How to Improve Solid-State Relay Reliability Under Load

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SSR Reliability Background and Objectives

Solid-state relays (SSRs) have evolved significantly since their introduction in the 1970s as alternatives to electromechanical relays. These semiconductor-based switching devices have transformed industrial control systems by offering silent operation, absence of moving parts, and compatibility with digital control systems. The technological trajectory of SSRs has been marked by continuous improvements in semiconductor materials, packaging techniques, and thermal management solutions, all aimed at enhancing reliability under various load conditions.

The reliability of SSRs under load conditions represents a critical concern for industries where unplanned downtime can result in substantial financial losses and safety risks. Historical data indicates that SSR failures account for approximately 15-20% of control system malfunctions in industrial environments, with load-related stress being the primary contributing factor in over 60% of these failures.

Current SSR technology faces significant challenges when operating under demanding load conditions, particularly with inductive and capacitive loads that generate voltage spikes and current surges. These transient electrical phenomena can degrade semiconductor junctions over time, leading to premature device failure. Additionally, thermal stress resulting from switching high currents remains a persistent challenge, with junction temperature management being a critical factor in determining operational lifespan.

The primary objective of improving SSR reliability under load is to develop robust solutions that can withstand electrical and thermal stresses while maintaining consistent performance over extended operational periods. Specifically, this involves achieving a mean time between failures (MTBF) exceeding 100,000 hours under full-load conditions, which represents a significant improvement over current industry standards of 50,000-70,000 hours.

Secondary objectives include reducing thermal sensitivity to enable operation in more extreme ambient temperature environments (-40°C to +125°C), enhancing immunity to voltage transients without requiring external suppression components, and developing advanced self-diagnostic capabilities to predict potential failures before they occur.

Recent advancements in wide-bandgap semiconductor materials such as silicon carbide (SiC) and gallium nitride (GaN) present promising opportunities for addressing these reliability challenges. These materials offer superior thermal conductivity, higher breakdown voltages, and faster switching capabilities compared to traditional silicon-based devices, potentially enabling SSRs to handle more demanding load conditions with improved reliability margins.

The technological evolution in this field is increasingly focused on integrated approaches that combine advanced semiconductor technologies with sophisticated thermal management systems and intelligent control algorithms. This holistic approach aims to create next-generation SSRs capable of adapting to varying load conditions while maintaining optimal performance parameters throughout their operational lifetime.

The reliability of SSRs under load conditions represents a critical concern for industries where unplanned downtime can result in substantial financial losses and safety risks. Historical data indicates that SSR failures account for approximately 15-20% of control system malfunctions in industrial environments, with load-related stress being the primary contributing factor in over 60% of these failures.

Current SSR technology faces significant challenges when operating under demanding load conditions, particularly with inductive and capacitive loads that generate voltage spikes and current surges. These transient electrical phenomena can degrade semiconductor junctions over time, leading to premature device failure. Additionally, thermal stress resulting from switching high currents remains a persistent challenge, with junction temperature management being a critical factor in determining operational lifespan.

The primary objective of improving SSR reliability under load is to develop robust solutions that can withstand electrical and thermal stresses while maintaining consistent performance over extended operational periods. Specifically, this involves achieving a mean time between failures (MTBF) exceeding 100,000 hours under full-load conditions, which represents a significant improvement over current industry standards of 50,000-70,000 hours.

Secondary objectives include reducing thermal sensitivity to enable operation in more extreme ambient temperature environments (-40°C to +125°C), enhancing immunity to voltage transients without requiring external suppression components, and developing advanced self-diagnostic capabilities to predict potential failures before they occur.

Recent advancements in wide-bandgap semiconductor materials such as silicon carbide (SiC) and gallium nitride (GaN) present promising opportunities for addressing these reliability challenges. These materials offer superior thermal conductivity, higher breakdown voltages, and faster switching capabilities compared to traditional silicon-based devices, potentially enabling SSRs to handle more demanding load conditions with improved reliability margins.

The technological evolution in this field is increasingly focused on integrated approaches that combine advanced semiconductor technologies with sophisticated thermal management systems and intelligent control algorithms. This holistic approach aims to create next-generation SSRs capable of adapting to varying load conditions while maintaining optimal performance parameters throughout their operational lifetime.

Market Demand Analysis for High-Reliability SSRs

The global market for high-reliability Solid-State Relays (SSRs) has been experiencing robust growth, driven primarily by increasing automation across industrial sectors and the growing emphasis on equipment reliability. Current market valuations place the high-reliability SSR segment at approximately 2.5 billion USD, with projections indicating a compound annual growth rate of 6.8% through 2028.

Industrial automation represents the largest demand sector, accounting for nearly 40% of the high-reliability SSR market. Manufacturing facilities are increasingly replacing traditional electromechanical relays with SSRs to reduce maintenance costs and improve system uptime. The automotive industry follows closely, particularly with the expansion of electric vehicle production, where high-reliability switching components are critical for battery management systems and power distribution.

Healthcare equipment manufacturers constitute another significant market segment, where equipment failure can have life-threatening consequences. Medical device manufacturers are willing to pay premium prices for components that offer superior reliability metrics, creating a high-value niche within the broader SSR market.

Geographically, North America and Europe currently lead in adoption rates for high-reliability SSRs, though Asia-Pacific markets are showing the fastest growth trajectory, particularly in countries with rapidly expanding industrial bases such as China, India, and South Korea.

Market research indicates that customers are increasingly prioritizing total cost of ownership over initial purchase price. This shift has created strong demand for SSRs that can demonstrate extended operational lifespans under challenging load conditions, with documented mean time between failures (MTBF) becoming a key purchasing criterion.

The renewable energy sector represents an emerging high-growth market for reliable SSRs, particularly in solar inverter applications and grid-tie systems where components must withstand significant power fluctuations. Industry forecasts suggest this segment could grow at twice the overall market rate over the next five years.

Customer requirements are evolving toward more comprehensive reliability data, with buyers increasingly requesting accelerated life testing results and detailed failure mode analyses. This trend is pushing manufacturers to invest in more sophisticated testing methodologies and to provide more transparent reliability documentation.

Price sensitivity varies significantly by application, with mission-critical systems showing relatively inelastic demand even at premium price points. Market surveys indicate customers would accept a 15-20% price premium for SSRs that can demonstrate a 30% improvement in operational reliability under variable load conditions.

Industrial automation represents the largest demand sector, accounting for nearly 40% of the high-reliability SSR market. Manufacturing facilities are increasingly replacing traditional electromechanical relays with SSRs to reduce maintenance costs and improve system uptime. The automotive industry follows closely, particularly with the expansion of electric vehicle production, where high-reliability switching components are critical for battery management systems and power distribution.

Healthcare equipment manufacturers constitute another significant market segment, where equipment failure can have life-threatening consequences. Medical device manufacturers are willing to pay premium prices for components that offer superior reliability metrics, creating a high-value niche within the broader SSR market.

Geographically, North America and Europe currently lead in adoption rates for high-reliability SSRs, though Asia-Pacific markets are showing the fastest growth trajectory, particularly in countries with rapidly expanding industrial bases such as China, India, and South Korea.

Market research indicates that customers are increasingly prioritizing total cost of ownership over initial purchase price. This shift has created strong demand for SSRs that can demonstrate extended operational lifespans under challenging load conditions, with documented mean time between failures (MTBF) becoming a key purchasing criterion.

The renewable energy sector represents an emerging high-growth market for reliable SSRs, particularly in solar inverter applications and grid-tie systems where components must withstand significant power fluctuations. Industry forecasts suggest this segment could grow at twice the overall market rate over the next five years.

Customer requirements are evolving toward more comprehensive reliability data, with buyers increasingly requesting accelerated life testing results and detailed failure mode analyses. This trend is pushing manufacturers to invest in more sophisticated testing methodologies and to provide more transparent reliability documentation.

Price sensitivity varies significantly by application, with mission-critical systems showing relatively inelastic demand even at premium price points. Market surveys indicate customers would accept a 15-20% price premium for SSRs that can demonstrate a 30% improvement in operational reliability under variable load conditions.

Current Challenges in SSR Performance Under Load

Solid-State Relays (SSRs) face significant performance challenges when operating under load conditions, which directly impact their reliability and service life. The primary challenge stems from thermal management issues. During operation, SSRs generate substantial heat due to the voltage drop across their semiconductor switching elements, typically ranging from 0.8V to 1.5V depending on the device type. This heat generation increases exponentially with current load, following the power dissipation equation P = I²R, creating hotspots that accelerate component degradation.

Voltage transients present another critical challenge for SSRs under load. When switching inductive loads such as motors or transformers, sudden current interruptions can generate voltage spikes exceeding 1000V. These transients stress the semiconductor junctions and can cause immediate failure or cumulative damage to the internal structure of the device, particularly affecting the integrity of the semiconductor-metal interfaces.

Environmental factors compound these challenges significantly. High ambient temperatures reduce the thermal headroom available for SSR operation, while humidity and contaminants can compromise insulation resistance between input and output circuits. Industry data indicates that operating an SSR at 10°C above its rated temperature can reduce its lifespan by approximately 50%, highlighting the sensitivity of these devices to environmental conditions.

Load characteristics introduce additional complexities. Inrush currents during load startup can be 5-10 times higher than normal operating currents, creating momentary stress conditions that test the SSR's surge handling capability. Similarly, highly reactive loads with poor power factors create phase shifts between voltage and current, resulting in switching at non-optimal points in the AC cycle and increasing thermal stress on the semiconductor elements.

The semiconductor aging process itself represents a fundamental challenge. Over time, thermal cycling causes micro-fractures in die-attach materials and bond wires, increasing thermal resistance and creating a self-accelerating degradation cycle. This manifests as a gradual increase in forward voltage drop across the device, further exacerbating heat generation under load.

Integration challenges also affect SSR reliability. Inadequate heat sinking, improper mounting techniques, and insufficient spacing between components in compact designs can create thermal bottlenecks. Studies show that up to 30% of SSR failures can be attributed to installation factors rather than inherent device limitations, highlighting the importance of system-level considerations in addressing reliability challenges.

Voltage transients present another critical challenge for SSRs under load. When switching inductive loads such as motors or transformers, sudden current interruptions can generate voltage spikes exceeding 1000V. These transients stress the semiconductor junctions and can cause immediate failure or cumulative damage to the internal structure of the device, particularly affecting the integrity of the semiconductor-metal interfaces.

Environmental factors compound these challenges significantly. High ambient temperatures reduce the thermal headroom available for SSR operation, while humidity and contaminants can compromise insulation resistance between input and output circuits. Industry data indicates that operating an SSR at 10°C above its rated temperature can reduce its lifespan by approximately 50%, highlighting the sensitivity of these devices to environmental conditions.

Load characteristics introduce additional complexities. Inrush currents during load startup can be 5-10 times higher than normal operating currents, creating momentary stress conditions that test the SSR's surge handling capability. Similarly, highly reactive loads with poor power factors create phase shifts between voltage and current, resulting in switching at non-optimal points in the AC cycle and increasing thermal stress on the semiconductor elements.

The semiconductor aging process itself represents a fundamental challenge. Over time, thermal cycling causes micro-fractures in die-attach materials and bond wires, increasing thermal resistance and creating a self-accelerating degradation cycle. This manifests as a gradual increase in forward voltage drop across the device, further exacerbating heat generation under load.

Integration challenges also affect SSR reliability. Inadequate heat sinking, improper mounting techniques, and insufficient spacing between components in compact designs can create thermal bottlenecks. Studies show that up to 30% of SSR failures can be attributed to installation factors rather than inherent device limitations, highlighting the importance of system-level considerations in addressing reliability challenges.

Current Solutions for SSR Reliability Enhancement

01 Thermal management for improved reliability

Effective thermal management is crucial for solid-state relay reliability. This includes heat dissipation techniques, thermal protection circuits, and temperature monitoring systems that prevent overheating. Proper heat sinking and thermal interface materials help maintain optimal operating temperatures, while thermal shutdown mechanisms protect against damage during excessive heat conditions. These approaches significantly extend the operational lifespan of solid-state relays by preventing thermal stress and degradation.- Thermal management for improved reliability: Effective thermal management is crucial for solid-state relay reliability. This includes heat dissipation techniques, thermal protection circuits, and temperature monitoring systems that prevent overheating. Proper heat sinking and thermal interface materials help maintain optimal operating temperatures, reducing thermal stress on semiconductor components and extending the relay's operational life. Advanced cooling solutions and temperature-compensated designs ensure stable performance under varying thermal conditions.

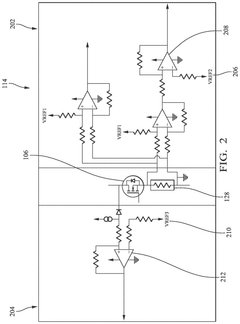

- Overvoltage and overcurrent protection mechanisms: Protection circuits are essential for solid-state relay reliability, guarding against damaging electrical conditions. These include surge suppression components, current limiting circuits, and voltage clamping devices that prevent electrical stress. Integrated fault detection systems can identify abnormal conditions and trigger protective responses before damage occurs. Multi-layer protection strategies combining various techniques provide comprehensive safeguarding against electrical transients, surges, and other potentially harmful events.

- Advanced semiconductor materials and structures: The choice of semiconductor materials significantly impacts solid-state relay reliability. Modern relays utilize advanced materials like silicon carbide (SiC) and gallium nitride (GaN) that offer superior thermal conductivity and electrical characteristics. Optimized semiconductor structures with improved junction designs reduce internal resistance and heat generation. Enhanced doping profiles and specialized fabrication techniques create more robust devices with better tolerance to electrical and thermal stress, resulting in extended operational lifetimes.

- Isolation and insulation techniques: Reliable electrical isolation is fundamental to solid-state relay performance. Advanced isolation techniques include optical coupling, magnetic isolation, and capacitive coupling that prevent signal interference while maintaining signal integrity. High-quality insulation materials and designs protect against voltage breakdown and leakage currents. Specialized packaging with optimized creepage and clearance distances enhances isolation reliability. These techniques ensure consistent operation in high-voltage applications and harsh environmental conditions.

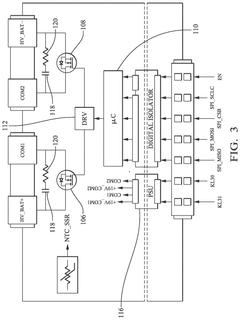

- Redundancy and fault-tolerant designs: Implementing redundancy and fault-tolerant architectures significantly enhances solid-state relay reliability. These designs include parallel relay configurations, backup switching paths, and self-diagnostic capabilities that detect and respond to component failures. Intelligent control systems can automatically switch to backup circuits when faults are detected. Modular designs allow for easy replacement of failed components without complete system shutdown. These approaches ensure continuous operation even when individual components experience failures.

02 Protection circuits and fault tolerance mechanisms

Implementing protection circuits enhances solid-state relay reliability by safeguarding against electrical faults. These include overvoltage protection, overcurrent detection, surge suppression, and short-circuit protection mechanisms. Fault tolerance designs incorporate redundancy systems and fail-safe modes that maintain operation during partial failures. Advanced diagnostic capabilities enable early detection of potential issues before catastrophic failure occurs, significantly improving the overall reliability of solid-state relay systems.Expand Specific Solutions03 Advanced semiconductor materials and packaging

The choice of semiconductor materials and packaging techniques significantly impacts solid-state relay reliability. High-quality semiconductor materials with improved thermal characteristics and lower leakage currents enhance performance under stress conditions. Hermetically sealed packages protect internal components from environmental factors like moisture and contaminants. Advanced bonding techniques and connection methods reduce mechanical stress on components, while specialized coatings provide additional protection against environmental degradation, extending operational lifetime.Expand Specific Solutions04 EMI/RFI immunity and environmental hardening

Enhancing electromagnetic interference (EMI) and radio frequency interference (RFI) immunity is essential for solid-state relay reliability in noisy electrical environments. Shielding techniques, filtering components, and isolation barriers prevent false triggering and operational disruptions. Environmental hardening measures protect against humidity, dust, vibration, and temperature fluctuations. These include conformal coatings, potting compounds, and robust mechanical designs that maintain performance integrity in harsh industrial conditions, ensuring consistent operation regardless of environmental challenges.Expand Specific Solutions05 Design optimization and reliability testing

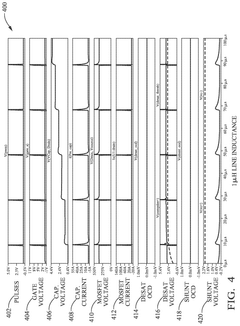

Optimized circuit designs and comprehensive reliability testing methodologies significantly improve solid-state relay performance. Advanced design techniques include snubber circuits to manage voltage transients, optimized gate drive circuits, and balanced component selection for stress distribution. Accelerated life testing, thermal cycling, power cycling, and environmental stress screening identify potential failure modes before deployment. Statistical reliability models help predict performance under various operating conditions, enabling manufacturers to develop more robust solid-state relay solutions with extended operational lifespans.Expand Specific Solutions

Key Manufacturers and Competitive Landscape

The solid-state relay reliability market is currently in a growth phase, with increasing demand driven by industrial automation and smart grid applications. The competitive landscape features established players like OMRON, Murata, and Panasonic dominating with mature technologies, alongside emerging competitors such as Huawei Digital Power and BYD developing innovative solutions. Market size is expanding at approximately 6-8% CAGR, reaching $1.5-2 billion globally. Technology maturity varies significantly, with companies like Littelfuse and Texas Instruments focusing on advanced thermal management solutions, while OMRON and Sanyou lead in high-current handling capabilities. Chinese manufacturers including Huawei and Suzhou Novosense are rapidly advancing in integration technologies, challenging traditional market leaders through cost-effective reliability improvements.

Murata Manufacturing Co. Ltd.

Technical Solution: Murata has developed innovative solid-state relay technology that addresses reliability challenges through advanced materials science and thermal engineering. Their approach incorporates specialized ceramic substrates with thermal conductivity values exceeding 170 W/m·K, significantly outperforming traditional alumina substrates used in conventional SSRs. Murata's solid-state relays feature proprietary die-attach materials that maintain mechanical integrity even after thousands of thermal cycles, reducing failure rates associated with thermal fatigue. Their design implements advanced current limiting circuits that respond within microseconds to overload conditions, protecting the semiconductor switching elements from damage during fault events. Additionally, Murata has pioneered the use of specialized encapsulation compounds that provide superior protection against moisture ingress while maintaining excellent thermal transfer characteristics, enabling their SSRs to maintain reliability even in condensing humidity environments common in industrial applications.

Strengths: Superior thermal cycling endurance, excellent moisture resistance properties, and advanced protection against electrical overload conditions. Weaknesses: More limited product range compared to some competitors, and potentially higher integration complexity when implementing in existing control systems.

OMRON Corp.

Technical Solution: OMRON has developed advanced solid-state relays with integrated thermal management systems that significantly improve reliability under load conditions. Their technology incorporates heat sink optimization and thermal interface materials that reduce junction temperatures by up to 20°C compared to conventional designs. OMRON's solid-state relays feature zero-cross switching circuits that minimize inrush current stress and reduce electromagnetic interference, extending relay lifespan in high-load applications. Their latest G3PE series implements predictive failure analysis through continuous monitoring of internal temperature and current patterns, allowing for preventive maintenance before critical failure occurs. Additionally, OMRON has pioneered the use of silicon carbide (SiC) MOSFETs in their high-power SSRs, which offer superior thermal performance and lower on-state resistance compared to traditional silicon-based components.

Strengths: Industry-leading thermal management technology, comprehensive predictive maintenance capabilities, and advanced semiconductor materials that significantly extend operational lifespan. Weaknesses: Higher initial cost compared to mechanical relays and some competitors, and proprietary monitoring systems may require specialized integration with existing control systems.

Critical Patents and Innovations in SSR Design

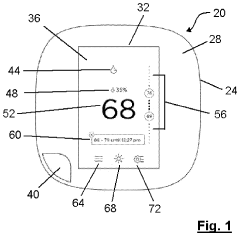

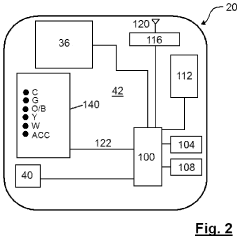

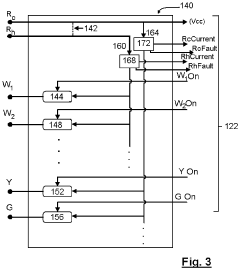

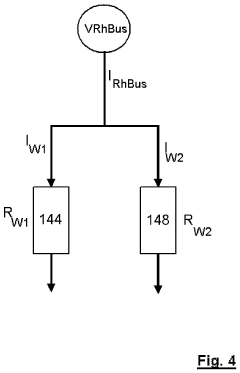

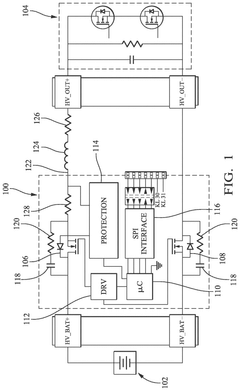

Control device with current protected solid state relays

PatentActiveUS20190338970A1

Innovation

- A control device with a processor that measures current flow through solid state relays to determine bulk heating, compensates temperature readings, and activates/deactivates relays to maintain a desired temperature range, while also implementing over-current protection by setting safety thresholds to prevent damage to the relays.

Solid state relay module with overcurrent protection

PatentPendingUS20240348241A1

Innovation

- A solid state relay module with shunt and desaturation overcurrent detection circuits that quickly respond to overcurrent conditions by turning off the electronic switches, eliminating the need for dedicated bypass relays and resistors, and utilizing pulsed energy to pre-charge capacitive loads, thereby preventing damage from in-rush currents.

Thermal Management Strategies for SSRs

Thermal management represents a critical factor in ensuring the reliability and longevity of Solid-State Relays (SSRs) under load conditions. As SSRs operate, they generate significant heat due to power dissipation across semiconductor junctions, particularly during high-current switching operations. Effective thermal management strategies must address both the internal heat generation mechanisms and the external environmental factors that influence device temperature.

Heat sinks serve as primary passive cooling solutions for SSRs, with aluminum and copper being the most commonly employed materials due to their excellent thermal conductivity properties. Advanced heat sink designs incorporate optimized fin structures that maximize surface area while maintaining efficient air flow patterns. Recent innovations include phase-change materials integrated into heat sink structures, which absorb thermal energy during peak loads and release it gradually during lower-demand periods.

Active cooling technologies provide enhanced thermal management capabilities for high-power SSR applications. Forced-air cooling systems utilizing strategically positioned fans can significantly reduce operating temperatures, with computational fluid dynamics (CFD) modeling enabling precise airflow optimization. For extreme environments, liquid cooling systems offer superior heat dissipation capacity, though at higher implementation costs and complexity.

Thermal interface materials (TIMs) play a crucial role in minimizing contact resistance between SSRs and heat dissipation components. Modern TIM formulations include high-performance thermal greases, phase-change compounds, and thermally conductive adhesives. Graphene-enhanced TIMs have emerged as particularly promising, demonstrating thermal conductivity improvements of up to 60% compared to conventional materials while maintaining excellent long-term stability.

Temperature monitoring and feedback systems represent an increasingly important aspect of comprehensive thermal management strategies. Embedded temperature sensors with real-time monitoring capabilities allow for dynamic load adjustment based on thermal conditions. Advanced systems incorporate predictive algorithms that anticipate thermal issues before critical thresholds are reached, enabling preemptive corrective actions.

Thermal isolation techniques focus on protecting sensitive components from heat transfer within the SSR assembly. Strategic placement of thermal barriers and the use of low thermal conductivity materials in non-critical pathways help direct heat flow toward designated dissipation channels. This approach is particularly valuable in compact designs where multiple heat-generating components operate in close proximity.

Emerging technologies in SSR thermal management include microfluidic cooling channels integrated directly into semiconductor substrates, providing cooling precisely where heat generation occurs. Additionally, thermoelectric cooling elements are being explored as active temperature control mechanisms for precision applications requiring tight thermal regulation.

Heat sinks serve as primary passive cooling solutions for SSRs, with aluminum and copper being the most commonly employed materials due to their excellent thermal conductivity properties. Advanced heat sink designs incorporate optimized fin structures that maximize surface area while maintaining efficient air flow patterns. Recent innovations include phase-change materials integrated into heat sink structures, which absorb thermal energy during peak loads and release it gradually during lower-demand periods.

Active cooling technologies provide enhanced thermal management capabilities for high-power SSR applications. Forced-air cooling systems utilizing strategically positioned fans can significantly reduce operating temperatures, with computational fluid dynamics (CFD) modeling enabling precise airflow optimization. For extreme environments, liquid cooling systems offer superior heat dissipation capacity, though at higher implementation costs and complexity.

Thermal interface materials (TIMs) play a crucial role in minimizing contact resistance between SSRs and heat dissipation components. Modern TIM formulations include high-performance thermal greases, phase-change compounds, and thermally conductive adhesives. Graphene-enhanced TIMs have emerged as particularly promising, demonstrating thermal conductivity improvements of up to 60% compared to conventional materials while maintaining excellent long-term stability.

Temperature monitoring and feedback systems represent an increasingly important aspect of comprehensive thermal management strategies. Embedded temperature sensors with real-time monitoring capabilities allow for dynamic load adjustment based on thermal conditions. Advanced systems incorporate predictive algorithms that anticipate thermal issues before critical thresholds are reached, enabling preemptive corrective actions.

Thermal isolation techniques focus on protecting sensitive components from heat transfer within the SSR assembly. Strategic placement of thermal barriers and the use of low thermal conductivity materials in non-critical pathways help direct heat flow toward designated dissipation channels. This approach is particularly valuable in compact designs where multiple heat-generating components operate in close proximity.

Emerging technologies in SSR thermal management include microfluidic cooling channels integrated directly into semiconductor substrates, providing cooling precisely where heat generation occurs. Additionally, thermoelectric cooling elements are being explored as active temperature control mechanisms for precision applications requiring tight thermal regulation.

Industry Standards and Certification Requirements

Solid-state relays (SSRs) must adhere to rigorous industry standards to ensure reliable operation under various load conditions. The International Electrotechnical Commission (IEC) has established several key standards, including IEC 60947-4-3 for AC semiconductor controllers and IEC 62314 specifically for solid-state relays. These standards define critical parameters such as voltage ratings, current handling capabilities, thermal characteristics, and electromagnetic compatibility requirements that manufacturers must meet.

In North America, Underwriters Laboratories (UL) certification is paramount, with UL 508 serving as the primary standard for industrial control equipment including SSRs. This certification ensures that relays can safely handle specified loads without overheating or creating electrical hazards. Additionally, UL 1577 addresses optical isolation requirements, which is crucial for SSRs utilizing optocoupling technology for input-output isolation.

The European market requires compliance with the Low Voltage Directive (LVD) and Electromagnetic Compatibility (EMC) Directive, with CE marking indicating conformity. These regulations ensure SSRs operate safely within electromagnetic environments without introducing unacceptable levels of interference. For applications in hazardous environments, ATEX certification becomes mandatory, specifying additional requirements for preventing ignition sources.

Testing protocols for SSR reliability certification include surge immunity testing (IEC 61000-4-5), electrostatic discharge immunity (IEC 61000-4-2), and electrical fast transient/burst immunity (IEC 61000-4-4). These tests verify that relays can withstand electrical disturbances commonly encountered in industrial environments. Temperature cycling tests according to IEC 60068-2-14 evaluate how relays perform under thermal stress, while humidity testing per IEC 60068-2-78 assesses reliability in high-moisture conditions.

Industry-specific standards impose additional requirements. Medical applications must meet IEC 60601-1 for electrical safety, while automotive applications require compliance with ISO 26262 for functional safety and AEC-Q100 for stress resistance. Railway applications follow EN 50155, which specifies stringent requirements for electronic equipment used in rolling stock.

Certification documentation must include detailed performance data, safety margins, and failure mode analyses. Manufacturers are increasingly expected to provide Mean Time Between Failure (MTBF) calculations and Failure Mode and Effects Analysis (FMEA) documentation to support reliability claims. These certifications not only ensure minimum safety standards but also serve as benchmarks for comparing relay performance across different manufacturers and technologies.

In North America, Underwriters Laboratories (UL) certification is paramount, with UL 508 serving as the primary standard for industrial control equipment including SSRs. This certification ensures that relays can safely handle specified loads without overheating or creating electrical hazards. Additionally, UL 1577 addresses optical isolation requirements, which is crucial for SSRs utilizing optocoupling technology for input-output isolation.

The European market requires compliance with the Low Voltage Directive (LVD) and Electromagnetic Compatibility (EMC) Directive, with CE marking indicating conformity. These regulations ensure SSRs operate safely within electromagnetic environments without introducing unacceptable levels of interference. For applications in hazardous environments, ATEX certification becomes mandatory, specifying additional requirements for preventing ignition sources.

Testing protocols for SSR reliability certification include surge immunity testing (IEC 61000-4-5), electrostatic discharge immunity (IEC 61000-4-2), and electrical fast transient/burst immunity (IEC 61000-4-4). These tests verify that relays can withstand electrical disturbances commonly encountered in industrial environments. Temperature cycling tests according to IEC 60068-2-14 evaluate how relays perform under thermal stress, while humidity testing per IEC 60068-2-78 assesses reliability in high-moisture conditions.

Industry-specific standards impose additional requirements. Medical applications must meet IEC 60601-1 for electrical safety, while automotive applications require compliance with ISO 26262 for functional safety and AEC-Q100 for stress resistance. Railway applications follow EN 50155, which specifies stringent requirements for electronic equipment used in rolling stock.

Certification documentation must include detailed performance data, safety margins, and failure mode analyses. Manufacturers are increasingly expected to provide Mean Time Between Failure (MTBF) calculations and Failure Mode and Effects Analysis (FMEA) documentation to support reliability claims. These certifications not only ensure minimum safety standards but also serve as benchmarks for comparing relay performance across different manufacturers and technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!