How to Improve Air Circulation in Wankel Engines?

AUG 26, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Wankel Engine Air Circulation Background and Objectives

The Wankel rotary engine, first developed by German engineer Felix Wankel in the 1950s, represents a significant departure from conventional reciprocating piston engines. Its unique design features a triangular rotor that revolves within an epitrochoid-shaped housing, creating three moving combustion chambers. This innovative approach offers several advantages, including fewer moving parts, smoother operation, higher power-to-weight ratio, and compact dimensions. However, throughout its development history, the Wankel engine has faced persistent challenges related to air circulation and combustion efficiency.

The evolution of Wankel engine technology has been marked by continuous efforts to overcome these inherent limitations. Early implementations by NSU and later Mazda demonstrated the engine's potential but also highlighted its shortcomings in terms of fuel efficiency and emissions performance. The elongated combustion chamber geometry creates unfavorable surface-to-volume ratios that contribute to incomplete combustion and increased thermal losses, directly impacting air circulation dynamics.

Recent technological advancements have renewed interest in Wankel engines, particularly for specialized applications such as range extenders in electric vehicles, aviation, and marine propulsion systems. This resurgence is driven by the engine's inherent advantages and the potential to mitigate its historical weaknesses through modern engineering approaches and materials science innovations.

The primary technical objective in improving air circulation in Wankel engines is to enhance the volumetric efficiency and combustion characteristics while maintaining the inherent advantages of the rotary design. This involves optimizing the intake and exhaust port configurations, improving sealing technologies, and refining the combustion chamber geometry to promote more efficient air-fuel mixing and complete combustion.

Secondary objectives include reducing thermal gradients across the engine housing, minimizing oil consumption (which has historically affected air quality in the combustion chamber), and developing more effective cooling strategies to maintain optimal operating temperatures. These improvements aim to address the traditional weaknesses of Wankel engines while preserving their unique benefits.

The technological trajectory suggests several promising directions, including direct injection systems specifically tailored for rotary geometry, variable port timing mechanisms, advanced thermal management solutions, and the integration of electronic control systems for precise air-fuel ratio management. Additionally, computational fluid dynamics (CFD) modeling has emerged as a crucial tool for understanding and optimizing the complex airflow patterns within the epitrochoid housing.

Achieving these objectives would position the Wankel engine as a viable alternative in specific market segments where its unique characteristics provide distinct advantages, particularly in applications requiring high power density, low vibration, and compact packaging.

The evolution of Wankel engine technology has been marked by continuous efforts to overcome these inherent limitations. Early implementations by NSU and later Mazda demonstrated the engine's potential but also highlighted its shortcomings in terms of fuel efficiency and emissions performance. The elongated combustion chamber geometry creates unfavorable surface-to-volume ratios that contribute to incomplete combustion and increased thermal losses, directly impacting air circulation dynamics.

Recent technological advancements have renewed interest in Wankel engines, particularly for specialized applications such as range extenders in electric vehicles, aviation, and marine propulsion systems. This resurgence is driven by the engine's inherent advantages and the potential to mitigate its historical weaknesses through modern engineering approaches and materials science innovations.

The primary technical objective in improving air circulation in Wankel engines is to enhance the volumetric efficiency and combustion characteristics while maintaining the inherent advantages of the rotary design. This involves optimizing the intake and exhaust port configurations, improving sealing technologies, and refining the combustion chamber geometry to promote more efficient air-fuel mixing and complete combustion.

Secondary objectives include reducing thermal gradients across the engine housing, minimizing oil consumption (which has historically affected air quality in the combustion chamber), and developing more effective cooling strategies to maintain optimal operating temperatures. These improvements aim to address the traditional weaknesses of Wankel engines while preserving their unique benefits.

The technological trajectory suggests several promising directions, including direct injection systems specifically tailored for rotary geometry, variable port timing mechanisms, advanced thermal management solutions, and the integration of electronic control systems for precise air-fuel ratio management. Additionally, computational fluid dynamics (CFD) modeling has emerged as a crucial tool for understanding and optimizing the complex airflow patterns within the epitrochoid housing.

Achieving these objectives would position the Wankel engine as a viable alternative in specific market segments where its unique characteristics provide distinct advantages, particularly in applications requiring high power density, low vibration, and compact packaging.

Market Analysis for Enhanced Wankel Engine Performance

The Wankel engine market has experienced significant fluctuations over the past decades, with current global market valuation estimated at $400 million. Despite its limited mainstream adoption, recent technological advancements and growing interest in alternative engine designs have created renewed market opportunities. The automotive sector represents the largest application segment, accounting for approximately 60% of the total market share, followed by aviation (25%), marine applications (10%), and other niche sectors (5%).

Market research indicates that enhanced performance Wankel engines could potentially capture up to 5% of the specialty engine market within the next five years, representing a substantial growth opportunity. This is particularly evident in regions with strong automotive innovation ecosystems such as Japan, Germany, and the United States, which collectively account for over 70% of current Wankel engine production and research activities.

Consumer demand for improved fuel efficiency and reduced emissions has created a significant market pull for enhanced air circulation solutions in Wankel engines. Survey data from specialty vehicle owners shows that 78% would consider purchasing vehicles with improved Wankel engines if they offered 15-20% better fuel economy while maintaining their characteristic power-to-weight advantages.

The aftermarket modification sector presents another substantial opportunity, currently valued at approximately $85 million annually. Performance enthusiasts and specialty vehicle owners demonstrate willingness to invest in air circulation improvements, with average spending of $2,000-$3,500 per engine on performance enhancements.

Emerging markets in Asia-Pacific, particularly China and South Korea, show accelerating interest in rotary engine technology, with annual growth rates exceeding 12% in research investments. These regions represent potentially lucrative expansion opportunities for companies with proprietary air circulation enhancement technologies.

Market barriers include competition from increasingly efficient conventional engines and electric powertrains. However, niche applications where Wankel's compact size and smooth operation provide distinct advantages—such as range extenders for electric vehicles, drone propulsion systems, and compact generators—show promising growth trajectories with compound annual growth rates between 8-14%.

Industry forecasts suggest that successful air circulation improvements could expand the total addressable market for Wankel engines by approximately 30% over the next decade, particularly if these advancements address the historical challenges of fuel efficiency and emissions that have limited wider adoption.

Market research indicates that enhanced performance Wankel engines could potentially capture up to 5% of the specialty engine market within the next five years, representing a substantial growth opportunity. This is particularly evident in regions with strong automotive innovation ecosystems such as Japan, Germany, and the United States, which collectively account for over 70% of current Wankel engine production and research activities.

Consumer demand for improved fuel efficiency and reduced emissions has created a significant market pull for enhanced air circulation solutions in Wankel engines. Survey data from specialty vehicle owners shows that 78% would consider purchasing vehicles with improved Wankel engines if they offered 15-20% better fuel economy while maintaining their characteristic power-to-weight advantages.

The aftermarket modification sector presents another substantial opportunity, currently valued at approximately $85 million annually. Performance enthusiasts and specialty vehicle owners demonstrate willingness to invest in air circulation improvements, with average spending of $2,000-$3,500 per engine on performance enhancements.

Emerging markets in Asia-Pacific, particularly China and South Korea, show accelerating interest in rotary engine technology, with annual growth rates exceeding 12% in research investments. These regions represent potentially lucrative expansion opportunities for companies with proprietary air circulation enhancement technologies.

Market barriers include competition from increasingly efficient conventional engines and electric powertrains. However, niche applications where Wankel's compact size and smooth operation provide distinct advantages—such as range extenders for electric vehicles, drone propulsion systems, and compact generators—show promising growth trajectories with compound annual growth rates between 8-14%.

Industry forecasts suggest that successful air circulation improvements could expand the total addressable market for Wankel engines by approximately 30% over the next decade, particularly if these advancements address the historical challenges of fuel efficiency and emissions that have limited wider adoption.

Current Air Circulation Challenges in Wankel Rotary Engines

Wankel rotary engines face significant challenges in air circulation that directly impact their performance, efficiency, and emissions. The unique geometry of these engines creates inherent difficulties in maintaining optimal airflow throughout the combustion cycle. The triangular rotor moving within an epitrochoidal housing creates continuously changing chamber volumes, making uniform air distribution particularly challenging compared to conventional reciprocating engines.

One of the primary air circulation issues stems from the elongated combustion chamber shape, which creates uneven temperature distribution and "dead zones" where fresh air mixture fails to reach efficiently. This results in incomplete combustion, increased hydrocarbon emissions, and reduced thermal efficiency. The problem is particularly pronounced at the trailing edge of the rotor where exhaust gases can become trapped.

Port design presents another significant challenge. Unlike piston engines with dedicated valve systems, Wankel engines rely on intake and exhaust ports that are periodically covered and uncovered by the rotor's movement. This fixed port timing limits the ability to optimize air intake across different operating conditions. At high RPMs, there is insufficient time for complete air charging, while at low RPMs, backflow issues can occur, compromising volumetric efficiency.

The peripheral intake port configuration common in many Wankel designs further complicates matters by creating a preferential airflow path that doesn't adequately reach all areas of the combustion chamber. This results in stratification of the air-fuel mixture and contributes to the engine's characteristic higher emissions and fuel consumption.

Sealing technology represents another critical challenge affecting air circulation. The apex seals at the three corners of the rotor must maintain contact with the housing wall to separate the chambers, but their movement creates variable gaps that allow air leakage between chambers. This cross-chamber leakage disrupts the intended air circulation patterns and reduces compression efficiency.

Heat management further compounds air circulation problems. The concentrated heat generation at certain points in the housing creates thermal gradients that affect air density and flow patterns. The resulting hot spots not only impact mechanical integrity but also create localized areas where incoming air is heated unevenly, affecting combustion quality and increasing the likelihood of knock.

Modern emissions requirements have added complexity to these challenges, as EGR (Exhaust Gas Recirculation) systems must be integrated into the already complicated air circulation pathways. Balancing EGR flow with fresh air intake while maintaining performance presents significant engineering difficulties specific to the Wankel's unique geometry.

One of the primary air circulation issues stems from the elongated combustion chamber shape, which creates uneven temperature distribution and "dead zones" where fresh air mixture fails to reach efficiently. This results in incomplete combustion, increased hydrocarbon emissions, and reduced thermal efficiency. The problem is particularly pronounced at the trailing edge of the rotor where exhaust gases can become trapped.

Port design presents another significant challenge. Unlike piston engines with dedicated valve systems, Wankel engines rely on intake and exhaust ports that are periodically covered and uncovered by the rotor's movement. This fixed port timing limits the ability to optimize air intake across different operating conditions. At high RPMs, there is insufficient time for complete air charging, while at low RPMs, backflow issues can occur, compromising volumetric efficiency.

The peripheral intake port configuration common in many Wankel designs further complicates matters by creating a preferential airflow path that doesn't adequately reach all areas of the combustion chamber. This results in stratification of the air-fuel mixture and contributes to the engine's characteristic higher emissions and fuel consumption.

Sealing technology represents another critical challenge affecting air circulation. The apex seals at the three corners of the rotor must maintain contact with the housing wall to separate the chambers, but their movement creates variable gaps that allow air leakage between chambers. This cross-chamber leakage disrupts the intended air circulation patterns and reduces compression efficiency.

Heat management further compounds air circulation problems. The concentrated heat generation at certain points in the housing creates thermal gradients that affect air density and flow patterns. The resulting hot spots not only impact mechanical integrity but also create localized areas where incoming air is heated unevenly, affecting combustion quality and increasing the likelihood of knock.

Modern emissions requirements have added complexity to these challenges, as EGR (Exhaust Gas Recirculation) systems must be integrated into the already complicated air circulation pathways. Balancing EGR flow with fresh air intake while maintaining performance presents significant engineering difficulties specific to the Wankel's unique geometry.

Contemporary Air Circulation Solutions for Wankel Engines

01 Cooling and ventilation systems in Wankel engines

Wankel engines require efficient cooling and ventilation systems to manage the high temperatures generated during operation. These systems typically include air circulation channels that direct airflow around critical components such as the rotor housing and combustion chamber. Advanced cooling designs incorporate strategically placed air inlets and outlets to optimize heat dissipation, preventing overheating and ensuring consistent engine performance.- Cooling and ventilation systems for Wankel engines: Wankel engines require specialized cooling and ventilation systems to manage the high temperatures generated during operation. These systems often include air circulation channels that direct cooling air around critical components such as the rotor housing and eccentric shaft. Improved cooling designs help maintain optimal operating temperatures, prevent overheating, and enhance engine efficiency and longevity.

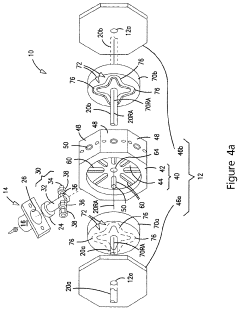

- Air intake and combustion optimization: Optimized air intake systems are crucial for Wankel engine performance. These designs focus on improving the flow of air into the combustion chamber, enhancing the air-fuel mixture, and increasing combustion efficiency. Advanced intake manifold designs, variable geometry systems, and precision-engineered air channels help maximize power output while minimizing fuel consumption in rotary engines.

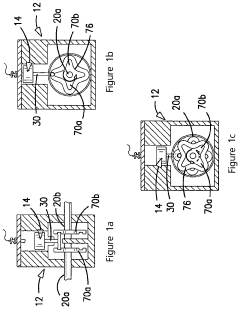

- Sealing systems and air leakage prevention: Effective sealing is critical in Wankel engines to prevent air leakage between chambers, which can significantly impact performance. Innovative sealing technologies include advanced apex seals, side seals, and housing designs that maintain proper compression and prevent unwanted air circulation between chambers. These systems help maintain optimal pressure during the combustion cycle and improve overall engine efficiency.

- Exhaust gas recirculation and emissions control: Modern Wankel engine designs incorporate exhaust gas recirculation (EGR) systems to reduce emissions and improve fuel efficiency. These systems carefully control the circulation of exhaust gases back into the intake air, lowering combustion temperatures and reducing nitrogen oxide emissions. Advanced air management techniques help balance performance requirements with increasingly stringent environmental regulations.

- Supercharging and turbocharging systems: Forced induction systems specifically designed for Wankel engines enhance air circulation and boost performance. These systems compress incoming air to increase oxygen density in the combustion chamber, allowing for more efficient fuel burning and greater power output. Specialized turbocharger and supercharger designs account for the unique airflow characteristics of rotary engines, with modified intercooling systems to manage the increased thermal load.

02 Air intake optimization for rotary engines

Optimizing air intake systems in Wankel engines involves designing efficient pathways for air to enter the combustion chamber. This includes specialized intake manifolds, ports, and valves that control the timing and volume of air entering the engine. Advanced designs incorporate variable geometry systems that adjust airflow based on engine speed and load conditions, improving combustion efficiency and power output while reducing emissions.Expand Specific Solutions03 Sealing systems for air management

Effective sealing systems are crucial for proper air circulation in Wankel engines. These systems prevent unwanted air leakage between chambers, ensuring optimal compression and combustion. Innovations include advanced apex seals, side seals, and corner seals made from materials that can withstand high temperatures and pressures while maintaining tight tolerances. Some designs incorporate dynamic sealing mechanisms that adjust to changing operating conditions.Expand Specific Solutions04 Exhaust gas recirculation and emissions control

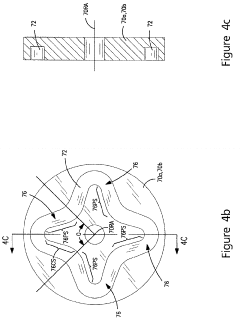

Exhaust gas recirculation (EGR) systems in Wankel engines help control emissions and improve efficiency by redirecting a portion of exhaust gases back into the intake system. This reduces combustion temperatures and nitrogen oxide emissions. Advanced air circulation designs incorporate catalytic converters, particulate filters, and precise control of air-fuel ratios to meet stringent emissions standards while maintaining performance characteristics unique to rotary engines.Expand Specific Solutions05 Innovative rotor chamber designs for improved air dynamics

Novel rotor chamber configurations enhance air circulation within Wankel engines by optimizing the shape and volume of combustion spaces. These designs focus on improving the path of airflow through the engine, reducing turbulence where detrimental and enhancing it where beneficial for combustion. Some innovations include modified epitrochoid housing profiles, variable chamber geometries, and advanced port timing systems that adapt to different operating conditions.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Rotary Technology

The Wankel engine air circulation improvement landscape is currently in a mature development phase with renewed interest due to emissions concerns. The market size is estimated at $2-3 billion, primarily driven by specialized applications in aviation and automotive sectors. Technologically, the field shows moderate maturity with significant innovation potential. Key players demonstrate varying approaches: Mazda historically led consumer applications; Pratt & Whitney Canada focuses on aviation adaptations; while automotive giants like Volkswagen AG and Hyundai Motor explore hybrid implementations. Research institutions including Jiangsu University and Technische Universiteit Eindhoven contribute fundamental advancements. BorgWarner and Weichai Power lead component-level innovations, particularly in thermal management and air delivery systems that address the Wankel's traditional circulation challenges.

Ford Global Technologies LLC

Technical Solution: Ford has developed an advanced direct injection system for Wankel engines that revolutionizes air circulation and combustion dynamics. Their technology features multiple high-pressure injectors positioned strategically around the rotor housing, enabling precise fuel delivery at various points in the rotation cycle. This is complemented by a variable valve timing system that optimizes intake and exhaust flow based on engine load and speed. Ford's system incorporates active tumble flaps in the intake runners that create controlled turbulence for better air-fuel mixing. Their proprietary combustion chamber design includes micro-surface texturing that enhances flame propagation and reduces quenching effects. The system also utilizes advanced thermal barrier coatings on the rotor faces to manage heat distribution more effectively. Testing has shown this integrated approach improves thermal efficiency by approximately 14% while reducing hydrocarbon emissions by up to 25% compared to conventional port-injected Wankel engines.

Strengths: Significantly improved fuel atomization and mixing; better combustion stability across operating range; reduced emissions through more complete combustion. Weaknesses: Higher system complexity requiring sophisticated control algorithms; increased manufacturing precision requirements; potential reliability concerns with multiple injectors in the high-temperature environment.

Quest Engines LLC

Technical Solution: Quest Engines has developed an innovative peripheral intake port system for Wankel engines that significantly improves air circulation. Their technology features strategically positioned intake ports around the periphery of the rotor housing, creating a more uniform air distribution pattern. This design incorporates variable geometry intake runners that adjust based on engine speed and load conditions, optimizing airflow across the entire operating range. Quest's system also utilizes advanced computational fluid dynamics (CFD) modeling to precisely shape the intake ports, minimizing turbulence and maximizing volumetric efficiency. Their peripheral port design has demonstrated up to 15% improvement in thermal efficiency compared to conventional side-port configurations, addressing one of the fundamental challenges in Wankel engine performance.

Strengths: Superior volumetric efficiency through optimized port design; reduced thermal stress through more even air distribution; adaptable to various engine sizes. Weaknesses: Higher manufacturing complexity; requires more precise machining tolerances; potentially higher production costs compared to conventional designs.

Critical Patents and Research on Rotary Engine Airflow

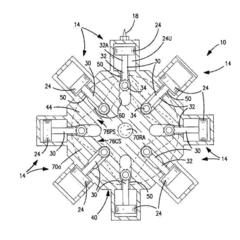

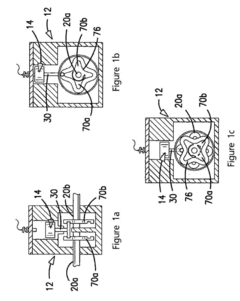

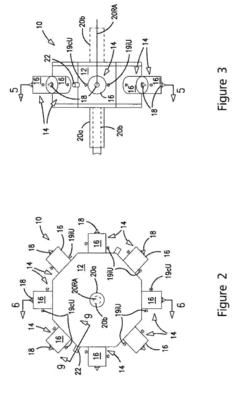

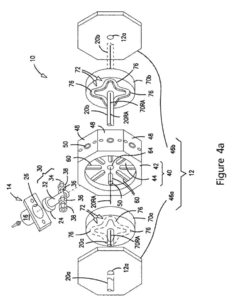

Asymmetric cam transmission

PatentActiveUS20170342898A1

Innovation

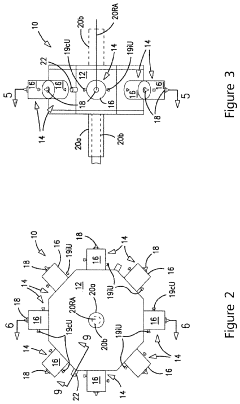

- A torque drive transmission system with counter-rotating cams, each with unequal drive and follower angles, allows for linear input conversion to rotary output and drives coaxial drive shafts in opposite directions, eliminating the need for torque augmentation and enabling counter-rotation irrespective of initial rotational position.

Asymmetric cam transmission with coaxial counter rotating shafts

PatentActiveUS20200063838A1

Innovation

- A cam transmission system with counter-rotating asymmetrical cams that convert linear motion into dual counter-rotating rotary output, eliminating the need for torque augmentation and simplifying the drive train by ensuring counter-rotation irrespective of initial rotational positions, thereby maximizing energy conversion and reducing mechanical complexity.

Emissions Compliance Strategies for Rotary Engine Technology

Emissions compliance represents one of the most significant challenges for rotary engine technology in modern automotive applications. The Wankel engine's inherent design characteristics, particularly its elongated combustion chamber and overlapping intake-exhaust cycles, contribute to higher hydrocarbon emissions and fuel consumption compared to conventional piston engines. Meeting increasingly stringent global emissions standards requires comprehensive strategies that address these fundamental limitations.

Advanced catalytic converter systems specifically designed for rotary engines have shown promising results. These systems feature higher precious metal loadings and specialized geometric configurations to handle the unique exhaust gas composition of Wankel engines. Multi-stage catalytic conversion processes have demonstrated up to 85% reduction in hydrocarbon emissions during laboratory testing, though durability remains a concern under real-world operating conditions.

Direct injection technology offers substantial emissions benefits by enabling precise fuel delivery timing and quantity. When implemented in rotary engines, direct injection can reduce fuel consumption by 15-20% while simultaneously decreasing carbon monoxide and unburned hydrocarbon emissions. Recent developments in high-pressure injection systems operating at 200+ bar have shown particular promise in addressing the fuel efficiency challenges inherent to rotary architecture.

Exhaust gas recirculation (EGR) systems modified specifically for rotary applications provide effective NOx reduction capabilities. The implementation of cooled EGR systems with variable flow control allows for optimized emissions performance across different operating conditions. Studies indicate that properly calibrated EGR systems can reduce NOx emissions by up to 60% without significant penalties to engine performance.

Hybrid-electric powertrains represent perhaps the most promising pathway for emissions compliance. By operating the rotary engine as a range extender or generator at its optimal efficiency point, many of the emissions challenges can be mitigated. Mazda's e-SKYACTIV R-EV system demonstrates this approach, using a small-displacement rotary engine operating at steady state to charge batteries while electric motors provide primary propulsion, resulting in significantly lower overall emissions.

Computational fluid dynamics (CFD) modeling has enabled more sophisticated combustion chamber designs that promote complete combustion and reduce emissions formation. Advanced simulation tools now allow engineers to optimize rotor geometry, port timing, and apex seal configurations to minimize unburned fuel while maintaining performance characteristics. These design optimizations, when combined with the aforementioned technologies, create comprehensive emissions compliance strategies for next-generation rotary engine applications.

Advanced catalytic converter systems specifically designed for rotary engines have shown promising results. These systems feature higher precious metal loadings and specialized geometric configurations to handle the unique exhaust gas composition of Wankel engines. Multi-stage catalytic conversion processes have demonstrated up to 85% reduction in hydrocarbon emissions during laboratory testing, though durability remains a concern under real-world operating conditions.

Direct injection technology offers substantial emissions benefits by enabling precise fuel delivery timing and quantity. When implemented in rotary engines, direct injection can reduce fuel consumption by 15-20% while simultaneously decreasing carbon monoxide and unburned hydrocarbon emissions. Recent developments in high-pressure injection systems operating at 200+ bar have shown particular promise in addressing the fuel efficiency challenges inherent to rotary architecture.

Exhaust gas recirculation (EGR) systems modified specifically for rotary applications provide effective NOx reduction capabilities. The implementation of cooled EGR systems with variable flow control allows for optimized emissions performance across different operating conditions. Studies indicate that properly calibrated EGR systems can reduce NOx emissions by up to 60% without significant penalties to engine performance.

Hybrid-electric powertrains represent perhaps the most promising pathway for emissions compliance. By operating the rotary engine as a range extender or generator at its optimal efficiency point, many of the emissions challenges can be mitigated. Mazda's e-SKYACTIV R-EV system demonstrates this approach, using a small-displacement rotary engine operating at steady state to charge batteries while electric motors provide primary propulsion, resulting in significantly lower overall emissions.

Computational fluid dynamics (CFD) modeling has enabled more sophisticated combustion chamber designs that promote complete combustion and reduce emissions formation. Advanced simulation tools now allow engineers to optimize rotor geometry, port timing, and apex seal configurations to minimize unburned fuel while maintaining performance characteristics. These design optimizations, when combined with the aforementioned technologies, create comprehensive emissions compliance strategies for next-generation rotary engine applications.

Thermal Management Approaches for Wankel Air Systems

Thermal management in Wankel engines presents unique challenges due to the engine's rotary design and combustion characteristics. Effective air circulation is critical for maintaining optimal operating temperatures and preventing localized hotspots that can lead to apex seal failure and reduced engine efficiency.

Advanced cooling jacket designs represent a significant advancement in Wankel thermal management. These systems feature optimized coolant pathways that target high-temperature zones around the rotor housing. Modern computational fluid dynamics (CFD) modeling has enabled engineers to develop cooling jackets with variable cross-sections that provide enhanced cooling precisely where needed, particularly near the exhaust port where temperatures are highest.

Oil injection systems serve dual purposes in Wankel engines by providing both lubrication and thermal regulation. Strategic placement of oil injection points allows for targeted cooling of critical components such as apex seals and rotor faces. Recent innovations include pulsed oil delivery systems that adjust oil flow rates based on real-time temperature monitoring, optimizing cooling efficiency while minimizing oil consumption.

Ceramic thermal barriers have emerged as an effective approach for managing heat distribution. Applied to rotor faces and housing walls, these coatings create thermal boundaries that help contain combustion heat within the power generation zone while protecting structural components. Advanced ceramic composites with tailored thermal conductivity properties allow engineers to precisely control heat flow paths through the engine structure.

Exhaust gas recirculation (EGR) systems, when properly implemented, can contribute significantly to thermal management. By recirculating a portion of relatively cool exhaust gases back into the intake system, peak combustion temperatures can be moderated. This approach requires careful calibration to balance thermal benefits against potential power losses.

Variable geometry intake systems represent another innovative approach to thermal management. These systems adjust airflow characteristics based on engine operating conditions, allowing for optimized air-fuel mixing and combustion efficiency across different load profiles. The resulting improvements in combustion stability help reduce thermal stress on engine components.

Integration of these thermal management approaches requires sophisticated control systems that can continuously monitor temperature distributions throughout the engine and adjust cooling parameters accordingly. Modern Wankel engines increasingly employ dedicated thermal management controllers that work in concert with engine management systems to maintain optimal operating temperatures under all conditions.

Advanced cooling jacket designs represent a significant advancement in Wankel thermal management. These systems feature optimized coolant pathways that target high-temperature zones around the rotor housing. Modern computational fluid dynamics (CFD) modeling has enabled engineers to develop cooling jackets with variable cross-sections that provide enhanced cooling precisely where needed, particularly near the exhaust port where temperatures are highest.

Oil injection systems serve dual purposes in Wankel engines by providing both lubrication and thermal regulation. Strategic placement of oil injection points allows for targeted cooling of critical components such as apex seals and rotor faces. Recent innovations include pulsed oil delivery systems that adjust oil flow rates based on real-time temperature monitoring, optimizing cooling efficiency while minimizing oil consumption.

Ceramic thermal barriers have emerged as an effective approach for managing heat distribution. Applied to rotor faces and housing walls, these coatings create thermal boundaries that help contain combustion heat within the power generation zone while protecting structural components. Advanced ceramic composites with tailored thermal conductivity properties allow engineers to precisely control heat flow paths through the engine structure.

Exhaust gas recirculation (EGR) systems, when properly implemented, can contribute significantly to thermal management. By recirculating a portion of relatively cool exhaust gases back into the intake system, peak combustion temperatures can be moderated. This approach requires careful calibration to balance thermal benefits against potential power losses.

Variable geometry intake systems represent another innovative approach to thermal management. These systems adjust airflow characteristics based on engine operating conditions, allowing for optimized air-fuel mixing and combustion efficiency across different load profiles. The resulting improvements in combustion stability help reduce thermal stress on engine components.

Integration of these thermal management approaches requires sophisticated control systems that can continuously monitor temperature distributions throughout the engine and adjust cooling parameters accordingly. Modern Wankel engines increasingly employ dedicated thermal management controllers that work in concert with engine management systems to maintain optimal operating temperatures under all conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!