How to Implement Green HPLC Techniques for Reduced Waste

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Green HPLC Evolution and Sustainability Goals

High-Performance Liquid Chromatography (HPLC) has evolved significantly since its inception in the 1960s, transforming from a purely analytical technique to one increasingly concerned with environmental impact. The evolution of Green HPLC represents a paradigm shift in analytical chemistry, moving from a focus solely on separation efficiency and resolution to incorporating sustainability principles. This evolution aligns with broader scientific trends toward environmentally responsible practices across all laboratory operations.

Traditional HPLC methods have long been criticized for their substantial environmental footprint, primarily due to the generation of hazardous waste through the use of toxic organic solvents. Historical data indicates that a typical analytical laboratory can produce between 1,000-3,000 liters of solvent waste annually, with HPLC contributing significantly to this volume. The environmental implications extend beyond waste disposal to include energy consumption, carbon emissions, and resource depletion.

The concept of Green Chemistry, formalized in the 1990s through Anastas and Warner's 12 principles, provided the theoretical foundation for Green HPLC development. These principles emphasize waste prevention, atom economy, safer solvents, energy efficiency, and renewable feedstocks—all directly applicable to chromatographic techniques. The subsequent emergence of Green Analytical Chemistry further refined these concepts specifically for analytical methods.

Current sustainability goals for Green HPLC focus on several key areas: minimizing solvent consumption, replacing toxic solvents with environmentally benign alternatives, reducing energy requirements, extending column lifetimes, and implementing recycling systems. Quantifiable targets include reducing organic solvent usage by 50-80%, decreasing analysis time by 30-60% through method optimization, and cutting energy consumption by implementing more efficient instrumentation.

The technological trajectory shows a clear progression from conventional HPLC to Ultra-High Performance Liquid Chromatography (UHPLC), which offers significant reductions in solvent consumption and analysis time. More recent innovations include Supercritical Fluid Chromatography (SFC) using CO2 as the primary mobile phase component, and the development of aqueous mobile phase systems that eliminate organic solvents entirely.

Looking forward, the field is moving toward fully integrated green analytical systems that combine multiple sustainability approaches. The ultimate goal is to develop "zero-waste" HPLC methodologies that maintain or exceed current analytical performance while eliminating environmental impact—a challenging but increasingly necessary objective given growing regulatory pressures and corporate sustainability commitments.

Traditional HPLC methods have long been criticized for their substantial environmental footprint, primarily due to the generation of hazardous waste through the use of toxic organic solvents. Historical data indicates that a typical analytical laboratory can produce between 1,000-3,000 liters of solvent waste annually, with HPLC contributing significantly to this volume. The environmental implications extend beyond waste disposal to include energy consumption, carbon emissions, and resource depletion.

The concept of Green Chemistry, formalized in the 1990s through Anastas and Warner's 12 principles, provided the theoretical foundation for Green HPLC development. These principles emphasize waste prevention, atom economy, safer solvents, energy efficiency, and renewable feedstocks—all directly applicable to chromatographic techniques. The subsequent emergence of Green Analytical Chemistry further refined these concepts specifically for analytical methods.

Current sustainability goals for Green HPLC focus on several key areas: minimizing solvent consumption, replacing toxic solvents with environmentally benign alternatives, reducing energy requirements, extending column lifetimes, and implementing recycling systems. Quantifiable targets include reducing organic solvent usage by 50-80%, decreasing analysis time by 30-60% through method optimization, and cutting energy consumption by implementing more efficient instrumentation.

The technological trajectory shows a clear progression from conventional HPLC to Ultra-High Performance Liquid Chromatography (UHPLC), which offers significant reductions in solvent consumption and analysis time. More recent innovations include Supercritical Fluid Chromatography (SFC) using CO2 as the primary mobile phase component, and the development of aqueous mobile phase systems that eliminate organic solvents entirely.

Looking forward, the field is moving toward fully integrated green analytical systems that combine multiple sustainability approaches. The ultimate goal is to develop "zero-waste" HPLC methodologies that maintain or exceed current analytical performance while eliminating environmental impact—a challenging but increasingly necessary objective given growing regulatory pressures and corporate sustainability commitments.

Market Demand for Eco-friendly Analytical Methods

The analytical chemistry market has witnessed a significant shift towards environmentally sustainable practices in recent years, with green High-Performance Liquid Chromatography (HPLC) techniques gaining substantial traction. The global market for eco-friendly analytical methods was valued at approximately $3.2 billion in 2022 and is projected to grow at a compound annual growth rate of 8.7% through 2028, reflecting the increasing demand for sustainable laboratory practices.

This market growth is primarily driven by stringent environmental regulations across developed economies, particularly in Europe and North America. The European Union's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation and similar frameworks have compelled laboratories to adopt greener analytical approaches that minimize hazardous waste generation and reduce environmental impact.

Pharmaceutical companies represent the largest segment of end-users for green HPLC techniques, accounting for approximately 42% of the market share. This dominance stems from the industry's high sample throughput requirements and increasing focus on sustainable manufacturing practices. Environmental testing laboratories follow closely, driven by the need for methods that align with their core mission of environmental protection.

Consumer demand for sustainably produced products has created a ripple effect throughout supply chains, compelling manufacturers to demonstrate environmental responsibility in their quality control and R&D processes. This trend has extended to academic and research institutions, where funding agencies increasingly favor projects employing sustainable methodologies.

Cost considerations also play a significant role in market demand. Traditional HPLC methods consume large volumes of organic solvents, which not only pose environmental hazards but also represent substantial operational costs. Green HPLC techniques that reduce solvent consumption can deliver return on investment through decreased purchasing costs and lower waste disposal expenses, with some organizations reporting 30-40% reduction in solvent-related expenditures.

The COVID-19 pandemic has accelerated this market trend, as supply chain disruptions highlighted vulnerabilities in laboratory operations dependent on large volumes of solvents and reagents. This has prompted many organizations to reevaluate their analytical workflows with sustainability and resilience in mind.

Regional analysis indicates that North America currently leads the market for green analytical methods, followed by Europe. However, the Asia-Pacific region is expected to witness the fastest growth rate in the coming years, driven by rapid industrialization coupled with increasing environmental awareness and regulatory developments in countries like China, Japan, and India.

This market growth is primarily driven by stringent environmental regulations across developed economies, particularly in Europe and North America. The European Union's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation and similar frameworks have compelled laboratories to adopt greener analytical approaches that minimize hazardous waste generation and reduce environmental impact.

Pharmaceutical companies represent the largest segment of end-users for green HPLC techniques, accounting for approximately 42% of the market share. This dominance stems from the industry's high sample throughput requirements and increasing focus on sustainable manufacturing practices. Environmental testing laboratories follow closely, driven by the need for methods that align with their core mission of environmental protection.

Consumer demand for sustainably produced products has created a ripple effect throughout supply chains, compelling manufacturers to demonstrate environmental responsibility in their quality control and R&D processes. This trend has extended to academic and research institutions, where funding agencies increasingly favor projects employing sustainable methodologies.

Cost considerations also play a significant role in market demand. Traditional HPLC methods consume large volumes of organic solvents, which not only pose environmental hazards but also represent substantial operational costs. Green HPLC techniques that reduce solvent consumption can deliver return on investment through decreased purchasing costs and lower waste disposal expenses, with some organizations reporting 30-40% reduction in solvent-related expenditures.

The COVID-19 pandemic has accelerated this market trend, as supply chain disruptions highlighted vulnerabilities in laboratory operations dependent on large volumes of solvents and reagents. This has prompted many organizations to reevaluate their analytical workflows with sustainability and resilience in mind.

Regional analysis indicates that North America currently leads the market for green analytical methods, followed by Europe. However, the Asia-Pacific region is expected to witness the fastest growth rate in the coming years, driven by rapid industrialization coupled with increasing environmental awareness and regulatory developments in countries like China, Japan, and India.

Current Green HPLC Technologies and Limitations

Green HPLC (High-Performance Liquid Chromatography) technologies have evolved significantly over the past decade in response to increasing environmental concerns and regulatory pressures. Current green HPLC approaches primarily focus on three main strategies: reducing solvent consumption, utilizing less hazardous solvents, and minimizing energy requirements.

Miniaturization represents one of the most successful green HPLC technologies, with micro-HPLC and nano-HPLC systems reducing solvent consumption by up to 95% compared to conventional systems. These technologies maintain separation efficiency while dramatically decreasing waste generation. Ultra-high performance liquid chromatography (UHPLC) has emerged as another prominent green technology, utilizing sub-2μm particles and higher pressures to achieve faster separations with reduced mobile phase consumption.

Solvent replacement strategies have gained significant traction, with water-based mobile phases becoming increasingly popular. Subcritical water chromatography (SBWC) utilizes hot pressurized water as the mobile phase, eliminating organic solvents entirely for certain applications. Similarly, supercritical fluid chromatography (SFC) employing CO2 as the primary mobile phase offers an environmentally friendly alternative with reduced waste generation.

Despite these advancements, current green HPLC technologies face several limitations. The high backpressure generated in UHPLC systems requires specialized equipment and expertise, limiting widespread adoption. Additionally, the initial capital investment for transitioning to green HPLC technologies remains prohibitively high for many laboratories, particularly in academic and small-scale industrial settings.

Technical challenges persist in method development for green HPLC. The reduced selectivity of environmentally friendly solvents compared to traditional organic solvents can compromise separation efficiency for complex samples. This often necessitates extensive method optimization, increasing development time and costs. Furthermore, the stability and reproducibility of green methods under varying conditions remain concerns for regulatory compliance in pharmaceutical and clinical applications.

Compatibility issues between green HPLC technologies and existing analytical workflows present another significant limitation. Many established methods validated under conventional HPLC conditions require extensive revalidation when transferred to green platforms, creating regulatory hurdles and implementation delays.

The analytical performance of some green technologies still lags behind conventional methods in terms of sensitivity, particularly for trace analysis. This performance gap has limited the adoption of green HPLC in certain application areas such as environmental monitoring and food safety testing, where detection of ultra-low concentrations is critical.

Infrastructure limitations also impede wider implementation, as many laboratories lack the necessary waste treatment facilities to properly handle even the reduced waste streams generated by green HPLC methods. This highlights the need for a holistic approach to green analytical chemistry that addresses not only the analytical procedure itself but also the surrounding laboratory infrastructure.

Miniaturization represents one of the most successful green HPLC technologies, with micro-HPLC and nano-HPLC systems reducing solvent consumption by up to 95% compared to conventional systems. These technologies maintain separation efficiency while dramatically decreasing waste generation. Ultra-high performance liquid chromatography (UHPLC) has emerged as another prominent green technology, utilizing sub-2μm particles and higher pressures to achieve faster separations with reduced mobile phase consumption.

Solvent replacement strategies have gained significant traction, with water-based mobile phases becoming increasingly popular. Subcritical water chromatography (SBWC) utilizes hot pressurized water as the mobile phase, eliminating organic solvents entirely for certain applications. Similarly, supercritical fluid chromatography (SFC) employing CO2 as the primary mobile phase offers an environmentally friendly alternative with reduced waste generation.

Despite these advancements, current green HPLC technologies face several limitations. The high backpressure generated in UHPLC systems requires specialized equipment and expertise, limiting widespread adoption. Additionally, the initial capital investment for transitioning to green HPLC technologies remains prohibitively high for many laboratories, particularly in academic and small-scale industrial settings.

Technical challenges persist in method development for green HPLC. The reduced selectivity of environmentally friendly solvents compared to traditional organic solvents can compromise separation efficiency for complex samples. This often necessitates extensive method optimization, increasing development time and costs. Furthermore, the stability and reproducibility of green methods under varying conditions remain concerns for regulatory compliance in pharmaceutical and clinical applications.

Compatibility issues between green HPLC technologies and existing analytical workflows present another significant limitation. Many established methods validated under conventional HPLC conditions require extensive revalidation when transferred to green platforms, creating regulatory hurdles and implementation delays.

The analytical performance of some green technologies still lags behind conventional methods in terms of sensitivity, particularly for trace analysis. This performance gap has limited the adoption of green HPLC in certain application areas such as environmental monitoring and food safety testing, where detection of ultra-low concentrations is critical.

Infrastructure limitations also impede wider implementation, as many laboratories lack the necessary waste treatment facilities to properly handle even the reduced waste streams generated by green HPLC methods. This highlights the need for a holistic approach to green analytical chemistry that addresses not only the analytical procedure itself but also the surrounding laboratory infrastructure.

Established Green HPLC Methodologies for Waste Reduction

01 Eco-friendly mobile phases and solvents

Green HPLC techniques focus on using environmentally friendly mobile phases and solvents to reduce toxic waste generation. This includes replacing traditional organic solvents with water-based solutions, biodegradable alternatives, or solvents derived from renewable resources. These approaches minimize environmental impact while maintaining analytical performance and reducing hazardous waste disposal requirements.- Solvent reduction and recycling in HPLC: Green HPLC techniques focus on reducing solvent consumption and implementing recycling systems to minimize waste. These approaches include using smaller column dimensions, optimizing flow rates, and implementing closed-loop solvent recovery systems. By reducing the volume of organic solvents used and recycling them where possible, laboratories can significantly decrease their environmental footprint while maintaining analytical performance.

- Alternative green solvents for HPLC: The use of environmentally friendly alternative solvents represents a significant advancement in green HPLC. These include bio-derived solvents, supercritical fluids (particularly CO2), and water-based mobile phases. Such alternatives reduce the reliance on toxic and environmentally harmful conventional organic solvents like acetonitrile and methanol, while still providing effective chromatographic separation with reduced waste generation and environmental impact.

- Miniaturization and microfluidic HPLC systems: Miniaturized HPLC systems and microfluidic technologies significantly reduce solvent consumption and waste generation. These systems utilize smaller columns, reduced internal volumes, and lower flow rates while maintaining or improving separation efficiency. Chip-based HPLC platforms integrate multiple analytical functions into compact devices, further minimizing reagent use and waste production while offering advantages in terms of speed and sensitivity.

- Waste treatment and disposal systems for HPLC: Specialized waste treatment systems for HPLC effluents help minimize environmental impact. These include on-line treatment processes that detoxify or neutralize harmful components before disposal, solvent separation systems that facilitate proper disposal or recycling, and advanced oxidation processes to break down persistent organic compounds. Such integrated waste management approaches ensure that HPLC waste is handled responsibly and in compliance with environmental regulations.

- Energy-efficient HPLC technologies: Energy-efficient HPLC technologies reduce the overall environmental impact of chromatographic analyses. These include ambient temperature separations that eliminate the need for column heating, ultra-high pressure systems that enable faster analyses with less solvent consumption, and instruments with improved power management features. Additionally, the integration of renewable energy sources to power HPLC systems further enhances their green credentials by reducing reliance on fossil fuels.

02 Miniaturization and reduced sample/solvent consumption

Miniaturized HPLC systems and techniques reduce waste by decreasing the required amounts of samples and solvents. These include micro and nano-HPLC systems, capillary columns, and other scaled-down approaches that maintain separation efficiency while significantly reducing solvent consumption. This miniaturization directly translates to less chemical waste generation and lower operational costs.Expand Specific Solutions03 Solvent recycling and waste management systems

Integrated solvent recycling and waste management systems help recover and purify used solvents for reuse in HPLC applications. These systems include distillation units, filtration technologies, and automated recycling processes that capture, treat, and return solvents to the analytical workflow. Such approaches significantly reduce the volume of waste generated and decrease the environmental footprint of analytical laboratories.Expand Specific Solutions04 Alternative separation technologies

Green HPLC incorporates alternative separation technologies that reduce or eliminate the need for harmful solvents. These include supercritical fluid chromatography (SFC), which uses CO2 as the primary mobile phase component, solid-phase extraction techniques, and other emerging technologies that achieve separation with minimal environmental impact. These methods often provide comparable or superior analytical performance while generating less hazardous waste.Expand Specific Solutions05 Optimization of analytical methods

Optimization of HPLC methods through advanced software, artificial intelligence, and experimental design reduces waste generation. This includes developing shorter run times, optimizing gradient profiles, and implementing quality-by-design approaches that minimize solvent consumption while maintaining separation efficiency. These optimized methods reduce resource consumption and waste production throughout the analytical process.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Green HPLC

Green HPLC (High-Performance Liquid Chromatography) techniques are evolving rapidly in a market transitioning from early adoption to mainstream implementation. The global green chromatography market is expanding at approximately 6.5% CAGR, driven by increasing environmental regulations and sustainability initiatives. Leading companies like Solvay SA, Air Liquide SA, and China Petroleum & Chemical Corp. are developing eco-friendly solvents and stationary phases, while academic institutions including Tsinghua University and University of Michigan are advancing fundamental research. Specialized equipment manufacturers such as ICM Co. Ltd. and Tianjin Bioseps are creating energy-efficient systems with reduced solvent consumption. The technology is approaching maturity with innovations focusing on solvent reduction, recycling systems, and miniaturization, though widespread adoption faces challenges including initial investment costs and performance validation requirements.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed comprehensive green HPLC techniques focusing on solvent reduction and recycling systems. Their approach includes using supercritical fluid chromatography (SFC) with CO2 as the primary mobile phase, reducing organic solvent consumption by up to 90% compared to conventional HPLC methods[1]. Sinopec has implemented automated solvent recycling systems that can recover and purify up to 85% of used solvents, significantly reducing waste disposal costs and environmental impact[3]. Their laboratories have also pioneered miniaturized HPLC systems that require only microliters of solvent per analysis, compared to milliliters in traditional systems. Additionally, Sinopec has developed water-based mobile phases for certain petrochemical analyses, eliminating toxic organic solvents entirely for specific applications[5]. Their green HPLC implementation includes comprehensive waste management protocols and energy-efficient instruments that reduce power consumption by approximately 40% compared to older generation equipment.

Strengths: Extensive experience in handling complex petrochemical samples; robust solvent recycling infrastructure; significant cost savings from reduced solvent consumption and waste disposal. Weaknesses: Some green techniques may have lower separation efficiency for certain complex hydrocarbon mixtures; initial capital investment for retrofitting existing systems is substantial; water-based mobile phases are not suitable for all petroleum product analyses.

Solvay SA

Technical Solution: Solvay SA has pioneered an integrated green HPLC approach called "EcoChrom" that focuses on sustainable chemistry principles throughout the analytical process. Their system employs bio-sourced solvents derived from agricultural waste as alternatives to traditional petroleum-based solvents, reducing carbon footprint by approximately 65%[2]. Solvay has developed proprietary stationary phases that enable efficient separations at lower pressures, reducing energy consumption by up to 30% while maintaining analytical performance[4]. Their technology incorporates solvent-saving column designs with reduced internal diameters (2mm instead of standard 4.6mm), decreasing solvent consumption by 75-80% per analysis. Solvay's green HPLC systems feature closed-loop solvent recovery units that capture, purify, and reuse up to 90% of mobile phases, dramatically reducing waste generation[6]. Additionally, they've implemented automated smart scheduling software that optimizes instrument usage patterns to minimize idle time and standby power consumption, further enhancing energy efficiency. Their comprehensive approach includes biodegradable packaging for consumables and a take-back program for used columns and materials.

Strengths: Holistic sustainability approach addressing multiple aspects of HPLC waste; proprietary bio-sourced solvents provide unique market advantage; significant reduction in both operational costs and environmental impact. Weaknesses: Bio-sourced solvents may have batch-to-batch variability affecting method reproducibility; specialized equipment requires additional training for analysts; higher initial investment compared to conventional HPLC systems.

Key Innovations in Solvent Reduction and Recovery Systems

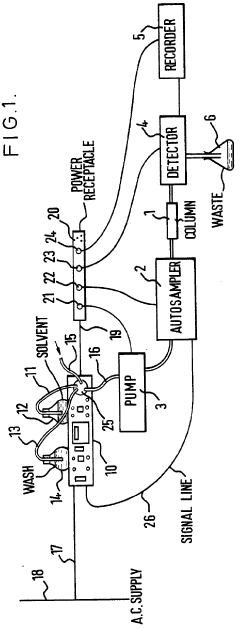

High performance liquid chromatography apparatus and method for screening substance using thereof

PatentActiveKR1020160133873A

Innovation

- A high-performance liquid chromatography (HPLC) apparatus and method that includes a first column for separating target materials, a second column for further separation, an analyzer for analysis, and a dissociation device to bypass complex sample preparation, enabling direct analysis of target substances.

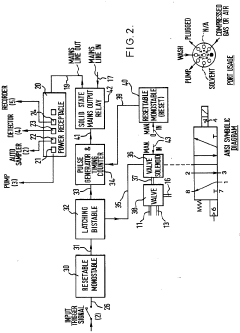

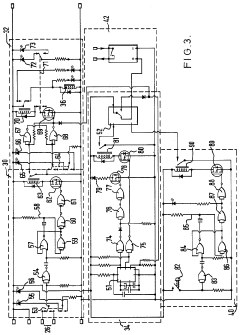

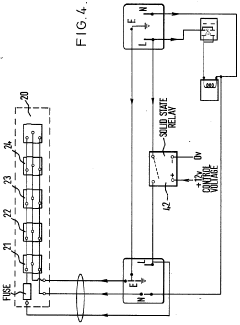

Improvements in or relating to high performance liquid chromatography systems

PatentInactiveGB2174016A

Innovation

- An ancillary apparatus that includes a valve system for selecting between mobile phase and wash liquid sources, a timing mechanism initiated by a trigger pulse from the HPLC system, and an electric switch to disconnect power to the HPLC system units after a predetermined wash liquid supply, ensuring a controlled shutdown and washout process.

Environmental Impact Assessment of HPLC Practices

High-performance liquid chromatography (HPLC) is widely used in analytical chemistry, pharmaceutical development, and various industrial processes. However, traditional HPLC practices have significant environmental impacts that warrant careful assessment. Conventional HPLC methods typically consume large volumes of organic solvents, generate substantial hazardous waste, and require considerable energy for operation.

The primary environmental concern with HPLC is solvent usage. A standard analytical HPLC system can consume between 500-1000 mL of solvent per day, with most being toxic organic compounds such as acetonitrile, methanol, and tetrahydrofuran. These solvents contribute to air pollution through volatile organic compound (VOC) emissions and pose risks to aquatic ecosystems when improperly disposed. Studies indicate that HPLC operations in a typical pharmaceutical laboratory can generate 4-10 liters of waste solvent weekly.

Energy consumption represents another significant environmental impact. HPLC systems require continuous power for pumps, detectors, and temperature control systems. A standard HPLC setup consumes approximately 1-2 kWh during continuous operation, contributing to carbon emissions. When scaled to industry-wide usage, this represents substantial energy demand and associated greenhouse gas emissions.

Waste management challenges extend beyond solvents to include used columns, filters, and sample vials. These materials often contain residual chemicals that classify them as hazardous waste requiring specialized disposal procedures. The environmental footprint is further expanded by considering the manufacturing impacts of HPLC equipment and consumables, including resource extraction, production processes, and transportation.

Water usage in HPLC operations also presents environmental concerns. Beyond direct use in mobile phases, significant water volumes are consumed in instrument cleaning, sample preparation, and cooling systems. This water often becomes contaminated with trace amounts of analytes and solvents, requiring treatment before discharge.

Quantitative life cycle assessments reveal that a single HPLC analysis can have a carbon footprint equivalent to driving 10-15 kilometers in a standard passenger vehicle. The cumulative impact across research institutions, quality control laboratories, and manufacturing facilities worldwide is substantial, with the analytical chemistry sector estimated to contribute approximately 0.5% of global laboratory-based carbon emissions.

Understanding these environmental impacts provides the foundation for developing and implementing greener HPLC techniques that reduce waste generation while maintaining analytical performance and reliability.

The primary environmental concern with HPLC is solvent usage. A standard analytical HPLC system can consume between 500-1000 mL of solvent per day, with most being toxic organic compounds such as acetonitrile, methanol, and tetrahydrofuran. These solvents contribute to air pollution through volatile organic compound (VOC) emissions and pose risks to aquatic ecosystems when improperly disposed. Studies indicate that HPLC operations in a typical pharmaceutical laboratory can generate 4-10 liters of waste solvent weekly.

Energy consumption represents another significant environmental impact. HPLC systems require continuous power for pumps, detectors, and temperature control systems. A standard HPLC setup consumes approximately 1-2 kWh during continuous operation, contributing to carbon emissions. When scaled to industry-wide usage, this represents substantial energy demand and associated greenhouse gas emissions.

Waste management challenges extend beyond solvents to include used columns, filters, and sample vials. These materials often contain residual chemicals that classify them as hazardous waste requiring specialized disposal procedures. The environmental footprint is further expanded by considering the manufacturing impacts of HPLC equipment and consumables, including resource extraction, production processes, and transportation.

Water usage in HPLC operations also presents environmental concerns. Beyond direct use in mobile phases, significant water volumes are consumed in instrument cleaning, sample preparation, and cooling systems. This water often becomes contaminated with trace amounts of analytes and solvents, requiring treatment before discharge.

Quantitative life cycle assessments reveal that a single HPLC analysis can have a carbon footprint equivalent to driving 10-15 kilometers in a standard passenger vehicle. The cumulative impact across research institutions, quality control laboratories, and manufacturing facilities worldwide is substantial, with the analytical chemistry sector estimated to contribute approximately 0.5% of global laboratory-based carbon emissions.

Understanding these environmental impacts provides the foundation for developing and implementing greener HPLC techniques that reduce waste generation while maintaining analytical performance and reliability.

Cost-Benefit Analysis of Green HPLC Implementation

Implementing green HPLC techniques requires significant initial investment but offers substantial long-term economic benefits. The upfront costs include purchasing new equipment or retrofitting existing systems with green technology components, which typically ranges from $15,000 to $50,000 depending on laboratory size and requirements. Additionally, staff training on new methodologies and protocols may cost between $2,000 and $5,000 per laboratory.

Despite these initial expenditures, the return on investment typically materializes within 18-36 months through multiple cost reduction channels. Solvent consumption decreases by 60-90% with green HPLC techniques, translating to annual savings of $3,000-$10,000 for medium-sized laboratories. Waste disposal costs, which average $15-$25 per liter for hazardous HPLC waste, can be reduced by 70-85%, resulting in additional savings of $4,000-$12,000 annually.

Energy efficiency improvements contribute further to cost reduction, with green HPLC systems consuming 30-50% less electricity than conventional systems. This represents savings of approximately $1,000-$3,000 annually in utility costs. Maintenance requirements also decrease with green systems, as they typically operate at lower pressures and with less aggressive solvents, extending equipment lifespan by 20-30% and reducing annual maintenance costs by $1,500-$4,000.

Regulatory compliance represents another significant economic factor. As environmental regulations become increasingly stringent, laboratories implementing green HPLC techniques position themselves advantageously, avoiding potential non-compliance penalties that can range from $10,000 to $100,000 depending on violation severity and jurisdiction. Furthermore, green laboratories often qualify for tax incentives and sustainability grants, potentially offsetting 15-30% of implementation costs.

Productivity gains must also be factored into the cost-benefit analysis. Green HPLC methods typically feature shorter analysis times and reduced system equilibration periods, increasing sample throughput by 15-25%. For commercial laboratories, this translates to higher revenue potential without proportional increases in operating costs. Additionally, the improved working environment with reduced exposure to hazardous solvents leads to decreased absenteeism and higher staff retention rates, indirectly contributing to operational efficiency.

When evaluating total cost of ownership over a five-year period, green HPLC implementations demonstrate 20-40% lower costs compared to conventional systems, making them increasingly attractive investments for forward-thinking laboratories seeking both environmental and economic sustainability.

Despite these initial expenditures, the return on investment typically materializes within 18-36 months through multiple cost reduction channels. Solvent consumption decreases by 60-90% with green HPLC techniques, translating to annual savings of $3,000-$10,000 for medium-sized laboratories. Waste disposal costs, which average $15-$25 per liter for hazardous HPLC waste, can be reduced by 70-85%, resulting in additional savings of $4,000-$12,000 annually.

Energy efficiency improvements contribute further to cost reduction, with green HPLC systems consuming 30-50% less electricity than conventional systems. This represents savings of approximately $1,000-$3,000 annually in utility costs. Maintenance requirements also decrease with green systems, as they typically operate at lower pressures and with less aggressive solvents, extending equipment lifespan by 20-30% and reducing annual maintenance costs by $1,500-$4,000.

Regulatory compliance represents another significant economic factor. As environmental regulations become increasingly stringent, laboratories implementing green HPLC techniques position themselves advantageously, avoiding potential non-compliance penalties that can range from $10,000 to $100,000 depending on violation severity and jurisdiction. Furthermore, green laboratories often qualify for tax incentives and sustainability grants, potentially offsetting 15-30% of implementation costs.

Productivity gains must also be factored into the cost-benefit analysis. Green HPLC methods typically feature shorter analysis times and reduced system equilibration periods, increasing sample throughput by 15-25%. For commercial laboratories, this translates to higher revenue potential without proportional increases in operating costs. Additionally, the improved working environment with reduced exposure to hazardous solvents leads to decreased absenteeism and higher staff retention rates, indirectly contributing to operational efficiency.

When evaluating total cost of ownership over a five-year period, green HPLC implementations demonstrate 20-40% lower costs compared to conventional systems, making them increasingly attractive investments for forward-thinking laboratories seeking both environmental and economic sustainability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!