How to Advance Thermoelectric Cooling Efficiency in Electronics

AUG 27, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Cooling Background and Efficiency Goals

Thermoelectric cooling technology, based on the Peltier effect discovered in 1834, has evolved significantly over the past century. This solid-state heat transfer mechanism occurs when electric current flows through junctions between different types of conductors, creating a temperature differential. The technology gained practical applications in the mid-20th century with the development of semiconductor materials, particularly bismuth telluride (Bi2Te3), which remains the industry standard material for commercial thermoelectric modules.

The evolution of thermoelectric cooling has been characterized by incremental improvements in efficiency rather than revolutionary breakthroughs. The figure of merit ZT, which measures thermoelectric performance, has increased from approximately 0.7 in the 1950s to around 1.5-2.0 in modern commercial devices. This relatively slow progress highlights the fundamental challenges in simultaneously optimizing the conflicting material properties required for high thermoelectric efficiency.

Recent technological advancements have focused on nanostructured materials, quantum well structures, and novel material combinations to overcome these inherent limitations. Particularly promising are developments in skutterudites, clathrates, and half-Heusler alloys, which demonstrate potential for higher ZT values through phonon-glass electron-crystal approaches that reduce thermal conductivity while maintaining electrical conductivity.

In the electronics cooling domain, thermoelectric technology offers unique advantages including compact size, absence of moving parts, precise temperature control, and localized cooling capabilities. These attributes make it particularly valuable for applications requiring spot cooling of sensitive components, temperature stabilization of optoelectronic devices, and thermal management in space-constrained environments.

The primary efficiency goal in thermoelectric cooling advancement is to achieve ZT values consistently above 3.0 in commercially viable materials, which would make thermoelectric cooling competitive with traditional vapor-compression systems in terms of energy efficiency. Secondary goals include reducing manufacturing costs, improving reliability under thermal cycling, and developing environmentally sustainable materials that reduce dependence on rare or toxic elements like tellurium.

For electronics applications specifically, technical objectives include developing modules capable of handling heat fluxes exceeding 500 W/cm² at temperature differentials of 50°C or greater, while maintaining coefficient of performance (COP) values above 2.0. Additional targets include miniaturization to accommodate the trend toward higher component density in electronic devices, and integration capabilities that allow thermoelectric elements to be directly incorporated into semiconductor manufacturing processes.

The trajectory of research suggests potential for significant breakthroughs in the next decade, particularly through interdisciplinary approaches combining materials science, nanotechnology, and advanced manufacturing techniques. These developments could position thermoelectric cooling as a mainstream solution for thermal management challenges in next-generation electronics, especially in applications where conventional cooling technologies face fundamental limitations.

The evolution of thermoelectric cooling has been characterized by incremental improvements in efficiency rather than revolutionary breakthroughs. The figure of merit ZT, which measures thermoelectric performance, has increased from approximately 0.7 in the 1950s to around 1.5-2.0 in modern commercial devices. This relatively slow progress highlights the fundamental challenges in simultaneously optimizing the conflicting material properties required for high thermoelectric efficiency.

Recent technological advancements have focused on nanostructured materials, quantum well structures, and novel material combinations to overcome these inherent limitations. Particularly promising are developments in skutterudites, clathrates, and half-Heusler alloys, which demonstrate potential for higher ZT values through phonon-glass electron-crystal approaches that reduce thermal conductivity while maintaining electrical conductivity.

In the electronics cooling domain, thermoelectric technology offers unique advantages including compact size, absence of moving parts, precise temperature control, and localized cooling capabilities. These attributes make it particularly valuable for applications requiring spot cooling of sensitive components, temperature stabilization of optoelectronic devices, and thermal management in space-constrained environments.

The primary efficiency goal in thermoelectric cooling advancement is to achieve ZT values consistently above 3.0 in commercially viable materials, which would make thermoelectric cooling competitive with traditional vapor-compression systems in terms of energy efficiency. Secondary goals include reducing manufacturing costs, improving reliability under thermal cycling, and developing environmentally sustainable materials that reduce dependence on rare or toxic elements like tellurium.

For electronics applications specifically, technical objectives include developing modules capable of handling heat fluxes exceeding 500 W/cm² at temperature differentials of 50°C or greater, while maintaining coefficient of performance (COP) values above 2.0. Additional targets include miniaturization to accommodate the trend toward higher component density in electronic devices, and integration capabilities that allow thermoelectric elements to be directly incorporated into semiconductor manufacturing processes.

The trajectory of research suggests potential for significant breakthroughs in the next decade, particularly through interdisciplinary approaches combining materials science, nanotechnology, and advanced manufacturing techniques. These developments could position thermoelectric cooling as a mainstream solution for thermal management challenges in next-generation electronics, especially in applications where conventional cooling technologies face fundamental limitations.

Market Demand Analysis for High-Efficiency Electronic Cooling

The global market for high-efficiency electronic cooling solutions is experiencing unprecedented growth, driven primarily by the rapid advancement of computing technologies and the increasing power density of electronic devices. Current market research indicates that the thermoelectric cooling segment within this market is expanding at a compound annual growth rate of approximately 8% through 2028, reflecting the urgent need for more efficient thermal management solutions across multiple industries.

Consumer electronics represents the largest market segment demanding advanced cooling technologies. As smartphones, tablets, and laptops continue to pack more processing power into smaller form factors, manufacturers face critical thermal challenges that directly impact device performance and longevity. Market surveys reveal that over 60% of premium smartphone users cite device overheating as a significant concern affecting their purchase decisions, creating a substantial commercial incentive for implementing superior cooling solutions.

The data center industry presents perhaps the most compelling case for advanced thermoelectric cooling technologies. With global data center electricity consumption projected to reach 8% of total worldwide usage by 2030, operators are under immense pressure to improve cooling efficiency. Traditional air cooling systems are increasingly inadequate for handling the thermal loads of high-density server racks, creating a market gap that thermoelectric solutions could potentially fill.

Automotive electronics constitute another rapidly expanding market segment, particularly with the rise of electric vehicles and autonomous driving technologies. The thermal management requirements for battery systems, power electronics, and sensor arrays in modern vehicles have created new opportunities for thermoelectric cooling applications. Industry analysts project that the automotive thermal management market will exceed $45 billion by 2027, with cooling technologies representing a significant portion of this growth.

Industrial automation and medical device sectors also demonstrate substantial demand for precise temperature control solutions. In medical imaging equipment, laboratory instrumentation, and pharmaceutical storage, thermoelectric cooling offers advantages in terms of precision, reliability, and form factor flexibility that conventional cooling technologies cannot match.

Market research further indicates that consumers and industrial buyers are increasingly willing to pay premium prices for products with superior thermal performance. This price elasticity suggests that investments in advanced thermoelectric cooling technologies could yield substantial returns through product differentiation and performance advantages.

The geographical distribution of market demand shows particular concentration in regions with advanced electronics manufacturing ecosystems, including East Asia, North America, and Western Europe. However, emerging markets in South Asia and Latin America are showing accelerated growth rates as their electronics manufacturing and consumption patterns evolve.

Consumer electronics represents the largest market segment demanding advanced cooling technologies. As smartphones, tablets, and laptops continue to pack more processing power into smaller form factors, manufacturers face critical thermal challenges that directly impact device performance and longevity. Market surveys reveal that over 60% of premium smartphone users cite device overheating as a significant concern affecting their purchase decisions, creating a substantial commercial incentive for implementing superior cooling solutions.

The data center industry presents perhaps the most compelling case for advanced thermoelectric cooling technologies. With global data center electricity consumption projected to reach 8% of total worldwide usage by 2030, operators are under immense pressure to improve cooling efficiency. Traditional air cooling systems are increasingly inadequate for handling the thermal loads of high-density server racks, creating a market gap that thermoelectric solutions could potentially fill.

Automotive electronics constitute another rapidly expanding market segment, particularly with the rise of electric vehicles and autonomous driving technologies. The thermal management requirements for battery systems, power electronics, and sensor arrays in modern vehicles have created new opportunities for thermoelectric cooling applications. Industry analysts project that the automotive thermal management market will exceed $45 billion by 2027, with cooling technologies representing a significant portion of this growth.

Industrial automation and medical device sectors also demonstrate substantial demand for precise temperature control solutions. In medical imaging equipment, laboratory instrumentation, and pharmaceutical storage, thermoelectric cooling offers advantages in terms of precision, reliability, and form factor flexibility that conventional cooling technologies cannot match.

Market research further indicates that consumers and industrial buyers are increasingly willing to pay premium prices for products with superior thermal performance. This price elasticity suggests that investments in advanced thermoelectric cooling technologies could yield substantial returns through product differentiation and performance advantages.

The geographical distribution of market demand shows particular concentration in regions with advanced electronics manufacturing ecosystems, including East Asia, North America, and Western Europe. However, emerging markets in South Asia and Latin America are showing accelerated growth rates as their electronics manufacturing and consumption patterns evolve.

Current Thermoelectric Technology Limitations and Challenges

Despite significant advancements in thermoelectric cooling technology over recent decades, several fundamental limitations continue to impede its widespread adoption in electronic cooling applications. The primary challenge remains the inherently low efficiency of thermoelectric materials, with most commercial Peltier coolers operating at only 5-10% of Carnot efficiency. This inefficiency stems from the intrinsic difficulty in simultaneously optimizing the three interdependent material properties that determine the figure of merit (ZT): electrical conductivity, thermal conductivity, and Seebeck coefficient.

Current bismuth telluride (Bi2Te3) based materials, which dominate the commercial market, have reached ZT values of approximately 1-1.2, far below the theoretical values needed for competitive efficiency with conventional cooling technologies. Additionally, these materials contain tellurium, which faces supply chain vulnerabilities due to its scarcity and geopolitical concentration, primarily in China and Russia.

Manufacturing challenges present another significant barrier, particularly in creating reliable electrical and thermal interfaces between thermoelectric elements and heat exchangers. Contact resistance at these interfaces can substantially degrade overall system performance, with losses often accounting for 20-30% of efficiency reduction in practical devices. Current manufacturing processes also struggle with miniaturization while maintaining performance, limiting applications in increasingly compact electronic devices.

Heat dissipation represents a critical bottleneck in thermoelectric cooling systems. The Joule heating effect inherently generates additional heat that must be managed, creating a counterproductive thermal load that reduces net cooling capacity. This challenge becomes particularly acute in confined spaces typical of modern electronics, where heat flux densities continue to increase exponentially.

Power consumption remains prohibitively high for many portable applications, with current thermoelectric coolers requiring significant electrical input relative to their cooling output. This limitation has restricted their use primarily to scenarios where efficiency is secondary to other factors such as reliability, silence, or precision temperature control.

Scalability issues further complicate widespread implementation, as performance often degrades when scaling from laboratory prototypes to commercial-sized modules. The thermal management systems required to support thermoelectric coolers add complexity, weight, and cost to the overall solution, making integration challenging in consumer electronics.

Environmental concerns also persist, with manufacturing processes for high-performance thermoelectric materials often involving toxic elements and energy-intensive production methods. End-of-life disposal presents additional challenges due to the presence of heavy metals and rare earth elements in many thermoelectric compositions.

Current bismuth telluride (Bi2Te3) based materials, which dominate the commercial market, have reached ZT values of approximately 1-1.2, far below the theoretical values needed for competitive efficiency with conventional cooling technologies. Additionally, these materials contain tellurium, which faces supply chain vulnerabilities due to its scarcity and geopolitical concentration, primarily in China and Russia.

Manufacturing challenges present another significant barrier, particularly in creating reliable electrical and thermal interfaces between thermoelectric elements and heat exchangers. Contact resistance at these interfaces can substantially degrade overall system performance, with losses often accounting for 20-30% of efficiency reduction in practical devices. Current manufacturing processes also struggle with miniaturization while maintaining performance, limiting applications in increasingly compact electronic devices.

Heat dissipation represents a critical bottleneck in thermoelectric cooling systems. The Joule heating effect inherently generates additional heat that must be managed, creating a counterproductive thermal load that reduces net cooling capacity. This challenge becomes particularly acute in confined spaces typical of modern electronics, where heat flux densities continue to increase exponentially.

Power consumption remains prohibitively high for many portable applications, with current thermoelectric coolers requiring significant electrical input relative to their cooling output. This limitation has restricted their use primarily to scenarios where efficiency is secondary to other factors such as reliability, silence, or precision temperature control.

Scalability issues further complicate widespread implementation, as performance often degrades when scaling from laboratory prototypes to commercial-sized modules. The thermal management systems required to support thermoelectric coolers add complexity, weight, and cost to the overall solution, making integration challenging in consumer electronics.

Environmental concerns also persist, with manufacturing processes for high-performance thermoelectric materials often involving toxic elements and energy-intensive production methods. End-of-life disposal presents additional challenges due to the presence of heavy metals and rare earth elements in many thermoelectric compositions.

Current Approaches to Enhance Thermoelectric Cooling Efficiency

01 Material selection for thermoelectric cooling efficiency

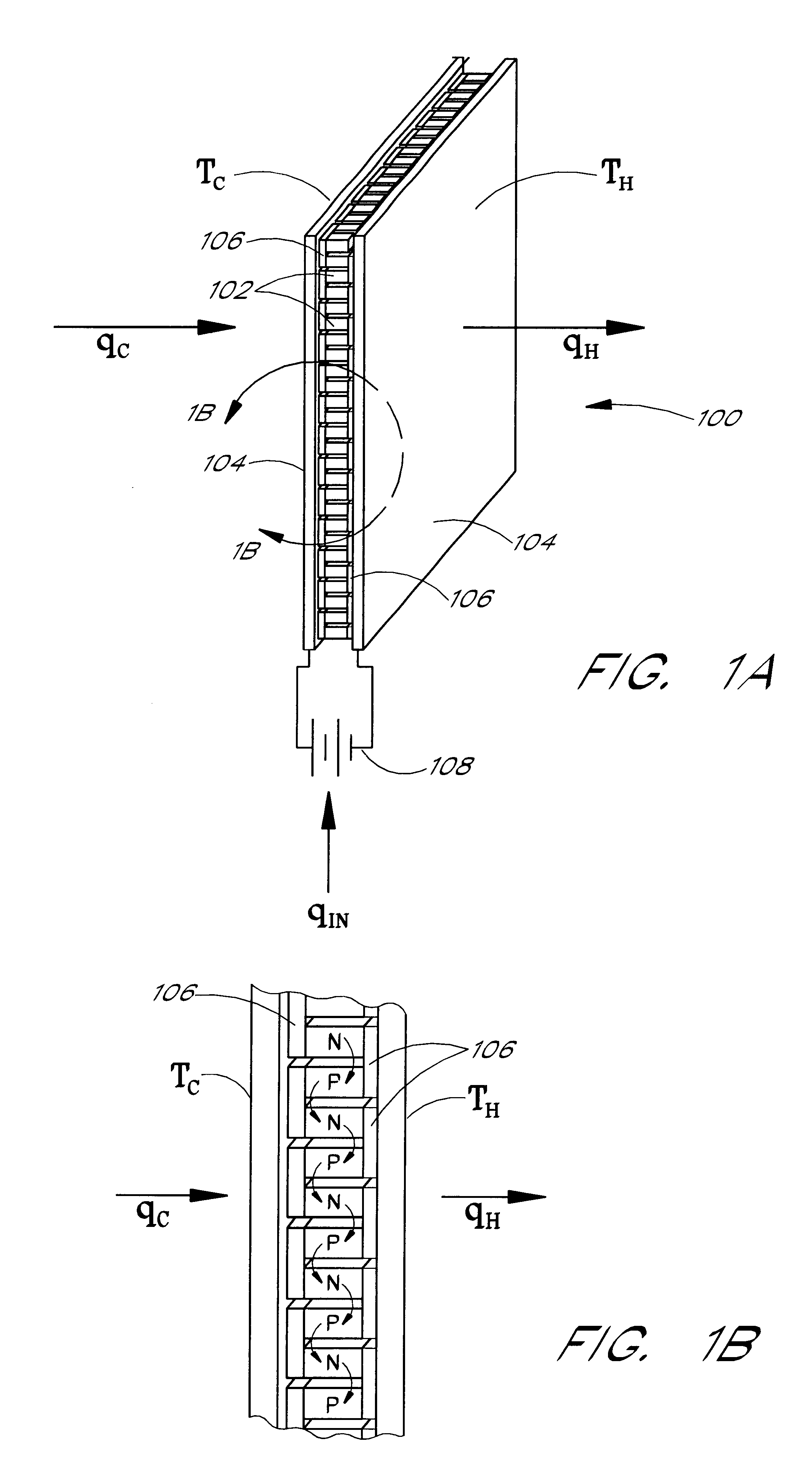

The efficiency of thermoelectric cooling systems is significantly influenced by the selection of thermoelectric materials. Advanced semiconductor materials with high figure of merit (ZT) values can enhance the cooling performance. These materials typically exhibit high electrical conductivity and low thermal conductivity, which are essential properties for efficient thermoelectric conversion. Innovations in material science, such as nanostructured thermoelectric materials and semiconductor alloys, have led to improvements in cooling efficiency by optimizing the Seebeck coefficient and reducing thermal losses.- Thermoelectric module design optimization: Optimizing the design of thermoelectric modules can significantly improve cooling efficiency. This includes considerations such as the geometry of thermoelectric elements, the arrangement of p-type and n-type semiconductors, and the selection of materials with high figure of merit (ZT). Advanced module designs can reduce thermal resistance and improve heat transfer, leading to enhanced cooling performance and energy efficiency.

- Heat dissipation and thermal management systems: Effective heat dissipation and thermal management are crucial for thermoelectric cooling efficiency. This includes the use of heat sinks, fans, and other cooling mechanisms to remove heat from the hot side of thermoelectric devices. Proper thermal interface materials and optimized heat exchanger designs can minimize thermal resistance and improve overall system performance, allowing thermoelectric coolers to operate more efficiently.

- Advanced thermoelectric materials: The development of advanced thermoelectric materials is key to improving cooling efficiency. Materials with higher Seebeck coefficients, lower thermal conductivity, and higher electrical conductivity can significantly enhance the figure of merit (ZT) and consequently the cooling performance. Novel materials such as nanostructured semiconductors, skutterudites, and bismuth telluride alloys with various dopants are being researched to achieve higher efficiency in thermoelectric cooling applications.

- Power supply and control systems: Optimized power supply and control systems can significantly improve the efficiency of thermoelectric cooling devices. This includes pulse width modulation techniques, intelligent temperature controllers, and adaptive power management systems that adjust the input current based on cooling demand. These control strategies can reduce power consumption while maintaining desired cooling performance, thereby increasing the coefficient of performance (COP) of thermoelectric cooling systems.

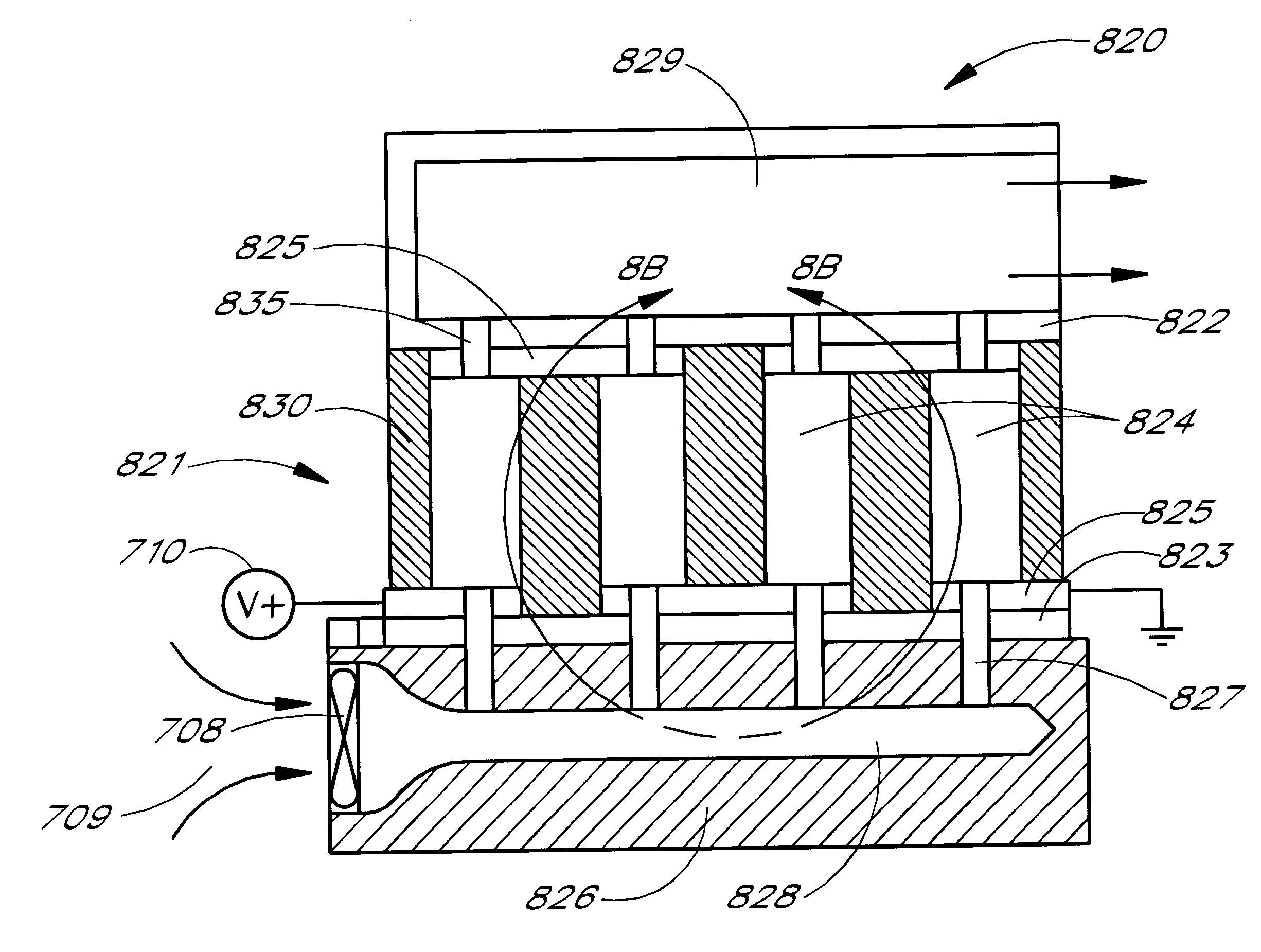

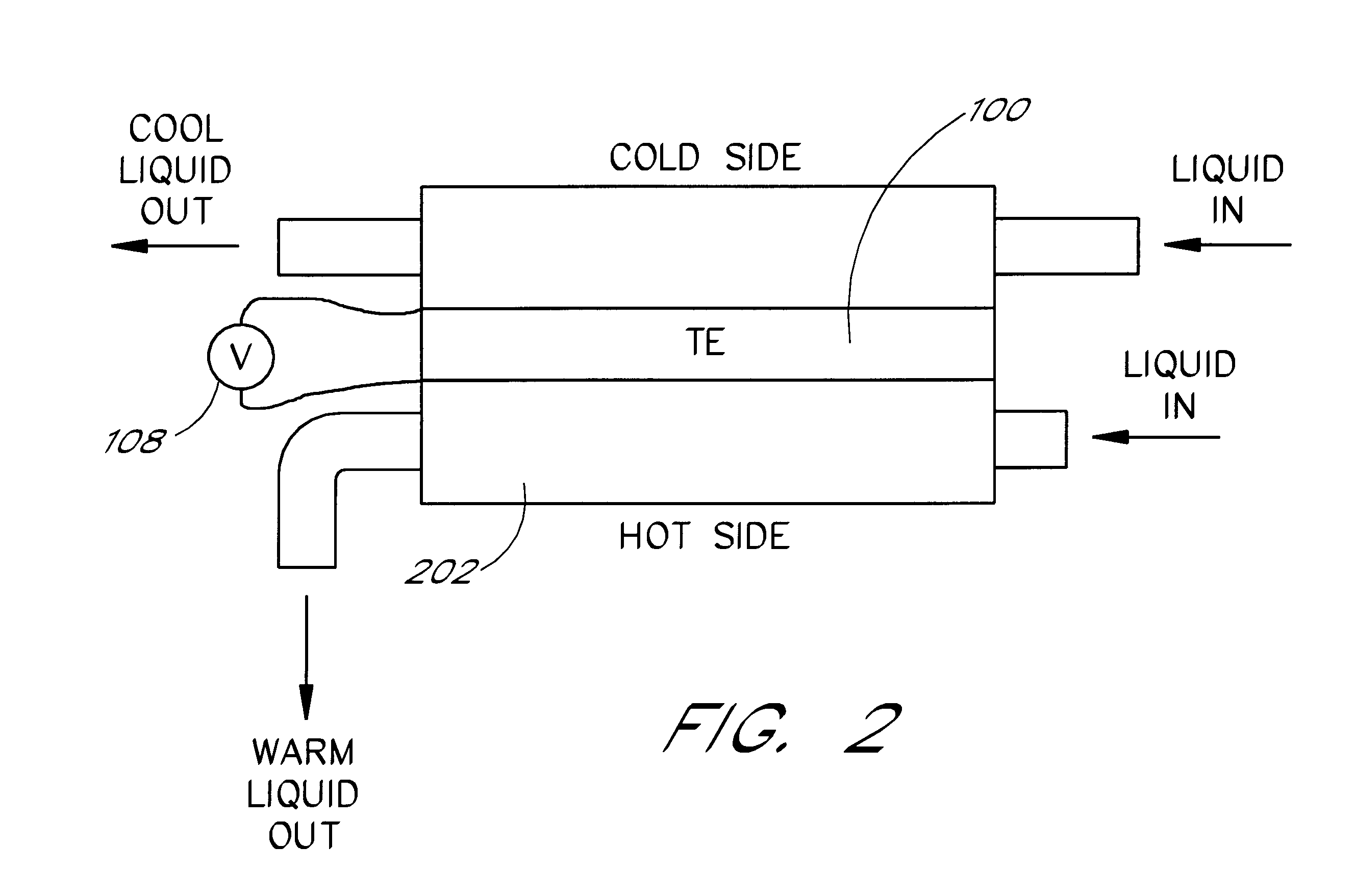

- Hybrid and cascaded cooling systems: Hybrid cooling systems that combine thermoelectric cooling with other cooling technologies, such as vapor compression or liquid cooling, can achieve higher efficiency than standalone thermoelectric systems. Additionally, cascaded thermoelectric coolers, where multiple stages of thermoelectric modules are arranged in series, can achieve lower temperatures and higher efficiency for specific applications. These integrated approaches leverage the strengths of different cooling methods to overcome the inherent limitations of thermoelectric cooling.

02 Structural design optimization for thermoelectric coolers

The structural design of thermoelectric cooling systems plays a crucial role in maximizing efficiency. This includes optimizing the geometry of thermoelectric modules, improving heat sink designs, and enhancing thermal interfaces between components. Multi-stage thermoelectric coolers with cascaded arrangements can achieve lower temperatures and higher efficiency. Additionally, innovative module configurations that minimize thermal resistance and electrical losses contribute to improved cooling performance. Proper thermal management through effective heat dissipation structures is essential for maintaining optimal temperature differentials across the thermoelectric elements.Expand Specific Solutions03 Power supply and control systems for thermoelectric cooling

Advanced power supply and control systems significantly impact the efficiency of thermoelectric cooling devices. Pulse width modulation (PWM) techniques, intelligent temperature controllers, and adaptive power management systems can optimize the electrical input to thermoelectric modules based on cooling demands. These control systems can adjust the current flow to maintain optimal operating conditions while preventing overcooling or undercooling. Energy-efficient power conversion circuits and voltage regulators designed specifically for thermoelectric applications help minimize electrical losses and improve overall system efficiency.Expand Specific Solutions04 Heat dissipation and thermal management techniques

Effective heat dissipation and thermal management are critical for maximizing thermoelectric cooling efficiency. This includes the integration of advanced heat sink designs, cooling fans, liquid cooling systems, and phase change materials to efficiently remove heat from the hot side of thermoelectric modules. Proper thermal interface materials between the thermoelectric elements and heat exchangers reduce thermal resistance and improve heat transfer. Optimized airflow patterns and strategic placement of cooling components help maintain temperature gradients necessary for efficient operation. These techniques prevent thermal saturation and ensure sustained cooling performance under various operating conditions.Expand Specific Solutions05 Hybrid and integrated cooling systems

Hybrid cooling systems that combine thermoelectric technology with other cooling methods can achieve higher efficiency than standalone thermoelectric coolers. These integrated approaches may incorporate conventional refrigeration cycles, passive cooling techniques, or renewable energy sources to power thermoelectric modules. Solar-powered thermoelectric cooling systems offer energy-efficient alternatives for specific applications. Additionally, waste heat recovery systems can capture and repurpose thermal energy to power thermoelectric coolers, creating more sustainable cooling solutions. The synergistic combination of multiple cooling technologies helps overcome the inherent limitations of pure thermoelectric systems and improves overall energy efficiency.Expand Specific Solutions

Leading Companies and Research Institutions in Thermoelectric Industry

Thermoelectric cooling in electronics is currently in a growth phase, with the market expected to reach significant expansion due to increasing demand for efficient thermal management solutions. The technology maturity varies across applications, with companies like Intel, IBM, and Samsung leading innovation in advanced semiconductor cooling solutions. Huawei, Microsoft, and Fujitsu are developing integrated thermoelectric systems for next-generation electronics, while specialized firms like CoolIT Systems and Hangzhou Dahe Thermo-Magnetics focus on niche applications. Research institutions including Japan Science & Technology Agency and National Institute for Materials Science are advancing fundamental thermoelectric materials science. The competitive landscape features both established technology giants and specialized thermal management companies working to overcome efficiency limitations and cost barriers.

International Business Machines Corp.

Technical Solution: IBM has developed an advanced thermoelectric cooling system specifically designed for high-density data center applications, where thermal management directly impacts computational performance and energy efficiency. Their solution integrates multi-stage thermoelectric modules with liquid cooling infrastructure to create a hybrid cooling approach that optimizes efficiency across varying workloads. IBM's thermoelectric modules utilize skutterudite-based materials with enhanced phonon scattering properties, achieving ZT values exceeding 1.7 at operating temperatures relevant to server environments (60-80°C)[1]. The company has implemented a cascaded TEC architecture that strategically distributes the temperature differential across multiple stages, improving overall system efficiency by up to 40% compared to single-stage designs[2]. IBM's solution incorporates machine learning algorithms that predict thermal loads based on workload characteristics and proactively adjust cooling parameters to maintain optimal operating temperatures while minimizing energy consumption. Their research has demonstrated that selective application of thermoelectric cooling to critical components can reduce overall cooling energy by up to 25% while improving computational performance by maintaining processors within optimal temperature ranges[3].

Strengths: Highly optimized for data center environments with excellent integration into existing liquid cooling infrastructure. Advanced materials science delivers superior performance at server operating temperatures. Weaknesses: Higher implementation complexity requires sophisticated control systems. Initial capital costs exceed conventional cooling solutions despite long-term operational savings.

Intel Corp.

Technical Solution: Intel has developed an integrated on-chip thermoelectric cooling (TEC) solution for high-performance processors that addresses localized hotspots, which can be 20-30°C hotter than average chip temperatures[1]. Their approach embeds microscale TEC modules directly into the processor package between the die and heat spreader, targeting specific high-heat-generating regions. Intel's solution utilizes advanced bismuth telluride alloys with precisely controlled doping profiles to optimize the Seebeck coefficient while minimizing electrical resistance. The company has implemented a proprietary manufacturing process that creates highly uniform thermoelectric elements with dimensions below 100μm, enabling precise placement near hotspots without affecting overall chip design[2]. Intel's integrated TEC modules are coupled with sophisticated power delivery and control systems that dynamically adjust cooling power based on workload demands, achieving up to 15°C reduction in hotspot temperatures while consuming less than 5% of the processor's total power budget[3]. Their latest research focuses on segmented thermoelectric materials that optimize performance across the temperature gradient between the junction and ambient environment.

Strengths: Direct integration with semiconductor manufacturing processes enables highly targeted cooling of processor hotspots. Sophisticated power management systems optimize energy efficiency. Weaknesses: Limited to specific high-value applications due to manufacturing complexity and cost. Requires careful thermal design to prevent condensation issues when cooling below ambient temperature.

Key Innovations in ZT Value Enhancement and Heat Transfer

Thermoelectric cooling apparatus

PatentWO2012113411A1

Innovation

- A thermoelectric cooling device design featuring multiple layers of n- and p-type conductivity elements in a series-parallel electrical circuit, where each layer's thermoelectric elements are connected to form a single circuit with additional layers of connecting plates, allowing for efficient heat flow compensation and operation from a single power source.

Efficiency thermoelectrics utilizing convective heat flow

PatentInactiveUS6672076B2

Innovation

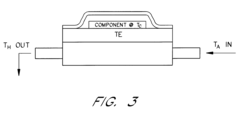

- The thermoelectric system incorporates a plurality of thermoelectric elements forming an array that facilitates convective heat transfer by allowing a convective medium to flow through or around the elements, enhancing heat transport through steady-state convective heat transport, and includes a control system to adjust characteristics for improved efficiency.

Environmental Impact and Sustainability of Thermoelectric Solutions

Thermoelectric cooling technologies present a complex environmental profile that must be carefully evaluated when considering their implementation in electronic systems. While these solutions offer significant advantages in terms of localized cooling without moving parts or refrigerants, their environmental impact extends across multiple dimensions throughout their lifecycle.

The manufacturing process of thermoelectric materials involves several rare and sometimes toxic elements, including bismuth, tellurium, antimony, and lead. The extraction and processing of these materials can lead to habitat disruption, water pollution, and energy-intensive refinement processes. Additionally, the semiconductor fabrication techniques used in producing high-performance thermoelectric modules generate substantial carbon emissions and chemical waste.

During operation, thermoelectric coolers demonstrate a mixed environmental profile. On one hand, they consume electricity at rates that can exceed conventional cooling methods due to their relatively low coefficient of performance (COP). This increased energy consumption translates to higher carbon emissions in regions dependent on fossil fuel power generation. On the other hand, they eliminate the need for refrigerants with high global warming potential that are common in traditional cooling systems.

The end-of-life management of thermoelectric devices presents another environmental challenge. The composite nature of these devices, combining various metals, semiconductors, and ceramic materials, complicates recycling efforts. Without proper recycling infrastructure, valuable and potentially harmful materials may end up in landfills, leading to soil and groundwater contamination.

Recent sustainability innovations are addressing these concerns through several approaches. Materials scientists are developing thermoelectric compounds using more abundant and less toxic elements, such as silicon-germanium alloys and oxide-based materials. Manufacturing processes are being optimized to reduce waste and energy consumption, with some facilities implementing closed-loop systems for chemical recovery and reuse.

The integration of thermoelectric cooling with renewable energy sources represents a promising pathway toward sustainability. Solar-powered thermoelectric cooling systems have been demonstrated in various applications, creating self-sufficient cooling solutions with minimal environmental impact. Furthermore, waste heat recovery applications of thermoelectric technology can improve overall system efficiency, potentially offsetting the environmental costs of manufacturing and operation.

For electronics cooling applications specifically, the environmental calculus must consider the extended lifespan and improved performance that precise thermal management can provide to electronic devices. By preventing premature failure and enabling higher performance in smaller form factors, thermoelectric cooling may indirectly reduce electronic waste and resource consumption associated with frequent device replacement.

The manufacturing process of thermoelectric materials involves several rare and sometimes toxic elements, including bismuth, tellurium, antimony, and lead. The extraction and processing of these materials can lead to habitat disruption, water pollution, and energy-intensive refinement processes. Additionally, the semiconductor fabrication techniques used in producing high-performance thermoelectric modules generate substantial carbon emissions and chemical waste.

During operation, thermoelectric coolers demonstrate a mixed environmental profile. On one hand, they consume electricity at rates that can exceed conventional cooling methods due to their relatively low coefficient of performance (COP). This increased energy consumption translates to higher carbon emissions in regions dependent on fossil fuel power generation. On the other hand, they eliminate the need for refrigerants with high global warming potential that are common in traditional cooling systems.

The end-of-life management of thermoelectric devices presents another environmental challenge. The composite nature of these devices, combining various metals, semiconductors, and ceramic materials, complicates recycling efforts. Without proper recycling infrastructure, valuable and potentially harmful materials may end up in landfills, leading to soil and groundwater contamination.

Recent sustainability innovations are addressing these concerns through several approaches. Materials scientists are developing thermoelectric compounds using more abundant and less toxic elements, such as silicon-germanium alloys and oxide-based materials. Manufacturing processes are being optimized to reduce waste and energy consumption, with some facilities implementing closed-loop systems for chemical recovery and reuse.

The integration of thermoelectric cooling with renewable energy sources represents a promising pathway toward sustainability. Solar-powered thermoelectric cooling systems have been demonstrated in various applications, creating self-sufficient cooling solutions with minimal environmental impact. Furthermore, waste heat recovery applications of thermoelectric technology can improve overall system efficiency, potentially offsetting the environmental costs of manufacturing and operation.

For electronics cooling applications specifically, the environmental calculus must consider the extended lifespan and improved performance that precise thermal management can provide to electronic devices. By preventing premature failure and enabling higher performance in smaller form factors, thermoelectric cooling may indirectly reduce electronic waste and resource consumption associated with frequent device replacement.

Integration Challenges with Modern Electronic Systems

The integration of thermoelectric cooling systems with modern electronics presents significant challenges that must be addressed to achieve optimal performance. Current electronic architectures are not inherently designed to accommodate thermoelectric modules, creating spatial constraints that limit cooling efficiency. The miniaturization trend in electronics compounds this issue, as smaller form factors leave minimal space for adequate thermal management solutions.

Heat dissipation pathways represent another critical integration challenge. Thermoelectric coolers require efficient heat sinks on their hot side to remove the heat pumped from the cold side plus the power dissipated by the module itself. In compact electronic systems, implementing these heat dissipation mechanisms becomes increasingly difficult, often resulting in thermal bottlenecks that reduce overall cooling performance.

Power management presents a substantial hurdle for thermoelectric integration. These cooling systems typically demand significant electrical input, which can strain the power budget of portable or energy-efficient electronic devices. The power consumption of thermoelectric modules must be carefully balanced against their cooling benefits, particularly in battery-operated systems where energy conservation is paramount.

Interface thermal resistance between thermoelectric modules and electronic components significantly impacts cooling efficiency. Imperfect thermal contacts create barriers to heat transfer, reducing the effective temperature differential that can be achieved. Advanced thermal interface materials and bonding techniques are required to minimize these resistances, but their implementation adds complexity to manufacturing processes.

Reliability concerns also emerge when integrating thermoelectric coolers with electronics. The different coefficients of thermal expansion between thermoelectric materials and electronic components can lead to mechanical stress during thermal cycling, potentially causing connection failures or material degradation over time. This mismatch in physical properties necessitates careful material selection and mounting strategies to ensure long-term operational stability.

Control system integration represents another significant challenge. Thermoelectric cooling efficiency is highly dependent on precise temperature regulation and power input. Developing control algorithms that can dynamically adjust cooling parameters based on varying thermal loads requires sophisticated sensing and processing capabilities, adding another layer of complexity to system design and integration.

Manufacturing scalability remains problematic for widespread adoption. Current production methods for thermoelectric modules often involve complex processes that are difficult to align with high-volume electronics manufacturing. This misalignment in production capabilities creates barriers to cost-effective integration, limiting the commercial viability of thermoelectric cooling solutions in mainstream electronic products.

Heat dissipation pathways represent another critical integration challenge. Thermoelectric coolers require efficient heat sinks on their hot side to remove the heat pumped from the cold side plus the power dissipated by the module itself. In compact electronic systems, implementing these heat dissipation mechanisms becomes increasingly difficult, often resulting in thermal bottlenecks that reduce overall cooling performance.

Power management presents a substantial hurdle for thermoelectric integration. These cooling systems typically demand significant electrical input, which can strain the power budget of portable or energy-efficient electronic devices. The power consumption of thermoelectric modules must be carefully balanced against their cooling benefits, particularly in battery-operated systems where energy conservation is paramount.

Interface thermal resistance between thermoelectric modules and electronic components significantly impacts cooling efficiency. Imperfect thermal contacts create barriers to heat transfer, reducing the effective temperature differential that can be achieved. Advanced thermal interface materials and bonding techniques are required to minimize these resistances, but their implementation adds complexity to manufacturing processes.

Reliability concerns also emerge when integrating thermoelectric coolers with electronics. The different coefficients of thermal expansion between thermoelectric materials and electronic components can lead to mechanical stress during thermal cycling, potentially causing connection failures or material degradation over time. This mismatch in physical properties necessitates careful material selection and mounting strategies to ensure long-term operational stability.

Control system integration represents another significant challenge. Thermoelectric cooling efficiency is highly dependent on precise temperature regulation and power input. Developing control algorithms that can dynamically adjust cooling parameters based on varying thermal loads requires sophisticated sensing and processing capabilities, adding another layer of complexity to system design and integration.

Manufacturing scalability remains problematic for widespread adoption. Current production methods for thermoelectric modules often involve complex processes that are difficult to align with high-volume electronics manufacturing. This misalignment in production capabilities creates barriers to cost-effective integration, limiting the commercial viability of thermoelectric cooling solutions in mainstream electronic products.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!