How to Excel in Hydrochloric Acid Lab Analysis Techniques?

JUL 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HCl Lab Analysis Background and Objectives

Hydrochloric acid (HCl) lab analysis techniques have been a cornerstone of analytical chemistry for decades. The evolution of these techniques has been driven by the need for more precise, efficient, and safe methods of handling and analyzing this corrosive substance. From its initial discovery in the early 17th century to its widespread use in modern laboratories, HCl has played a crucial role in various scientific and industrial applications.

The primary objective of excelling in HCl lab analysis techniques is to enhance the accuracy, reliability, and safety of analytical processes involving this versatile acid. This goal encompasses improving detection limits, reducing interference from other substances, and developing more robust methodologies for quantitative and qualitative analysis. Additionally, there is a growing emphasis on developing eco-friendly and sustainable practices in HCl handling and analysis.

Throughout its history, HCl analysis has undergone significant transformations. Early methods relied heavily on titration and gravimetric techniques, which, while effective, were time-consuming and often prone to human error. The advent of spectroscopic methods in the mid-20th century, such as atomic absorption spectroscopy (AAS) and inductively coupled plasma mass spectrometry (ICP-MS), revolutionized HCl analysis by offering higher sensitivity and faster results.

In recent years, the focus has shifted towards automation and miniaturization of analytical processes. The development of microfluidic devices and lab-on-a-chip technologies has opened new avenues for HCl analysis, allowing for reduced sample volumes, faster analysis times, and improved portability of analytical instruments. These advancements are particularly crucial in fields such as environmental monitoring, where rapid on-site analysis is often necessary.

The current technological landscape for HCl lab analysis is characterized by a blend of traditional wet chemistry methods and cutting-edge instrumental techniques. While classical titration methods remain relevant for certain applications, there is a growing trend towards non-destructive, real-time monitoring systems. This includes the use of ion-selective electrodes, Raman spectroscopy, and advanced chromatographic techniques coupled with mass spectrometry.

As we look to the future, the trajectory of HCl lab analysis techniques is likely to be influenced by emerging technologies such as artificial intelligence and machine learning. These tools have the potential to enhance data interpretation, predict analytical outcomes, and optimize experimental conditions. Furthermore, the integration of Internet of Things (IoT) devices in laboratory settings promises to improve the connectivity and remote monitoring capabilities of HCl analysis systems.

The primary objective of excelling in HCl lab analysis techniques is to enhance the accuracy, reliability, and safety of analytical processes involving this versatile acid. This goal encompasses improving detection limits, reducing interference from other substances, and developing more robust methodologies for quantitative and qualitative analysis. Additionally, there is a growing emphasis on developing eco-friendly and sustainable practices in HCl handling and analysis.

Throughout its history, HCl analysis has undergone significant transformations. Early methods relied heavily on titration and gravimetric techniques, which, while effective, were time-consuming and often prone to human error. The advent of spectroscopic methods in the mid-20th century, such as atomic absorption spectroscopy (AAS) and inductively coupled plasma mass spectrometry (ICP-MS), revolutionized HCl analysis by offering higher sensitivity and faster results.

In recent years, the focus has shifted towards automation and miniaturization of analytical processes. The development of microfluidic devices and lab-on-a-chip technologies has opened new avenues for HCl analysis, allowing for reduced sample volumes, faster analysis times, and improved portability of analytical instruments. These advancements are particularly crucial in fields such as environmental monitoring, where rapid on-site analysis is often necessary.

The current technological landscape for HCl lab analysis is characterized by a blend of traditional wet chemistry methods and cutting-edge instrumental techniques. While classical titration methods remain relevant for certain applications, there is a growing trend towards non-destructive, real-time monitoring systems. This includes the use of ion-selective electrodes, Raman spectroscopy, and advanced chromatographic techniques coupled with mass spectrometry.

As we look to the future, the trajectory of HCl lab analysis techniques is likely to be influenced by emerging technologies such as artificial intelligence and machine learning. These tools have the potential to enhance data interpretation, predict analytical outcomes, and optimize experimental conditions. Furthermore, the integration of Internet of Things (IoT) devices in laboratory settings promises to improve the connectivity and remote monitoring capabilities of HCl analysis systems.

Industrial Demand for HCl Analysis

The demand for hydrochloric acid (HCl) analysis in industrial settings has grown significantly in recent years, driven by the expanding applications of HCl across various sectors. Industries such as chemical manufacturing, pharmaceuticals, food processing, and environmental monitoring rely heavily on accurate and efficient HCl analysis techniques to ensure product quality, process control, and regulatory compliance.

In the chemical manufacturing sector, HCl analysis is crucial for maintaining the purity and concentration of products. Companies producing chlorine, PVC, and other chlorinated compounds require precise HCl measurements to optimize their production processes and meet stringent quality standards. The pharmaceutical industry also demands rigorous HCl analysis for drug formulation, quality control, and research purposes, as many active pharmaceutical ingredients involve HCl in their synthesis or as a salt form.

The food processing industry utilizes HCl analysis for various applications, including pH adjustment, flavor enhancement, and food preservation. Accurate measurement of HCl concentration is essential for ensuring food safety and maintaining consistent product quality. Additionally, the beverage industry relies on HCl analysis for controlling acidity levels in soft drinks and other products.

Environmental monitoring and waste management sectors have seen an increased need for HCl analysis techniques. Industrial emissions, particularly from coal-fired power plants and waste incineration facilities, often contain HCl, which must be monitored and controlled to comply with environmental regulations. Wastewater treatment plants also require HCl analysis to manage pH levels and ensure proper treatment processes.

The metal processing industry uses HCl for metal surface treatment, pickling, and cleaning. Precise control of HCl concentration is critical for achieving desired surface properties and preventing corrosion. This has led to a growing demand for reliable and rapid HCl analysis methods in metal processing facilities.

As industries strive for greater efficiency and automation, there is an increasing demand for real-time, in-line HCl analysis techniques. This trend is driving the development of advanced sensors and analytical instruments capable of providing continuous monitoring and feedback for process control systems. The integration of these technologies with Industry 4.0 concepts and IoT platforms is further enhancing the value of HCl analysis in industrial settings.

The global focus on sustainability and environmental protection has also influenced the demand for HCl analysis. Industries are seeking more environmentally friendly alternatives to traditional HCl-based processes, which in turn requires sophisticated analysis techniques to evaluate and optimize these new approaches. This shift is creating opportunities for innovative analytical methods that can support the transition to greener industrial practices while maintaining high levels of accuracy and reliability.

In the chemical manufacturing sector, HCl analysis is crucial for maintaining the purity and concentration of products. Companies producing chlorine, PVC, and other chlorinated compounds require precise HCl measurements to optimize their production processes and meet stringent quality standards. The pharmaceutical industry also demands rigorous HCl analysis for drug formulation, quality control, and research purposes, as many active pharmaceutical ingredients involve HCl in their synthesis or as a salt form.

The food processing industry utilizes HCl analysis for various applications, including pH adjustment, flavor enhancement, and food preservation. Accurate measurement of HCl concentration is essential for ensuring food safety and maintaining consistent product quality. Additionally, the beverage industry relies on HCl analysis for controlling acidity levels in soft drinks and other products.

Environmental monitoring and waste management sectors have seen an increased need for HCl analysis techniques. Industrial emissions, particularly from coal-fired power plants and waste incineration facilities, often contain HCl, which must be monitored and controlled to comply with environmental regulations. Wastewater treatment plants also require HCl analysis to manage pH levels and ensure proper treatment processes.

The metal processing industry uses HCl for metal surface treatment, pickling, and cleaning. Precise control of HCl concentration is critical for achieving desired surface properties and preventing corrosion. This has led to a growing demand for reliable and rapid HCl analysis methods in metal processing facilities.

As industries strive for greater efficiency and automation, there is an increasing demand for real-time, in-line HCl analysis techniques. This trend is driving the development of advanced sensors and analytical instruments capable of providing continuous monitoring and feedback for process control systems. The integration of these technologies with Industry 4.0 concepts and IoT platforms is further enhancing the value of HCl analysis in industrial settings.

The global focus on sustainability and environmental protection has also influenced the demand for HCl analysis. Industries are seeking more environmentally friendly alternatives to traditional HCl-based processes, which in turn requires sophisticated analysis techniques to evaluate and optimize these new approaches. This shift is creating opportunities for innovative analytical methods that can support the transition to greener industrial practices while maintaining high levels of accuracy and reliability.

Current Challenges in HCl Lab Techniques

Hydrochloric acid (HCl) lab analysis techniques face several significant challenges in today's research and industrial environments. One of the primary issues is the corrosive nature of HCl, which poses risks to both personnel and equipment. This necessitates stringent safety protocols and specialized handling procedures, often slowing down analytical processes and increasing operational costs.

Accuracy and precision in HCl concentration measurements remain critical challenges, particularly when dealing with low concentrations or complex matrices. Traditional titration methods, while reliable, can be time-consuming and subject to human error. Spectrophotometric techniques offer faster analysis but may suffer from interferences in complex samples, leading to potential inaccuracies.

The volatility of HCl presents another hurdle, especially during sample preparation and storage. Maintaining sample integrity over time can be problematic, as HCl may evaporate or react with container materials, altering the concentration and potentially skewing results. This issue is particularly pronounced in long-term studies or when dealing with trace analysis.

Environmental concerns and regulatory compliance add another layer of complexity to HCl lab techniques. Proper disposal of HCl waste and adherence to increasingly stringent environmental regulations require sophisticated waste management systems and continuous monitoring, which can be resource-intensive for laboratories.

Interference from other ions or compounds in complex matrices is a persistent challenge in HCl analysis. This is particularly evident in environmental or industrial samples where multiple chemical species coexist. Developing selective and sensitive analytical methods that can accurately quantify HCl in the presence of interfering substances remains an ongoing area of research.

Automation and high-throughput analysis present both opportunities and challenges. While automated systems can increase efficiency and reduce human error, they often require significant initial investment and ongoing maintenance. Adapting HCl analysis techniques to high-throughput platforms without compromising accuracy or safety is a complex task that many laboratories are grappling with.

Standardization of HCl analysis methods across different industries and research fields is another challenge. The diversity of applications, from water treatment to pharmaceutical manufacturing, makes it difficult to establish universally accepted protocols. This lack of standardization can lead to discrepancies in results between different laboratories or sectors.

Lastly, the integration of HCl analysis with emerging technologies, such as miniaturized sensors or real-time monitoring systems, presents both exciting possibilities and significant technical hurdles. Developing robust, reliable, and cost-effective solutions that can withstand the corrosive nature of HCl while providing accurate, real-time data is a frontier challenge in this field.

Accuracy and precision in HCl concentration measurements remain critical challenges, particularly when dealing with low concentrations or complex matrices. Traditional titration methods, while reliable, can be time-consuming and subject to human error. Spectrophotometric techniques offer faster analysis but may suffer from interferences in complex samples, leading to potential inaccuracies.

The volatility of HCl presents another hurdle, especially during sample preparation and storage. Maintaining sample integrity over time can be problematic, as HCl may evaporate or react with container materials, altering the concentration and potentially skewing results. This issue is particularly pronounced in long-term studies or when dealing with trace analysis.

Environmental concerns and regulatory compliance add another layer of complexity to HCl lab techniques. Proper disposal of HCl waste and adherence to increasingly stringent environmental regulations require sophisticated waste management systems and continuous monitoring, which can be resource-intensive for laboratories.

Interference from other ions or compounds in complex matrices is a persistent challenge in HCl analysis. This is particularly evident in environmental or industrial samples where multiple chemical species coexist. Developing selective and sensitive analytical methods that can accurately quantify HCl in the presence of interfering substances remains an ongoing area of research.

Automation and high-throughput analysis present both opportunities and challenges. While automated systems can increase efficiency and reduce human error, they often require significant initial investment and ongoing maintenance. Adapting HCl analysis techniques to high-throughput platforms without compromising accuracy or safety is a complex task that many laboratories are grappling with.

Standardization of HCl analysis methods across different industries and research fields is another challenge. The diversity of applications, from water treatment to pharmaceutical manufacturing, makes it difficult to establish universally accepted protocols. This lack of standardization can lead to discrepancies in results between different laboratories or sectors.

Lastly, the integration of HCl analysis with emerging technologies, such as miniaturized sensors or real-time monitoring systems, presents both exciting possibilities and significant technical hurdles. Developing robust, reliable, and cost-effective solutions that can withstand the corrosive nature of HCl while providing accurate, real-time data is a frontier challenge in this field.

State-of-the-Art HCl Analysis Techniques

01 Electrochemical analysis techniques

Electrochemical methods are used for analyzing hydrochloric acid concentrations. These techniques involve measuring electrical properties of the solution, such as conductivity or potential difference, to determine acid concentration. Electrochemical analysis offers rapid and accurate results for hydrochloric acid determination in various industrial and laboratory settings.- Electrochemical analysis techniques: Electrochemical methods are used for analyzing hydrochloric acid concentration and purity. These techniques involve measuring electrical properties of the acid solution, such as conductivity or potential difference, to determine its composition and concentration. Electrochemical analysis offers high precision and can be used for both qualitative and quantitative measurements of hydrochloric acid.

- Spectroscopic analysis methods: Spectroscopic techniques, including UV-Vis, infrared, and Raman spectroscopy, are employed for hydrochloric acid analysis. These methods provide information about the molecular structure and concentration of the acid by measuring its interaction with electromagnetic radiation. Spectroscopic analysis is non-destructive and can be used for both qualitative and quantitative determination of hydrochloric acid in various matrices.

- Titration-based analysis: Titration methods, such as acid-base titration and potentiometric titration, are commonly used for quantitative analysis of hydrochloric acid. These techniques involve neutralizing the acid with a standard base solution and measuring the endpoint to determine the acid concentration. Titration-based analysis is simple, accurate, and widely applicable for determining hydrochloric acid content in various samples.

- Chromatographic techniques: Chromatographic methods, including ion chromatography and gas chromatography, are utilized for separating and analyzing hydrochloric acid and its impurities. These techniques allow for the simultaneous determination of multiple components in complex matrices. Chromatographic analysis provides high sensitivity and selectivity for hydrochloric acid determination in various environmental and industrial samples.

- Online monitoring and process analysis: Online monitoring systems and process analyzers are developed for continuous analysis of hydrochloric acid in industrial settings. These techniques employ various sensors and analytical methods to provide real-time measurements of acid concentration, purity, and other parameters. Online analysis ensures efficient process control and quality assurance in hydrochloric acid production and utilization.

02 Spectroscopic analysis methods

Spectroscopic techniques are employed for hydrochloric acid analysis, including UV-Vis spectroscopy, infrared spectroscopy, and Raman spectroscopy. These methods analyze the interaction between electromagnetic radiation and the acid molecules, providing information about concentration and purity. Spectroscopic analysis offers non-destructive and highly sensitive measurements for hydrochloric acid characterization.Expand Specific Solutions03 Titration-based analysis

Titration methods are widely used for quantitative analysis of hydrochloric acid. These techniques involve neutralizing the acid with a standard base solution and determining the endpoint using indicators or potentiometric measurements. Titration provides accurate concentration determination and is suitable for both laboratory and industrial applications.Expand Specific Solutions04 Chromatographic techniques

Chromatographic methods, such as ion chromatography and gas chromatography, are utilized for hydrochloric acid analysis. These techniques separate and quantify the acid components based on their interactions with a stationary phase. Chromatography offers high sensitivity and selectivity for analyzing hydrochloric acid in complex matrices or at trace levels.Expand Specific Solutions05 Online monitoring and process analysis

Online monitoring systems and process analyzers are developed for continuous hydrochloric acid analysis in industrial settings. These techniques incorporate various analytical methods, such as conductivity measurements or spectroscopic analysis, to provide real-time data on acid concentration and quality. Online monitoring enables efficient process control and quality assurance in hydrochloric acid production and utilization.Expand Specific Solutions

Key Players in HCl Analysis Equipment

The hydrochloric acid lab analysis techniques market is in a growth phase, driven by increasing demand for precise chemical analysis across various industries. The global market size is estimated to be in the hundreds of millions of dollars, with steady annual growth. Technologically, the field is advancing rapidly, with companies like Shimadzu Corp. and Versitech Ltd. leading innovation in analytical instruments and software solutions. Established players such as GlaxoSmithKline Biologicals SA and Novartis AG contribute to the market's maturity through their extensive R&D capabilities. Emerging companies like Jiangsu Yimai Technology Co., Ltd. are introducing novel approaches, indicating a dynamic competitive landscape with opportunities for both incumbents and new entrants to excel in this specialized field.

Covestro Deutschland AG

Technical Solution: Covestro has developed innovative techniques for hydrochloric acid analysis in polymer production and quality control. Their approach includes the use of online Fourier Transform Infrared (FTIR) spectroscopy for real-time monitoring of HCl evolution during polymer synthesis and degradation studies[15]. They have also implemented advanced titration techniques using photometric endpoints for precise determination of acid content in polymer additives and stabilizers[16]. Covestro has pioneered the use of headspace gas chromatography coupled with mass spectrometry (HS-GC-MS) for trace analysis of HCl and other volatile acids in polymer matrices[17]. Additionally, they have developed novel colorimetric sensors for rapid, on-site detection of HCl in air and process gases, crucial for workplace safety in chemical production facilities[18].

Strengths: Real-time monitoring capabilities, techniques optimized for polymer applications, and integration with process control systems. Weaknesses: Methods may be too specialized for general laboratory use and may require adaptation for non-polymer samples.

Praxair Technology, Inc.

Technical Solution: Praxair Technology has developed innovative techniques for hydrochloric acid analysis in industrial settings. Their approach focuses on real-time monitoring systems using tunable diode laser absorption spectroscopy (TDLAS) for in-situ HCl measurements in process streams[4]. This technology allows for continuous, non-intrusive analysis without the need for sample extraction. Praxair has also pioneered the use of fiber-optic sensors coated with HCl-sensitive materials for rapid detection of acid leaks in production facilities[5]. Additionally, they have implemented advanced data analytics to correlate HCl concentrations with process parameters, enabling predictive maintenance and optimization of acid-based processes[6].

Strengths: Real-time monitoring capabilities, non-intrusive analysis methods, and integration with process control systems. Weaknesses: Limited applicability in laboratory settings and potential sensitivity to interfering gases in complex industrial environments.

Innovative HCl Detection Technologies

Substantially pure vilazodone hydrochloride and a process thereof

PatentWO2014199313A1

Innovation

- A cost-effective process involving the condensation of 5-(piperaziny-l-yl)-1-benzofuran-2-carboxamide with 3-(4-chlorobutyl)-1H-indole-5-carbonitrile in the presence of a condensing agent and solvent, followed by purification using methods like filtration and charcoalization, to obtain substantially pure Vilazodone Hydrochloride.

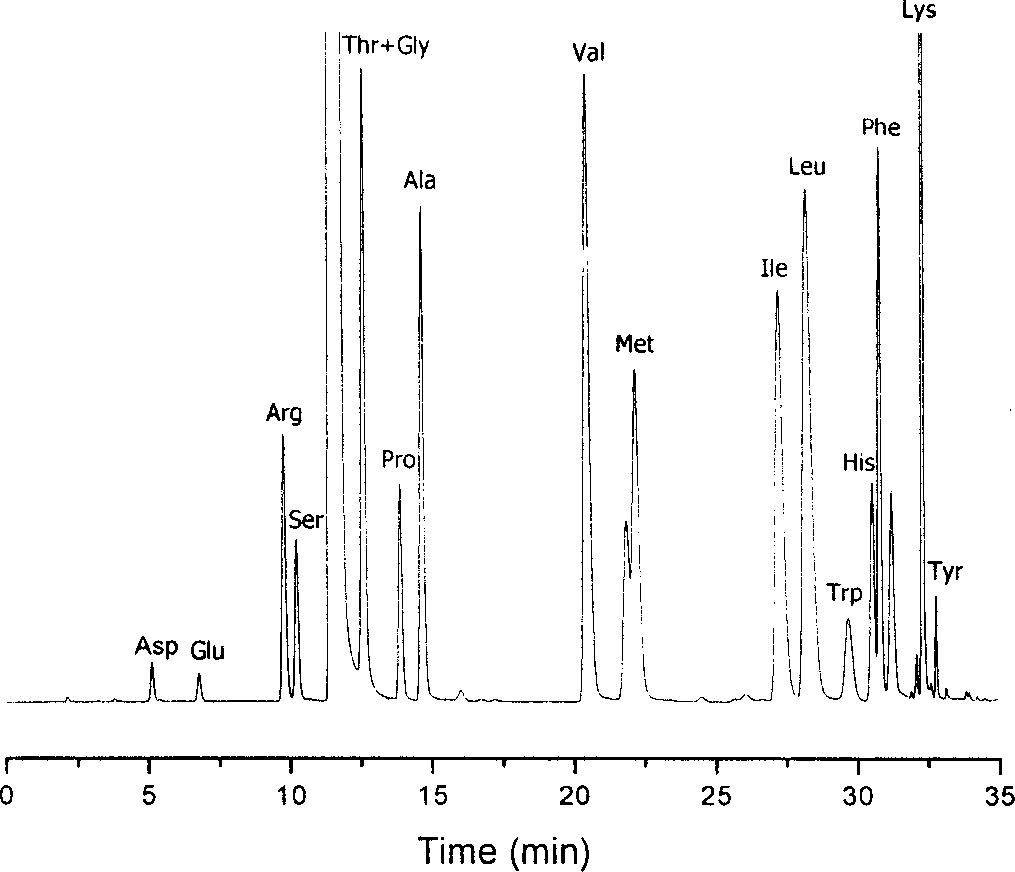

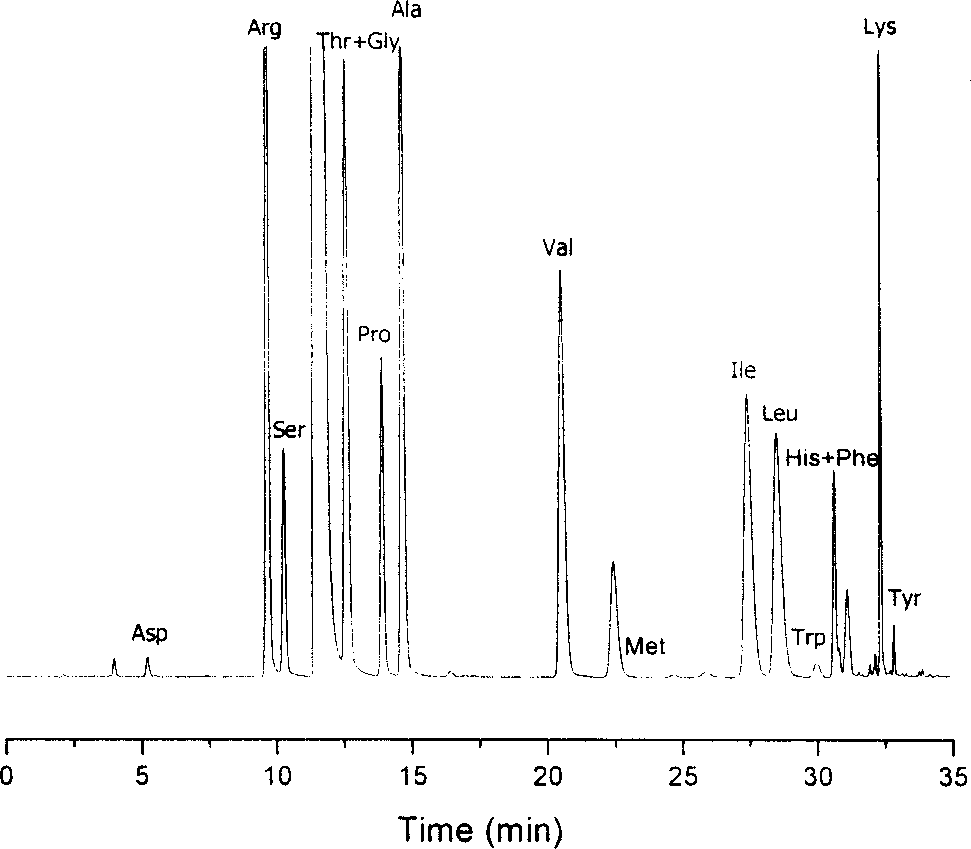

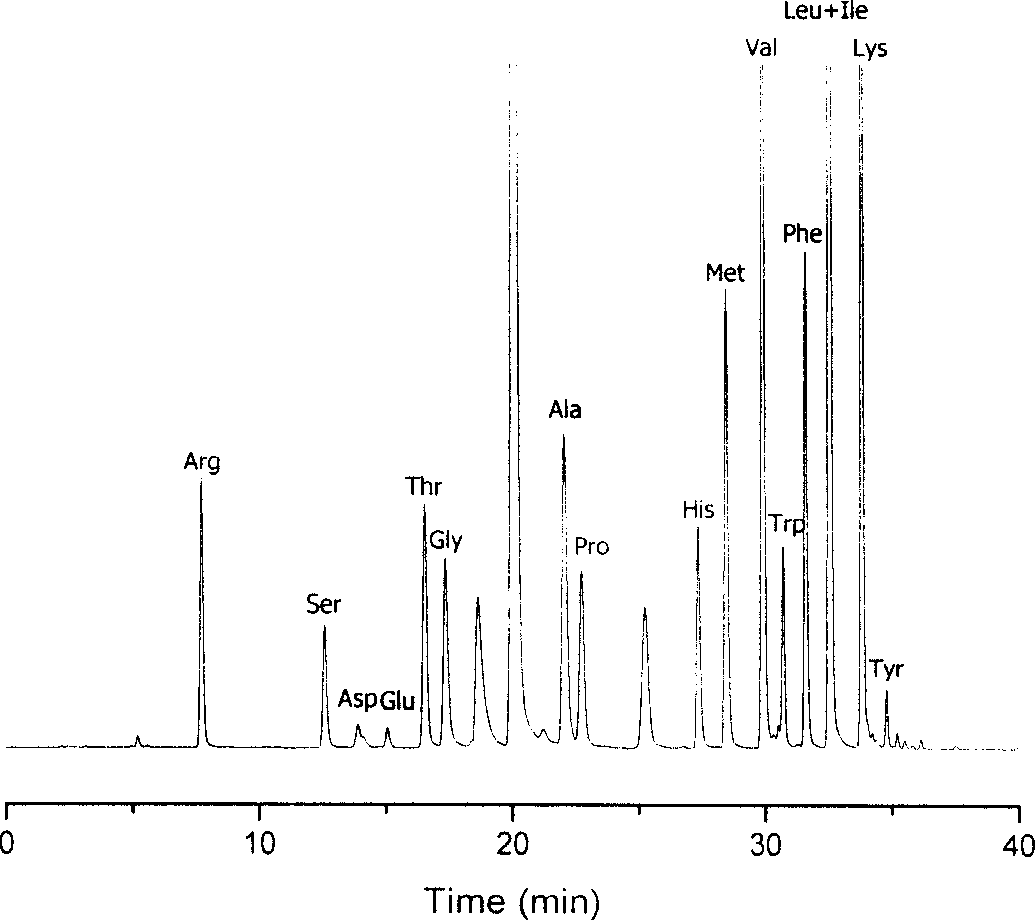

Method for analysizing amino acid

PatentActiveCN1749748A

Innovation

- Triethylamine phosphate/acetonitrile is used as the mobile phase. By adjusting the aqueous phase buffer interval and pH value, the adaptability to different brands of chromatographic columns and sample types is achieved. Pre-column derivatization and reversed-phase chromatography are used to separate amino acid-2,4 -Dinitrofluorobenzene derivatives, which improves the reproducibility and accuracy of analytical results.

Safety Protocols in HCl Handling

Safety protocols in hydrochloric acid (HCl) handling are paramount for excelling in lab analysis techniques. Proper safety measures not only protect personnel but also ensure the integrity of analytical results. The first line of defense is personal protective equipment (PPE). Lab technicians must wear chemical-resistant gloves, safety goggles, and a lab coat when handling HCl. For higher concentrations or larger volumes, additional protection such as a face shield and chemical-resistant apron may be necessary.

Ventilation is crucial when working with HCl due to its corrosive nature and potential to release harmful vapors. All procedures involving HCl should be conducted in a fume hood with proper airflow. The fume hood sash should be kept at the lowest possible position to maximize protection while allowing for comfortable work.

Proper storage of HCl is essential to prevent accidents and maintain the quality of the acid. HCl should be stored in a cool, dry area, away from direct sunlight and heat sources. Containers must be clearly labeled and kept in a designated acid storage cabinet. Incompatible chemicals, particularly bases and active metals, should be stored separately to prevent hazardous reactions.

Spill response procedures must be established and communicated to all lab personnel. Spill kits specifically designed for acid spills should be readily available. In the event of a small spill, neutralization with sodium bicarbonate or a commercial acid neutralizer is recommended, followed by absorption with an inert material. Large spills require immediate evacuation and professional cleanup.

Proper waste disposal is critical for environmental protection and regulatory compliance. HCl waste must be collected in designated containers and never disposed of down the drain. Neutralization may be required before disposal, depending on local regulations and concentration levels.

Training and education are fundamental aspects of safety protocols. All personnel working with HCl should receive comprehensive training on its properties, hazards, and proper handling techniques. Regular refresher courses and safety drills help maintain awareness and preparedness.

Emergency response planning is essential. Eye wash stations and safety showers must be easily accessible and regularly tested. Emergency contact information and procedures should be prominently displayed in the lab. A written emergency action plan should detail steps to be taken in case of exposure, spills, or other incidents involving HCl.

Implementing a robust safety culture is crucial for long-term success in HCl handling. This includes encouraging open communication about safety concerns, conducting regular safety audits, and continuously improving protocols based on feedback and incident analysis. By prioritizing these safety protocols, laboratories can excel in HCl analysis techniques while maintaining a safe and productive work environment.

Ventilation is crucial when working with HCl due to its corrosive nature and potential to release harmful vapors. All procedures involving HCl should be conducted in a fume hood with proper airflow. The fume hood sash should be kept at the lowest possible position to maximize protection while allowing for comfortable work.

Proper storage of HCl is essential to prevent accidents and maintain the quality of the acid. HCl should be stored in a cool, dry area, away from direct sunlight and heat sources. Containers must be clearly labeled and kept in a designated acid storage cabinet. Incompatible chemicals, particularly bases and active metals, should be stored separately to prevent hazardous reactions.

Spill response procedures must be established and communicated to all lab personnel. Spill kits specifically designed for acid spills should be readily available. In the event of a small spill, neutralization with sodium bicarbonate or a commercial acid neutralizer is recommended, followed by absorption with an inert material. Large spills require immediate evacuation and professional cleanup.

Proper waste disposal is critical for environmental protection and regulatory compliance. HCl waste must be collected in designated containers and never disposed of down the drain. Neutralization may be required before disposal, depending on local regulations and concentration levels.

Training and education are fundamental aspects of safety protocols. All personnel working with HCl should receive comprehensive training on its properties, hazards, and proper handling techniques. Regular refresher courses and safety drills help maintain awareness and preparedness.

Emergency response planning is essential. Eye wash stations and safety showers must be easily accessible and regularly tested. Emergency contact information and procedures should be prominently displayed in the lab. A written emergency action plan should detail steps to be taken in case of exposure, spills, or other incidents involving HCl.

Implementing a robust safety culture is crucial for long-term success in HCl handling. This includes encouraging open communication about safety concerns, conducting regular safety audits, and continuously improving protocols based on feedback and incident analysis. By prioritizing these safety protocols, laboratories can excel in HCl analysis techniques while maintaining a safe and productive work environment.

Environmental Impact of HCl Analysis

The environmental impact of hydrochloric acid (HCl) analysis techniques is a critical consideration in laboratory practices. These techniques, while essential for various scientific and industrial applications, can pose significant risks to the environment if not properly managed.

One of the primary environmental concerns associated with HCl analysis is the potential for acid release into water systems. Even small quantities of HCl can dramatically alter the pH of aquatic environments, leading to detrimental effects on flora and fauna. This acidification can disrupt ecosystems, harm aquatic life, and potentially contaminate drinking water sources.

Air pollution is another significant environmental issue related to HCl analysis. Volatile HCl fumes can contribute to the formation of acid rain when released into the atmosphere. This phenomenon can have far-reaching consequences, affecting soil quality, vegetation, and even accelerating the corrosion of buildings and infrastructure.

Proper waste management is crucial in mitigating the environmental impact of HCl analysis. Improper disposal of acid waste can lead to soil contamination, affecting plant growth and potentially entering the food chain. Furthermore, the interaction between HCl and certain metals can result in the release of hydrogen gas, posing explosion risks and contributing to greenhouse gas emissions.

The production and transportation of HCl for laboratory use also carry environmental implications. The manufacturing process of HCl can be energy-intensive and may involve the emission of various pollutants. Additionally, the transportation of this corrosive substance presents risks of accidental spills, which can have immediate and severe environmental consequences.

To address these environmental concerns, laboratories are increasingly adopting more sustainable practices. This includes implementing closed-loop systems to minimize waste, using less hazardous alternatives where possible, and improving fume hood efficiency to reduce energy consumption and emissions. Advanced neutralization techniques are being developed to treat HCl waste more effectively before disposal.

The use of microanalysis techniques is gaining popularity as they require smaller sample sizes and, consequently, less acid. This approach not only reduces the environmental footprint but also aligns with the principles of green chemistry. Furthermore, the development of in-situ analysis methods is helping to minimize the need for sample transportation and associated risks.

As environmental regulations become more stringent, there is a growing emphasis on life cycle assessments of laboratory processes. This holistic approach considers the environmental impact from the production of reagents to the final disposal of waste, encouraging more sustainable practices throughout the entire analytical process.

One of the primary environmental concerns associated with HCl analysis is the potential for acid release into water systems. Even small quantities of HCl can dramatically alter the pH of aquatic environments, leading to detrimental effects on flora and fauna. This acidification can disrupt ecosystems, harm aquatic life, and potentially contaminate drinking water sources.

Air pollution is another significant environmental issue related to HCl analysis. Volatile HCl fumes can contribute to the formation of acid rain when released into the atmosphere. This phenomenon can have far-reaching consequences, affecting soil quality, vegetation, and even accelerating the corrosion of buildings and infrastructure.

Proper waste management is crucial in mitigating the environmental impact of HCl analysis. Improper disposal of acid waste can lead to soil contamination, affecting plant growth and potentially entering the food chain. Furthermore, the interaction between HCl and certain metals can result in the release of hydrogen gas, posing explosion risks and contributing to greenhouse gas emissions.

The production and transportation of HCl for laboratory use also carry environmental implications. The manufacturing process of HCl can be energy-intensive and may involve the emission of various pollutants. Additionally, the transportation of this corrosive substance presents risks of accidental spills, which can have immediate and severe environmental consequences.

To address these environmental concerns, laboratories are increasingly adopting more sustainable practices. This includes implementing closed-loop systems to minimize waste, using less hazardous alternatives where possible, and improving fume hood efficiency to reduce energy consumption and emissions. Advanced neutralization techniques are being developed to treat HCl waste more effectively before disposal.

The use of microanalysis techniques is gaining popularity as they require smaller sample sizes and, consequently, less acid. This approach not only reduces the environmental footprint but also aligns with the principles of green chemistry. Furthermore, the development of in-situ analysis methods is helping to minimize the need for sample transportation and associated risks.

As environmental regulations become more stringent, there is a growing emphasis on life cycle assessments of laboratory processes. This holistic approach considers the environmental impact from the production of reagents to the final disposal of waste, encouraging more sustainable practices throughout the entire analytical process.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!