How to Ensure Quality Assurance in Ethyl Acetate Use?

JUN 27, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ethyl Acetate QA Background and Objectives

Ethyl acetate, a versatile organic compound, has been widely used in various industries for decades. Its applications range from solvents in paints and coatings to flavoring agents in the food industry. As the demand for high-quality products continues to grow, ensuring quality assurance in ethyl acetate use has become increasingly critical.

The evolution of quality control measures for ethyl acetate can be traced back to the mid-20th century when its industrial applications began to expand rapidly. Initially, quality assurance focused primarily on basic purity tests and physical property measurements. However, as analytical techniques advanced and regulatory requirements became more stringent, the scope of quality assurance has broadened significantly.

In recent years, the focus has shifted towards more comprehensive quality control strategies that encompass the entire lifecycle of ethyl acetate use. This includes not only the production and storage phases but also its application in various products and processes. The trend is moving towards implementing robust quality management systems that integrate advanced analytical methods, real-time monitoring, and data-driven decision-making processes.

The primary objective of quality assurance in ethyl acetate use is to ensure consistent product quality, safety, and performance across diverse applications. This involves maintaining the chemical's purity, stability, and desired properties throughout its production, storage, and utilization. Additionally, there is an increasing emphasis on minimizing environmental impact and ensuring compliance with evolving regulatory standards.

Key technological goals in this field include developing more sensitive and accurate analytical methods for impurity detection, implementing automated quality control systems, and enhancing traceability throughout the supply chain. There is also a growing interest in sustainable production methods and the development of bio-based alternatives to traditional petrochemical-derived ethyl acetate.

As industries continue to innovate and diversify their use of ethyl acetate, the quality assurance landscape is expected to evolve further. Future objectives may include the integration of artificial intelligence and machine learning in quality prediction and control, the development of non-destructive testing methods, and the establishment of global standardization in quality assurance practices for ethyl acetate use across different sectors.

The evolution of quality control measures for ethyl acetate can be traced back to the mid-20th century when its industrial applications began to expand rapidly. Initially, quality assurance focused primarily on basic purity tests and physical property measurements. However, as analytical techniques advanced and regulatory requirements became more stringent, the scope of quality assurance has broadened significantly.

In recent years, the focus has shifted towards more comprehensive quality control strategies that encompass the entire lifecycle of ethyl acetate use. This includes not only the production and storage phases but also its application in various products and processes. The trend is moving towards implementing robust quality management systems that integrate advanced analytical methods, real-time monitoring, and data-driven decision-making processes.

The primary objective of quality assurance in ethyl acetate use is to ensure consistent product quality, safety, and performance across diverse applications. This involves maintaining the chemical's purity, stability, and desired properties throughout its production, storage, and utilization. Additionally, there is an increasing emphasis on minimizing environmental impact and ensuring compliance with evolving regulatory standards.

Key technological goals in this field include developing more sensitive and accurate analytical methods for impurity detection, implementing automated quality control systems, and enhancing traceability throughout the supply chain. There is also a growing interest in sustainable production methods and the development of bio-based alternatives to traditional petrochemical-derived ethyl acetate.

As industries continue to innovate and diversify their use of ethyl acetate, the quality assurance landscape is expected to evolve further. Future objectives may include the integration of artificial intelligence and machine learning in quality prediction and control, the development of non-destructive testing methods, and the establishment of global standardization in quality assurance practices for ethyl acetate use across different sectors.

Market Demand Analysis for High-Quality Ethyl Acetate

The global market for high-quality ethyl acetate has been experiencing steady growth, driven by increasing demand across various industries. The pharmaceutical sector stands out as a key consumer, utilizing ethyl acetate in the production of medicines and as a solvent in drug formulations. This demand is further amplified by the stringent quality requirements in pharmaceutical manufacturing, necessitating high-purity ethyl acetate to ensure product safety and efficacy.

In the food and beverage industry, the demand for high-quality ethyl acetate continues to rise, particularly in the production of flavorings and fragrances. As consumers become more health-conscious, there is a growing preference for natural and clean-label products, leading to increased use of ethyl acetate as a natural solvent in flavor extraction processes.

The electronics industry represents another significant market for high-quality ethyl acetate. With the ongoing miniaturization of electronic components and the increasing complexity of circuit boards, the need for precise cleaning solvents has escalated. High-purity ethyl acetate is favored for its effectiveness in removing flux residues and other contaminants without damaging sensitive components.

The packaging industry, especially in the production of flexible packaging materials, has also contributed to the growing demand for high-quality ethyl acetate. Its use as a solvent in printing inks and adhesives has become more prevalent due to its low toxicity and favorable environmental profile compared to some alternative solvents.

Market analysis indicates a shift towards sustainable and eco-friendly products, which has positively impacted the demand for bio-based ethyl acetate. This trend is particularly strong in regions with strict environmental regulations, such as Europe and North America, where manufacturers are increasingly seeking renewable alternatives to petrochemical-based solvents.

The Asia-Pacific region, led by China and India, is expected to be the fastest-growing market for high-quality ethyl acetate. This growth is attributed to rapid industrialization, expanding manufacturing sectors, and increasing adoption of quality standards in production processes. The region's burgeoning pharmaceutical and electronics industries are key drivers of this demand.

Despite the positive market outlook, challenges such as price volatility of raw materials and stringent regulatory requirements for high-purity chemicals pose potential constraints to market growth. Manufacturers are responding by investing in advanced purification technologies and exploring alternative production methods to ensure consistent quality while managing costs.

In the food and beverage industry, the demand for high-quality ethyl acetate continues to rise, particularly in the production of flavorings and fragrances. As consumers become more health-conscious, there is a growing preference for natural and clean-label products, leading to increased use of ethyl acetate as a natural solvent in flavor extraction processes.

The electronics industry represents another significant market for high-quality ethyl acetate. With the ongoing miniaturization of electronic components and the increasing complexity of circuit boards, the need for precise cleaning solvents has escalated. High-purity ethyl acetate is favored for its effectiveness in removing flux residues and other contaminants without damaging sensitive components.

The packaging industry, especially in the production of flexible packaging materials, has also contributed to the growing demand for high-quality ethyl acetate. Its use as a solvent in printing inks and adhesives has become more prevalent due to its low toxicity and favorable environmental profile compared to some alternative solvents.

Market analysis indicates a shift towards sustainable and eco-friendly products, which has positively impacted the demand for bio-based ethyl acetate. This trend is particularly strong in regions with strict environmental regulations, such as Europe and North America, where manufacturers are increasingly seeking renewable alternatives to petrochemical-based solvents.

The Asia-Pacific region, led by China and India, is expected to be the fastest-growing market for high-quality ethyl acetate. This growth is attributed to rapid industrialization, expanding manufacturing sectors, and increasing adoption of quality standards in production processes. The region's burgeoning pharmaceutical and electronics industries are key drivers of this demand.

Despite the positive market outlook, challenges such as price volatility of raw materials and stringent regulatory requirements for high-purity chemicals pose potential constraints to market growth. Manufacturers are responding by investing in advanced purification technologies and exploring alternative production methods to ensure consistent quality while managing costs.

Current Challenges in Ethyl Acetate Quality Control

Quality control in ethyl acetate production and use faces several significant challenges that require continuous attention and innovative solutions. One of the primary concerns is the presence of impurities, which can significantly affect the product's performance and safety. Ethyl acetate is highly susceptible to contamination during production, storage, and transportation, necessitating rigorous monitoring and control measures throughout its lifecycle.

The volatility of ethyl acetate poses another major challenge in quality control. Its low boiling point and high vapor pressure make it prone to evaporation, leading to potential changes in concentration and purity over time. This characteristic demands specialized storage conditions and handling procedures to maintain product integrity.

Consistency in product specifications across different batches remains a persistent challenge. Variations in raw materials, production processes, and environmental conditions can lead to fluctuations in the final product's properties. Achieving uniformity in parameters such as purity, density, and moisture content requires sophisticated process control systems and analytical techniques.

The hygroscopic nature of ethyl acetate further complicates quality assurance efforts. Its tendency to absorb moisture from the environment can alter its chemical composition and physical properties, potentially compromising its effectiveness in various applications. Implementing moisture control measures and conducting regular moisture content analyses are crucial but often challenging aspects of quality control.

Another significant hurdle is the detection and quantification of trace contaminants. Some impurities, even in minute quantities, can have detrimental effects on the product's performance or safety. Developing and implementing highly sensitive analytical methods for identifying and measuring these trace contaminants is an ongoing challenge in the industry.

The increasing demand for high-purity ethyl acetate in specialized applications, such as in the electronics and pharmaceutical industries, has raised the bar for quality control standards. Meeting these stringent requirements while maintaining cost-effectiveness in production is a complex balancing act that quality control professionals must navigate.

Regulatory compliance adds another layer of complexity to quality control efforts. Keeping up with evolving regulations and standards across different regions and industries requires constant vigilance and adaptability in quality assurance protocols. Ensuring that ethyl acetate meets diverse regulatory requirements without compromising its intended functionality is a continuous challenge.

The volatility of ethyl acetate poses another major challenge in quality control. Its low boiling point and high vapor pressure make it prone to evaporation, leading to potential changes in concentration and purity over time. This characteristic demands specialized storage conditions and handling procedures to maintain product integrity.

Consistency in product specifications across different batches remains a persistent challenge. Variations in raw materials, production processes, and environmental conditions can lead to fluctuations in the final product's properties. Achieving uniformity in parameters such as purity, density, and moisture content requires sophisticated process control systems and analytical techniques.

The hygroscopic nature of ethyl acetate further complicates quality assurance efforts. Its tendency to absorb moisture from the environment can alter its chemical composition and physical properties, potentially compromising its effectiveness in various applications. Implementing moisture control measures and conducting regular moisture content analyses are crucial but often challenging aspects of quality control.

Another significant hurdle is the detection and quantification of trace contaminants. Some impurities, even in minute quantities, can have detrimental effects on the product's performance or safety. Developing and implementing highly sensitive analytical methods for identifying and measuring these trace contaminants is an ongoing challenge in the industry.

The increasing demand for high-purity ethyl acetate in specialized applications, such as in the electronics and pharmaceutical industries, has raised the bar for quality control standards. Meeting these stringent requirements while maintaining cost-effectiveness in production is a complex balancing act that quality control professionals must navigate.

Regulatory compliance adds another layer of complexity to quality control efforts. Keeping up with evolving regulations and standards across different regions and industries requires constant vigilance and adaptability in quality assurance protocols. Ensuring that ethyl acetate meets diverse regulatory requirements without compromising its intended functionality is a continuous challenge.

Existing Quality Assurance Protocols for Ethyl Acetate

01 Automated quality control systems

Implementation of automated systems for quality assurance of ethyl acetate production. These systems utilize advanced sensors, image processing, and data analysis techniques to monitor and control the production process, ensuring consistent quality and reducing human error.- Automated quality control systems: Implementation of automated systems for quality assurance of ethyl acetate production. These systems utilize advanced sensors, machine learning algorithms, and real-time monitoring to ensure consistent product quality, detect anomalies, and optimize production processes.

- Spectroscopic analysis techniques: Utilization of spectroscopic methods, such as infrared or Raman spectroscopy, for rapid and non-destructive quality assessment of ethyl acetate. These techniques allow for real-time monitoring of chemical composition and purity, enabling quick identification of impurities or deviations from quality standards.

- Statistical process control: Application of statistical methods and tools for monitoring and controlling the quality of ethyl acetate production. This includes the use of control charts, sampling techniques, and data analysis to identify trends, reduce variability, and maintain consistent product quality.

- Integration of quality assurance with supply chain management: Incorporation of quality assurance processes into the broader supply chain management system for ethyl acetate. This approach ensures quality control throughout the entire production and distribution process, from raw material sourcing to final product delivery.

- Advanced chromatography techniques: Utilization of high-performance liquid chromatography (HPLC) or gas chromatography (GC) for precise analysis of ethyl acetate purity and detection of trace impurities. These methods provide detailed compositional information and are crucial for maintaining high-quality standards in ethyl acetate production.

02 Spectroscopic analysis for purity assessment

Utilization of spectroscopic techniques, such as infrared or Raman spectroscopy, for rapid and accurate assessment of ethyl acetate purity. These methods allow for non-destructive, real-time analysis of chemical composition and detection of impurities.Expand Specific Solutions03 Statistical process control and data analytics

Application of statistical process control methods and advanced data analytics to monitor and optimize ethyl acetate production. These techniques help identify trends, predict potential quality issues, and maintain consistent product quality over time.Expand Specific Solutions04 Integration of quality assurance in supply chain management

Incorporation of quality assurance processes throughout the ethyl acetate supply chain, from raw material sourcing to final product delivery. This approach ensures traceability, reduces risks, and maintains product integrity across the entire production and distribution process.Expand Specific Solutions05 Continuous improvement and compliance management

Implementation of continuous improvement methodologies and compliance management systems for ethyl acetate quality assurance. These systems help maintain adherence to regulatory standards, facilitate audits, and drive ongoing enhancements in product quality and production efficiency.Expand Specific Solutions

Key Players in Ethyl Acetate Production and QA

The quality assurance of ethyl acetate use is at a mature stage in the chemical industry, with a well-established global market. The technology is highly developed, with major players like Celanese International Corp., Eastman Chemical Co., and SABIC Global Technologies BV leading the field. These companies have extensive experience in manufacturing and quality control of ethyl acetate. The market is characterized by a mix of large multinational corporations and specialized chemical manufacturers, such as Zhuhai Qianxin New Materials Co., Ltd. and Jiangmen Qianxin Chemical Development Co. Ltd. Academic institutions like Tianjin University and Nanjing Tech University contribute to ongoing research and development, ensuring continuous improvement in quality assurance techniques for ethyl acetate production and application.

Celanese International Corp.

Technical Solution: Celanese has implemented a comprehensive quality assurance program for ethyl acetate production and use. Their approach includes the use of advanced process simulation tools to optimize production parameters and predict potential quality issues before they occur[11]. Celanese employs a multi-step purification process that includes distillation and adsorption techniques to remove impurities and ensure consistent product quality[12]. They have also developed a proprietary quality tracking system that allows for full traceability of each batch of ethyl acetate from raw materials to final product[13]. Additionally, Celanese conducts regular stability studies to assess the long-term quality of their ethyl acetate under various storage and use conditions.

Strengths: Advanced process simulation, multi-step purification, and comprehensive traceability system. Weaknesses: Potential for higher production costs due to extensive purification and quality control measures.

Eastman Chemical Co.

Technical Solution: Eastman Chemical Co. has developed a comprehensive quality assurance system for ethyl acetate production and use. Their approach includes advanced process control systems that monitor and adjust production parameters in real-time[1]. They employ in-line spectroscopic analysis to continuously assess product purity and detect impurities[2]. Eastman has also implemented a rigorous testing protocol that includes gas chromatography and mass spectrometry to ensure product consistency and compliance with industry standards[3]. Additionally, they have developed proprietary stabilization additives that extend the shelf life of ethyl acetate and maintain its quality during storage and transportation[4].

Strengths: Advanced process control, real-time monitoring, and proprietary stabilization technology. Weaknesses: Potentially higher production costs due to extensive quality control measures.

Innovative Techniques in Ethyl Acetate Purity Testing

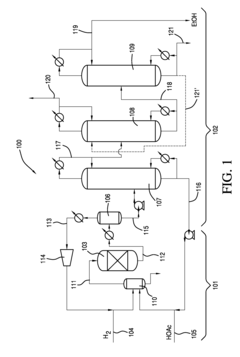

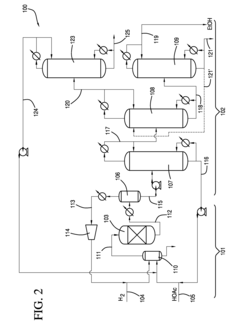

Process for producing an ethyl acetate solvent and co-production of ethanol

PatentInactiveUS20110190531A1

Innovation

- A process involving the hydrogenation of acetic acid in the presence of a catalyst, followed by a series of distillation columns to separate and recover ethanol and ethyl acetate solvent, with specific catalyst compositions and conditions to optimize ethanol and ethyl acetate production, including the use of platinum-based catalysts and modified silica supports.

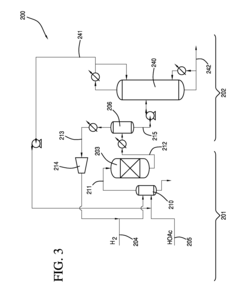

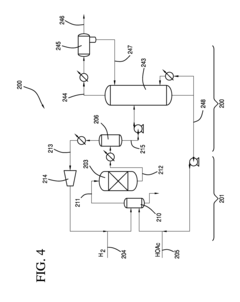

Method for producing ethyl acetate

PatentPendingUS20250002441A1

Innovation

- Controlling the palladium content in the catalyst within the range of 0.1 to 14 ppb by mass in a heteropolyacid or its salt supported on a carrier, such as silica, suppresses side reactions and ensures stable long-term operation.

Regulatory Framework for Ethyl Acetate Production

The regulatory framework for ethyl acetate production encompasses a comprehensive set of guidelines and standards designed to ensure the safe manufacture, handling, and use of this important chemical compound. At the international level, organizations such as the International Organization for Standardization (ISO) and the World Health Organization (WHO) provide overarching principles for chemical safety and quality management.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating ethyl acetate production under the Toxic Substances Control Act (TSCA). The EPA mandates strict reporting, record-keeping, and testing requirements for manufacturers and importers. Additionally, the Occupational Safety and Health Administration (OSHA) sets workplace safety standards, including permissible exposure limits and personal protective equipment requirements for workers handling ethyl acetate.

The European Union's regulatory framework is governed by the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation. REACH requires manufacturers and importers to register substances like ethyl acetate with the European Chemicals Agency (ECHA) and provide detailed safety information. The Classification, Labeling, and Packaging (CLP) Regulation further ensures that hazards associated with ethyl acetate are clearly communicated to workers and consumers.

In Asia, countries like China and Japan have their own regulatory bodies overseeing chemical production. China's Ministry of Ecology and Environment (MEE) enforces regulations similar to REACH, while Japan's Chemical Substances Control Law (CSCL) governs the manufacture and import of chemicals, including ethyl acetate.

Quality assurance in ethyl acetate production is further supported by industry-specific standards and best practices. The American Chemistry Council's Responsible Care program, for instance, promotes continuous improvement in environmental, health, safety, and security performance among chemical manufacturers.

Regulatory compliance also extends to transportation and storage of ethyl acetate. The International Maritime Dangerous Goods (IMDG) Code and the International Air Transport Association (IATA) Dangerous Goods Regulations provide guidelines for the safe transport of ethyl acetate by sea and air, respectively.

As environmental concerns grow, regulations are evolving to address sustainability in chemical production. Many jurisdictions are implementing stricter emissions controls and encouraging the adoption of green chemistry principles in ethyl acetate manufacturing processes. This includes promoting the use of bio-based feedstocks and more energy-efficient production methods.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating ethyl acetate production under the Toxic Substances Control Act (TSCA). The EPA mandates strict reporting, record-keeping, and testing requirements for manufacturers and importers. Additionally, the Occupational Safety and Health Administration (OSHA) sets workplace safety standards, including permissible exposure limits and personal protective equipment requirements for workers handling ethyl acetate.

The European Union's regulatory framework is governed by the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation. REACH requires manufacturers and importers to register substances like ethyl acetate with the European Chemicals Agency (ECHA) and provide detailed safety information. The Classification, Labeling, and Packaging (CLP) Regulation further ensures that hazards associated with ethyl acetate are clearly communicated to workers and consumers.

In Asia, countries like China and Japan have their own regulatory bodies overseeing chemical production. China's Ministry of Ecology and Environment (MEE) enforces regulations similar to REACH, while Japan's Chemical Substances Control Law (CSCL) governs the manufacture and import of chemicals, including ethyl acetate.

Quality assurance in ethyl acetate production is further supported by industry-specific standards and best practices. The American Chemistry Council's Responsible Care program, for instance, promotes continuous improvement in environmental, health, safety, and security performance among chemical manufacturers.

Regulatory compliance also extends to transportation and storage of ethyl acetate. The International Maritime Dangerous Goods (IMDG) Code and the International Air Transport Association (IATA) Dangerous Goods Regulations provide guidelines for the safe transport of ethyl acetate by sea and air, respectively.

As environmental concerns grow, regulations are evolving to address sustainability in chemical production. Many jurisdictions are implementing stricter emissions controls and encouraging the adoption of green chemistry principles in ethyl acetate manufacturing processes. This includes promoting the use of bio-based feedstocks and more energy-efficient production methods.

Environmental Impact of Ethyl Acetate Manufacturing

The manufacturing process of ethyl acetate, while essential for various industries, carries significant environmental implications that warrant careful consideration. The production of this versatile solvent involves several stages, each with potential environmental impacts. The primary raw materials, ethanol and acetic acid, are derived from petrochemical sources or fermentation processes, both of which have their own ecological footprints.

During the manufacturing process, the reaction between ethanol and acetic acid generates ethyl acetate along with water as a byproduct. This reaction typically requires elevated temperatures and the presence of catalysts, often sulfuric acid. The energy consumption for heating and maintaining reaction conditions contributes to greenhouse gas emissions if non-renewable energy sources are used. Additionally, the use of sulfuric acid as a catalyst poses risks of soil and water contamination if not properly handled and disposed of.

The purification stage, involving distillation to separate ethyl acetate from water and unreacted materials, is energy-intensive and may result in further emissions. The disposal or treatment of waste products, including unreacted raw materials and byproducts, presents another environmental challenge. Improper management of these wastes can lead to soil and water pollution, affecting local ecosystems and potentially human health.

Volatile organic compound (VOC) emissions are a significant concern in ethyl acetate production. As a highly volatile substance, ethyl acetate can easily escape into the atmosphere during manufacturing, storage, and transportation. These emissions contribute to air pollution and the formation of ground-level ozone, which has detrimental effects on human health and vegetation.

Water usage in the production process, particularly for cooling and cleaning purposes, is another environmental factor to consider. The discharge of wastewater, if not properly treated, can lead to water pollution and disrupt aquatic ecosystems. Furthermore, the transportation of raw materials and finished products contributes to carbon emissions and potential risks of spills or accidents.

To mitigate these environmental impacts, manufacturers are increasingly adopting cleaner production technologies and implementing stringent environmental management systems. This includes the use of more efficient catalysts, closed-loop systems to minimize waste and emissions, and the integration of renewable energy sources in the production process. Advanced wastewater treatment technologies and air pollution control measures are also being employed to reduce the environmental footprint of ethyl acetate manufacturing.

During the manufacturing process, the reaction between ethanol and acetic acid generates ethyl acetate along with water as a byproduct. This reaction typically requires elevated temperatures and the presence of catalysts, often sulfuric acid. The energy consumption for heating and maintaining reaction conditions contributes to greenhouse gas emissions if non-renewable energy sources are used. Additionally, the use of sulfuric acid as a catalyst poses risks of soil and water contamination if not properly handled and disposed of.

The purification stage, involving distillation to separate ethyl acetate from water and unreacted materials, is energy-intensive and may result in further emissions. The disposal or treatment of waste products, including unreacted raw materials and byproducts, presents another environmental challenge. Improper management of these wastes can lead to soil and water pollution, affecting local ecosystems and potentially human health.

Volatile organic compound (VOC) emissions are a significant concern in ethyl acetate production. As a highly volatile substance, ethyl acetate can easily escape into the atmosphere during manufacturing, storage, and transportation. These emissions contribute to air pollution and the formation of ground-level ozone, which has detrimental effects on human health and vegetation.

Water usage in the production process, particularly for cooling and cleaning purposes, is another environmental factor to consider. The discharge of wastewater, if not properly treated, can lead to water pollution and disrupt aquatic ecosystems. Furthermore, the transportation of raw materials and finished products contributes to carbon emissions and potential risks of spills or accidents.

To mitigate these environmental impacts, manufacturers are increasingly adopting cleaner production technologies and implementing stringent environmental management systems. This includes the use of more efficient catalysts, closed-loop systems to minimize waste and emissions, and the integration of renewable energy sources in the production process. Advanced wastewater treatment technologies and air pollution control measures are also being employed to reduce the environmental footprint of ethyl acetate manufacturing.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!