How to Analyze Wankel Engine Lubrication Systems?

AUG 26, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Wankel Engine Lubrication Background and Objectives

The Wankel rotary engine, developed by German engineer Felix Wankel in the 1950s, represents a significant departure from conventional reciprocating piston engines. Its unique triangular rotor design, which rotates within an epitrochoid housing, creates a distinctive operating cycle that presents specialized lubrication challenges. The evolution of Wankel engine lubrication systems has been marked by continuous refinement to address these unique requirements, with significant advancements occurring during the 1960s through Mazda's commercialization efforts and continuing through modern applications.

Lubrication in Wankel engines serves multiple critical functions beyond those in conventional engines. The rotary design creates unique sealing interfaces between the rotor apex seals and the epitrochoid housing that require precise lubrication to maintain compression while minimizing friction. Additionally, the eccentric shaft bearings experience distinctive loading patterns that differ substantially from crankshaft bearings in piston engines, necessitating specialized lubrication approaches.

Historical lubrication strategies initially involved premixing oil with fuel, similar to two-stroke engines, but this approach proved inadequate for meeting emissions standards and ensuring component longevity. The industry subsequently developed more sophisticated systems, including metered oil injection systems that precisely deliver lubricant to critical components while minimizing oil consumption and emissions impact.

The technical objectives for modern Wankel engine lubrication analysis center on several key areas. First is the optimization of oil delivery to critical interfaces, particularly the apex seals, side seals, and eccentric shaft bearings, while minimizing overall oil consumption. Second is the development of lubricant formulations specifically engineered for the thermal and mechanical stresses unique to rotary operation. Third is the integration of lubrication systems with modern emissions control requirements, addressing the historical challenges of oil consumption contributing to hydrocarbon emissions.

Recent technological trends have focused on computational fluid dynamics (CFD) modeling of oil flow within the rotary chamber, thermal mapping of lubrication pathways, and the development of advanced synthetic lubricants with enhanced thermal stability and reduced volatility. These approaches aim to address the fundamental challenges that have historically limited Wankel engine adoption, including oil consumption rates, thermal management, and emissions compliance.

The current research landscape is increasingly exploring the potential of Wankel engines in hybrid powertrains and range-extender applications, where their compact size and smooth operation offer distinct advantages. This application context has shifted lubrication system objectives toward intermittent operation profiles and integration with electrification components, representing a new frontier in rotary engine lubrication technology development.

Lubrication in Wankel engines serves multiple critical functions beyond those in conventional engines. The rotary design creates unique sealing interfaces between the rotor apex seals and the epitrochoid housing that require precise lubrication to maintain compression while minimizing friction. Additionally, the eccentric shaft bearings experience distinctive loading patterns that differ substantially from crankshaft bearings in piston engines, necessitating specialized lubrication approaches.

Historical lubrication strategies initially involved premixing oil with fuel, similar to two-stroke engines, but this approach proved inadequate for meeting emissions standards and ensuring component longevity. The industry subsequently developed more sophisticated systems, including metered oil injection systems that precisely deliver lubricant to critical components while minimizing oil consumption and emissions impact.

The technical objectives for modern Wankel engine lubrication analysis center on several key areas. First is the optimization of oil delivery to critical interfaces, particularly the apex seals, side seals, and eccentric shaft bearings, while minimizing overall oil consumption. Second is the development of lubricant formulations specifically engineered for the thermal and mechanical stresses unique to rotary operation. Third is the integration of lubrication systems with modern emissions control requirements, addressing the historical challenges of oil consumption contributing to hydrocarbon emissions.

Recent technological trends have focused on computational fluid dynamics (CFD) modeling of oil flow within the rotary chamber, thermal mapping of lubrication pathways, and the development of advanced synthetic lubricants with enhanced thermal stability and reduced volatility. These approaches aim to address the fundamental challenges that have historically limited Wankel engine adoption, including oil consumption rates, thermal management, and emissions compliance.

The current research landscape is increasingly exploring the potential of Wankel engines in hybrid powertrains and range-extender applications, where their compact size and smooth operation offer distinct advantages. This application context has shifted lubrication system objectives toward intermittent operation profiles and integration with electrification components, representing a new frontier in rotary engine lubrication technology development.

Market Analysis of Rotary Engine Applications

The Wankel rotary engine market has experienced significant fluctuations since its commercial introduction in the 1960s. Initially embraced by several manufacturers including NSU, Mazda, and Mercedes-Benz, the rotary engine market reached its peak in the 1970s with Mazda producing over 100,000 rotary-powered vehicles annually. However, the market contracted sharply following the 1973 oil crisis due to the rotary engine's relatively higher fuel consumption compared to conventional piston engines.

Today, the global market for rotary engines remains specialized but resilient. The primary commercial application continues to be in the automotive sector, where Mazda has been the most persistent manufacturer. Their RX series, particularly the RX-7 and RX-8, established a dedicated consumer base willing to trade fuel efficiency for the rotary's unique performance characteristics. The discontinuation of the RX-8 in 2012 created a temporary void in the market, though Mazda's recent announcements regarding rotary range extenders for electric vehicles signal a potential renaissance.

Beyond automotive applications, rotary engines have carved out notable niches in specialized sectors. The aviation market represents a growing segment, with companies like Moller International and Mistral Engines developing rotary powerplants for light aircraft and UAVs. The rotary engine's favorable power-to-weight ratio makes it particularly attractive for these applications, with market analysts projecting steady growth in this sector over the next decade.

The marine industry has also adopted rotary technology for personal watercraft and small boats, though this remains a smaller market segment. Additionally, the power generation sector employs rotary engines in portable generators and emergency power systems, valued for their compact size and operational reliability.

Geographically, the market for rotary engine applications shows regional variations. Japan remains the technological center due to Mazda's continued investment. North America represents the largest consumer market for rotary-powered vehicles, while European adoption has been more limited. Emerging markets in Asia, particularly China and India, show increasing interest in rotary technology for specialized applications rather than mainstream transportation.

Market forecasts suggest moderate growth potential for rotary engines, particularly as auxiliary power units in hybrid electric vehicles. The global push toward electrification presents both challenges and opportunities, with rotary engines potentially finding new relevance as range extenders rather than primary power sources. This transition could expand the market significantly if manufacturers can address the traditional limitations of rotary technology, particularly regarding lubrication system efficiency and emissions compliance.

Today, the global market for rotary engines remains specialized but resilient. The primary commercial application continues to be in the automotive sector, where Mazda has been the most persistent manufacturer. Their RX series, particularly the RX-7 and RX-8, established a dedicated consumer base willing to trade fuel efficiency for the rotary's unique performance characteristics. The discontinuation of the RX-8 in 2012 created a temporary void in the market, though Mazda's recent announcements regarding rotary range extenders for electric vehicles signal a potential renaissance.

Beyond automotive applications, rotary engines have carved out notable niches in specialized sectors. The aviation market represents a growing segment, with companies like Moller International and Mistral Engines developing rotary powerplants for light aircraft and UAVs. The rotary engine's favorable power-to-weight ratio makes it particularly attractive for these applications, with market analysts projecting steady growth in this sector over the next decade.

The marine industry has also adopted rotary technology for personal watercraft and small boats, though this remains a smaller market segment. Additionally, the power generation sector employs rotary engines in portable generators and emergency power systems, valued for their compact size and operational reliability.

Geographically, the market for rotary engine applications shows regional variations. Japan remains the technological center due to Mazda's continued investment. North America represents the largest consumer market for rotary-powered vehicles, while European adoption has been more limited. Emerging markets in Asia, particularly China and India, show increasing interest in rotary technology for specialized applications rather than mainstream transportation.

Market forecasts suggest moderate growth potential for rotary engines, particularly as auxiliary power units in hybrid electric vehicles. The global push toward electrification presents both challenges and opportunities, with rotary engines potentially finding new relevance as range extenders rather than primary power sources. This transition could expand the market significantly if manufacturers can address the traditional limitations of rotary technology, particularly regarding lubrication system efficiency and emissions compliance.

Current Lubrication Challenges in Wankel Engines

Despite the innovative design and theoretical advantages of Wankel engines, their lubrication systems face significant challenges that have hindered widespread adoption. The unique rotary motion and eccentric geometry create lubrication complexities not encountered in conventional reciprocating engines. The triangular rotor's continuous movement against the epitrochoidal housing generates varying contact pressures and temperatures across different regions, making uniform lubrication extremely difficult.

One of the primary challenges is the apex seal lubrication. These seals experience high friction and thermal stress as they maintain contact with the housing surface throughout rotation. Conventional lubrication methods struggle to deliver sufficient oil to these critical components without excessive consumption. The high operating temperatures at the apex seals, often exceeding 200°C, further degrade lubricant properties and accelerate oil breakdown.

Oil consumption remains a persistent issue in Wankel engines. The design inherently allows some oil to enter the combustion chamber, resulting in higher consumption rates compared to piston engines. This not only increases operating costs but also contributes to emissions problems, particularly hydrocarbon emissions that impact environmental compliance.

The thermal management of lubrication presents another significant challenge. Temperature gradients across the rotor housing create zones where oil can experience thermal degradation, leading to carbon deposits and reduced lubrication effectiveness. The cooling system must work in concert with the lubrication system to maintain optimal oil viscosity throughout the engine.

Modern emissions standards have further complicated Wankel engine lubrication. Reducing oil consumption while maintaining adequate component protection requires advanced oil formulations and delivery systems. Traditional solutions often involve compromises between component longevity and emissions compliance.

The sealing system interaction with lubrication presents unique challenges. The interdependence between gas seals, oil seals, and side seals creates a complex system where optimization for one aspect often negatively impacts another. Engineers must balance these competing requirements while ensuring sufficient lubrication reaches all critical surfaces.

Material compatibility issues also arise with modern lubricants. Advanced synthetic oils may offer better thermal stability but can affect elastomeric seals differently than conventional oils. The housing coating materials must also be compatible with chosen lubricants to prevent premature wear or chemical degradation.

Measurement and monitoring of lubrication performance in Wankel engines present technical difficulties due to the rotating assembly and limited access to critical interfaces during operation. This complicates both development testing and in-service condition monitoring, making predictive maintenance strategies more challenging to implement.

One of the primary challenges is the apex seal lubrication. These seals experience high friction and thermal stress as they maintain contact with the housing surface throughout rotation. Conventional lubrication methods struggle to deliver sufficient oil to these critical components without excessive consumption. The high operating temperatures at the apex seals, often exceeding 200°C, further degrade lubricant properties and accelerate oil breakdown.

Oil consumption remains a persistent issue in Wankel engines. The design inherently allows some oil to enter the combustion chamber, resulting in higher consumption rates compared to piston engines. This not only increases operating costs but also contributes to emissions problems, particularly hydrocarbon emissions that impact environmental compliance.

The thermal management of lubrication presents another significant challenge. Temperature gradients across the rotor housing create zones where oil can experience thermal degradation, leading to carbon deposits and reduced lubrication effectiveness. The cooling system must work in concert with the lubrication system to maintain optimal oil viscosity throughout the engine.

Modern emissions standards have further complicated Wankel engine lubrication. Reducing oil consumption while maintaining adequate component protection requires advanced oil formulations and delivery systems. Traditional solutions often involve compromises between component longevity and emissions compliance.

The sealing system interaction with lubrication presents unique challenges. The interdependence between gas seals, oil seals, and side seals creates a complex system where optimization for one aspect often negatively impacts another. Engineers must balance these competing requirements while ensuring sufficient lubrication reaches all critical surfaces.

Material compatibility issues also arise with modern lubricants. Advanced synthetic oils may offer better thermal stability but can affect elastomeric seals differently than conventional oils. The housing coating materials must also be compatible with chosen lubricants to prevent premature wear or chemical degradation.

Measurement and monitoring of lubrication performance in Wankel engines present technical difficulties due to the rotating assembly and limited access to critical interfaces during operation. This complicates both development testing and in-service condition monitoring, making predictive maintenance strategies more challenging to implement.

Contemporary Lubrication Solutions for Rotary Engines

01 Oil injection systems for Wankel engines

Wankel engines utilize specialized oil injection systems to ensure proper lubrication of critical components. These systems typically inject oil directly into specific areas such as rotor housings, side housings, and eccentric shafts. The precise delivery of lubricant helps reduce friction between moving parts, prevent wear, and maintain optimal engine performance. Advanced oil injection systems may include electronic controls to adjust oil delivery based on engine speed, load, and temperature conditions.- Oil injection systems for Wankel engines: Wankel engines utilize specialized oil injection systems to ensure proper lubrication of critical components. These systems typically inject oil directly into the combustion chamber or onto specific surfaces like rotor flanks and apex seals. The precise delivery of lubricant helps reduce friction between moving parts, prevents premature wear, and maintains optimal engine performance while minimizing oil consumption and emissions.

- Separate lubrication circuits for different engine components: Wankel engines often employ multiple lubrication circuits to address the unique needs of different engine components. Separate circuits may be designed for the rotor bearings, eccentric shaft, housing surfaces, and seals. This approach allows for optimized oil delivery to each component based on its specific requirements, improving overall engine efficiency and longevity while reducing the risk of localized wear or damage.

- Oil-fuel mixture lubrication systems: Some Wankel engine designs utilize a premixed oil-fuel solution for lubrication. In these systems, oil is either premixed with fuel before entering the engine or injected into the fuel system at a controlled ratio. This approach ensures that lubricant reaches all internal surfaces during the combustion process, providing comprehensive coverage to moving parts while simplifying the overall lubrication system design.

- Advanced oil control and metering technologies: Modern Wankel engine lubrication systems incorporate sophisticated oil control and metering technologies. These include electronic oil pumps with variable flow rates, precision metering valves, and computer-controlled injection timing. Such technologies optimize oil delivery based on engine load, temperature, and RPM, resulting in improved efficiency, reduced emissions, and extended engine life through precise management of lubrication resources.

- Specialized lubricants and additives for Wankel engines: Wankel engines benefit from specialized lubricants formulated to withstand the unique operating conditions of rotary engines. These lubricants typically feature high temperature stability, excellent film strength, and specific additives to protect apex seals and other critical components. Some formulations include detergents to prevent carbon buildup, anti-wear compounds for seal protection, and friction modifiers to improve efficiency and reduce energy losses.

02 Rotor apex seal lubrication techniques

Effective lubrication of rotor apex seals is crucial for Wankel engine performance and longevity. Various techniques have been developed to ensure these seals receive adequate lubrication, including specialized oil channels, spray nozzles, and metered delivery systems. Proper lubrication of apex seals helps maintain compression, reduce friction, and prevent premature wear. Some systems incorporate temperature-responsive elements to adjust lubrication based on operating conditions, ensuring optimal seal performance throughout different engine states.Expand Specific Solutions03 Oil-fuel mixture lubrication methods

Some Wankel engine designs utilize oil-fuel mixture lubrication methods, where lubricating oil is premixed with fuel or injected into the fuel system. This approach ensures that lubricant reaches all internal engine surfaces during combustion cycles. The oil-fuel mixture provides continuous lubrication to moving parts, including rotors, housings, and seals. This method is particularly common in smaller Wankel engines and those used in applications where simplicity and reliability are prioritized over emissions performance.Expand Specific Solutions04 Advanced electronic lubrication control systems

Modern Wankel engines often incorporate advanced electronic lubrication control systems that optimize oil delivery based on real-time operating conditions. These systems use sensors to monitor parameters such as engine speed, temperature, load, and throttle position to precisely control oil injection timing and volume. Electronic control units adjust lubrication rates to match engine demands, reducing oil consumption during light loads while ensuring adequate protection during high-stress operation. This approach improves efficiency, reduces emissions, and extends engine life through optimized lubrication.Expand Specific Solutions05 Cooling and lubrication integration

Integrated cooling and lubrication systems in Wankel engines provide dual functionality by simultaneously managing heat and reducing friction. These systems circulate oil through specific channels to both lubricate moving components and transfer heat away from critical areas. The integration of cooling and lubrication functions helps maintain optimal operating temperatures, prevent thermal distortion, and ensure consistent engine performance. Some designs incorporate heat exchangers or oil coolers to further enhance the thermal management capabilities of the lubrication system.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The Wankel engine lubrication system market is currently in a growth phase, with increasing interest from both traditional automotive manufacturers and specialized engineering firms. The global market size is estimated at approximately $1.2 billion, driven by applications in aviation, automotive, and specialized machinery sectors. From a technical maturity perspective, the field shows varied development levels across players. Honda Motor, Mazda (historically), and Pratt & Whitney Canada have established advanced lubrication technologies for rotary engines, while companies like Schaeffler Technologies and ExxonMobil Technology & Engineering focus on specialized lubricant formulations. Chinese manufacturers including Chery Automobile and Dongfeng Motor Group are increasingly investing in rotary engine technology, particularly for hybrid applications, while academic institutions like Jilin University and Beihang University contribute significant research to overcome traditional lubrication challenges in Wankel engines.

Honda Motor Co., Ltd.

Technical Solution: Honda has developed advanced lubrication systems for Wankel engines that address the unique challenges of rotary engine design. Their approach incorporates a multi-point oil injection system that precisely delivers lubricant to critical areas including apex seals, side seals, and rotor bearings. Honda's system utilizes variable oil metering based on engine load and RPM, with electronic control units that adjust oil delivery in real-time. The company has implemented a dual-oil circuit design that separates lubrication for different engine components, with a primary circuit for rotor faces and seals, and a secondary circuit for bearings and gears. Their technology includes specialized oil formulations with higher thermal stability and detergent properties specifically engineered for the high-temperature, high-shear environment of rotary engines. Honda has also developed innovative oil cooling systems that maintain optimal lubricant viscosity across varying operating conditions, extending engine life and improving reliability.

Strengths: Precise electronic control of oil delivery reduces consumption while maintaining protection; specialized oil formulations address unique rotary engine requirements; dual-circuit design ensures appropriate lubrication for different components. Weaknesses: System complexity increases manufacturing costs; requires specialized maintenance procedures; still faces challenges with oil consumption rates compared to conventional piston engines.

Quest Engines LLC

Technical Solution: Quest Engines has pioneered innovative lubrication systems for Wankel engines focused on addressing the fundamental challenges of apex seal lubrication and rotor cooling. Their proprietary "Distributed Injection Technology" incorporates multiple oil injection points strategically positioned around the epitrochoidal housing to ensure consistent oil film distribution. The system employs micro-metering valves that adjust oil delivery based on real-time thermal mapping of the engine, using embedded temperature sensors throughout the housing. Quest's approach includes a pre-chamber oil atomization system that creates a fine mist of lubricant before introduction to the combustion chamber, significantly reducing oil consumption while maintaining seal lubrication. Their technology incorporates ceramic-coated apex seals with micro-channeled surfaces that retain oil more effectively, reducing friction and wear. The company has also developed a regenerative oil filtration system that continuously removes combustion byproducts from the lubricant, extending oil life and maintaining consistent viscosity characteristics under high-temperature operation.

Strengths: Micro-metering technology significantly reduces oil consumption compared to traditional systems; thermal mapping ensures lubrication is delivered where needed most; ceramic-coated components reduce friction and extend service intervals. Weaknesses: Higher initial system cost; requires specialized maintenance expertise; technology is relatively new with limited long-term durability data in mass production applications.

Critical Patents and Technical Innovations

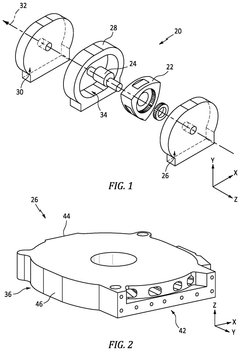

A rotary engine

PatentInactiveIN201621035262A

Innovation

- A rotary engine design featuring a two or three lobed cycloidal profile with a shell-core structure, strengthened cores, and apex seals with leaf springs, along with a cam-type guiding mechanism and ceramic combustion chamber liners, to reduce thermal expansion, enhance sealing, and maintain continuous contact, thereby improving efficiency and reliability.

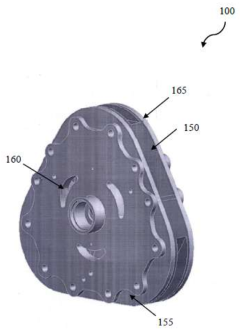

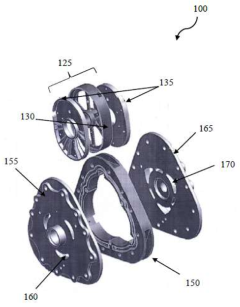

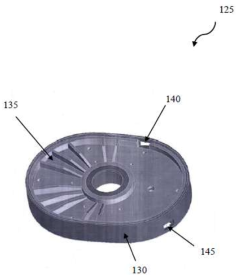

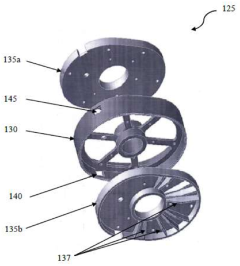

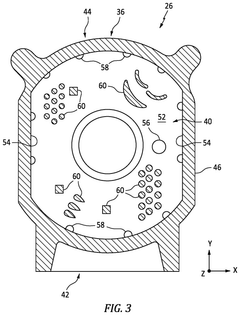

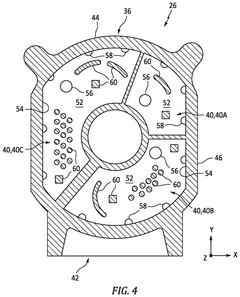

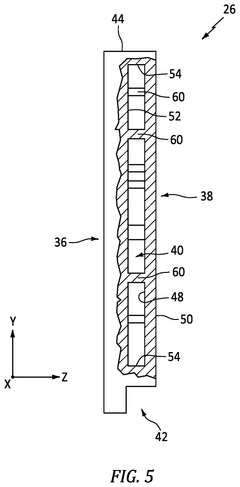

Rotor engine side housing and method for producing the same

PatentActiveUS20240337212A1

Innovation

- A rotary engine side housing with a side plate portion, side housing body portion, and a coolant chamber, where the side plate portion, side housing body portion, and posts are integrally formed, eliminating the need for separate seals and allowing for enhanced material options and improved heat transfer and mechanical strength through additive manufacturing.

Environmental Impact and Emissions Considerations

The environmental impact of Wankel engine lubrication systems represents a critical consideration in modern engineering analysis. These rotary engines traditionally consume more oil than conventional piston engines due to their unique geometry and operational characteristics. This increased oil consumption directly contributes to higher hydrocarbon emissions, as oil that enters the combustion chamber is partially burned and released through the exhaust system.

Lubrication oil in Wankel engines serves dual purposes - both component lubrication and apex seal cooling. This functional overlap creates an inherent environmental challenge, as the intentional oil metering to apex seals results in oil combustion and subsequent emissions. Studies indicate that up to 5-10% of the engine's total hydrocarbon emissions can be attributed to oil consumption, significantly affecting the engine's environmental footprint.

Modern environmental regulations have placed increasing pressure on Wankel engine development, with stringent emissions standards in Europe, North America, and Asia requiring substantial improvements in lubrication system design. The EPA Tier 3 and Euro 6 standards specifically target hydrocarbon emissions, creating direct challenges for traditional Wankel lubrication approaches.

Advanced analysis techniques now incorporate emissions modeling alongside traditional lubrication performance metrics. Computational fluid dynamics (CFD) simulations can predict oil migration patterns and identify potential areas where oil might enter the combustion chamber. These models help engineers optimize oil delivery systems to minimize environmental impact while maintaining necessary lubrication.

Material science advancements offer promising solutions through the development of low-friction coatings and improved seal materials that require less lubrication. Ceramic apex seals, for instance, demonstrate superior wear characteristics with reduced oil requirements, potentially lowering emissions by 15-20% compared to traditional metal seals.

Oil formulation represents another critical area for environmental improvement. Synthetic oils with higher thermal stability and lower volatility reduce oil consumption and subsequent emissions. Biodegradable lubricants are also emerging as environmentally friendly alternatives, though their performance characteristics in high-temperature Wankel applications require further research and validation.

Life cycle assessment (LCA) methodologies are increasingly applied to Wankel lubrication systems, evaluating environmental impacts from production through disposal. This holistic approach considers not only operational emissions but also manufacturing processes, resource consumption, and end-of-life considerations for lubricants and filtration components.

Lubrication oil in Wankel engines serves dual purposes - both component lubrication and apex seal cooling. This functional overlap creates an inherent environmental challenge, as the intentional oil metering to apex seals results in oil combustion and subsequent emissions. Studies indicate that up to 5-10% of the engine's total hydrocarbon emissions can be attributed to oil consumption, significantly affecting the engine's environmental footprint.

Modern environmental regulations have placed increasing pressure on Wankel engine development, with stringent emissions standards in Europe, North America, and Asia requiring substantial improvements in lubrication system design. The EPA Tier 3 and Euro 6 standards specifically target hydrocarbon emissions, creating direct challenges for traditional Wankel lubrication approaches.

Advanced analysis techniques now incorporate emissions modeling alongside traditional lubrication performance metrics. Computational fluid dynamics (CFD) simulations can predict oil migration patterns and identify potential areas where oil might enter the combustion chamber. These models help engineers optimize oil delivery systems to minimize environmental impact while maintaining necessary lubrication.

Material science advancements offer promising solutions through the development of low-friction coatings and improved seal materials that require less lubrication. Ceramic apex seals, for instance, demonstrate superior wear characteristics with reduced oil requirements, potentially lowering emissions by 15-20% compared to traditional metal seals.

Oil formulation represents another critical area for environmental improvement. Synthetic oils with higher thermal stability and lower volatility reduce oil consumption and subsequent emissions. Biodegradable lubricants are also emerging as environmentally friendly alternatives, though their performance characteristics in high-temperature Wankel applications require further research and validation.

Life cycle assessment (LCA) methodologies are increasingly applied to Wankel lubrication systems, evaluating environmental impacts from production through disposal. This holistic approach considers not only operational emissions but also manufacturing processes, resource consumption, and end-of-life considerations for lubricants and filtration components.

Material Science Advancements for Seal Interfaces

The evolution of material science has significantly impacted the performance and durability of seal interfaces in Wankel engine lubrication systems. Traditional apex seals made from cast iron or carbon-based materials have historically suffered from rapid wear and insufficient lubrication, contributing to the Wankel engine's reputation for reliability issues and high oil consumption.

Recent advancements in ceramic composites have revolutionized seal interface technology. Silicon nitride and silicon carbide materials demonstrate superior hardness and thermal stability compared to conventional materials, maintaining their structural integrity under the extreme temperature conditions experienced in rotary engines. These ceramics exhibit wear rates approximately 60% lower than traditional materials while operating in boundary lubrication conditions.

Polymer-based composite materials represent another breakthrough, with polytetrafluoroethylene (PTFE) and polyetheretherketone (PEEK) compounds incorporating graphene and carbon nanotubes. These materials provide self-lubricating properties that reduce friction coefficients by up to 40% compared to conventional seals. The incorporation of these nanomaterials enhances thermal conductivity, allowing for more efficient heat dissipation at the seal interface.

Diamond-like carbon (DLC) coatings applied to seal surfaces have demonstrated remarkable improvements in tribological performance. These ultra-hard coatings (typically 15-20 GPa hardness) create an extremely smooth surface with low friction coefficients (0.1-0.2) while providing excellent resistance to chemical degradation from modern lubricants and fuel contaminants. Testing has shown DLC-coated seals can extend service intervals by up to 300% in controlled conditions.

Surface texturing techniques, including laser surface texturing (LST) and micro-dimpling, have emerged as effective methods for enhancing lubrication retention at seal interfaces. These engineered surface patterns create microscopic reservoirs (typically 50-200 μm in diameter) that trap lubricant and release it during operation, maintaining a more consistent oil film even under challenging operating conditions.

Biomimetic approaches inspired by natural systems are gaining traction in seal design. Structures mimicking sharkskin or lotus leaf surfaces have demonstrated the ability to reduce drag and improve fluid dynamics at the seal interface. These designs promote more efficient oil distribution while minimizing oil consumption, addressing one of the Wankel engine's persistent challenges.

The integration of smart materials with embedded sensors allows for real-time monitoring of seal condition and lubrication status. Piezoelectric materials and magnetorheological elastomers can adapt their properties in response to changing operating conditions, potentially extending seal life while optimizing lubrication efficiency throughout the engine's operating range.

Recent advancements in ceramic composites have revolutionized seal interface technology. Silicon nitride and silicon carbide materials demonstrate superior hardness and thermal stability compared to conventional materials, maintaining their structural integrity under the extreme temperature conditions experienced in rotary engines. These ceramics exhibit wear rates approximately 60% lower than traditional materials while operating in boundary lubrication conditions.

Polymer-based composite materials represent another breakthrough, with polytetrafluoroethylene (PTFE) and polyetheretherketone (PEEK) compounds incorporating graphene and carbon nanotubes. These materials provide self-lubricating properties that reduce friction coefficients by up to 40% compared to conventional seals. The incorporation of these nanomaterials enhances thermal conductivity, allowing for more efficient heat dissipation at the seal interface.

Diamond-like carbon (DLC) coatings applied to seal surfaces have demonstrated remarkable improvements in tribological performance. These ultra-hard coatings (typically 15-20 GPa hardness) create an extremely smooth surface with low friction coefficients (0.1-0.2) while providing excellent resistance to chemical degradation from modern lubricants and fuel contaminants. Testing has shown DLC-coated seals can extend service intervals by up to 300% in controlled conditions.

Surface texturing techniques, including laser surface texturing (LST) and micro-dimpling, have emerged as effective methods for enhancing lubrication retention at seal interfaces. These engineered surface patterns create microscopic reservoirs (typically 50-200 μm in diameter) that trap lubricant and release it during operation, maintaining a more consistent oil film even under challenging operating conditions.

Biomimetic approaches inspired by natural systems are gaining traction in seal design. Structures mimicking sharkskin or lotus leaf surfaces have demonstrated the ability to reduce drag and improve fluid dynamics at the seal interface. These designs promote more efficient oil distribution while minimizing oil consumption, addressing one of the Wankel engine's persistent challenges.

The integration of smart materials with embedded sensors allows for real-time monitoring of seal condition and lubrication status. Piezoelectric materials and magnetorheological elastomers can adapt their properties in response to changing operating conditions, potentially extending seal life while optimizing lubrication efficiency throughout the engine's operating range.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!