How To Control Residual Stress In DED-Repaired Components

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DED Repair Technology Background and Objectives

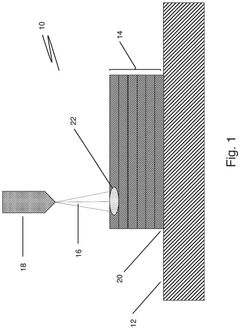

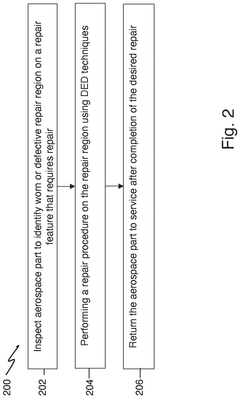

Directed Energy Deposition (DED) has emerged as a transformative additive manufacturing technology with significant applications in component repair across aerospace, defense, and industrial sectors. The technology utilizes focused thermal energy to fuse materials as they are deposited, enabling precise material addition to damaged components. Since its inception in the early 2000s, DED has evolved from experimental applications to becoming an established repair methodology for high-value components.

The evolution of DED repair technology has been driven by increasing demands for sustainable manufacturing practices and the need to extend the service life of critical components. Traditional repair methods often involve complete component replacement, resulting in substantial material waste and production costs. DED offers a more sustainable alternative by enabling targeted material deposition only where needed, significantly reducing material consumption and environmental impact.

A persistent challenge in DED repair processes is the management of residual stress—internal stresses that remain within a component after the repair process is complete. These stresses arise from the rapid heating and cooling cycles inherent to the DED process, creating thermal gradients that lead to non-uniform expansion and contraction of materials. Uncontrolled residual stress can result in dimensional inaccuracies, reduced fatigue life, and even catastrophic component failure during service.

The primary objective of current research in this field is to develop comprehensive strategies for controlling residual stress in DED-repaired components. This includes advancing process monitoring techniques, optimizing deposition parameters, implementing effective pre- and post-processing treatments, and developing predictive models that can accurately forecast stress distribution. The ultimate goal is to ensure that repaired components maintain or exceed the mechanical properties and service life of the original parts.

Recent technological advancements have enabled more precise control over the DED process, including improved laser systems, multi-axis deposition capabilities, and real-time monitoring solutions. These developments have expanded the application scope of DED repairs to increasingly complex geometries and a wider range of materials, including high-performance alloys used in critical applications.

The trajectory of DED repair technology is moving toward digital integration, with emphasis on closed-loop control systems that can dynamically adjust process parameters based on real-time data. This evolution aligns with Industry 4.0 principles, where intelligent manufacturing systems can adapt to changing conditions to optimize outcomes—in this case, minimizing residual stress while maintaining repair quality and efficiency.

The evolution of DED repair technology has been driven by increasing demands for sustainable manufacturing practices and the need to extend the service life of critical components. Traditional repair methods often involve complete component replacement, resulting in substantial material waste and production costs. DED offers a more sustainable alternative by enabling targeted material deposition only where needed, significantly reducing material consumption and environmental impact.

A persistent challenge in DED repair processes is the management of residual stress—internal stresses that remain within a component after the repair process is complete. These stresses arise from the rapid heating and cooling cycles inherent to the DED process, creating thermal gradients that lead to non-uniform expansion and contraction of materials. Uncontrolled residual stress can result in dimensional inaccuracies, reduced fatigue life, and even catastrophic component failure during service.

The primary objective of current research in this field is to develop comprehensive strategies for controlling residual stress in DED-repaired components. This includes advancing process monitoring techniques, optimizing deposition parameters, implementing effective pre- and post-processing treatments, and developing predictive models that can accurately forecast stress distribution. The ultimate goal is to ensure that repaired components maintain or exceed the mechanical properties and service life of the original parts.

Recent technological advancements have enabled more precise control over the DED process, including improved laser systems, multi-axis deposition capabilities, and real-time monitoring solutions. These developments have expanded the application scope of DED repairs to increasingly complex geometries and a wider range of materials, including high-performance alloys used in critical applications.

The trajectory of DED repair technology is moving toward digital integration, with emphasis on closed-loop control systems that can dynamically adjust process parameters based on real-time data. This evolution aligns with Industry 4.0 principles, where intelligent manufacturing systems can adapt to changing conditions to optimize outcomes—in this case, minimizing residual stress while maintaining repair quality and efficiency.

Market Analysis for DED Repair Solutions

The global market for Directed Energy Deposition (DED) repair solutions has experienced significant growth in recent years, driven primarily by the aerospace, defense, and heavy machinery sectors. Current market valuations indicate that the DED repair technology segment represents approximately 18% of the overall additive manufacturing repair market, with an estimated compound annual growth rate of 24% projected through 2028.

The aerospace industry remains the dominant consumer of DED repair solutions, accounting for nearly 42% of the total market share. This dominance stems from the critical need to extend the service life of high-value components such as turbine blades, combustion chambers, and structural elements where residual stress control is paramount. The defense sector follows closely at 27% market share, with similar applications but with additional emphasis on field deployability and rapid repair capabilities.

Heavy machinery and energy sectors collectively represent about 22% of the market, with growing adoption rates as these industries increasingly recognize the cost benefits of component repair versus replacement. The remaining market share is distributed among automotive, medical, and other industrial applications where precision repair with minimal residual stress is becoming increasingly valuable.

Geographically, North America leads the market with approximately 38% share, followed by Europe (29%) and Asia-Pacific (24%). The Asia-Pacific region, particularly China and South Korea, demonstrates the fastest growth trajectory, with increasing investments in advanced manufacturing technologies and repair capabilities.

Customer demand patterns reveal a clear shift toward integrated solutions that address the entire repair workflow, with particular emphasis on residual stress prediction, monitoring, and control. End-users increasingly require not just the DED technology itself, but comprehensive solutions that include pre-process simulation, in-situ monitoring, and post-process treatments to manage residual stress effectively.

Market research indicates that price sensitivity varies significantly by sector. While aerospace and defense customers prioritize performance and reliability over cost, industrial sectors demonstrate greater price sensitivity, creating distinct market segments with different value propositions. This bifurcation has led to the emergence of tiered solution offerings, with premium solutions focusing on advanced residual stress control technologies commanding price premiums of 30-45% over basic systems.

The competitive landscape shows consolidation among major players, with strategic acquisitions focused on integrating complementary technologies for residual stress management. Simultaneously, specialized startups offering innovative approaches to stress control are attracting significant venture capital, indicating strong market confidence in continued growth and technological advancement.

The aerospace industry remains the dominant consumer of DED repair solutions, accounting for nearly 42% of the total market share. This dominance stems from the critical need to extend the service life of high-value components such as turbine blades, combustion chambers, and structural elements where residual stress control is paramount. The defense sector follows closely at 27% market share, with similar applications but with additional emphasis on field deployability and rapid repair capabilities.

Heavy machinery and energy sectors collectively represent about 22% of the market, with growing adoption rates as these industries increasingly recognize the cost benefits of component repair versus replacement. The remaining market share is distributed among automotive, medical, and other industrial applications where precision repair with minimal residual stress is becoming increasingly valuable.

Geographically, North America leads the market with approximately 38% share, followed by Europe (29%) and Asia-Pacific (24%). The Asia-Pacific region, particularly China and South Korea, demonstrates the fastest growth trajectory, with increasing investments in advanced manufacturing technologies and repair capabilities.

Customer demand patterns reveal a clear shift toward integrated solutions that address the entire repair workflow, with particular emphasis on residual stress prediction, monitoring, and control. End-users increasingly require not just the DED technology itself, but comprehensive solutions that include pre-process simulation, in-situ monitoring, and post-process treatments to manage residual stress effectively.

Market research indicates that price sensitivity varies significantly by sector. While aerospace and defense customers prioritize performance and reliability over cost, industrial sectors demonstrate greater price sensitivity, creating distinct market segments with different value propositions. This bifurcation has led to the emergence of tiered solution offerings, with premium solutions focusing on advanced residual stress control technologies commanding price premiums of 30-45% over basic systems.

The competitive landscape shows consolidation among major players, with strategic acquisitions focused on integrating complementary technologies for residual stress management. Simultaneously, specialized startups offering innovative approaches to stress control are attracting significant venture capital, indicating strong market confidence in continued growth and technological advancement.

Residual Stress Challenges in DED Repair

Residual stress represents one of the most significant challenges in Directed Energy Deposition (DED) repair processes for high-value components. These stresses develop due to the rapid heating and cooling cycles inherent in the additive manufacturing process, creating thermal gradients that lead to non-uniform expansion and contraction of material. When repairing critical components such as turbine blades or aerospace structures, these residual stresses can compromise the mechanical integrity of the repaired part, potentially leading to premature failure during service.

The primary concern with residual stress in DED repairs is its tendency to cause distortion, cracking, and reduced fatigue life. Tensile residual stresses are particularly problematic as they can accelerate crack initiation and propagation, especially in components subjected to cyclic loading conditions. Furthermore, the interaction between the substrate material and the deposited layers creates complex stress fields that are difficult to predict and control without sophisticated modeling and monitoring systems.

Material-specific challenges further complicate residual stress management. High-strength alloys, commonly used in aerospace and energy sectors, are particularly susceptible to residual stress-induced issues due to their lower ductility and higher thermal expansion coefficients. Nickel-based superalloys, titanium alloys, and tool steels each present unique challenges regarding stress development during the DED repair process.

Geometric complexity adds another dimension to the residual stress challenge. Components with intricate features, thin walls, or varying cross-sections experience non-uniform heat distribution during deposition, resulting in localized stress concentrations. These stress hotspots can lead to unexpected deformation or failure modes that may not be apparent immediately after repair but emerge during subsequent service.

Current measurement techniques for residual stress assessment also present limitations. Non-destructive methods such as X-ray diffraction provide surface-level stress information but fail to capture the full three-dimensional stress state within the component. Destructive techniques offer more comprehensive data but obviously cannot be applied to finished components intended for service.

The multi-physics nature of residual stress formation makes computational prediction extremely challenging. Models must account for thermal gradients, phase transformations, microstructural evolution, and mechanical behavior simultaneously. This complexity often leads to significant discrepancies between predicted and actual residual stress distributions, hampering efforts to develop reliable process parameters for stress mitigation.

The primary concern with residual stress in DED repairs is its tendency to cause distortion, cracking, and reduced fatigue life. Tensile residual stresses are particularly problematic as they can accelerate crack initiation and propagation, especially in components subjected to cyclic loading conditions. Furthermore, the interaction between the substrate material and the deposited layers creates complex stress fields that are difficult to predict and control without sophisticated modeling and monitoring systems.

Material-specific challenges further complicate residual stress management. High-strength alloys, commonly used in aerospace and energy sectors, are particularly susceptible to residual stress-induced issues due to their lower ductility and higher thermal expansion coefficients. Nickel-based superalloys, titanium alloys, and tool steels each present unique challenges regarding stress development during the DED repair process.

Geometric complexity adds another dimension to the residual stress challenge. Components with intricate features, thin walls, or varying cross-sections experience non-uniform heat distribution during deposition, resulting in localized stress concentrations. These stress hotspots can lead to unexpected deformation or failure modes that may not be apparent immediately after repair but emerge during subsequent service.

Current measurement techniques for residual stress assessment also present limitations. Non-destructive methods such as X-ray diffraction provide surface-level stress information but fail to capture the full three-dimensional stress state within the component. Destructive techniques offer more comprehensive data but obviously cannot be applied to finished components intended for service.

The multi-physics nature of residual stress formation makes computational prediction extremely challenging. Models must account for thermal gradients, phase transformations, microstructural evolution, and mechanical behavior simultaneously. This complexity often leads to significant discrepancies between predicted and actual residual stress distributions, hampering efforts to develop reliable process parameters for stress mitigation.

Current Residual Stress Mitigation Strategies

01 Measurement and analysis of residual stress in DED-repaired components

Various methods and systems for measuring and analyzing residual stress in components repaired using Directed Energy Deposition (DED) technology. These techniques help in understanding the stress distribution patterns and their effects on the mechanical properties of the repaired parts. Advanced analytical tools and computational models are used to predict and evaluate residual stress formation during the repair process, enabling better quality control and performance assessment.- Measurement and analysis of residual stress in DED-repaired components: Various methods and techniques are used to measure and analyze residual stress in components repaired using Directed Energy Deposition (DED). These include X-ray diffraction, neutron diffraction, and computational modeling. The analysis helps in understanding the distribution and magnitude of residual stresses, which is crucial for ensuring the structural integrity and performance of repaired components.

- Stress reduction techniques in DED repair processes: Several techniques are employed to reduce residual stress during and after DED repair processes. These include controlled heating and cooling cycles, post-process heat treatments, and mechanical stress relief methods. By managing the thermal gradients and material transformations during the repair process, these techniques help minimize the formation of harmful residual stresses in the repaired components.

- Monitoring and control systems for residual stress management: Advanced monitoring and control systems are developed to manage residual stress in real-time during DED repair operations. These systems utilize sensors, cameras, and feedback control algorithms to adjust process parameters based on thermal and mechanical data. By maintaining optimal conditions throughout the repair process, these systems help achieve more consistent and predictable residual stress profiles in the repaired components.

- Material selection and composition for improved residual stress characteristics: The selection of appropriate materials and their composition plays a significant role in managing residual stress in DED-repaired components. By choosing materials with compatible thermal expansion coefficients, similar mechanical properties, and optimized microstructural characteristics, the development of harmful residual stresses can be minimized. Additionally, the use of specialized powder blends or wire feedstock can help create more favorable stress distributions in the repaired regions.

- Process parameter optimization for residual stress control: Optimization of process parameters such as laser power, scanning speed, layer thickness, and deposition pattern significantly impacts the residual stress in DED-repaired components. Through experimental studies and computational modeling, optimal parameter combinations can be identified to minimize harmful residual stresses while maintaining good mechanical properties and dimensional accuracy of the repaired components. This approach enables more reliable and durable repairs for critical applications.

02 Stress reduction techniques in DED repair processes

Methods for reducing residual stress during and after DED repair operations. These include controlled heating and cooling cycles, specific deposition patterns, and post-processing treatments. By managing thermal gradients and material transformation during the repair process, these techniques help minimize distortion and improve the structural integrity of repaired components, leading to enhanced service life and reliability.Expand Specific Solutions03 Monitoring systems for residual stress during DED repair

Real-time monitoring systems and sensors designed to track residual stress development during the DED repair process. These systems provide immediate feedback on stress formation, allowing for process adjustments to maintain optimal repair conditions. Integration of advanced sensing technologies with control systems enables adaptive processing to minimize harmful stress accumulation in critical components.Expand Specific Solutions04 Post-processing treatments for residual stress management

Various post-processing treatments applied to DED-repaired components to manage residual stress. These include heat treatment, shot peening, ultrasonic impact treatment, and other mechanical or thermal processes. Such treatments help redistribute or relieve accumulated stresses, improving the dimensional stability and fatigue resistance of repaired parts, particularly in high-performance applications.Expand Specific Solutions05 Material selection and composition for stress-optimized DED repairs

Strategic selection and development of materials and powder compositions specifically designed to minimize residual stress in DED repair applications. These materials feature optimized thermal expansion properties, phase transformation characteristics, and microstructural stability. By tailoring the material composition to the specific repair requirements, improved stress distribution and enhanced bonding between the substrate and deposited material can be achieved.Expand Specific Solutions

Leading Companies in DED Repair Technology

The Direct Energy Deposition (DED) repair technology market is currently in a growth phase, characterized by increasing adoption across aerospace and defense sectors. The market is expanding as companies seek cost-effective solutions for component repair rather than replacement. Key players like RTX Corp. and Rolls-Royce are leading commercial implementation, while research institutions such as Beijing Institute of Technology and Huazhong University of Science & Technology are advancing fundamental understanding of residual stress control. Norsk Titanium has pioneered proprietary plasma arc technology specifically addressing stress management in titanium components. The technology is approaching maturity in aerospace applications but remains in development for broader industrial adoption, with GE Avio and IHI Corp. integrating DED repair into maintenance operations for critical engine components.

Norsk Titanium AS

Technical Solution: Norsk Titanium has pioneered the Rapid Plasma Deposition (RPD) technology specifically designed to minimize residual stress in titanium components during repair and manufacturing. Their approach focuses on precise control of the plasma arc energy input and material deposition rate to maintain optimal thermal conditions throughout the process. The RPD system incorporates a multi-axis deposition strategy that distributes heat input evenly, preventing localized stress concentrations. A key innovation in their technology is the implementation of a closed-loop control system that continuously adjusts deposition parameters based on real-time thermal measurements from an array of infrared sensors. This system maintains the substrate and previously deposited layers within a narrow temperature band, significantly reducing thermal gradients that lead to residual stress. Norsk's process also includes a proprietary substrate preheating protocol and controlled cooling rates that have been demonstrated to reduce residual stress by up to 60% compared to conventional DED methods for titanium alloys.

Strengths: Highly specialized for titanium alloys with proven results in aerospace applications; Advanced closed-loop control system providing real-time parameter adjustment; Significant reduction in post-processing requirements due to lower residual stress. Weaknesses: Limited material versatility beyond titanium alloys; Requires substantial initial investment in specialized equipment; Process optimization can be time-consuming for new component geometries.

Beijing Institute of Technology

Technical Solution: Beijing Institute of Technology has developed an innovative approach to residual stress control in DED-repaired components through their Synchronized Multi-Beam Deposition (SMBD) technology. This system utilizes multiple coordinated laser sources with differential power settings to create a controlled thermal field around the deposition zone. Their research has demonstrated that by precisely manipulating the primary deposition beam and secondary preheating/post-heating beams, thermal gradients can be significantly reduced, resulting in up to 45% lower residual stress compared to conventional single-beam approaches. The institute has also pioneered an ultrasonic vibration-assisted DED process where controlled high-frequency vibrations are applied to the substrate during deposition, promoting dynamic stress relief through localized plastic deformation. Their comprehensive solution includes a machine learning algorithm that predicts optimal process parameters based on material properties, component geometry, and repair requirements. This predictive model continuously improves through feedback from post-process residual stress measurements using their non-destructive evaluation techniques combining X-ray diffraction and ultrasonic methods.

Strengths: Innovative multi-beam approach provides superior thermal gradient control; Integration of machine learning for process optimization reduces development time; Non-destructive evaluation techniques allow for quality verification without component sacrifice. Weaknesses: Technology still primarily in research phase with limited industrial implementation; Higher equipment complexity compared to conventional DED systems; Requires significant computational resources for real-time process control.

Key Patents and Research on Stress Control

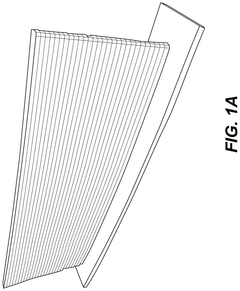

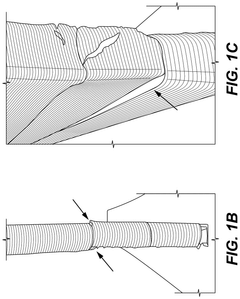

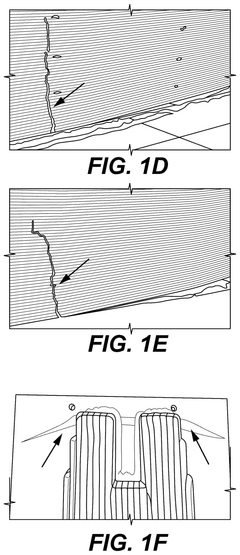

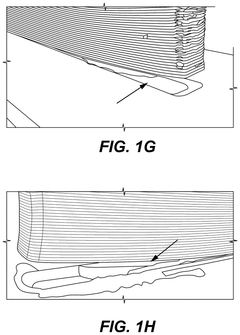

Engineered residual stress state for enhanced performance during directed energy deposition repair process

PatentPendingEP4599978A1

Innovation

- A directed energy deposition (DED) process is used to create layers with pre-determined residual stress states by controlling parameters like powder feed rate, energy intensity, traversal speed, and auxiliary heating/cooling, enabling controlled residual stress management during the repair process.

Distortion mitigation in directed energy deposition

PatentPendingUS20250065404A1

Innovation

- The use of a mount system and pin support system that pre-bends and pre-heats the substrate, combined with controlled heat transfer and an inert atmosphere, to minimize residual stress and distortion during DED manufacturing.

Material Selection Impact on Residual Stress

Material selection plays a crucial role in controlling residual stress in Directed Energy Deposition (DED) repair processes. The thermal and mechanical properties of the selected materials directly influence stress development during deposition and subsequent cooling phases. Materials with lower thermal expansion coefficients generally produce less residual stress due to reduced thermal strain during temperature fluctuations. For instance, Inconel 718 exhibits better stress characteristics compared to certain stainless steels when used in DED repairs due to its more favorable thermal expansion behavior.

Thermal conductivity represents another critical property affecting residual stress formation. Materials with higher thermal conductivity distribute heat more efficiently throughout the component, resulting in more uniform temperature gradients and consequently lower stress concentrations. This explains why copper alloys, despite their higher thermal expansion, may sometimes exhibit lower residual stress than expected due to superior heat distribution capabilities.

The yield strength and elastic modulus of the selected material significantly impact residual stress retention. Materials with lower yield strength can accommodate plastic deformation more readily, allowing for stress relaxation during the repair process. Conversely, high-strength materials tend to lock in residual stresses, making them more challenging to manage in DED applications. This phenomenon necessitates careful material selection based on the specific repair requirements and operating conditions.

Compatibility between substrate and deposition materials represents a fundamental consideration in DED repairs. Mismatches in coefficient of thermal expansion (CTE) between these materials can generate substantial interfacial stresses during cooling. Research indicates that minimizing CTE differences to within 10% can significantly reduce residual stress at material interfaces. This principle guides the selection of compatible material combinations for repair operations.

Material phase transformations during heating and cooling cycles can either exacerbate or mitigate residual stress. For example, martensitic transformations in certain steels can introduce additional volumetric changes that contribute to stress formation. Conversely, materials designed with controlled transformation characteristics can leverage these phase changes to counteract thermal stresses. Advanced nickel-based superalloys with carefully engineered precipitation hardening sequences exemplify this approach.

Pre-alloyed powders versus blended elemental powders present different residual stress profiles in DED repairs. Studies show that pre-alloyed powders typically result in more predictable and often lower residual stress distributions due to their homogeneous composition and consistent thermal behavior during processing. This knowledge informs powder selection strategies for stress-sensitive repair applications.

Thermal conductivity represents another critical property affecting residual stress formation. Materials with higher thermal conductivity distribute heat more efficiently throughout the component, resulting in more uniform temperature gradients and consequently lower stress concentrations. This explains why copper alloys, despite their higher thermal expansion, may sometimes exhibit lower residual stress than expected due to superior heat distribution capabilities.

The yield strength and elastic modulus of the selected material significantly impact residual stress retention. Materials with lower yield strength can accommodate plastic deformation more readily, allowing for stress relaxation during the repair process. Conversely, high-strength materials tend to lock in residual stresses, making them more challenging to manage in DED applications. This phenomenon necessitates careful material selection based on the specific repair requirements and operating conditions.

Compatibility between substrate and deposition materials represents a fundamental consideration in DED repairs. Mismatches in coefficient of thermal expansion (CTE) between these materials can generate substantial interfacial stresses during cooling. Research indicates that minimizing CTE differences to within 10% can significantly reduce residual stress at material interfaces. This principle guides the selection of compatible material combinations for repair operations.

Material phase transformations during heating and cooling cycles can either exacerbate or mitigate residual stress. For example, martensitic transformations in certain steels can introduce additional volumetric changes that contribute to stress formation. Conversely, materials designed with controlled transformation characteristics can leverage these phase changes to counteract thermal stresses. Advanced nickel-based superalloys with carefully engineered precipitation hardening sequences exemplify this approach.

Pre-alloyed powders versus blended elemental powders present different residual stress profiles in DED repairs. Studies show that pre-alloyed powders typically result in more predictable and often lower residual stress distributions due to their homogeneous composition and consistent thermal behavior during processing. This knowledge informs powder selection strategies for stress-sensitive repair applications.

Process Parameter Optimization Guidelines

Optimizing process parameters represents a critical approach to controlling residual stress in DED-repaired components. The selection of appropriate laser power, scanning speed, powder feed rate, and layer thickness must be systematically determined through both experimental validation and computational modeling. Research indicates that lower heat input generally results in reduced residual stress formation. This can be achieved by utilizing moderate laser power (typically 300-500W for repair applications) combined with higher scanning speeds (20-40 mm/s), which minimizes the heat-affected zone while maintaining adequate fusion between layers.

The powder feed rate should be calibrated to ensure consistent material deposition without excessive build-up, typically ranging from 2-8 g/min depending on the specific alloy and repair geometry. Layer thickness optimization is equally important, with thinner layers (0.2-0.5 mm) generally producing lower residual stress profiles due to more uniform heat distribution and cooling rates, albeit at the cost of increased processing time.

Preheating the substrate to 200-300°C has demonstrated significant benefits in reducing thermal gradients during deposition, thereby minimizing residual stress development. This approach is particularly effective for high-strength alloys and complex geometries where stress concentration is problematic. Implementation requires precise temperature control systems integrated with the DED equipment.

Path planning strategies significantly impact residual stress distribution. Alternating scan directions (0°/90° rotation between layers) and island scanning techniques have shown up to 30% reduction in peak residual stress compared to unidirectional scanning. For repair applications specifically, spiral-outward deposition paths from the center of the repair zone have demonstrated more uniform stress distribution than linear raster patterns.

Cooling rate management through controlled interlayer dwell times (typically 10-30 seconds) allows for more uniform temperature distribution throughout the component. Advanced systems may implement active cooling strategies using compressed air or inert gas jets directed at specific locations to achieve targeted cooling profiles based on real-time thermal monitoring.

Parameter optimization should follow a structured methodology, beginning with material-specific baseline parameters from literature, followed by design of experiments (DOE) approaches to identify key parameter interactions. Response surface methodology (RSM) has proven particularly effective for optimizing multiple parameters simultaneously while minimizing experimental iterations. Validation through residual stress measurement techniques such as hole-drilling, X-ray diffraction, or neutron diffraction should be incorporated into the optimization workflow.

The powder feed rate should be calibrated to ensure consistent material deposition without excessive build-up, typically ranging from 2-8 g/min depending on the specific alloy and repair geometry. Layer thickness optimization is equally important, with thinner layers (0.2-0.5 mm) generally producing lower residual stress profiles due to more uniform heat distribution and cooling rates, albeit at the cost of increased processing time.

Preheating the substrate to 200-300°C has demonstrated significant benefits in reducing thermal gradients during deposition, thereby minimizing residual stress development. This approach is particularly effective for high-strength alloys and complex geometries where stress concentration is problematic. Implementation requires precise temperature control systems integrated with the DED equipment.

Path planning strategies significantly impact residual stress distribution. Alternating scan directions (0°/90° rotation between layers) and island scanning techniques have shown up to 30% reduction in peak residual stress compared to unidirectional scanning. For repair applications specifically, spiral-outward deposition paths from the center of the repair zone have demonstrated more uniform stress distribution than linear raster patterns.

Cooling rate management through controlled interlayer dwell times (typically 10-30 seconds) allows for more uniform temperature distribution throughout the component. Advanced systems may implement active cooling strategies using compressed air or inert gas jets directed at specific locations to achieve targeted cooling profiles based on real-time thermal monitoring.

Parameter optimization should follow a structured methodology, beginning with material-specific baseline parameters from literature, followed by design of experiments (DOE) approaches to identify key parameter interactions. Response surface methodology (RSM) has proven particularly effective for optimizing multiple parameters simultaneously while minimizing experimental iterations. Validation through residual stress measurement techniques such as hole-drilling, X-ray diffraction, or neutron diffraction should be incorporated into the optimization workflow.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!