overall sustainability. Proper handling and containment of tungsten powders are essential to protect worker health and prevent environmental contamination. Developing safer processing methods and implementing robust safety protocols are integral to sustainable practice in this field.

As the technology advances, life cycle assessment (LCA) becomes increasingly important in evaluating and improving the sustainability of tungsten additive manufacturing. Comprehensive LCA studies can identify hotspots in the production process, guiding targeted improvements in material efficiency, energy use, and waste reduction. This holistic approach ensures that sustainability efforts are focused on the most impactful areas of the manufacturing lifecycle.