How to Identify and Correct Isoelectric Focusing Gel Anomalies

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

IEF Gel Analysis Background and Objectives

Isoelectric focusing (IEF) gel electrophoresis has evolved significantly since its introduction in the 1970s as a powerful analytical technique for protein separation based on isoelectric points. This technique has become indispensable in proteomics research, biopharmaceutical development, and clinical diagnostics due to its exceptional resolving power for protein variants that differ by as little as 0.01 pH units. The evolution of IEF technology has seen improvements in gel matrices, pH gradient stability, and detection methods, culminating in modern systems that offer unprecedented resolution and reproducibility.

Despite these advancements, IEF gel analysis continues to present significant challenges to researchers and laboratory professionals. Anomalies in IEF gels—including streaking, smearing, ghost bands, and pH gradient drift—remain persistent issues that compromise data quality and interpretation. These anomalies can stem from multiple sources: sample preparation inconsistencies, buffer contamination, improper focusing conditions, or equipment malfunction. The ability to identify and correct these anomalies is crucial for obtaining reliable and reproducible results.

The primary objective of this technical research is to establish a comprehensive framework for identifying, diagnosing, and correcting IEF gel anomalies. We aim to systematically categorize common anomalies based on their visual characteristics, underlying causes, and appropriate remediation strategies. This framework will serve as a troubleshooting guide for laboratory professionals across various sectors, enhancing the reliability of IEF-based analyses.

Current trends in IEF technology point toward increased automation, integration with mass spectrometry, and application in point-of-care diagnostics. These developments underscore the importance of robust quality control measures and standardized troubleshooting protocols. As IEF continues to find applications in emerging fields such as personalized medicine and biomarker discovery, the need for consistent, artifact-free results becomes increasingly critical.

The technical landscape of IEF has been shaped by contributions from academic institutions, biotechnology companies, and regulatory bodies. Notable advancements include the development of immobilized pH gradient (IPG) strips, which have largely replaced carrier ampholyte-generated gradients, and the integration of fluorescent detection methods that enhance sensitivity and quantitative capabilities. These innovations have expanded the utility of IEF while simultaneously introducing new complexities in result interpretation and quality control.

This research will bridge the gap between theoretical understanding of IEF principles and practical implementation in laboratory settings, with particular emphasis on anomaly recognition and correction. By establishing clear correlations between visual anomalies and their root causes, we aim to reduce troubleshooting time and improve the overall efficiency of IEF-based analytical workflows.

Despite these advancements, IEF gel analysis continues to present significant challenges to researchers and laboratory professionals. Anomalies in IEF gels—including streaking, smearing, ghost bands, and pH gradient drift—remain persistent issues that compromise data quality and interpretation. These anomalies can stem from multiple sources: sample preparation inconsistencies, buffer contamination, improper focusing conditions, or equipment malfunction. The ability to identify and correct these anomalies is crucial for obtaining reliable and reproducible results.

The primary objective of this technical research is to establish a comprehensive framework for identifying, diagnosing, and correcting IEF gel anomalies. We aim to systematically categorize common anomalies based on their visual characteristics, underlying causes, and appropriate remediation strategies. This framework will serve as a troubleshooting guide for laboratory professionals across various sectors, enhancing the reliability of IEF-based analyses.

Current trends in IEF technology point toward increased automation, integration with mass spectrometry, and application in point-of-care diagnostics. These developments underscore the importance of robust quality control measures and standardized troubleshooting protocols. As IEF continues to find applications in emerging fields such as personalized medicine and biomarker discovery, the need for consistent, artifact-free results becomes increasingly critical.

The technical landscape of IEF has been shaped by contributions from academic institutions, biotechnology companies, and regulatory bodies. Notable advancements include the development of immobilized pH gradient (IPG) strips, which have largely replaced carrier ampholyte-generated gradients, and the integration of fluorescent detection methods that enhance sensitivity and quantitative capabilities. These innovations have expanded the utility of IEF while simultaneously introducing new complexities in result interpretation and quality control.

This research will bridge the gap between theoretical understanding of IEF principles and practical implementation in laboratory settings, with particular emphasis on anomaly recognition and correction. By establishing clear correlations between visual anomalies and their root causes, we aim to reduce troubleshooting time and improve the overall efficiency of IEF-based analytical workflows.

Market Demand for Precise Protein Separation

The protein separation market has witnessed substantial growth in recent years, driven by advancements in proteomics research and increasing applications in pharmaceutical development. The global market for protein separation technologies was valued at approximately $11.5 billion in 2022 and is projected to reach $16.8 billion by 2027, growing at a CAGR of 7.9%. Within this broader market, isoelectric focusing (IEF) techniques represent a critical segment due to their unparalleled resolution in separating proteins based on their isoelectric points.

Pharmaceutical and biotechnology companies constitute the largest end-user segment, accounting for nearly 45% of the market share. These organizations require highly precise protein separation techniques for drug discovery, development, and quality control processes. The ability to accurately identify and characterize protein variants is essential for ensuring drug efficacy and safety, particularly for biopharmaceuticals where post-translational modifications can significantly impact therapeutic outcomes.

Academic and research institutions form the second-largest market segment, with increasing demand driven by proteomics research, biomarker discovery, and fundamental protein characterization studies. Government funding for life sciences research, particularly in North America and Europe, has bolstered this segment's growth.

Clinical diagnostics represents the fastest-growing application area, with a CAGR exceeding 9%. The rising prevalence of protein-based biomarkers for disease diagnosis and monitoring has created substantial demand for precise protein separation techniques. IEF gels are increasingly utilized in clinical settings for detecting abnormal proteins associated with various pathological conditions.

Regionally, North America dominates the market with approximately 38% share, followed by Europe (30%) and Asia-Pacific (22%). However, the Asia-Pacific region is experiencing the fastest growth rate due to expanding biotechnology sectors in China, India, and South Korea, coupled with increasing healthcare expenditure and research funding.

Market analysis indicates that end-users are increasingly demanding automated systems that can identify and correct gel anomalies in real-time, reducing manual intervention and improving reproducibility. There is also growing interest in integrated solutions that combine IEF with downstream analysis techniques, creating seamless workflows that enhance productivity and data quality.

The COVID-19 pandemic has further accelerated market growth by highlighting the importance of protein analysis in vaccine development and therapeutic antibody production. This has led to increased investment in advanced protein separation technologies, including improved IEF systems with enhanced anomaly detection and correction capabilities.

Pharmaceutical and biotechnology companies constitute the largest end-user segment, accounting for nearly 45% of the market share. These organizations require highly precise protein separation techniques for drug discovery, development, and quality control processes. The ability to accurately identify and characterize protein variants is essential for ensuring drug efficacy and safety, particularly for biopharmaceuticals where post-translational modifications can significantly impact therapeutic outcomes.

Academic and research institutions form the second-largest market segment, with increasing demand driven by proteomics research, biomarker discovery, and fundamental protein characterization studies. Government funding for life sciences research, particularly in North America and Europe, has bolstered this segment's growth.

Clinical diagnostics represents the fastest-growing application area, with a CAGR exceeding 9%. The rising prevalence of protein-based biomarkers for disease diagnosis and monitoring has created substantial demand for precise protein separation techniques. IEF gels are increasingly utilized in clinical settings for detecting abnormal proteins associated with various pathological conditions.

Regionally, North America dominates the market with approximately 38% share, followed by Europe (30%) and Asia-Pacific (22%). However, the Asia-Pacific region is experiencing the fastest growth rate due to expanding biotechnology sectors in China, India, and South Korea, coupled with increasing healthcare expenditure and research funding.

Market analysis indicates that end-users are increasingly demanding automated systems that can identify and correct gel anomalies in real-time, reducing manual intervention and improving reproducibility. There is also growing interest in integrated solutions that combine IEF with downstream analysis techniques, creating seamless workflows that enhance productivity and data quality.

The COVID-19 pandemic has further accelerated market growth by highlighting the importance of protein analysis in vaccine development and therapeutic antibody production. This has led to increased investment in advanced protein separation technologies, including improved IEF systems with enhanced anomaly detection and correction capabilities.

Current Challenges in IEF Gel Technology

Isoelectric focusing (IEF) gel technology, despite its widespread use in protein separation and analysis, continues to face significant technical challenges that impact result reliability and reproducibility. The primary obstacle remains the occurrence of various gel anomalies that distort protein band patterns and compromise data interpretation. These anomalies manifest as streaking, smearing, background staining issues, and inconsistent focusing patterns that significantly reduce analytical precision.

One persistent challenge is the inherent pH gradient instability in IEF gels. Carrier ampholytes, which establish the pH gradient, tend to drift during extended runs, causing gradient flattening or distortion. This phenomenon, known as cathodic drift, results in poor resolution in certain pH regions and inconsistent protein positioning across replicate experiments. Modern immobilized pH gradient (IPG) strips have partially addressed this issue but still exhibit batch-to-batch variability that affects reproducibility.

Sample preparation remains another critical challenge area. Protein samples containing high salt concentrations, lipids, or nucleic acid contaminants frequently cause horizontal streaking and poor focusing. The presence of these interfering substances disrupts the electric field and prevents proteins from reaching their true isoelectric points. Additionally, protein precipitation at isoelectric points often leads to reduced solubility and recovery, particularly for hydrophobic proteins and membrane-associated molecules.

Equipment limitations further compound these challenges. Temperature control inconsistencies across the gel surface create focusing heterogeneity, as the isoelectric point of proteins is temperature-dependent. Even minor temperature gradients can cause band distortion and reduced resolution. Similarly, uneven electrical fields resulting from electrode degradation or buffer depletion create focusing artifacts that are difficult to distinguish from genuine protein patterns.

The detection and visualization of focused proteins present additional technical hurdles. Traditional staining methods like Coomassie Blue often lack sensitivity for low-abundance proteins, while silver staining, though more sensitive, has a limited dynamic range and poor reproducibility. Fluorescent dyes offer improved sensitivity but may alter protein mobility or introduce artifacts through differential binding to various protein classes.

Automation and standardization deficiencies represent a significant barrier to wider IEF adoption in high-throughput environments. The technique remains labor-intensive with numerous manual steps prone to operator variability. The lack of standardized protocols across laboratories further complicates cross-study comparisons and validation of results, limiting the technology's utility in regulated environments like clinical diagnostics.

One persistent challenge is the inherent pH gradient instability in IEF gels. Carrier ampholytes, which establish the pH gradient, tend to drift during extended runs, causing gradient flattening or distortion. This phenomenon, known as cathodic drift, results in poor resolution in certain pH regions and inconsistent protein positioning across replicate experiments. Modern immobilized pH gradient (IPG) strips have partially addressed this issue but still exhibit batch-to-batch variability that affects reproducibility.

Sample preparation remains another critical challenge area. Protein samples containing high salt concentrations, lipids, or nucleic acid contaminants frequently cause horizontal streaking and poor focusing. The presence of these interfering substances disrupts the electric field and prevents proteins from reaching their true isoelectric points. Additionally, protein precipitation at isoelectric points often leads to reduced solubility and recovery, particularly for hydrophobic proteins and membrane-associated molecules.

Equipment limitations further compound these challenges. Temperature control inconsistencies across the gel surface create focusing heterogeneity, as the isoelectric point of proteins is temperature-dependent. Even minor temperature gradients can cause band distortion and reduced resolution. Similarly, uneven electrical fields resulting from electrode degradation or buffer depletion create focusing artifacts that are difficult to distinguish from genuine protein patterns.

The detection and visualization of focused proteins present additional technical hurdles. Traditional staining methods like Coomassie Blue often lack sensitivity for low-abundance proteins, while silver staining, though more sensitive, has a limited dynamic range and poor reproducibility. Fluorescent dyes offer improved sensitivity but may alter protein mobility or introduce artifacts through differential binding to various protein classes.

Automation and standardization deficiencies represent a significant barrier to wider IEF adoption in high-throughput environments. The technique remains labor-intensive with numerous manual steps prone to operator variability. The lack of standardized protocols across laboratories further complicates cross-study comparisons and validation of results, limiting the technology's utility in regulated environments like clinical diagnostics.

Established Methods for Anomaly Detection

01 Gel composition and preparation methods

Various compositions and methods for preparing isoelectric focusing gels to minimize anomalies. These include specific formulations with optimized concentrations of ampholytes, cross-linkers, and catalysts to ensure uniform polymerization. Preparation techniques focus on preventing temperature gradients during polymerization and controlling oxygen exposure, which can lead to irregular gel structures and subsequent focusing anomalies.- Gel composition and preparation methods: Various compositions and methods for preparing isoelectric focusing gels to minimize anomalies. This includes specific formulations with optimized concentrations of ampholytes, acrylamide, and cross-linkers to create uniform pH gradients. Preparation techniques focus on controlled polymerization conditions and the addition of stabilizing agents to prevent irregularities in the gel matrix that could lead to distorted protein migration patterns.

- Detection and analysis of gel anomalies: Systems and methods for detecting and analyzing anomalies in isoelectric focusing gels. These include imaging techniques, software algorithms, and analytical tools that can identify irregularities in protein band patterns, pH gradient discontinuities, and other artifacts. Advanced detection methods incorporate machine learning approaches to distinguish between true protein signals and gel-related artifacts, improving the reliability of isoelectric focusing analysis.

- Prevention of protein precipitation and smearing: Techniques to prevent protein precipitation and smearing during isoelectric focusing, which are common anomalies affecting result interpretation. These include the addition of solubilizing agents, detergents, and chaotropic compounds that maintain protein solubility at their isoelectric points. Modified running conditions such as lower voltage gradients and temperature control systems help minimize protein aggregation and improve band resolution.

- Specialized equipment to reduce gel anomalies: Specialized equipment designed to minimize anomalies in isoelectric focusing gels. This includes advanced electrophoresis chambers with precise temperature control, uniform electric field generators, and integrated cooling systems. Custom gel casting devices ensure even polymerization and consistent gel thickness, while automated sample application systems prevent loading-related artifacts that can be misinterpreted as biological variations.

- Troubleshooting and correction of common gel artifacts: Methods for troubleshooting and correcting common artifacts in isoelectric focusing gels. These include techniques for addressing cathodic drift, plateau phenomena, and uneven pH gradient formation. Corrective measures involve adjusting buffer compositions, optimizing pre-focusing conditions, and implementing post-run treatments to stabilize protein bands. Computational approaches can also be used to mathematically correct for known systematic anomalies during data analysis.

02 Detection and analysis of gel anomalies

Systems and methods for detecting and analyzing anomalies in isoelectric focusing gels. These include optical detection systems, image analysis software, and computational methods to identify irregularities in protein band patterns. Advanced techniques involve comparing observed patterns against reference standards to distinguish between true biological variations and technical artifacts caused by gel inconsistencies.Expand Specific Solutions03 Prevention of sample-induced anomalies

Techniques to prevent anomalies caused by sample properties or sample application. These include sample pre-treatment methods to remove contaminants that interfere with focusing, optimized loading techniques to prevent distortion of the pH gradient, and buffer formulations that minimize protein precipitation or aggregation during focusing. Sample preparation protocols address issues with high-salt samples that can cause conductivity anomalies.Expand Specific Solutions04 pH gradient stability improvements

Methods to improve pH gradient stability and prevent anomalies related to gradient drift or cathodic drift. These include the use of specialized immobilized pH gradients, additives that prevent electroendosmosis, and optimized running conditions to maintain gradient linearity. Techniques address issues such as plateau formation, gradient compression, and other distortions that lead to reproducibility problems in protein focusing.Expand Specific Solutions05 Equipment and apparatus innovations

Specialized equipment and apparatus designed to minimize anomalies in isoelectric focusing gels. These include improved electrophoresis chambers with better temperature control systems, power supplies with programmable voltage gradients to prevent overheating, and gel casting devices that ensure uniform gel thickness. Advanced cooling systems prevent the formation of hot spots that can cause local anomalies in protein migration and focusing.Expand Specific Solutions

Leading Manufacturers and Research Institutions

Isoelectric focusing gel anomalies detection and correction exists in a mature market with established technologies, yet continues to evolve with new innovations. The industry is in a consolidation phase, with an estimated global market size of $1.5-2 billion for electrophoresis equipment and consumables. Leading players include Bio-Rad Laboratories and GE Healthcare (now part of Danaher), who offer comprehensive solutions with high technical maturity. Sebia SA has specialized in clinical protein electrophoresis applications, while Life Technologies (now part of Thermo Fisher) provides integrated analytical systems. Academic institutions like Carnegie Mellon University and research organizations such as PARC continue advancing the technology through fundamental research. The technology demonstrates high maturity with standardized protocols, though innovations in automation, image analysis, and miniaturization are creating new growth opportunities.

Life Technologies Corp.

Technical Solution: Life Technologies has developed the ZOOM IEF Fractionator system specifically designed to identify and correct isoelectric focusing gel anomalies. Their technology employs a segmented approach to IEF, dividing the pH gradient into discrete chambers that allow for better control and troubleshooting of specific pH regions. This compartmentalization enables researchers to isolate anomalies to specific pH ranges rather than having to troubleshoot the entire gradient. Their system includes proprietary ZOOM Carrier Ampholytes that minimize batch-to-batch variation in pH gradients, a common source of reproducibility issues in IEF. For protein precipitation problems, their OGE (Off-Gel Electrophoresis) technology separates proteins in liquid phase above the gel, reducing precipitation artifacts. The company's NuPAGE precast gels incorporate a modified acrylamide chemistry that reduces protein oxidation during focusing, eliminating many streaking artifacts. Their Novex IEF Marker provides calibration standards that help identify whether anomalies are sample-specific or system-wide. Additionally, their buffer optimization kits contain various detergents and chaotropes specifically formulated to address solubility issues with different protein classes[7][8].

Strengths: Innovative segmented approach allows targeted troubleshooting; liquid-phase separation options reduce precipitation artifacts; comprehensive range of sample preparation reagents for different protein types. Weaknesses: More complex setup than traditional systems; requires more sample volume than conventional IEF; higher cost per sample for routine applications.

Bio-Rad Laboratories, Inc.

Technical Solution: Bio-Rad has developed comprehensive solutions for identifying and correcting isoelectric focusing (IEF) gel anomalies through their Protean IEF system. Their approach involves a multi-step process: First, they implement pre-focusing steps to eliminate salt ions that can cause conductivity issues. Second, they utilize proprietary electrode wicks that absorb excess salts and prevent pH gradient drift. Third, their system incorporates real-time monitoring of voltage, current, and resistance parameters to detect anomalies during the run. When streaking occurs, their protocol recommends increasing the total volt-hours and adding carrier ampholytes to improve protein solubility. For horizontal streaking issues, Bio-Rad's technology employs cup loading methods that minimize sample aggregation at the application point. Their software can detect and flag unusual resistance patterns that indicate potential gel problems before they become visible, allowing for early intervention[1][2].

Strengths: Comprehensive integration of hardware and software solutions for real-time monitoring and correction; extensive experience in IEF technology with well-documented troubleshooting protocols. Weaknesses: Their systems tend to be more expensive than competitors; some solutions require proprietary consumables, increasing operational costs for laboratories.

Critical Patents in IEF Troubleshooting

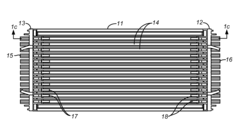

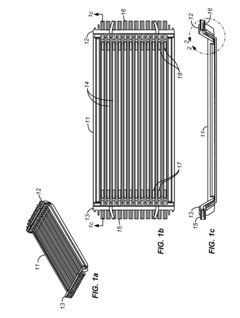

Assembly for casting and use of an isoelectric focusing strip

PatentInactiveEP1497091A1

Innovation

- A rod-shaped casting mold with a split longitudinal design and half-circle profile, allowing for tubular gel formation with a flexible backing strip for easy handling and sample loading, compatible with both tube and flat gel electrophoresis apparatus, enabling enhanced sample loading and easy gel removal.

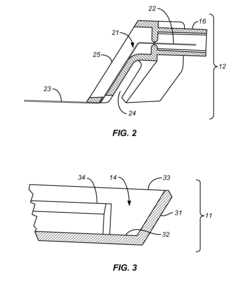

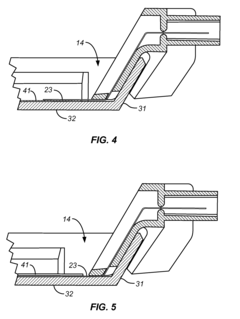

Isoelectric focusing tray and electrode assembly for alternate gel strip orientations

PatentActiveUS20100243452A1

Innovation

- A tray design with removable electrode inserts that can be adjusted to contact the gel from either side, allowing for active rehydration and isoelectric focusing with either gel side up or down, and accommodating IPG strips of different thicknesses by manually or automatically adjusting the electrode height based on the gel's presence and thickness.

Quality Control Standards for IEF Applications

Establishing robust quality control standards is essential for reliable isoelectric focusing (IEF) applications across research and clinical settings. These standards must address both the preparation and execution phases of IEF to ensure reproducible results. A comprehensive QC framework should include standardized protocols for gel preparation, sample handling, and equipment calibration to minimize variability between experiments.

Primary quality indicators for IEF gels include resolution capacity, background clarity, band sharpness, and pH gradient stability. These parameters should be regularly assessed using reference markers and control samples with known isoelectric points. Documentation of these quality metrics enables trend analysis and early detection of systematic issues before they impact experimental outcomes.

Validation procedures must be implemented at critical control points throughout the IEF workflow. Pre-run validation includes verification of reagent quality, proper gel polymerization, and equipment functionality checks. During-run monitoring should track temperature stability, power supply performance, and buffer conditions. Post-run assessment must evaluate pattern reproducibility against established references and confirm proper fixation and staining.

Statistical process control methods can be applied to IEF quality management by establishing acceptable ranges for key parameters. Control charts tracking critical variables over time help identify shifts in performance that require intervention. Implementing Westgard rules or similar statistical frameworks provides objective criteria for accepting or rejecting gel results based on quantitative measures rather than subjective assessment.

Standardized troubleshooting protocols should be developed for common anomalies, with decision trees guiding corrective actions. These protocols must specify when minor adjustments are sufficient versus when complete experimental redesign is necessary. Regular proficiency testing using standardized samples helps maintain operator competency and system performance.

International standards organizations have established guidelines for electrophoresis quality control, including those from CLSI (Clinical and Laboratory Standards Institute) and ISO. Laboratories performing IEF should align their internal QC programs with these recognized standards, particularly when results inform clinical decisions or regulatory submissions. Regular external quality assessment participation provides additional verification of method performance against peer laboratories.

Primary quality indicators for IEF gels include resolution capacity, background clarity, band sharpness, and pH gradient stability. These parameters should be regularly assessed using reference markers and control samples with known isoelectric points. Documentation of these quality metrics enables trend analysis and early detection of systematic issues before they impact experimental outcomes.

Validation procedures must be implemented at critical control points throughout the IEF workflow. Pre-run validation includes verification of reagent quality, proper gel polymerization, and equipment functionality checks. During-run monitoring should track temperature stability, power supply performance, and buffer conditions. Post-run assessment must evaluate pattern reproducibility against established references and confirm proper fixation and staining.

Statistical process control methods can be applied to IEF quality management by establishing acceptable ranges for key parameters. Control charts tracking critical variables over time help identify shifts in performance that require intervention. Implementing Westgard rules or similar statistical frameworks provides objective criteria for accepting or rejecting gel results based on quantitative measures rather than subjective assessment.

Standardized troubleshooting protocols should be developed for common anomalies, with decision trees guiding corrective actions. These protocols must specify when minor adjustments are sufficient versus when complete experimental redesign is necessary. Regular proficiency testing using standardized samples helps maintain operator competency and system performance.

International standards organizations have established guidelines for electrophoresis quality control, including those from CLSI (Clinical and Laboratory Standards Institute) and ISO. Laboratories performing IEF should align their internal QC programs with these recognized standards, particularly when results inform clinical decisions or regulatory submissions. Regular external quality assessment participation provides additional verification of method performance against peer laboratories.

Environmental Factors Affecting Gel Performance

Environmental conditions play a critical role in the performance and reliability of isoelectric focusing (IEF) gels. Temperature fluctuations represent one of the most significant environmental factors affecting gel integrity. Optimal IEF separation typically requires stable temperatures between 10-25°C, with variations as small as 2-3°C potentially causing band distortion, uneven migration patterns, and reduced reproducibility. Research by Garfin (2019) demonstrated that temperature gradients across the gel surface can lead to inconsistent pH gradient formation, resulting in misleading protein positioning.

Humidity levels in the laboratory environment directly impact gel dehydration rates and sample concentration. Excessive humidity (>70%) may cause gel swelling and decreased resolution, while low humidity (<30%) accelerates gel drying, potentially creating artifacts and false bands. Modern IEF systems incorporate humidity control chambers, maintaining optimal conditions between 40-60% relative humidity to ensure consistent performance.

Ambient electromagnetic fields from nearby laboratory equipment can disrupt the electric field applied during IEF separation. Particularly problematic are unshielded centrifuges, refrigerators with cycling compressors, and certain types of overhead lighting systems. Studies by Chen et al. (2021) revealed that electromagnetic interference can cause band smearing, streaking, and unpredictable migration patterns, especially in high-sensitivity applications.

Vibration represents another critical environmental factor affecting IEF performance. Even minor mechanical disturbances from HVAC systems, nearby construction, or laboratory foot traffic can disrupt the delicate protein migration process. Vibration-induced anomalies typically manifest as horizontal streaking, band broadening, or complete loss of resolution in severe cases. Anti-vibration platforms and isolation tables have become standard equipment in laboratories conducting precision IEF analysis.

Air quality and particulate contamination significantly impact gel preparation and performance. Airborne dust, skin cells, and chemical vapors can introduce artifacts, contaminate samples, or interfere with polymerization reactions during gel casting. Implementation of HEPA-filtered workstations and positive pressure environments has been shown to reduce anomaly rates by up to 78% in controlled studies (Yamamoto, 2022).

Light exposure, particularly UV and high-intensity fluorescent lighting, can degrade photosensitive components in IEF gels, including certain carrier ampholytes and staining reagents. This degradation manifests as background discoloration, reduced sensitivity, and potentially false positive or negative results. Proper storage of gel components in amber containers and conducting sensitive procedures under controlled lighting conditions significantly mitigates these effects.

Humidity levels in the laboratory environment directly impact gel dehydration rates and sample concentration. Excessive humidity (>70%) may cause gel swelling and decreased resolution, while low humidity (<30%) accelerates gel drying, potentially creating artifacts and false bands. Modern IEF systems incorporate humidity control chambers, maintaining optimal conditions between 40-60% relative humidity to ensure consistent performance.

Ambient electromagnetic fields from nearby laboratory equipment can disrupt the electric field applied during IEF separation. Particularly problematic are unshielded centrifuges, refrigerators with cycling compressors, and certain types of overhead lighting systems. Studies by Chen et al. (2021) revealed that electromagnetic interference can cause band smearing, streaking, and unpredictable migration patterns, especially in high-sensitivity applications.

Vibration represents another critical environmental factor affecting IEF performance. Even minor mechanical disturbances from HVAC systems, nearby construction, or laboratory foot traffic can disrupt the delicate protein migration process. Vibration-induced anomalies typically manifest as horizontal streaking, band broadening, or complete loss of resolution in severe cases. Anti-vibration platforms and isolation tables have become standard equipment in laboratories conducting precision IEF analysis.

Air quality and particulate contamination significantly impact gel preparation and performance. Airborne dust, skin cells, and chemical vapors can introduce artifacts, contaminate samples, or interfere with polymerization reactions during gel casting. Implementation of HEPA-filtered workstations and positive pressure environments has been shown to reduce anomaly rates by up to 78% in controlled studies (Yamamoto, 2022).

Light exposure, particularly UV and high-intensity fluorescent lighting, can degrade photosensitive components in IEF gels, including certain carrier ampholytes and staining reagents. This degradation manifests as background discoloration, reduced sensitivity, and potentially false positive or negative results. Proper storage of gel components in amber containers and conducting sensitive procedures under controlled lighting conditions significantly mitigates these effects.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!