How to Evaluate Solid-State Relay for Automated Control Adjustments

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SSR Technology Background and Evaluation Objectives

Solid-State Relays (SSRs) emerged in the late 1960s as an evolution from traditional electromechanical relays, offering a revolutionary approach to electrical switching without moving parts. The technology utilizes semiconductor devices, primarily thyristors, triacs, or MOSFETs, to control load circuits through electrical isolation between control and load sides. This fundamental design has positioned SSRs as critical components in modern automated control systems across industrial, commercial, and residential applications.

The evolution of SSR technology has been marked by significant improvements in switching speed, reliability, and integration capabilities. Early generations suffered from limited current handling capacity and vulnerability to voltage transients, but contemporary SSRs feature enhanced thermal management, improved isolation barriers, and sophisticated protection circuits. The miniaturization trend has also enabled higher density installations while maintaining performance parameters.

Industry adoption of SSRs has accelerated particularly in precision control environments where rapid cycling, noise-free operation, and longevity are paramount requirements. The absence of mechanical contacts eliminates contact bounce, arcing, and wear-related failures that plague traditional relays, making SSRs especially valuable in applications requiring millions of operational cycles.

The primary objective of this technical evaluation is to establish a comprehensive framework for assessing SSR performance specifically within automated control adjustment systems. These systems demand precise, reliable, and responsive switching capabilities to maintain optimal process parameters across varying operational conditions. The evaluation aims to identify key performance indicators that directly impact control system stability, accuracy, and longevity.

Secondary objectives include determining the optimal SSR specifications for different automated control scenarios, quantifying the relationship between SSR characteristics and system response times, and establishing testing protocols that accurately predict field performance. The evaluation will also address thermal management considerations, as heat dissipation remains a critical factor in SSR implementation.

This assessment will further explore the integration challenges when implementing SSRs within existing control architectures, particularly focusing on compatibility with various control signals, noise immunity in industrial environments, and failure mode behaviors. Understanding these aspects is essential for designing robust automated systems that leverage the advantages of solid-state switching while mitigating potential limitations.

The technological trajectory suggests that future SSRs will incorporate more intelligent features, including self-diagnostics, network connectivity, and adaptive control capabilities. This evaluation will therefore also consider the readiness of current SSR technologies to support these emerging requirements in next-generation automated control systems.

The evolution of SSR technology has been marked by significant improvements in switching speed, reliability, and integration capabilities. Early generations suffered from limited current handling capacity and vulnerability to voltage transients, but contemporary SSRs feature enhanced thermal management, improved isolation barriers, and sophisticated protection circuits. The miniaturization trend has also enabled higher density installations while maintaining performance parameters.

Industry adoption of SSRs has accelerated particularly in precision control environments where rapid cycling, noise-free operation, and longevity are paramount requirements. The absence of mechanical contacts eliminates contact bounce, arcing, and wear-related failures that plague traditional relays, making SSRs especially valuable in applications requiring millions of operational cycles.

The primary objective of this technical evaluation is to establish a comprehensive framework for assessing SSR performance specifically within automated control adjustment systems. These systems demand precise, reliable, and responsive switching capabilities to maintain optimal process parameters across varying operational conditions. The evaluation aims to identify key performance indicators that directly impact control system stability, accuracy, and longevity.

Secondary objectives include determining the optimal SSR specifications for different automated control scenarios, quantifying the relationship between SSR characteristics and system response times, and establishing testing protocols that accurately predict field performance. The evaluation will also address thermal management considerations, as heat dissipation remains a critical factor in SSR implementation.

This assessment will further explore the integration challenges when implementing SSRs within existing control architectures, particularly focusing on compatibility with various control signals, noise immunity in industrial environments, and failure mode behaviors. Understanding these aspects is essential for designing robust automated systems that leverage the advantages of solid-state switching while mitigating potential limitations.

The technological trajectory suggests that future SSRs will incorporate more intelligent features, including self-diagnostics, network connectivity, and adaptive control capabilities. This evaluation will therefore also consider the readiness of current SSR technologies to support these emerging requirements in next-generation automated control systems.

Market Demand Analysis for Automated Control Systems

The global market for automated control systems has been experiencing robust growth, driven by increasing industrial automation, smart manufacturing initiatives, and the growing adoption of Industry 4.0 technologies. The demand for solid-state relays (SSRs) as critical components in these systems has consequently seen significant expansion across various sectors including manufacturing, energy management, building automation, and transportation systems.

Recent market research indicates that the global automated control systems market is projected to grow at a compound annual growth rate of approximately 9% through 2028. This growth is particularly pronounced in regions with strong manufacturing bases such as East Asia, North America, and Western Europe. The solid-state relay segment within this market is experiencing even faster growth due to its superior performance characteristics compared to traditional electromechanical relays.

Key demand drivers for SSRs in automated control applications include the need for higher reliability in mission-critical systems, increased switching frequency requirements, and the growing complexity of industrial processes requiring precise control. Industries such as semiconductor manufacturing, pharmaceutical production, and advanced materials processing have particularly stringent requirements for switching accuracy and reliability, creating premium market segments for high-performance SSRs.

The energy efficiency imperative across industries has also significantly boosted demand for solid-state relays. As organizations worldwide face increasing pressure to reduce energy consumption and carbon footprints, the superior efficiency and precise control capabilities of SSRs make them increasingly preferred over traditional relay technologies. This trend is especially evident in building management systems and industrial heating applications where precise power control translates directly to energy savings.

Market segmentation analysis reveals that while traditional industrial automation remains the largest application segment for SSRs, emerging applications in renewable energy systems, electric vehicle charging infrastructure, and smart grid technologies are showing the highest growth rates. These new application areas often require advanced features such as integrated diagnostics, network connectivity, and enhanced thermal management capabilities.

Customer requirements are evolving toward more integrated solutions that combine solid-state switching with intelligent control capabilities. This shift is creating new market opportunities for manufacturers who can provide comprehensive solutions rather than standalone components. The ability to offer SSRs with built-in monitoring, protection features, and communication interfaces is increasingly becoming a competitive differentiator in the market.

Regional analysis shows that while mature markets focus on replacement and upgrade of existing systems with more efficient alternatives, emerging economies are experiencing rapid growth in new installations, particularly in manufacturing and infrastructure development projects. This dual market dynamic creates diverse opportunities for SSR manufacturers who can address both replacement and new installation market segments with appropriate product offerings.

Recent market research indicates that the global automated control systems market is projected to grow at a compound annual growth rate of approximately 9% through 2028. This growth is particularly pronounced in regions with strong manufacturing bases such as East Asia, North America, and Western Europe. The solid-state relay segment within this market is experiencing even faster growth due to its superior performance characteristics compared to traditional electromechanical relays.

Key demand drivers for SSRs in automated control applications include the need for higher reliability in mission-critical systems, increased switching frequency requirements, and the growing complexity of industrial processes requiring precise control. Industries such as semiconductor manufacturing, pharmaceutical production, and advanced materials processing have particularly stringent requirements for switching accuracy and reliability, creating premium market segments for high-performance SSRs.

The energy efficiency imperative across industries has also significantly boosted demand for solid-state relays. As organizations worldwide face increasing pressure to reduce energy consumption and carbon footprints, the superior efficiency and precise control capabilities of SSRs make them increasingly preferred over traditional relay technologies. This trend is especially evident in building management systems and industrial heating applications where precise power control translates directly to energy savings.

Market segmentation analysis reveals that while traditional industrial automation remains the largest application segment for SSRs, emerging applications in renewable energy systems, electric vehicle charging infrastructure, and smart grid technologies are showing the highest growth rates. These new application areas often require advanced features such as integrated diagnostics, network connectivity, and enhanced thermal management capabilities.

Customer requirements are evolving toward more integrated solutions that combine solid-state switching with intelligent control capabilities. This shift is creating new market opportunities for manufacturers who can provide comprehensive solutions rather than standalone components. The ability to offer SSRs with built-in monitoring, protection features, and communication interfaces is increasingly becoming a competitive differentiator in the market.

Regional analysis shows that while mature markets focus on replacement and upgrade of existing systems with more efficient alternatives, emerging economies are experiencing rapid growth in new installations, particularly in manufacturing and infrastructure development projects. This dual market dynamic creates diverse opportunities for SSR manufacturers who can address both replacement and new installation market segments with appropriate product offerings.

Current SSR Technology Landscape and Challenges

Solid-State Relays (SSRs) have evolved significantly over the past decades, transforming from niche components to essential elements in modern automated control systems. The current technological landscape reveals a market dominated by semiconductor-based solutions utilizing primarily MOSFETs, IGBTs, and thyristors as switching elements. These technologies offer varying performance characteristics in terms of switching speed, voltage handling capability, and thermal management requirements.

The global SSR market is experiencing rapid growth, with particular acceleration in industrial automation, smart grid applications, and IoT-enabled control systems. Recent advancements have focused on miniaturization, improved thermal performance, and enhanced integration capabilities with digital control systems. Notably, the emergence of SiC (Silicon Carbide) and GaN (Gallium Nitride) based SSRs represents a significant technological leap, offering superior switching characteristics and thermal performance compared to traditional silicon-based devices.

Despite these advancements, several critical challenges persist in SSR technology. Heat dissipation remains a primary concern, as SSRs generate significant heat during operation due to their inherent on-state resistance. This thermal management challenge often necessitates oversized heat sinks or active cooling solutions, limiting miniaturization efforts and increasing overall system costs.

Another significant challenge is the voltage drop across SSRs in their on-state, which results in power losses and efficiency reduction. This issue becomes particularly problematic in high-current applications where even small efficiency losses translate to substantial energy waste and operational costs. Additionally, SSRs exhibit leakage current in their off-state, which can be problematic in sensitive applications requiring complete isolation.

EMI (Electromagnetic Interference) generation during switching operations presents another technical hurdle. The rapid voltage and current transitions in SSRs can create electromagnetic disturbances that affect nearby electronic equipment, necessitating additional filtering and shielding measures.

Reliability under extreme conditions remains challenging, with SSRs showing vulnerability to voltage transients, temperature fluctuations, and aging effects. The semiconductor junctions within SSRs can degrade over time, particularly when subjected to thermal cycling or overvoltage events, leading to premature failure or unpredictable behavior.

From a geographical perspective, SSR technology development is concentrated primarily in East Asia, North America, and Europe, with Japan, China, South Korea, the United States, and Germany leading in patents and innovations. This distribution reflects both manufacturing capabilities and research investment patterns in semiconductor technologies.

The global SSR market is experiencing rapid growth, with particular acceleration in industrial automation, smart grid applications, and IoT-enabled control systems. Recent advancements have focused on miniaturization, improved thermal performance, and enhanced integration capabilities with digital control systems. Notably, the emergence of SiC (Silicon Carbide) and GaN (Gallium Nitride) based SSRs represents a significant technological leap, offering superior switching characteristics and thermal performance compared to traditional silicon-based devices.

Despite these advancements, several critical challenges persist in SSR technology. Heat dissipation remains a primary concern, as SSRs generate significant heat during operation due to their inherent on-state resistance. This thermal management challenge often necessitates oversized heat sinks or active cooling solutions, limiting miniaturization efforts and increasing overall system costs.

Another significant challenge is the voltage drop across SSRs in their on-state, which results in power losses and efficiency reduction. This issue becomes particularly problematic in high-current applications where even small efficiency losses translate to substantial energy waste and operational costs. Additionally, SSRs exhibit leakage current in their off-state, which can be problematic in sensitive applications requiring complete isolation.

EMI (Electromagnetic Interference) generation during switching operations presents another technical hurdle. The rapid voltage and current transitions in SSRs can create electromagnetic disturbances that affect nearby electronic equipment, necessitating additional filtering and shielding measures.

Reliability under extreme conditions remains challenging, with SSRs showing vulnerability to voltage transients, temperature fluctuations, and aging effects. The semiconductor junctions within SSRs can degrade over time, particularly when subjected to thermal cycling or overvoltage events, leading to premature failure or unpredictable behavior.

From a geographical perspective, SSR technology development is concentrated primarily in East Asia, North America, and Europe, with Japan, China, South Korea, the United States, and Germany leading in patents and innovations. This distribution reflects both manufacturing capabilities and research investment patterns in semiconductor technologies.

Current Evaluation Methods for SSR in Automation

01 Performance and reliability metrics

Evaluation of solid-state relays includes measuring key performance parameters such as switching speed, on-state resistance, and reliability under various operating conditions. These metrics help determine the relay's efficiency, power handling capability, and expected lifetime. Performance testing typically involves measuring response times, voltage drop across the relay when conducting, and behavior under different load conditions to ensure reliable operation in the intended application.- Performance and reliability metrics: Evaluation of solid-state relays includes measuring key performance parameters such as switching speed, on-state resistance, leakage current, and overall reliability. These metrics determine the relay's efficiency in power handling applications and its longevity under various operating conditions. Testing procedures typically involve measuring response times, voltage drop across the relay when conducting, and current leakage when in the off state to ensure the relay meets specified performance requirements.

- Thermal management evaluation: Thermal performance is a critical evaluation metric for solid-state relays, as heat dissipation directly impacts reliability and operational life. Evaluation includes measuring junction temperature, thermal resistance, and heat dissipation efficiency under various load conditions. Testing protocols assess the relay's ability to maintain safe operating temperatures during continuous operation and transient overload conditions, which helps determine appropriate heat sink requirements and maximum operational ratings.

- Switching characteristics assessment: Evaluation of switching characteristics focuses on metrics such as turn-on/turn-off times, dv/dt immunity, di/dt capability, and zero-crossing functionality. These parameters are crucial for determining the relay's suitability for specific applications, particularly in sensitive electronic circuits or high-frequency switching environments. Testing includes measuring response to voltage transients, current surge handling capability, and electromagnetic interference generation during switching operations.

- Isolation and safety performance: Isolation performance is a fundamental evaluation metric for solid-state relays, measuring the electrical separation between input and output circuits. Key metrics include isolation voltage, insulation resistance, and common-mode rejection. Testing procedures verify the relay's ability to withstand high voltage differentials without breakdown and maintain isolation integrity over time and under environmental stress, ensuring compliance with safety standards for electrical equipment.

- Environmental and operational robustness: Evaluation of solid-state relays includes testing their performance across various environmental conditions such as temperature extremes, humidity, vibration, and electromagnetic interference. These tests assess the relay's operational stability and longevity in challenging environments. Metrics include temperature coefficient of key parameters, moisture resistance, mechanical shock tolerance, and susceptibility to electromagnetic interference, which help determine the relay's suitability for industrial, automotive, or outdoor applications.

02 Thermal management evaluation

Thermal performance is a critical evaluation metric for solid-state relays, as heat dissipation directly impacts reliability and operational life. Testing includes measuring junction temperature, thermal resistance, and performance under various ambient temperatures. Effective thermal management assessment involves evaluating heat sink requirements, thermal cycling endurance, and temperature rise during continuous operation to prevent overheating and ensure stable long-term performance.Expand Specific Solutions03 Electrical isolation characteristics

Evaluation of isolation properties is essential for solid-state relay safety and functionality. This includes measuring isolation voltage, leakage current, and common-mode rejection. Testing procedures assess the relay's ability to maintain separation between input and output circuits under normal and fault conditions. High-quality isolation prevents unwanted signal coupling and protects connected equipment from voltage surges and electrical noise, which is particularly important in sensitive electronic applications.Expand Specific Solutions04 Switching characteristics and load compatibility

Assessment of switching behavior includes evaluating turn-on/turn-off times, voltage and current ratings, and compatibility with different load types. Testing involves measuring the relay's performance with resistive, inductive, and capacitive loads, as well as behavior during surge conditions. Evaluation metrics include dv/dt immunity, zero-crossing switching capability for AC applications, and transient response characteristics to ensure reliable operation across various application scenarios.Expand Specific Solutions05 EMI/EMC performance evaluation

Electromagnetic interference (EMI) and electromagnetic compatibility (EMC) testing are important evaluation metrics for solid-state relays. This includes measuring conducted and radiated emissions, susceptibility to external electromagnetic fields, and compliance with relevant standards. Testing procedures assess the relay's ability to operate without generating excessive electromagnetic noise and to function reliably in electromagnetically noisy environments, which is crucial for applications in sensitive electronic systems.Expand Specific Solutions

Major Manufacturers and Competitive Analysis

The solid-state relay (SSR) market for automated control adjustments is currently in a growth phase, driven by increasing industrial automation demands. The market size is expanding significantly as industries transition from mechanical relays to more reliable electronic solutions. Technologically, SSRs are reaching maturity with companies like OMRON, Crouzet, and Siemens leading innovation in reliability and performance metrics. State Grid Corporation of China and ZF Friedrichshafen are implementing large-scale SSR applications in power distribution and automotive sectors respectively. Emerging players like Zhejiang Great Electrical and Advanced Energy Management are focusing on specialized applications, while academic institutions such as Shandong University and National University of Singapore are advancing next-generation SSR technologies through research in semiconductor materials and thermal management solutions.

Advanced Energy Management Ltd.

Technical Solution: Advanced Energy Management has developed the "SmartRelay Evaluation Platform" specifically designed for building automation and energy management applications. Their approach focuses on evaluating solid-state relays within the context of complete building management systems, assessing not only individual relay performance but also system-level interactions. The platform incorporates continuous monitoring of electrical parameters (voltage, current, power factor) alongside environmental conditions (temperature, humidity) to provide contextual performance evaluation. Their methodology includes specialized testing for evaluating SSR performance in applications requiring precise load control, such as HVAC systems, lighting control, and demand response programs. The SmartRelay platform features automated load profiling capabilities that simulate various usage patterns to assess SSR performance under real-world conditions[5]. Advanced Energy Management has developed proprietary algorithms that analyze performance data to identify optimal control strategies, automatically adjusting switching patterns to maximize energy efficiency while minimizing wear on the relays. Their evaluation system includes integration testing with various building automation protocols (BACnet, LonWorks, Modbus) to ensure seamless operation within existing infrastructure. The platform also incorporates power quality analysis to evaluate how SSRs affect and are affected by harmonics, voltage fluctuations, and other power quality issues common in commercial buildings.

Strengths: Holistic evaluation approach that considers SSRs within the context of complete building systems. Specialized testing for energy efficiency applications with automated optimization capabilities. Weaknesses: Less suitable for industrial or utility-scale applications requiring higher power ratings. Limited focus on extreme operating conditions that might be encountered in more demanding environments.

Siemens Industry, Inc.

Technical Solution: Siemens has developed a comprehensive SSR evaluation framework called "SIRIUS Monitoring System" specifically designed for industrial automation applications. This system employs a multi-parameter approach to solid-state relay evaluation that incorporates both electrical and thermal performance metrics. Their methodology includes continuous monitoring of switching characteristics, voltage drop, leakage current, and thermal behavior under various load conditions. Siemens' evaluation technology utilizes advanced data analytics to establish performance baselines and detect deviations that might indicate potential failures. Their system implements a closed-loop feedback mechanism that automatically adjusts control parameters based on real-time performance data, optimizing relay operation for changing environmental conditions[2]. The SIRIUS platform integrates with industrial control systems via standardized communication protocols (PROFINET, PROFIBUS, etc.), enabling centralized monitoring and adjustment of distributed SSR installations. Siemens has also developed specialized testing procedures for evaluating SSR performance in high-frequency switching applications, where traditional evaluation methods often fail to capture transient behaviors that affect long-term reliability.

Strengths: Seamless integration with existing industrial automation systems through standardized protocols. Sophisticated analytics that can predict potential failures before they occur, enabling proactive maintenance. Weaknesses: Complex implementation requiring significant engineering expertise. Higher cost compared to simpler evaluation methods, making it less suitable for small-scale applications.

Key Technical Parameters and Performance Metrics

Reliability test method based on solid-state relay

PatentWO2024109081A1

Innovation

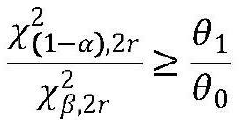

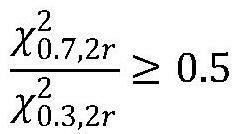

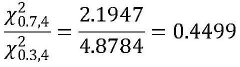

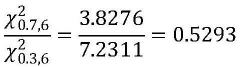

- Adopt a reliability test method based on solid-state relays, set environmental stress parameters and design test profiles, including pre-vibration tests and multiple state tests, and use the GJB899A-2009 sequential test statistical scheme to calculate the total test duration and determine test passability .

Static relay with condition detecting

PatentInactiveEP0895671A1

Innovation

- A static relay with a pair of light-emitting diodes connected in parallel head-to-tail and series with an RC circuit, optically coupled to transistors, which are connected in parallel with semiconductor components, allowing for state detection by monitoring voltage changes across the relay terminals during alternating current cycles.

Reliability Testing and Failure Analysis

Reliability testing and failure analysis are critical components in evaluating solid-state relays (SSRs) for automated control adjustments. These processes ensure that SSRs can withstand the rigorous demands of industrial automation environments while maintaining consistent performance over their operational lifetime.

Standard reliability testing protocols for SSRs typically include accelerated life testing, where relays are subjected to elevated temperatures, voltages, and switching frequencies beyond normal operating conditions. This approach helps identify potential failure modes that might only emerge after extended periods of standard operation. Temperature cycling tests are particularly important, as they simulate the thermal stress experienced during normal operation cycles, revealing weaknesses in internal connections and semiconductor junctions.

Surge immunity testing represents another crucial evaluation metric, assessing how effectively SSRs can withstand voltage spikes without degradation or failure. This is especially relevant in industrial environments where power fluctuations are common. Similarly, load cycling tests evaluate relay performance under repeated switching of various load types, from resistive to highly inductive loads, which can generate significant back-EMF.

Failure analysis methodologies for SSRs have evolved significantly with advanced diagnostic tools. Infrared thermography can detect hotspots indicating potential failure points before catastrophic breakdown occurs. Electron microscopy enables examination of semiconductor structures at the microscopic level, identifying manufacturing defects or material degradation. Electrical characterization through I-V curve analysis helps quantify performance degradation over time.

Common failure modes in solid-state relays include thermal runaway, where increasing temperature leads to increased leakage current, creating a destructive feedback loop. Junction degradation represents another significant failure mechanism, particularly in applications with frequent switching or high-current loads. Environmental factors such as humidity and contamination can accelerate these failure processes by compromising the integrity of semiconductor materials.

Statistical analysis of failure data provides valuable insights for reliability prediction. Weibull analysis and Mean Time Between Failures (MTBF) calculations help quantify expected service life under specific operating conditions. These metrics enable system designers to implement appropriate maintenance schedules and redundancy measures.

For automated control applications, reliability testing must incorporate real-world operating scenarios. This includes evaluating SSR performance under varying control signal conditions, assessing response times, and measuring consistency of switching behavior. Particular attention should be paid to failure modes that might result in unsafe conditions, such as failure-to-open scenarios in critical safety applications.

Standard reliability testing protocols for SSRs typically include accelerated life testing, where relays are subjected to elevated temperatures, voltages, and switching frequencies beyond normal operating conditions. This approach helps identify potential failure modes that might only emerge after extended periods of standard operation. Temperature cycling tests are particularly important, as they simulate the thermal stress experienced during normal operation cycles, revealing weaknesses in internal connections and semiconductor junctions.

Surge immunity testing represents another crucial evaluation metric, assessing how effectively SSRs can withstand voltage spikes without degradation or failure. This is especially relevant in industrial environments where power fluctuations are common. Similarly, load cycling tests evaluate relay performance under repeated switching of various load types, from resistive to highly inductive loads, which can generate significant back-EMF.

Failure analysis methodologies for SSRs have evolved significantly with advanced diagnostic tools. Infrared thermography can detect hotspots indicating potential failure points before catastrophic breakdown occurs. Electron microscopy enables examination of semiconductor structures at the microscopic level, identifying manufacturing defects or material degradation. Electrical characterization through I-V curve analysis helps quantify performance degradation over time.

Common failure modes in solid-state relays include thermal runaway, where increasing temperature leads to increased leakage current, creating a destructive feedback loop. Junction degradation represents another significant failure mechanism, particularly in applications with frequent switching or high-current loads. Environmental factors such as humidity and contamination can accelerate these failure processes by compromising the integrity of semiconductor materials.

Statistical analysis of failure data provides valuable insights for reliability prediction. Weibull analysis and Mean Time Between Failures (MTBF) calculations help quantify expected service life under specific operating conditions. These metrics enable system designers to implement appropriate maintenance schedules and redundancy measures.

For automated control applications, reliability testing must incorporate real-world operating scenarios. This includes evaluating SSR performance under varying control signal conditions, assessing response times, and measuring consistency of switching behavior. Particular attention should be paid to failure modes that might result in unsafe conditions, such as failure-to-open scenarios in critical safety applications.

Integration Standards and Compatibility Issues

The integration of Solid-State Relays (SSRs) into automated control systems requires adherence to established standards and careful consideration of compatibility issues. Various international standards govern SSR implementation, including IEC 60947-4-3 for AC semiconductor controllers, UL 508 for industrial control equipment, and IEC 61131-2 for programmable controllers. These standards define critical parameters such as voltage ratings, current capabilities, isolation requirements, and electromagnetic compatibility specifications that must be met for safe and reliable operation.

When evaluating SSRs for automated control adjustments, engineers must consider interface compatibility with existing control systems. Modern industrial environments typically utilize various communication protocols such as Modbus, PROFINET, EtherCAT, or EtherNet/IP. The selected SSR must either directly support these protocols or be compatible with appropriate interface modules. This compatibility extends to signal levels, where control signals may range from traditional 24VDC to lower voltage TTL/CMOS levels in newer systems.

Physical integration presents another set of challenges. Form factors vary significantly across manufacturers, with DIN rail mounting, panel mounting, and PCB mounting options available. The physical dimensions, terminal configurations, and cooling requirements must align with the installation environment constraints. Heat dissipation is particularly critical, as inadequate thermal management can lead to premature failure or reduced operational lifespan of SSRs.

Power supply compatibility must be carefully evaluated, especially in systems with mixed voltage requirements. SSRs designed for specific voltage ranges (low voltage DC, industrial AC, or high-voltage applications) must be matched appropriately to both control and load circuits. Additionally, the presence of surge protection, EMI filtering, and isolation barriers significantly impacts compatibility with sensitive electronic equipment in the vicinity.

Software integration considerations include driver compatibility, configuration tools, and diagnostic capabilities. Modern SSRs increasingly offer digital configuration options, status monitoring, and predictive maintenance features that require compatible software interfaces. The ability to integrate with existing SCADA systems, HMIs, or IoT platforms may significantly impact the overall system architecture and performance.

Backward compatibility with legacy systems presents unique challenges, particularly when upgrading partial components of an established control system. Hybrid solutions may be necessary, incorporating interface adapters or signal conditioning circuits to ensure seamless operation between new SSRs and existing equipment.

When evaluating SSRs for automated control adjustments, engineers must consider interface compatibility with existing control systems. Modern industrial environments typically utilize various communication protocols such as Modbus, PROFINET, EtherCAT, or EtherNet/IP. The selected SSR must either directly support these protocols or be compatible with appropriate interface modules. This compatibility extends to signal levels, where control signals may range from traditional 24VDC to lower voltage TTL/CMOS levels in newer systems.

Physical integration presents another set of challenges. Form factors vary significantly across manufacturers, with DIN rail mounting, panel mounting, and PCB mounting options available. The physical dimensions, terminal configurations, and cooling requirements must align with the installation environment constraints. Heat dissipation is particularly critical, as inadequate thermal management can lead to premature failure or reduced operational lifespan of SSRs.

Power supply compatibility must be carefully evaluated, especially in systems with mixed voltage requirements. SSRs designed for specific voltage ranges (low voltage DC, industrial AC, or high-voltage applications) must be matched appropriately to both control and load circuits. Additionally, the presence of surge protection, EMI filtering, and isolation barriers significantly impacts compatibility with sensitive electronic equipment in the vicinity.

Software integration considerations include driver compatibility, configuration tools, and diagnostic capabilities. Modern SSRs increasingly offer digital configuration options, status monitoring, and predictive maintenance features that require compatible software interfaces. The ability to integrate with existing SCADA systems, HMIs, or IoT platforms may significantly impact the overall system architecture and performance.

Backward compatibility with legacy systems presents unique challenges, particularly when upgrading partial components of an established control system. Hybrid solutions may be necessary, incorporating interface adapters or signal conditioning circuits to ensure seamless operation between new SSRs and existing equipment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!