How to Improve Wankel Engine Fuel Efficiency?

AUG 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Wankel Engine Evolution and Efficiency Targets

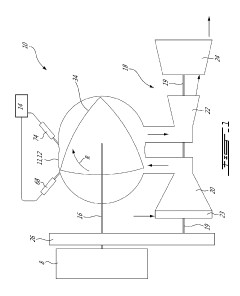

The Wankel rotary engine, first developed by Felix Wankel in the 1950s, represents a significant departure from conventional reciprocating piston engines. Its evolution began with the DKM prototype in 1957, followed by the more practical KKM design that became the foundation for commercial applications. The technology gained prominence in the 1960s when NSU and later Mazda invested heavily in its development, with Mazda's 1967 Cosmo Sport marking the first mass-produced rotary-powered vehicle.

Throughout its development history, the Wankel engine has been prized for its compact design, high power-to-weight ratio, and mechanical simplicity with fewer moving parts than conventional engines. However, fuel efficiency has consistently remained its Achilles' heel, with early models consuming significantly more fuel than comparable piston engines while producing higher emissions.

The efficiency targets for modern Wankel engine development focus on several key metrics. Primary among these is the reduction of fuel consumption to levels competitive with conventional internal combustion engines, aiming for at least 20-30% improvement over previous rotary designs. This includes targeting brake specific fuel consumption (BSFC) values below 270 g/kWh, comparable to modern gasoline engines.

Emissions reduction represents another critical target, with particular emphasis on decreasing hydrocarbon emissions that have historically plagued rotary engines due to their long combustion chambers and issues with apex seal leakage. Current development aims to meet Euro 6 and equivalent global standards without excessive reliance on after-treatment systems.

Thermal efficiency improvement constitutes a fundamental goal, with research targeting increases from the historical 15-25% range toward the 35-40% achieved by advanced piston engines. This requires addressing the unfavorable surface-to-volume ratio inherent in the rotary design that contributes to heat loss and incomplete combustion.

The evolution trajectory shows promising developments in materials science, with silicon carbide apex seals and ceramic rotor housings emerging as potential solutions to the sealing and thermal management challenges. Advanced direct injection systems, variable geometry intake systems, and turbocharging technologies are being integrated to optimize combustion efficiency across operating conditions.

Recent technological trends indicate a potential renaissance for Wankel engines in hybrid powertrains, where they can operate as range extenders at constant, optimized RPM—mitigating traditional efficiency weaknesses while leveraging their compact size and smooth operation. Mazda's SKYACTIV-R technology and their hydrogen rotary research represent significant steps in this evolutionary path.

Throughout its development history, the Wankel engine has been prized for its compact design, high power-to-weight ratio, and mechanical simplicity with fewer moving parts than conventional engines. However, fuel efficiency has consistently remained its Achilles' heel, with early models consuming significantly more fuel than comparable piston engines while producing higher emissions.

The efficiency targets for modern Wankel engine development focus on several key metrics. Primary among these is the reduction of fuel consumption to levels competitive with conventional internal combustion engines, aiming for at least 20-30% improvement over previous rotary designs. This includes targeting brake specific fuel consumption (BSFC) values below 270 g/kWh, comparable to modern gasoline engines.

Emissions reduction represents another critical target, with particular emphasis on decreasing hydrocarbon emissions that have historically plagued rotary engines due to their long combustion chambers and issues with apex seal leakage. Current development aims to meet Euro 6 and equivalent global standards without excessive reliance on after-treatment systems.

Thermal efficiency improvement constitutes a fundamental goal, with research targeting increases from the historical 15-25% range toward the 35-40% achieved by advanced piston engines. This requires addressing the unfavorable surface-to-volume ratio inherent in the rotary design that contributes to heat loss and incomplete combustion.

The evolution trajectory shows promising developments in materials science, with silicon carbide apex seals and ceramic rotor housings emerging as potential solutions to the sealing and thermal management challenges. Advanced direct injection systems, variable geometry intake systems, and turbocharging technologies are being integrated to optimize combustion efficiency across operating conditions.

Recent technological trends indicate a potential renaissance for Wankel engines in hybrid powertrains, where they can operate as range extenders at constant, optimized RPM—mitigating traditional efficiency weaknesses while leveraging their compact size and smooth operation. Mazda's SKYACTIV-R technology and their hydrogen rotary research represent significant steps in this evolutionary path.

Market Analysis for Fuel-Efficient Rotary Engines

The global market for fuel-efficient rotary engines represents a niche but potentially significant segment within the broader automotive and power generation industries. Current market analysis indicates that while Wankel engines have historically occupied a specialized position due to their compact design and high power-to-weight ratio, their adoption has been limited primarily by fuel efficiency concerns. This market inefficiency creates both challenges and opportunities for technological innovation.

Market size projections suggest that with substantial improvements in fuel efficiency, rotary engines could capture a growing share of several key sectors. The automotive market presents the most immediate opportunity, particularly in sports cars, motorcycles, and hybrid vehicles where the rotary engine's compact size offers distinct advantages. The aviation sector also shows promise, especially for unmanned aerial vehicles (UAVs) and small aircraft where weight considerations are paramount.

Consumer demand patterns reveal increasing interest in fuel-efficient alternatives that don't compromise on performance. Market research indicates that consumers are willing to pay a premium for vehicles that combine the unique characteristics of rotary engines with improved fuel economy. This trend aligns with broader market movements toward sustainability without sacrificing performance attributes.

Regional market analysis shows varying levels of potential adoption. Asian markets, particularly Japan and South Korea, demonstrate the highest receptivity due to their historical connection with rotary technology and emphasis on compact, efficient engineering solutions. North American and European markets show moderate interest, primarily in performance and specialty vehicle segments.

Competitive landscape assessment reveals limited but dedicated players. Mazda remains the most recognized brand associated with rotary technology, having recently signaled renewed interest in rotary engines as range extenders for electric vehicles. Several startups and research institutions are also exploring advanced rotary concepts with improved efficiency profiles.

Market barriers include established perceptions about rotary engine efficiency, significant R&D investment requirements, and competition from increasingly efficient conventional engines and electric powertrains. However, these barriers are counterbalanced by growing demand for range extenders in hybrid vehicles and specialized applications where rotary advantages outweigh efficiency concerns.

Growth projections indicate that successful fuel efficiency improvements could expand the rotary engine market substantially over the next decade, particularly as a complementary technology within hybrid systems rather than as a standalone power solution. The market appears most receptive to innovations that address the specific efficiency challenges while maintaining the inherent advantages of the Wankel design.

Market size projections suggest that with substantial improvements in fuel efficiency, rotary engines could capture a growing share of several key sectors. The automotive market presents the most immediate opportunity, particularly in sports cars, motorcycles, and hybrid vehicles where the rotary engine's compact size offers distinct advantages. The aviation sector also shows promise, especially for unmanned aerial vehicles (UAVs) and small aircraft where weight considerations are paramount.

Consumer demand patterns reveal increasing interest in fuel-efficient alternatives that don't compromise on performance. Market research indicates that consumers are willing to pay a premium for vehicles that combine the unique characteristics of rotary engines with improved fuel economy. This trend aligns with broader market movements toward sustainability without sacrificing performance attributes.

Regional market analysis shows varying levels of potential adoption. Asian markets, particularly Japan and South Korea, demonstrate the highest receptivity due to their historical connection with rotary technology and emphasis on compact, efficient engineering solutions. North American and European markets show moderate interest, primarily in performance and specialty vehicle segments.

Competitive landscape assessment reveals limited but dedicated players. Mazda remains the most recognized brand associated with rotary technology, having recently signaled renewed interest in rotary engines as range extenders for electric vehicles. Several startups and research institutions are also exploring advanced rotary concepts with improved efficiency profiles.

Market barriers include established perceptions about rotary engine efficiency, significant R&D investment requirements, and competition from increasingly efficient conventional engines and electric powertrains. However, these barriers are counterbalanced by growing demand for range extenders in hybrid vehicles and specialized applications where rotary advantages outweigh efficiency concerns.

Growth projections indicate that successful fuel efficiency improvements could expand the rotary engine market substantially over the next decade, particularly as a complementary technology within hybrid systems rather than as a standalone power solution. The market appears most receptive to innovations that address the specific efficiency challenges while maintaining the inherent advantages of the Wankel design.

Current Limitations and Technical Challenges

Despite its innovative design and theoretical advantages, the Wankel rotary engine faces significant efficiency challenges that have limited its widespread adoption in the automotive industry. The most critical limitation is its inherently poor fuel efficiency compared to conventional reciprocating engines. This inefficiency stems primarily from the elongated combustion chamber geometry, which creates a high surface-to-volume ratio and results in incomplete combustion of the air-fuel mixture.

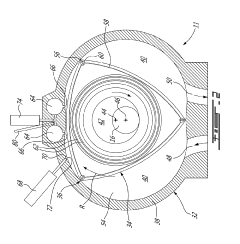

The unique rotor housing design presents substantial sealing challenges at the apex of the triangular rotor. These apex seals experience extreme thermal and mechanical stress during operation, leading to accelerated wear and eventual leakage. When seal integrity is compromised, combustion gases escape the chamber, reducing compression and further diminishing fuel efficiency. Modern materials science has yet to develop sealing solutions that can maintain optimal performance throughout the engine's service life.

Thermal management represents another significant technical hurdle. The asymmetrical heating of the rotor housing creates thermal distortion that exacerbates sealing problems. The concentrated heat in specific areas of the housing requires complex cooling systems that add weight and complexity while still struggling to maintain optimal operating temperatures across all engine components.

Oil consumption remains problematically high in Wankel engines due to the necessity of lubricating the apex seals. This oil is inevitably exposed to the combustion process, resulting in increased emissions and reduced efficiency. Modern emission standards have made this characteristic increasingly problematic from both regulatory and environmental perspectives.

The fundamental thermodynamic cycle of the Wankel engine presents efficiency limitations as well. The engine's operating cycle features a lower expansion ratio compared to its compression ratio, which thermodynamically restricts its maximum theoretical efficiency below that of conventional piston engines. This inherent disadvantage creates a ceiling for efficiency improvements regardless of other optimizations.

Manufacturing precision requirements for Wankel engines exceed those of conventional engines. The complex epitrochoid housing shape and precise rotor dimensions demand specialized manufacturing processes with tight tolerances. These requirements increase production costs and limit the number of manufacturers capable of producing these engines at scale.

Recent regulatory pressures focusing on emissions and fuel economy have further challenged Wankel engine development. While companies like Mazda have invested significantly in addressing these limitations through technologies like direct injection and improved sealing materials, the fundamental challenges remain substantial barriers to achieving parity with modern reciprocating engines in terms of fuel efficiency and emissions compliance.

The unique rotor housing design presents substantial sealing challenges at the apex of the triangular rotor. These apex seals experience extreme thermal and mechanical stress during operation, leading to accelerated wear and eventual leakage. When seal integrity is compromised, combustion gases escape the chamber, reducing compression and further diminishing fuel efficiency. Modern materials science has yet to develop sealing solutions that can maintain optimal performance throughout the engine's service life.

Thermal management represents another significant technical hurdle. The asymmetrical heating of the rotor housing creates thermal distortion that exacerbates sealing problems. The concentrated heat in specific areas of the housing requires complex cooling systems that add weight and complexity while still struggling to maintain optimal operating temperatures across all engine components.

Oil consumption remains problematically high in Wankel engines due to the necessity of lubricating the apex seals. This oil is inevitably exposed to the combustion process, resulting in increased emissions and reduced efficiency. Modern emission standards have made this characteristic increasingly problematic from both regulatory and environmental perspectives.

The fundamental thermodynamic cycle of the Wankel engine presents efficiency limitations as well. The engine's operating cycle features a lower expansion ratio compared to its compression ratio, which thermodynamically restricts its maximum theoretical efficiency below that of conventional piston engines. This inherent disadvantage creates a ceiling for efficiency improvements regardless of other optimizations.

Manufacturing precision requirements for Wankel engines exceed those of conventional engines. The complex epitrochoid housing shape and precise rotor dimensions demand specialized manufacturing processes with tight tolerances. These requirements increase production costs and limit the number of manufacturers capable of producing these engines at scale.

Recent regulatory pressures focusing on emissions and fuel economy have further challenged Wankel engine development. While companies like Mazda have invested significantly in addressing these limitations through technologies like direct injection and improved sealing materials, the fundamental challenges remain substantial barriers to achieving parity with modern reciprocating engines in terms of fuel efficiency and emissions compliance.

Modern Approaches to Rotary Engine Efficiency

01 Combustion chamber design improvements

Modifications to the combustion chamber design of Wankel engines can significantly improve fuel efficiency. These improvements include optimized chamber geometry, enhanced sealing mechanisms, and modified rotor designs that promote more complete combustion. By reducing leakage between chambers and ensuring more efficient burning of fuel, these design enhancements help to address one of the traditional weaknesses of rotary engines.- Combustion chamber design improvements: Modifications to the combustion chamber design of Wankel engines can significantly improve fuel efficiency. These improvements include optimized chamber geometry, enhanced sealing mechanisms, and modified rotor designs that promote more complete combustion. By reducing leakage between chambers and ensuring more efficient burning of the fuel-air mixture, these design enhancements help to address one of the traditional weaknesses of Wankel engines.

- Fuel injection and delivery systems: Advanced fuel injection and delivery systems can enhance the fuel efficiency of Wankel engines. These systems include direct injection technologies, precision fuel metering, and optimized spray patterns that ensure proper fuel atomization and distribution within the combustion chamber. By delivering the precise amount of fuel at the optimal time in the combustion cycle, these systems minimize waste and maximize energy extraction from the fuel.

- Hybrid and alternative fuel adaptations: Integrating Wankel engines into hybrid powertrains or adapting them to use alternative fuels can significantly improve overall efficiency. These adaptations include electric-Wankel hybrids, hydrogen fuel compatibility, and multi-fuel capabilities. By leveraging the compact size and smooth operation of Wankel engines in combination with electric motors or cleaner-burning fuels, these approaches address traditional efficiency limitations while maintaining the engine's inherent advantages.

- Thermal management and heat recovery: Improved thermal management systems and heat recovery mechanisms can enhance Wankel engine efficiency. These innovations include advanced cooling systems, waste heat recovery technologies, and thermal barrier coatings that optimize operating temperatures and recover energy that would otherwise be lost. By managing heat more effectively and recapturing thermal energy, these approaches help to improve the overall energy conversion efficiency of the engine.

- Electronic control and optimization systems: Advanced electronic control systems can optimize Wankel engine operation for maximum fuel efficiency. These systems include adaptive engine management, real-time combustion monitoring, and intelligent control algorithms that continuously adjust operating parameters based on conditions and demands. By precisely controlling ignition timing, fuel delivery, and other variables, these electronic systems ensure that the engine operates at peak efficiency across various operating conditions.

02 Advanced fuel injection systems

Implementation of sophisticated fuel injection technologies can enhance the fuel efficiency of Wankel engines. Direct injection systems, precise fuel metering, and optimized injection timing allow for better control over the combustion process. These systems can adjust fuel delivery based on operating conditions, resulting in improved combustion efficiency and reduced fuel consumption across various engine loads.Expand Specific Solutions03 Hybrid and electrification integration

Combining Wankel engines with electric motors in hybrid configurations offers significant improvements in overall fuel efficiency. The rotary engine can be operated at its most efficient points while electric power supplements performance when needed. Some designs use the Wankel engine as a range extender or generator, leveraging its compact size and smooth operation while mitigating its traditional efficiency challenges.Expand Specific Solutions04 Thermal management and heat recovery

Enhanced thermal management systems can improve Wankel engine fuel efficiency by optimizing operating temperatures and recovering waste heat. These innovations include advanced cooling systems, thermal barrier coatings, and exhaust heat recovery mechanisms. By managing heat more effectively and recapturing energy that would otherwise be lost, these technologies help to improve the overall energy conversion efficiency of rotary engines.Expand Specific Solutions05 Alternative fuel adaptations

Modifications to enable Wankel engines to operate efficiently on alternative fuels can improve their environmental performance and efficiency. These adaptations include changes to accommodate hydrogen, natural gas, or biofuels, with corresponding adjustments to ignition timing, compression ratios, and fuel delivery systems. The unique combustion characteristics of rotary engines can be advantageous for certain alternative fuels, potentially offering efficiency improvements over traditional gasoline operation.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The Wankel engine fuel efficiency improvement landscape is currently in a mature development phase with renewed interest due to emissions concerns. The market size remains niche but growing, particularly in specialized applications where power-to-weight ratio is valued. Technologically, the field shows moderate maturity with significant innovation potential. Leading players demonstrate varying approaches: automotive manufacturers like Mazda (historically), Hyundai, and Great Wall Motor focus on commercial applications; while research institutions like Jiangsu University and South China University of Technology drive fundamental improvements. Engineering-focused companies including Pratt & Whitney Canada, United Technologies, and Ford Global Technologies contribute specialized expertise in materials and combustion optimization. The competitive landscape suggests collaborative opportunities between academic research and industrial implementation to overcome the Wankel engine's inherent efficiency challenges.

Quest Engines LLC

Technical Solution: Quest Engines has developed a revolutionary approach to Wankel engine efficiency through their Detonation Cycle Gas Turbine (DCGT) technology. This system fundamentally reimagines the rotary engine by incorporating controlled detonation combustion rather than traditional deflagration. Their design features a modified epitrochoidal housing with specialized detonation wave guides that direct the controlled detonation energy to maximize power extraction while minimizing mechanical stress. Quest's approach includes advanced ceramic composite materials for the rotor and housing that can withstand higher combustion temperatures while providing superior thermal insulation, significantly reducing cooling losses that plague traditional Wankel designs. Their patented apex seal system uses a dynamic pressure-balanced design that maintains optimal sealing force throughout the rotation cycle without excessive friction. The system incorporates direct fuel injection with precise timing control to achieve ideal fuel-air mixture stratification for controlled detonation. Quest has also implemented waste heat recovery systems that capture thermal energy from exhaust gases to power auxiliary systems or provide additional mechanical energy through a secondary power cycle, further improving overall system efficiency.

Strengths: The detonation cycle approach offers theoretical thermal efficiency improvements of up to 25% over conventional Wankel designs by utilizing more complete combustion and higher expansion ratios. The ceramic composite materials significantly reduce heat rejection requirements, addressing a major source of efficiency loss. Weaknesses: The controlled detonation technology requires extremely precise control systems and may face durability challenges due to the more intense combustion process. The advanced materials increase manufacturing costs and may present repairability challenges in field service.

GM Global Technology Operations LLC

Technical Solution: General Motors has developed an innovative hybrid Wankel engine system that combines rotary engine advantages with electrification to address fuel efficiency challenges. Their approach utilizes a smaller-displacement Wankel engine operating primarily at its most efficient points, coupled with electric motors to handle transient loads and low-efficiency operating regions. GM's system incorporates advanced combustion chamber designs with peripheral porting that optimizes gas flow dynamics and reduces pumping losses. Their patented rotor cooling technology uses targeted oil jets and internal cooling passages to maintain optimal thermal conditions, preventing overheating while reducing cooling system parasitic losses. GM has also implemented variable intake geometry that adjusts airflow characteristics based on engine speed and load, optimizing volumetric efficiency across the operating range. The system includes regenerative braking capabilities that capture energy normally lost during deceleration, storing it in a battery system for later use during acceleration or to power auxiliary systems when the rotary engine would otherwise operate inefficiently.

Strengths: The hybrid approach allows the Wankel engine to operate primarily in its efficiency sweet spot while using electric power to compensate for traditional rotary weaknesses. The system maintains the compact size and smooth operation advantages of Wankel engines while significantly improving overall efficiency. Weaknesses: The addition of electric motors, batteries, and control systems increases weight, complexity, and cost compared to conventional Wankel designs. The system requires sophisticated control algorithms and may face challenges in extreme operating conditions where battery performance is compromised.

Key Patents and Innovations in Sealing Technology

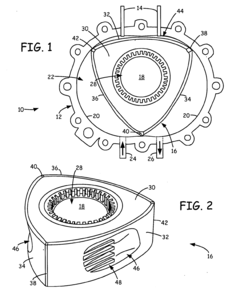

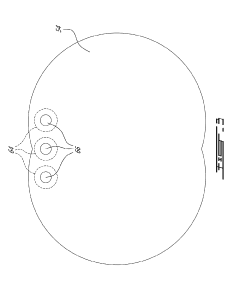

Rotors having flow-modifying members for use in rotary engines

PatentInactiveEP1933016A2

Innovation

- Incorporating recessed pockets with flow-modifying members, such as ramp-shaped, tapered, V-shaped, bluff body, or diagonal ramp-shaped structures on the rotor faces to control fuel/air mixing and flame propagation by generating vortex flows and turbulence, which extend beyond the recessed pockets into the combustion chamber.

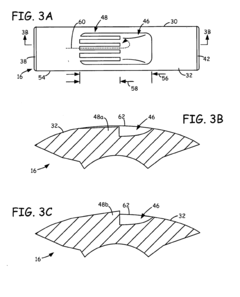

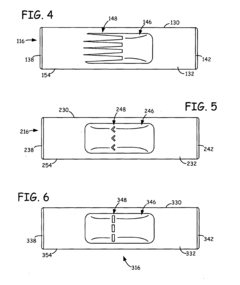

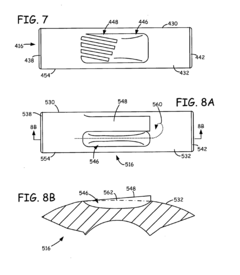

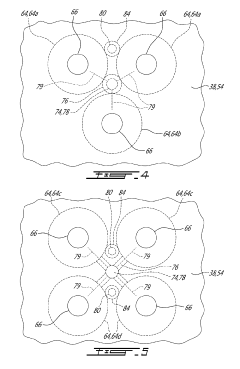

Rotary engine with pilot subchambers

PatentActiveUS20190162108A1

Innovation

- The implementation of at least two pilot subchambers in parallel fluid communication with the combustion chambers, where a pilot quantity of fuel is ignited and directed into the combustion chamber through transfer holes that partially restrict the flow, enhancing the ignition of the main fuel quantity and achieving a lean fuel-air mixture.

Environmental Regulations Impact on Rotary Engine Development

Environmental regulations have become a significant driving force in shaping the development trajectory of rotary engine technology, particularly the Wankel engine. Since the early 2000s, increasingly stringent emissions standards across major automotive markets have posed substantial challenges for rotary engine manufacturers. The inherent design characteristics of the Wankel engine, including its elongated combustion chamber and high surface-to-volume ratio, have traditionally resulted in higher hydrocarbon emissions and fuel consumption compared to conventional piston engines.

The European Union's Euro 6 standards and the United States EPA's Tier 3 regulations have established particularly demanding limits on nitrogen oxides (NOx), carbon monoxide (CO), and unburned hydrocarbon emissions. These regulatory frameworks have forced manufacturers like Mazda, historically the primary commercial producer of rotary engines, to significantly alter their development approaches or temporarily withdraw rotary-powered vehicles from certain markets.

Japan's implementation of the Post New Long-Term Emissions Standards in 2009 directly impacted Mazda's RX-8 production, ultimately contributing to its discontinuation in 2012. This regulatory pressure has shifted rotary engine development toward hybrid applications rather than standalone power units. Mazda's recent MX-30 R-EV represents this adaptation, utilizing a rotary engine as a range extender rather than the primary propulsion system.

China's rapidly evolving emissions policies have also influenced global rotary engine development strategies. As the world's largest automotive market implements increasingly stringent standards modeled after European regulations, manufacturers must consider these requirements when developing next-generation rotary technologies for global deployment.

The regulatory landscape has catalyzed significant innovations in rotary engine design focused on efficiency improvements. Direct injection systems, advanced thermal management solutions, and variable rotor timing mechanisms have emerged as technical responses to emissions challenges. Additionally, research into alternative combustion cycles and hydrogen compatibility for rotary engines has accelerated, partly motivated by regulatory incentives for alternative fuel vehicles.

Looking forward, upcoming regulations like Euro 7 and equivalent standards in other regions will likely further constrain traditional rotary engine applications unless significant efficiency breakthroughs occur. The regulatory environment has effectively transformed the rotary engine from a primary power source to a specialized component within electrified powertrains, where its compact size and smooth operation can complement battery systems while meeting emissions requirements through careful operational control.

The European Union's Euro 6 standards and the United States EPA's Tier 3 regulations have established particularly demanding limits on nitrogen oxides (NOx), carbon monoxide (CO), and unburned hydrocarbon emissions. These regulatory frameworks have forced manufacturers like Mazda, historically the primary commercial producer of rotary engines, to significantly alter their development approaches or temporarily withdraw rotary-powered vehicles from certain markets.

Japan's implementation of the Post New Long-Term Emissions Standards in 2009 directly impacted Mazda's RX-8 production, ultimately contributing to its discontinuation in 2012. This regulatory pressure has shifted rotary engine development toward hybrid applications rather than standalone power units. Mazda's recent MX-30 R-EV represents this adaptation, utilizing a rotary engine as a range extender rather than the primary propulsion system.

China's rapidly evolving emissions policies have also influenced global rotary engine development strategies. As the world's largest automotive market implements increasingly stringent standards modeled after European regulations, manufacturers must consider these requirements when developing next-generation rotary technologies for global deployment.

The regulatory landscape has catalyzed significant innovations in rotary engine design focused on efficiency improvements. Direct injection systems, advanced thermal management solutions, and variable rotor timing mechanisms have emerged as technical responses to emissions challenges. Additionally, research into alternative combustion cycles and hydrogen compatibility for rotary engines has accelerated, partly motivated by regulatory incentives for alternative fuel vehicles.

Looking forward, upcoming regulations like Euro 7 and equivalent standards in other regions will likely further constrain traditional rotary engine applications unless significant efficiency breakthroughs occur. The regulatory environment has effectively transformed the rotary engine from a primary power source to a specialized component within electrified powertrains, where its compact size and smooth operation can complement battery systems while meeting emissions requirements through careful operational control.

Materials Science Advancements for Wankel Engine Components

Recent advancements in materials science have opened new pathways for enhancing the Wankel engine's fuel efficiency. Traditional materials used in Wankel engines, such as cast iron and aluminum alloys, have inherent limitations regarding thermal management, friction, and durability. Modern ceramic coatings, particularly silicon nitride and zirconia-based compounds, demonstrate superior thermal barrier properties that significantly reduce heat loss through the housing walls, allowing more thermal energy to be converted into mechanical work.

Carbon-based materials represent another frontier in Wankel engine component development. Diamond-like carbon (DLC) coatings applied to rotor faces and housing surfaces have shown friction reduction of up to 20% compared to conventional materials, directly translating to improved fuel efficiency. These coatings also exhibit exceptional wear resistance, extending component lifespan and maintaining performance characteristics over longer operational periods.

Advanced aluminum-silicon alloys with enhanced thermal conductivity properties are being developed specifically for Wankel engine housings. These materials facilitate more uniform heat distribution, reducing thermal distortion and improving sealing efficiency at the apex seals—a critical factor in preventing combustion gas leakage that directly impacts fuel consumption.

Composite materials incorporating ceramic particles within metal matrices (cermet composites) show promise for apex seal applications. These materials combine the wear resistance of ceramics with the toughness of metals, addressing the historical weakness of apex seal durability while maintaining tight tolerances against the epitrochoid surface.

Thermal spray technologies have evolved to enable precise application of specialized coatings on internal engine surfaces. Plasma-sprayed molybdenum coatings on the trochoid surface have demonstrated a 15% reduction in friction losses while providing enhanced corrosion resistance against combustion byproducts.

Nano-engineered surface treatments represent the cutting edge of materials science application in Wankel engines. These treatments modify surface structures at the nanometer scale to create optimized oil retention patterns, reducing lubrication requirements while maintaining effective sealing—directly addressing one of the primary sources of fuel inefficiency in rotary engines.

The integration of these advanced materials must be approached holistically, considering not only individual component performance but also the interaction between different materials under varying thermal and mechanical stress conditions. Testing indicates that properly matched material combinations can yield fuel efficiency improvements of 8-12% compared to traditional Wankel engine designs, making materials science a critical pathway toward addressing the rotary engine's historical fuel consumption challenges.

Carbon-based materials represent another frontier in Wankel engine component development. Diamond-like carbon (DLC) coatings applied to rotor faces and housing surfaces have shown friction reduction of up to 20% compared to conventional materials, directly translating to improved fuel efficiency. These coatings also exhibit exceptional wear resistance, extending component lifespan and maintaining performance characteristics over longer operational periods.

Advanced aluminum-silicon alloys with enhanced thermal conductivity properties are being developed specifically for Wankel engine housings. These materials facilitate more uniform heat distribution, reducing thermal distortion and improving sealing efficiency at the apex seals—a critical factor in preventing combustion gas leakage that directly impacts fuel consumption.

Composite materials incorporating ceramic particles within metal matrices (cermet composites) show promise for apex seal applications. These materials combine the wear resistance of ceramics with the toughness of metals, addressing the historical weakness of apex seal durability while maintaining tight tolerances against the epitrochoid surface.

Thermal spray technologies have evolved to enable precise application of specialized coatings on internal engine surfaces. Plasma-sprayed molybdenum coatings on the trochoid surface have demonstrated a 15% reduction in friction losses while providing enhanced corrosion resistance against combustion byproducts.

Nano-engineered surface treatments represent the cutting edge of materials science application in Wankel engines. These treatments modify surface structures at the nanometer scale to create optimized oil retention patterns, reducing lubrication requirements while maintaining effective sealing—directly addressing one of the primary sources of fuel inefficiency in rotary engines.

The integration of these advanced materials must be approached holistically, considering not only individual component performance but also the interaction between different materials under varying thermal and mechanical stress conditions. Testing indicates that properly matched material combinations can yield fuel efficiency improvements of 8-12% compared to traditional Wankel engine designs, making materials science a critical pathway toward addressing the rotary engine's historical fuel consumption challenges.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!