How to Apply Turbine Engine Thermodynamics for Better Fuel Economy

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Turbine Engine Thermodynamics Background and Objectives

Turbine engine thermodynamics has evolved significantly since the development of the first jet engines in the 1930s. The fundamental principles governing these engines are rooted in the Brayton cycle, which describes the thermodynamic processes occurring in gas turbine engines. Over decades, engineers have refined these principles to achieve remarkable improvements in efficiency, power output, and environmental performance.

The evolution of turbine engine technology has been characterized by continuous advancements in materials science, computational fluid dynamics, and combustion chemistry. Early engines operated at thermal efficiencies below 20%, whereas modern high-bypass turbofan engines can achieve thermal efficiencies approaching 40%. This progression represents a significant technological achievement driven by the fundamental understanding and application of thermodynamic principles.

Current trends in turbine engine development focus on pushing the boundaries of operating temperatures, pressure ratios, and component efficiencies. Advanced cooling techniques, innovative combustor designs, and sophisticated control systems are being developed to extract maximum energy from fuel while minimizing environmental impact. The industry is witnessing a paradigm shift toward more sustainable operation, with thermodynamic optimization playing a central role.

The primary objective of applying turbine engine thermodynamics for better fuel economy is to maximize the conversion of chemical energy in fuel to useful work while minimizing losses throughout the engine cycle. This involves optimizing each component of the engine—compressor, combustor, turbine, and nozzle—to work in harmony at their peak efficiency points across various operating conditions.

Specific technical goals include increasing overall pressure ratios to improve thermal efficiency, developing more effective cooling systems to allow higher turbine inlet temperatures, reducing internal leakages to minimize work losses, and implementing advanced combustion techniques to ensure complete fuel utilization with minimal emissions. These objectives align with broader industry goals of reducing specific fuel consumption by 15-20% in the next generation of engines.

Another critical objective is to develop robust thermodynamic models that accurately predict engine performance across the entire flight envelope, enabling more precise control strategies and adaptive optimization during operation. This includes real-time adjustment of engine parameters based on thermodynamic principles to maintain optimal efficiency regardless of altitude, speed, or ambient conditions.

The ultimate aim is to create a new generation of turbine engines that not only deliver superior fuel economy but also accommodate alternative fuels and hybrid propulsion systems, establishing a technological foundation for sustainable aviation and power generation in the coming decades.

The evolution of turbine engine technology has been characterized by continuous advancements in materials science, computational fluid dynamics, and combustion chemistry. Early engines operated at thermal efficiencies below 20%, whereas modern high-bypass turbofan engines can achieve thermal efficiencies approaching 40%. This progression represents a significant technological achievement driven by the fundamental understanding and application of thermodynamic principles.

Current trends in turbine engine development focus on pushing the boundaries of operating temperatures, pressure ratios, and component efficiencies. Advanced cooling techniques, innovative combustor designs, and sophisticated control systems are being developed to extract maximum energy from fuel while minimizing environmental impact. The industry is witnessing a paradigm shift toward more sustainable operation, with thermodynamic optimization playing a central role.

The primary objective of applying turbine engine thermodynamics for better fuel economy is to maximize the conversion of chemical energy in fuel to useful work while minimizing losses throughout the engine cycle. This involves optimizing each component of the engine—compressor, combustor, turbine, and nozzle—to work in harmony at their peak efficiency points across various operating conditions.

Specific technical goals include increasing overall pressure ratios to improve thermal efficiency, developing more effective cooling systems to allow higher turbine inlet temperatures, reducing internal leakages to minimize work losses, and implementing advanced combustion techniques to ensure complete fuel utilization with minimal emissions. These objectives align with broader industry goals of reducing specific fuel consumption by 15-20% in the next generation of engines.

Another critical objective is to develop robust thermodynamic models that accurately predict engine performance across the entire flight envelope, enabling more precise control strategies and adaptive optimization during operation. This includes real-time adjustment of engine parameters based on thermodynamic principles to maintain optimal efficiency regardless of altitude, speed, or ambient conditions.

The ultimate aim is to create a new generation of turbine engines that not only deliver superior fuel economy but also accommodate alternative fuels and hybrid propulsion systems, establishing a technological foundation for sustainable aviation and power generation in the coming decades.

Fuel Economy Market Demands and Industry Trends

The global fuel economy market is experiencing significant growth driven by stringent environmental regulations, rising fuel costs, and increasing consumer awareness about carbon footprints. According to recent market analyses, the automotive fuel efficiency market is projected to reach $740 billion by 2026, growing at a CAGR of 5.8% from 2021. This growth trajectory reflects the intensifying pressure on manufacturers to develop more fuel-efficient transportation solutions.

In the aviation sector, fuel represents approximately 30% of operating costs for commercial airlines, creating substantial economic incentives for improved fuel economy. The International Air Transport Association (IATA) reports that a 1% reduction in fuel consumption across the global fleet could save the industry $1.8 billion annually. These economic drivers have positioned fuel efficiency as a critical competitive advantage in both commercial and military aviation markets.

Consumer preferences are increasingly favoring fuel-efficient vehicles, with surveys indicating that 68% of new car buyers consider fuel economy a top purchasing factor. This trend extends beyond personal vehicles to commercial transportation, where logistics companies actively seek solutions to reduce fuel costs across their fleets. The emergence of carbon pricing mechanisms in various regions has further accelerated this shift, as organizations face direct financial consequences for carbon emissions.

Industry trends show a multi-faceted approach to improving fuel economy. Manufacturers are pursuing advancements in materials science, aerodynamics, and propulsion systems simultaneously. The integration of digital technologies for real-time engine performance optimization represents a rapidly growing segment, with the engine management systems market expanding at 8.3% annually.

Regulatory frameworks worldwide continue to tighten fuel economy standards. The European Union's CO2 emission performance standards require a 37.5% reduction in new passenger car emissions by 2030. Similarly, the U.S. Corporate Average Fuel Economy (CAFE) standards mandate fleet-wide fuel efficiency improvements, while China's dual-credit policy system incentivizes fuel-efficient vehicle production.

The turbine engine market specifically shows increasing demand for thermodynamic efficiency improvements. With thermal efficiency in modern turbine engines typically ranging from 30-40%, significant room for improvement exists. Industry analysts estimate that advanced thermodynamic optimization techniques could potentially improve fuel economy by 15-20% in next-generation engines, representing a substantial market opportunity for innovative solutions in this space.

In the aviation sector, fuel represents approximately 30% of operating costs for commercial airlines, creating substantial economic incentives for improved fuel economy. The International Air Transport Association (IATA) reports that a 1% reduction in fuel consumption across the global fleet could save the industry $1.8 billion annually. These economic drivers have positioned fuel efficiency as a critical competitive advantage in both commercial and military aviation markets.

Consumer preferences are increasingly favoring fuel-efficient vehicles, with surveys indicating that 68% of new car buyers consider fuel economy a top purchasing factor. This trend extends beyond personal vehicles to commercial transportation, where logistics companies actively seek solutions to reduce fuel costs across their fleets. The emergence of carbon pricing mechanisms in various regions has further accelerated this shift, as organizations face direct financial consequences for carbon emissions.

Industry trends show a multi-faceted approach to improving fuel economy. Manufacturers are pursuing advancements in materials science, aerodynamics, and propulsion systems simultaneously. The integration of digital technologies for real-time engine performance optimization represents a rapidly growing segment, with the engine management systems market expanding at 8.3% annually.

Regulatory frameworks worldwide continue to tighten fuel economy standards. The European Union's CO2 emission performance standards require a 37.5% reduction in new passenger car emissions by 2030. Similarly, the U.S. Corporate Average Fuel Economy (CAFE) standards mandate fleet-wide fuel efficiency improvements, while China's dual-credit policy system incentivizes fuel-efficient vehicle production.

The turbine engine market specifically shows increasing demand for thermodynamic efficiency improvements. With thermal efficiency in modern turbine engines typically ranging from 30-40%, significant room for improvement exists. Industry analysts estimate that advanced thermodynamic optimization techniques could potentially improve fuel economy by 15-20% in next-generation engines, representing a substantial market opportunity for innovative solutions in this space.

Current Thermodynamic Challenges in Turbine Engines

Turbine engines face several critical thermodynamic challenges that limit their fuel efficiency and overall performance. The fundamental issue lies in the Brayton cycle efficiency limitations, where theoretical maximum efficiency is constrained by compression ratio and maximum temperature. Modern turbine engines operate at compression ratios between 30:1 and 45:1, with combustion temperatures approaching 1600°C, yet material limitations prevent further increases that would theoretically improve efficiency.

Heat management represents another significant challenge, as approximately 30-40% of energy input is lost as waste heat through exhaust gases. Current heat recovery systems like regenerators and recuperators add weight and complexity, creating design trade-offs between efficiency gains and practical implementation. The aviation industry particularly struggles with this balance, as weight penalties directly impact fuel consumption.

Combustion inefficiencies further compound these challenges. Even with advanced combustion chamber designs, incomplete combustion and non-uniform temperature distribution reduce thermodynamic efficiency by 3-7%. Modern combustors achieve 99% combustion efficiency under ideal conditions, but this decreases significantly during transient operations like takeoff and landing.

Component integration presents additional thermodynamic hurdles. The thermal interaction between compressors, combustors, and turbines creates complex efficiency cascades where losses in one component amplify through the system. Studies indicate that a 1% efficiency loss in the compressor can result in a 1.5-2% overall engine efficiency reduction due to these interdependencies.

Material constraints severely limit advancement in turbine engine thermodynamics. Despite developments in ceramic matrix composites and single-crystal superalloys, current materials can only withstand temperatures up to approximately 1200°C without cooling, while optimal thermodynamic efficiency would require temperatures exceeding 1800°C. This necessitates complex cooling systems that themselves reduce overall efficiency by 2-5%.

Operational variability further complicates optimization efforts. Turbine engines must function across diverse conditions—from sea level to high altitude, and from idle to maximum thrust—making it impossible to optimize thermodynamic efficiency for all operational states simultaneously. Current adaptive control systems can only partially mitigate these efficiency variations, typically achieving optimal efficiency in a narrow operational band that represents just 60-70% of the actual operating envelope.

Heat management represents another significant challenge, as approximately 30-40% of energy input is lost as waste heat through exhaust gases. Current heat recovery systems like regenerators and recuperators add weight and complexity, creating design trade-offs between efficiency gains and practical implementation. The aviation industry particularly struggles with this balance, as weight penalties directly impact fuel consumption.

Combustion inefficiencies further compound these challenges. Even with advanced combustion chamber designs, incomplete combustion and non-uniform temperature distribution reduce thermodynamic efficiency by 3-7%. Modern combustors achieve 99% combustion efficiency under ideal conditions, but this decreases significantly during transient operations like takeoff and landing.

Component integration presents additional thermodynamic hurdles. The thermal interaction between compressors, combustors, and turbines creates complex efficiency cascades where losses in one component amplify through the system. Studies indicate that a 1% efficiency loss in the compressor can result in a 1.5-2% overall engine efficiency reduction due to these interdependencies.

Material constraints severely limit advancement in turbine engine thermodynamics. Despite developments in ceramic matrix composites and single-crystal superalloys, current materials can only withstand temperatures up to approximately 1200°C without cooling, while optimal thermodynamic efficiency would require temperatures exceeding 1800°C. This necessitates complex cooling systems that themselves reduce overall efficiency by 2-5%.

Operational variability further complicates optimization efforts. Turbine engines must function across diverse conditions—from sea level to high altitude, and from idle to maximum thrust—making it impossible to optimize thermodynamic efficiency for all operational states simultaneously. Current adaptive control systems can only partially mitigate these efficiency variations, typically achieving optimal efficiency in a narrow operational band that represents just 60-70% of the actual operating envelope.

Current Thermodynamic Optimization Approaches

01 Thermodynamic cycle optimization for fuel efficiency

Optimizing the thermodynamic cycle of turbine engines can significantly improve fuel economy. This involves modifications to the compression ratio, combustion temperature, and expansion processes to extract maximum energy from fuel. Advanced cycle designs such as recuperated cycles, intercooled cycles, and combined cycles help reduce fuel consumption by recovering waste heat and improving overall thermal efficiency.- Advanced combustion control systems: Modern turbine engines employ sophisticated combustion control systems to optimize fuel economy. These systems monitor and adjust fuel-air ratios, combustion timing, and flame stability to ensure efficient fuel utilization. By precisely controlling the combustion process based on thermodynamic principles, these systems can significantly reduce fuel consumption while maintaining power output. Advanced sensors and electronic control units continuously analyze engine parameters to achieve optimal thermodynamic efficiency across various operating conditions.

- Heat recovery and thermal management: Turbine engine fuel economy can be improved through effective heat recovery and thermal management systems. These technologies capture waste heat from exhaust gases and cooling systems, redirecting it to preheat incoming air or fuel, or converting it to useful energy. By improving the overall thermal efficiency of the engine cycle, less fuel is required to produce the same power output. Advanced thermal barrier coatings and cooling techniques also help maintain optimal operating temperatures, reducing thermal losses and improving thermodynamic efficiency.

- Fuel composition and additives: The composition of fuel and use of specialized additives can significantly impact turbine engine thermodynamic efficiency and fuel economy. Engineered fuel formulations with optimized energy density and combustion characteristics improve the energy conversion process. Certain additives can enhance fuel atomization, reduce deposit formation, and promote more complete combustion. These improvements lead to better thermodynamic performance by maximizing the energy extracted from each unit of fuel while minimizing losses due to incomplete combustion or fouling of engine components.

- Variable geometry components and adaptive systems: Turbine engines with variable geometry components can adapt to changing operating conditions to maintain optimal thermodynamic efficiency. These systems include adjustable inlet guide vanes, variable stator vanes, and adaptive exhaust nozzles that modify flow paths based on engine speed, load, and ambient conditions. By continuously optimizing the compression ratio, expansion ratio, and flow characteristics, these systems ensure the engine operates at peak efficiency points across its operating envelope, resulting in improved fuel economy through better thermodynamic matching to power requirements.

- Advanced cycle configurations and hybrid systems: Innovative turbine engine cycle configurations offer pathways to improved thermodynamic efficiency and fuel economy. These include combined cycle systems, intercooled recuperated cycles, and hybrid power arrangements that integrate turbines with other power generation technologies. By modifying the traditional Brayton cycle with additional heat exchangers, multiple compression stages, or alternative working fluids, these advanced configurations can achieve higher thermal efficiencies. The integration of turbine engines with electric systems in hybrid configurations also allows for operation at optimal thermodynamic conditions, further enhancing fuel economy.

02 Fuel composition and additives for improved combustion

Specialized fuel compositions and additives can enhance combustion efficiency in turbine engines. These formulations reduce carbon deposits, improve atomization, and promote complete combustion. Certain additives can modify the thermodynamic properties of the fuel, resulting in better energy release during combustion and reduced thermal losses, ultimately improving the fuel economy of turbine engines.Expand Specific Solutions03 Advanced control systems for optimizing engine parameters

Sophisticated control systems can continuously adjust turbine engine parameters to maintain optimal thermodynamic conditions across various operating regimes. These systems monitor factors such as fuel-air ratio, combustion timing, and turbine inlet temperature to maximize efficiency. Real-time adjustments based on sensor feedback allow for dynamic optimization of the thermodynamic processes, resulting in significant fuel economy improvements.Expand Specific Solutions04 Heat recovery and waste energy utilization systems

Implementing heat recovery systems in turbine engines captures waste thermal energy that would otherwise be lost to the environment. Technologies such as regenerators, recuperators, and waste heat recovery units redirect exhaust heat back into the thermodynamic cycle. This recaptured energy reduces the amount of fuel needed to achieve the same power output, thereby improving overall fuel economy and thermodynamic efficiency.Expand Specific Solutions05 Aerodynamic and mechanical efficiency improvements

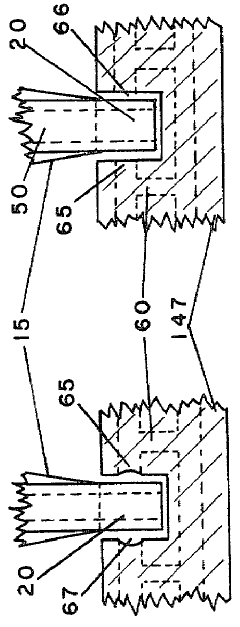

Enhancing the aerodynamic design of turbine components and reducing mechanical losses can improve the thermodynamic efficiency of the engine. Advanced blade designs, improved sealing technologies, and reduced friction in bearings and other moving parts minimize energy losses throughout the system. These improvements allow more of the fuel's energy to be converted into useful work rather than being lost as heat, significantly improving fuel economy.Expand Specific Solutions

Leading Turbine Engine Manufacturers and Researchers

The turbine engine thermodynamics market for fuel economy is currently in a growth phase, with increasing demand driven by stringent emissions regulations and rising fuel costs. The market is projected to reach significant scale as aerospace and automotive industries prioritize efficiency. Leading players include established aerospace giants like General Electric, Rolls-Royce, and Pratt & Whitney Canada, who possess advanced thermodynamic modeling capabilities. Automotive manufacturers such as Ford, GM, and Mazda are increasingly investing in turbine thermodynamics for hybrid applications. Academic institutions like Beihang University and Nanjing University of Aeronautics & Astronautics are contributing significant research. The technology shows varying maturity levels across sectors, with aerospace applications being more advanced than automotive implementations, though cross-industry collaboration is accelerating development.

General Electric Company

Technical Solution: GE's advanced turbine engine thermodynamics approach focuses on their proprietary Combined Cycle technology that integrates gas and steam turbines to maximize thermal efficiency. Their HA-class gas turbines achieve over 64% combined cycle efficiency by implementing advanced aerodynamics, optimized combustion systems, and innovative cooling techniques. GE has developed a multi-stage combustion process that reduces emissions while maintaining high thermal performance. Their turbines incorporate advanced materials like ceramic matrix composites (CMCs) that can withstand higher temperatures, allowing engines to operate at more thermodynamically efficient conditions. GE's digital twin technology enables real-time monitoring and predictive analytics to optimize fuel consumption based on operational conditions, with their Digital Power Plant solution demonstrating fuel savings of up to 1% through continuous thermodynamic optimization.

Strengths: Industry-leading combined cycle efficiency; proprietary materials technology allowing higher temperature operation; extensive digital monitoring capabilities for real-time optimization. Weaknesses: Higher initial capital costs; complex systems requiring specialized maintenance; optimization benefits may diminish over time as components wear.

Rolls-Royce Plc

Technical Solution: Rolls-Royce has pioneered the UltraFan® engine design incorporating a geared architecture that allows the fan and turbine to rotate at their optimal speeds, significantly improving thermodynamic efficiency. Their Advance3 core technology features a new high-pressure turbine design with improved aerodynamics and cooling systems that can withstand temperatures exceeding 2,000°C. Rolls-Royce implements advanced thermal barrier coatings that reduce heat transfer to critical components, allowing higher combustion temperatures without compromising component life. Their ALECSys (Advanced Low Emissions Combustion System) technology optimizes the fuel-air mixture for more complete combustion while minimizing emissions. Rolls-Royce's intelligent engine concept incorporates embedded sensors that continuously monitor thermodynamic parameters and adjust operating conditions in real-time, achieving up to 25% better fuel efficiency compared to previous generation engines through optimized thermodynamic cycles.

Strengths: Geared architecture provides excellent thermodynamic optimization across different operating conditions; advanced materials research enables higher temperature operation; comprehensive digital monitoring system. Weaknesses: Complex mechanical systems with additional potential failure points; higher manufacturing costs; requires more sophisticated maintenance procedures.

Key Thermodynamic Innovations and Patents

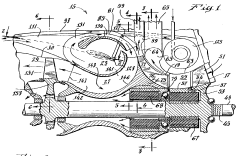

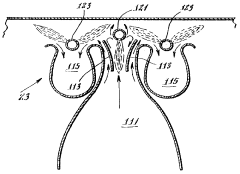

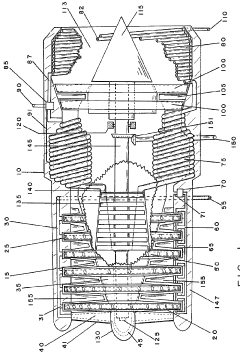

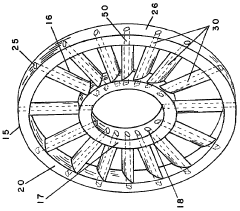

Small gas turbine engine having enhanced fuel economy

PatentInactiveUS6047540A

Innovation

- A compact and lightweight gas turbine engine design featuring a ducted structure with a single-stage axial-flow compressor, a hybrid axial-radial centrifugal compressor, inward flow radial turbine, and axial-flow high-pressure turbine, utilizing a common face between the compressor and turbine made of porous material for air seepage and cooling, and incorporating 'folded-comma' shaped burners for efficient fuel combustion and reduced infrared radiation.

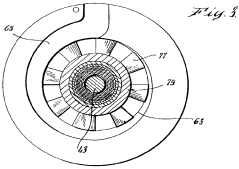

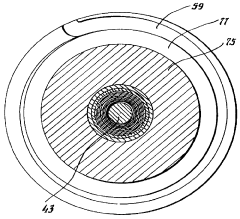

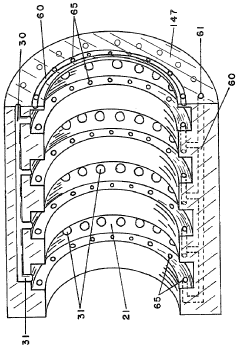

Steam assisted gas turbine engine

PatentInactiveUS4333309A

Innovation

- A dual-purpose rotary heat exchanger compresses air and condenses steam to a liquid state, using the heat from combustion and exhaust processes to generate steam that powers a steam turbine attached to the main drive shaft, thereby improving engine efficiency and fuel economy.

Environmental Impact and Emission Regulations

The environmental impact of turbine engines represents a critical consideration in modern aviation and power generation industries. As global environmental concerns intensify, regulatory bodies worldwide have implemented increasingly stringent emission standards that directly influence turbine engine design and operation. These regulations primarily target the reduction of nitrogen oxides (NOx), carbon monoxide (CO), unburned hydrocarbons (UHC), and particulate matter emissions, which contribute significantly to air pollution and climate change.

The International Civil Aviation Organization (ICAO) has established the Committee on Aviation Environmental Protection (CAEP) standards, which have progressively tightened emission limits for aircraft engines. Similarly, the Environmental Protection Agency (EPA) in the United States and the European Union Emissions Trading System (EU ETS) have implemented comprehensive frameworks governing industrial turbine emissions. These regulatory frameworks create both challenges and opportunities for thermodynamic optimization of turbine engines.

Thermodynamic improvements for better fuel economy inherently align with emission reduction goals. Higher thermal efficiency directly correlates with reduced carbon dioxide emissions per unit of power output. Advanced combustion techniques, such as lean premixed combustion and rich-burn quick-quench lean-burn (RQL) designs, leverage thermodynamic principles to minimize NOx formation while maintaining combustion stability and efficiency.

Water or steam injection represents another thermodynamically-driven approach that reduces combustion temperatures, thereby decreasing NOx formation. This technique, while effective for emission control, presents a complex thermodynamic trade-off that must be carefully balanced against overall system efficiency and water resource considerations.

Selective catalytic reduction (SCR) systems, though primarily post-combustion technologies, interact with engine thermodynamics by creating backpressure that must be accounted for in overall system design. The integration of these systems requires sophisticated thermodynamic modeling to ensure optimal performance without compromising fuel economy.

Future regulatory trends indicate a continued push toward near-zero emission standards, particularly in urban environments and sensitive ecological zones. This regulatory trajectory necessitates fundamental innovations in turbine thermodynamics rather than incremental improvements. Concepts such as flameless oxidation, catalytic combustion, and hybrid electric propulsion systems represent promising avenues that may simultaneously address emission regulations while enhancing thermodynamic efficiency.

The economic implications of these regulations cannot be overlooked, as non-compliance penalties and carbon taxation schemes increasingly influence the cost-benefit analysis of thermodynamic optimization strategies. This economic dimension adds urgency to the development of thermodynamically efficient solutions that can meet both environmental standards and market demands for reduced operational costs.

The International Civil Aviation Organization (ICAO) has established the Committee on Aviation Environmental Protection (CAEP) standards, which have progressively tightened emission limits for aircraft engines. Similarly, the Environmental Protection Agency (EPA) in the United States and the European Union Emissions Trading System (EU ETS) have implemented comprehensive frameworks governing industrial turbine emissions. These regulatory frameworks create both challenges and opportunities for thermodynamic optimization of turbine engines.

Thermodynamic improvements for better fuel economy inherently align with emission reduction goals. Higher thermal efficiency directly correlates with reduced carbon dioxide emissions per unit of power output. Advanced combustion techniques, such as lean premixed combustion and rich-burn quick-quench lean-burn (RQL) designs, leverage thermodynamic principles to minimize NOx formation while maintaining combustion stability and efficiency.

Water or steam injection represents another thermodynamically-driven approach that reduces combustion temperatures, thereby decreasing NOx formation. This technique, while effective for emission control, presents a complex thermodynamic trade-off that must be carefully balanced against overall system efficiency and water resource considerations.

Selective catalytic reduction (SCR) systems, though primarily post-combustion technologies, interact with engine thermodynamics by creating backpressure that must be accounted for in overall system design. The integration of these systems requires sophisticated thermodynamic modeling to ensure optimal performance without compromising fuel economy.

Future regulatory trends indicate a continued push toward near-zero emission standards, particularly in urban environments and sensitive ecological zones. This regulatory trajectory necessitates fundamental innovations in turbine thermodynamics rather than incremental improvements. Concepts such as flameless oxidation, catalytic combustion, and hybrid electric propulsion systems represent promising avenues that may simultaneously address emission regulations while enhancing thermodynamic efficiency.

The economic implications of these regulations cannot be overlooked, as non-compliance penalties and carbon taxation schemes increasingly influence the cost-benefit analysis of thermodynamic optimization strategies. This economic dimension adds urgency to the development of thermodynamically efficient solutions that can meet both environmental standards and market demands for reduced operational costs.

Materials Science Advancements for Thermal Management

Recent advancements in materials science have revolutionized thermal management capabilities in turbine engines, directly impacting fuel economy. High-temperature ceramic matrix composites (CMCs) have emerged as game-changers, allowing engines to operate at temperatures exceeding 1300°C—significantly higher than traditional nickel-based superalloys. These materials maintain structural integrity while reducing cooling requirements, enabling more thermodynamically efficient combustion cycles.

Thermal barrier coatings (TBCs) have undergone substantial evolution, with yttria-stabilized zirconia (YSZ) systems now incorporating complex rare earth elements that reduce thermal conductivity by up to 40% compared to conventional coatings. This advancement allows engine components to withstand higher temperatures without compromising structural integrity, directly translating to improved thermodynamic efficiency and reduced fuel consumption.

Additive manufacturing techniques have enabled the production of components with integrated cooling channels that were previously impossible to manufacture. These complex geometries optimize heat transfer while minimizing material usage, creating lighter components that require less energy to operate. Lattice structures and topology-optimized designs now provide superior thermal management with reduced mass, contributing to overall system efficiency.

Nanostructured materials represent another frontier in thermal management. Carbon nanotubes and graphene-enhanced composites demonstrate thermal conductivity values up to five times higher than copper while weighing significantly less. When strategically incorporated into heat exchangers and thermal management systems, these materials facilitate more efficient heat transfer away from critical components, allowing for more aggressive thermodynamic cycles.

Shape memory alloys and phase-change materials are being integrated into adaptive thermal management systems that respond dynamically to operating conditions. These smart materials can alter their properties based on temperature, optimizing thermal performance across the entire operating envelope rather than at a single design point, which is particularly valuable for engines that operate across varied flight regimes.

Environmental barrier coatings (EBCs) have been developed to protect advanced materials from water vapor and other combustion byproducts, extending component lifespan in harsh operating environments. This longevity ensures that thermodynamic performance remains consistent throughout the service life, preventing the efficiency degradation that typically occurs as conventional materials deteriorate under thermal cycling.

Thermal barrier coatings (TBCs) have undergone substantial evolution, with yttria-stabilized zirconia (YSZ) systems now incorporating complex rare earth elements that reduce thermal conductivity by up to 40% compared to conventional coatings. This advancement allows engine components to withstand higher temperatures without compromising structural integrity, directly translating to improved thermodynamic efficiency and reduced fuel consumption.

Additive manufacturing techniques have enabled the production of components with integrated cooling channels that were previously impossible to manufacture. These complex geometries optimize heat transfer while minimizing material usage, creating lighter components that require less energy to operate. Lattice structures and topology-optimized designs now provide superior thermal management with reduced mass, contributing to overall system efficiency.

Nanostructured materials represent another frontier in thermal management. Carbon nanotubes and graphene-enhanced composites demonstrate thermal conductivity values up to five times higher than copper while weighing significantly less. When strategically incorporated into heat exchangers and thermal management systems, these materials facilitate more efficient heat transfer away from critical components, allowing for more aggressive thermodynamic cycles.

Shape memory alloys and phase-change materials are being integrated into adaptive thermal management systems that respond dynamically to operating conditions. These smart materials can alter their properties based on temperature, optimizing thermal performance across the entire operating envelope rather than at a single design point, which is particularly valuable for engines that operate across varied flight regimes.

Environmental barrier coatings (EBCs) have been developed to protect advanced materials from water vapor and other combustion byproducts, extending component lifespan in harsh operating environments. This longevity ensures that thermodynamic performance remains consistent throughout the service life, preventing the efficiency degradation that typically occurs as conventional materials deteriorate under thermal cycling.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!