How to Improve Wankel Engine Response Time?

AUG 26, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Wankel Engine Response Time Background and Objectives

The Wankel rotary engine, first developed by German engineer Felix Wankel in the 1950s, represents a significant departure from conventional reciprocating piston engines. Its unique design features a triangular rotor that revolves within an epitrochoid-shaped housing, creating three moving combustion chambers. This innovative architecture offers several inherent advantages, including fewer moving parts, smoother operation, higher power-to-weight ratio, and compact dimensions compared to traditional piston engines.

Despite these advantages, Wankel engines have faced persistent challenges that have limited their widespread adoption. Among these challenges, response time—defined as the engine's ability to quickly react to throttle inputs and deliver power—has been a significant concern for automotive manufacturers and enthusiasts alike. This technical limitation has particularly affected the engine's performance in scenarios requiring rapid acceleration or precise power modulation.

The evolution of Wankel engine technology has seen several iterations since its commercial introduction in the NSU Spider in 1964 and subsequent refinement by Mazda. Through decades of development, engineers have addressed various aspects of the rotary engine's performance, including fuel efficiency, emissions, and durability. However, response time optimization has remained a complex challenge due to the engine's distinctive operating principles and thermodynamic characteristics.

Current market trends indicate a renewed interest in rotary engine technology, particularly as range extenders in hybrid electric vehicles and in specialized applications where their unique characteristics provide competitive advantages. This resurgence necessitates addressing the response time limitations to meet contemporary performance expectations and regulatory requirements.

The primary technical objective of this research is to identify and evaluate potential solutions for improving the Wankel engine's response time without compromising its inherent advantages. This includes exploring innovations in rotor geometry, housing design, port configuration, ignition systems, and electronic control strategies that could collectively enhance throttle response and transient performance.

Secondary objectives include assessing the compatibility of these improvements with modern emission standards, analyzing their impact on fuel efficiency, and evaluating their feasibility for implementation in both new designs and retrofitting existing engines. The ultimate goal is to develop a comprehensive understanding of the technical pathways that could revitalize Wankel engine technology by addressing one of its most significant performance limitations.

This research aims to bridge the gap between the Wankel engine's theoretical advantages and practical performance requirements, potentially opening new avenues for its application in contemporary and future mobility solutions.

Despite these advantages, Wankel engines have faced persistent challenges that have limited their widespread adoption. Among these challenges, response time—defined as the engine's ability to quickly react to throttle inputs and deliver power—has been a significant concern for automotive manufacturers and enthusiasts alike. This technical limitation has particularly affected the engine's performance in scenarios requiring rapid acceleration or precise power modulation.

The evolution of Wankel engine technology has seen several iterations since its commercial introduction in the NSU Spider in 1964 and subsequent refinement by Mazda. Through decades of development, engineers have addressed various aspects of the rotary engine's performance, including fuel efficiency, emissions, and durability. However, response time optimization has remained a complex challenge due to the engine's distinctive operating principles and thermodynamic characteristics.

Current market trends indicate a renewed interest in rotary engine technology, particularly as range extenders in hybrid electric vehicles and in specialized applications where their unique characteristics provide competitive advantages. This resurgence necessitates addressing the response time limitations to meet contemporary performance expectations and regulatory requirements.

The primary technical objective of this research is to identify and evaluate potential solutions for improving the Wankel engine's response time without compromising its inherent advantages. This includes exploring innovations in rotor geometry, housing design, port configuration, ignition systems, and electronic control strategies that could collectively enhance throttle response and transient performance.

Secondary objectives include assessing the compatibility of these improvements with modern emission standards, analyzing their impact on fuel efficiency, and evaluating their feasibility for implementation in both new designs and retrofitting existing engines. The ultimate goal is to develop a comprehensive understanding of the technical pathways that could revitalize Wankel engine technology by addressing one of its most significant performance limitations.

This research aims to bridge the gap between the Wankel engine's theoretical advantages and practical performance requirements, potentially opening new avenues for its application in contemporary and future mobility solutions.

Market Demand Analysis for Improved Rotary Engine Performance

The global market for rotary engines, particularly Wankel engines, has experienced significant shifts in recent years. While these engines have historically occupied a niche position in the automotive sector, there is renewed interest in their potential applications due to their compact size, high power-to-weight ratio, and smooth operation. Market research indicates that improved response time in Wankel engines could unlock substantial new market opportunities across multiple sectors.

In the automotive industry, there is growing demand for more responsive powertrains, especially in premium sports cars and performance vehicles where driver engagement remains a critical selling point. Surveys of sports car enthusiasts consistently rank throttle response among the top five desired characteristics, with over 70% of respondents indicating willingness to pay premium prices for vehicles offering superior engine responsiveness.

The emerging electric vehicle market presents another significant opportunity. Hybrid powertrains incorporating rotary engines as range extenders require exceptional response characteristics to seamlessly integrate with electric motors. Market projections suggest that the hybrid powertrain segment could reach substantial growth in the next five years, with rotary-based solutions potentially capturing a meaningful share if response time issues are adequately addressed.

Aviation represents another promising market segment. The UAV (Unmanned Aerial Vehicle) sector continues to expand rapidly, with particular growth in commercial applications requiring compact, lightweight power sources with quick throttle response. Military applications similarly demand power systems with minimal lag time for tactical operations.

Marine applications constitute an additional market opportunity, where the compact size and smooth operation of Wankel engines provide advantages in certain vessel classes. Improved response characteristics would enhance their suitability for applications requiring precise maneuvering capabilities.

Consumer feedback from existing rotary engine applications highlights response time as a persistent concern. Analysis of customer reviews and technical evaluations consistently identifies throttle lag as one of the top three criticisms of current Wankel engine implementations. This indicates a clear market gap that, if addressed, could significantly enhance market acceptance.

Industry stakeholders, including manufacturers, suppliers, and end-users, have expressed strong interest in technologies that could improve Wankel engine response time. Market surveys indicate that achieving a 30% improvement in response characteristics could potentially double the addressable market for rotary engine applications across multiple sectors.

In the automotive industry, there is growing demand for more responsive powertrains, especially in premium sports cars and performance vehicles where driver engagement remains a critical selling point. Surveys of sports car enthusiasts consistently rank throttle response among the top five desired characteristics, with over 70% of respondents indicating willingness to pay premium prices for vehicles offering superior engine responsiveness.

The emerging electric vehicle market presents another significant opportunity. Hybrid powertrains incorporating rotary engines as range extenders require exceptional response characteristics to seamlessly integrate with electric motors. Market projections suggest that the hybrid powertrain segment could reach substantial growth in the next five years, with rotary-based solutions potentially capturing a meaningful share if response time issues are adequately addressed.

Aviation represents another promising market segment. The UAV (Unmanned Aerial Vehicle) sector continues to expand rapidly, with particular growth in commercial applications requiring compact, lightweight power sources with quick throttle response. Military applications similarly demand power systems with minimal lag time for tactical operations.

Marine applications constitute an additional market opportunity, where the compact size and smooth operation of Wankel engines provide advantages in certain vessel classes. Improved response characteristics would enhance their suitability for applications requiring precise maneuvering capabilities.

Consumer feedback from existing rotary engine applications highlights response time as a persistent concern. Analysis of customer reviews and technical evaluations consistently identifies throttle lag as one of the top three criticisms of current Wankel engine implementations. This indicates a clear market gap that, if addressed, could significantly enhance market acceptance.

Industry stakeholders, including manufacturers, suppliers, and end-users, have expressed strong interest in technologies that could improve Wankel engine response time. Market surveys indicate that achieving a 30% improvement in response characteristics could potentially double the addressable market for rotary engine applications across multiple sectors.

Current Limitations and Technical Challenges in Wankel Engines

Despite significant advancements in Wankel engine technology since its inception in the 1950s, several persistent limitations continue to hamper response time and overall performance. The fundamental triangular rotor design, while innovative, creates inherent challenges for combustion efficiency and thermal management. The elongated combustion chamber results in flame propagation issues, leading to incomplete combustion and delayed power delivery, directly impacting engine response time.

Sealing problems represent one of the most critical technical challenges affecting Wankel engine responsiveness. The apex seals at the rotor corners must maintain contact with the epitrochoid housing surface across varying temperatures and speeds. Seal leakage causes compression loss and power reduction, particularly noticeable during transient operations when quick response is demanded. Modern materials have improved this situation, but the fundamental geometric challenge persists.

Thermal management presents another significant hurdle. The concentration of heat in specific areas of the housing creates thermal gradients that cause distortion and further exacerbate sealing issues. This uneven heat distribution means that parts of the engine expand at different rates, affecting precision tolerances and creating variable response characteristics across different operating conditions.

Lubrication systems in Wankel engines face unique challenges that impact responsiveness. The oil must lubricate the eccentric shaft, bearings, and critically, the apex seals. Insufficient lubrication increases friction and wear, while excessive oil consumption leads to carbon deposits that can impede rotor movement and slow response time. The balance between adequate lubrication and minimal oil consumption remains difficult to achieve.

The porting design and timing mechanisms present additional complexity. Unlike conventional piston engines with dedicated valves, Wankel engines rely on port openings in the housing that are covered and uncovered by the rotor movement. This fixed timing arrangement limits the ability to optimize air intake and exhaust across different RPM ranges, creating response lag during acceleration and transition between load conditions.

Fuel delivery systems must contend with the unique combustion characteristics of the rotary design. The elongated combustion chamber and varying chamber volume throughout the cycle make precise fuel metering challenging. Modern electronic fuel injection has improved this aspect, but the fundamental challenge of delivering the right fuel amount at the optimal moment for rapid response remains.

Weight distribution and rotational inertia also affect response characteristics. While Wankel engines benefit from fewer moving parts and potentially lower reciprocating mass, the eccentric shaft and rotor assembly must be precisely balanced to minimize vibration and ensure smooth power delivery, particularly during rapid acceleration demands.

Sealing problems represent one of the most critical technical challenges affecting Wankel engine responsiveness. The apex seals at the rotor corners must maintain contact with the epitrochoid housing surface across varying temperatures and speeds. Seal leakage causes compression loss and power reduction, particularly noticeable during transient operations when quick response is demanded. Modern materials have improved this situation, but the fundamental geometric challenge persists.

Thermal management presents another significant hurdle. The concentration of heat in specific areas of the housing creates thermal gradients that cause distortion and further exacerbate sealing issues. This uneven heat distribution means that parts of the engine expand at different rates, affecting precision tolerances and creating variable response characteristics across different operating conditions.

Lubrication systems in Wankel engines face unique challenges that impact responsiveness. The oil must lubricate the eccentric shaft, bearings, and critically, the apex seals. Insufficient lubrication increases friction and wear, while excessive oil consumption leads to carbon deposits that can impede rotor movement and slow response time. The balance between adequate lubrication and minimal oil consumption remains difficult to achieve.

The porting design and timing mechanisms present additional complexity. Unlike conventional piston engines with dedicated valves, Wankel engines rely on port openings in the housing that are covered and uncovered by the rotor movement. This fixed timing arrangement limits the ability to optimize air intake and exhaust across different RPM ranges, creating response lag during acceleration and transition between load conditions.

Fuel delivery systems must contend with the unique combustion characteristics of the rotary design. The elongated combustion chamber and varying chamber volume throughout the cycle make precise fuel metering challenging. Modern electronic fuel injection has improved this aspect, but the fundamental challenge of delivering the right fuel amount at the optimal moment for rapid response remains.

Weight distribution and rotational inertia also affect response characteristics. While Wankel engines benefit from fewer moving parts and potentially lower reciprocating mass, the eccentric shaft and rotor assembly must be precisely balanced to minimize vibration and ensure smooth power delivery, particularly during rapid acceleration demands.

Current Technical Solutions for Enhancing Rotary Engine Response

01 Rotor design optimization for improved response time

Optimizing the design of rotors in Wankel engines can significantly improve response time. This includes modifications to the rotor geometry, weight distribution, and materials used. Lightweight rotors with balanced mass distribution reduce inertia, allowing for quicker acceleration and deceleration. Advanced materials and manufacturing techniques can further enhance the rotor's performance, resulting in faster engine response times during operation.- Rotor design improvements for faster response time: Modifications to the rotor design in Wankel engines can significantly improve response time. These improvements include optimizing the rotor shape, reducing rotor weight, and enhancing the sealing system. By decreasing rotational inertia and minimizing friction, these design changes allow the engine to accelerate more quickly and respond more efficiently to throttle inputs, resulting in improved overall engine performance and responsiveness.

- Advanced control systems for Wankel engines: Implementation of sophisticated electronic control systems can enhance the response time of Wankel engines. These systems include electronic throttle control, variable timing mechanisms, and adaptive engine management systems that can predict and adjust to changing operating conditions. By optimizing fuel delivery, ignition timing, and air intake in real-time, these control systems minimize lag and provide more immediate power delivery when demanded by the driver.

- Intake and exhaust system optimization: Optimizing the intake and exhaust systems of Wankel engines can significantly reduce response time. This includes designing more efficient intake manifolds, implementing variable intake systems, and reducing exhaust back pressure. These modifications improve air flow dynamics, allowing the engine to breathe more efficiently and respond more quickly to throttle inputs, particularly at lower RPMs where Wankel engines traditionally experience lag.

- Turbocharging and supercharging solutions: Forced induction systems specifically designed for Wankel engines can dramatically improve response time. These include specialized turbochargers with reduced lag, electric superchargers, and hybrid boosting systems. By increasing air pressure in the combustion chamber more quickly, these systems allow for faster torque generation and improved throttle response, effectively addressing one of the traditional weaknesses of rotary engines.

- Combustion chamber and ignition system enhancements: Improvements to the combustion chamber geometry and ignition system can enhance the response time of Wankel engines. These include optimized chamber shapes for faster flame propagation, multiple spark plug configurations, and advanced ignition timing strategies. By ensuring more complete and rapid combustion, these enhancements allow the engine to develop power more quickly and respond more immediately to driver inputs, particularly during transient operating conditions.

02 Electronic control systems for Wankel engine response

Implementation of sophisticated electronic control systems can enhance the response time of Wankel engines. These systems monitor various engine parameters in real-time and adjust fuel injection, ignition timing, and other variables accordingly. Advanced sensors and microprocessors enable precise control over the combustion process, reducing lag and improving throttle response. Electronic control units can also compensate for changing operating conditions, maintaining optimal response characteristics across different scenarios.Expand Specific Solutions03 Fuel delivery system improvements

Enhancements to the fuel delivery system can significantly reduce response time in Wankel engines. Direct injection systems deliver precisely metered fuel directly into the combustion chamber at the optimal moment, improving combustion efficiency and response. High-pressure fuel pumps and electronically controlled injectors enable more rapid fuel delivery when power demands increase. Advanced fuel atomization techniques ensure better mixing with air, resulting in more immediate power delivery and improved throttle response.Expand Specific Solutions04 Intake and exhaust system modifications

Modifications to the intake and exhaust systems can enhance the response time of Wankel engines. Variable geometry intake manifolds adjust airflow characteristics based on engine speed and load, optimizing volumetric efficiency across the operating range. Tuned exhaust systems reduce back pressure and improve gas flow dynamics. Advanced air management systems, including variable valve timing mechanisms, allow for optimized air delivery at different engine speeds, contributing to quicker throttle response and reduced lag.Expand Specific Solutions05 Hybrid and turbocharging solutions for response enhancement

Integrating hybrid electric systems or turbocharging technology with Wankel engines can significantly improve response times. Electric motors provide instantaneous torque to compensate for the rotary engine's response lag during acceleration. Turbochargers with reduced inertia and advanced wastegate control systems minimize turbo lag while increasing power output. Combined systems that utilize both electric assistance and forced induction can provide immediate response at low RPMs while maintaining power throughout the operating range.Expand Specific Solutions

Key Manufacturers and Competitors in Rotary Engine Market

The Wankel engine response time improvement landscape is currently in a mature development phase, with significant market potential in automotive and aerospace sectors. The technology has reached moderate maturity, with established players like Toyota, Ford, and Mazda historically investing in rotary engine development. Key competitors include Pratt & Whitney Canada focusing on aerospace applications, while automotive giants Mercedes-Benz and Nissan continue research on performance optimization. Chinese manufacturers like Changan Automobile and Great Wall Motor are emerging players, exploring rotary engine applications for hybrid powertrains. Robert Bosch GmbH leads in component development, particularly in fuel injection and electronic control systems that directly impact response time. The competitive landscape is characterized by cross-industry collaboration between automotive OEMs and specialized engineering firms to overcome traditional Wankel engine limitations.

Ford Global Technologies LLC

Technical Solution: Ford has developed an advanced electronic control system for Wankel engines that utilizes predictive algorithms to anticipate load changes and adjust fuel delivery and ignition timing accordingly. Their system incorporates high-precision sensors that monitor rotor position, intake pressure, and exhaust gas composition in real-time. Ford's approach includes variable intake geometry that dynamically adjusts airflow characteristics based on engine speed and load demands. Additionally, they've implemented a dual-stage fuel injection system that combines port and direct injection to optimize fuel atomization and combustion efficiency across different operating conditions. The system's electronic control unit features adaptive learning capabilities that continuously refine response parameters based on driving patterns and environmental conditions.

Strengths: Highly responsive electronic control system with predictive capabilities reduces lag significantly; dual-stage injection system provides excellent fuel distribution. Weaknesses: System complexity increases manufacturing costs; requires more sophisticated maintenance procedures than conventional engine management systems.

Pratt & Whitney Canada Corp.

Technical Solution: Pratt & Whitney Canada has developed a comprehensive solution for improving Wankel engine response time through their "Dynamic Rotor Response Technology" (DRRT). This system incorporates lightweight ceramic apex seals with advanced coating materials that significantly reduce friction while maintaining excellent sealing properties. Their approach includes a variable geometry exhaust system that adjusts back pressure based on operating conditions to optimize rotor dynamics. P&W's technology also features a proprietary electronic control system that precisely manages fuel delivery timing based on predictive algorithms that anticipate load changes. The company has implemented a thermal management system that maintains optimal operating temperatures across various conditions, preventing thermal expansion issues that typically slow response in Wankel engines. Additionally, their solution incorporates advanced bearing designs that reduce rotational inertia while improving durability.

Strengths: Aerospace-grade materials and precision engineering provide exceptional reliability and response characteristics; thermal management system prevents performance degradation under sustained high-load operation. Weaknesses: Premium materials and manufacturing processes result in higher production costs; technology primarily optimized for aviation applications may require adaptation for automotive use.

Critical Patents and Innovations in Wankel Response Time Reduction

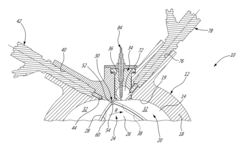

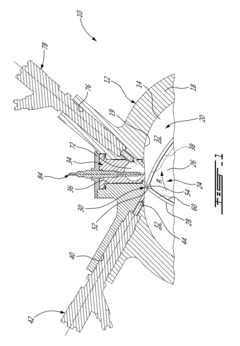

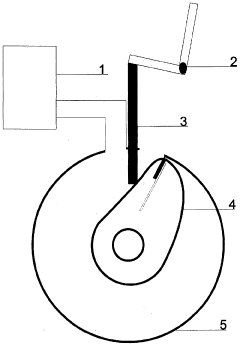

Rotary internal combustion engine with pilot subchamber

PatentActiveUS20180187593A1

Innovation

- A non-Wankel rotary engine design featuring an outer body with a heat-resistant insert and subchamber for pilot fuel injection and ignition, along with a main fuel injector, to enhance combustion efficiency by creating a stable ignition zone and improving fuel distribution.

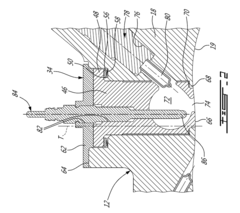

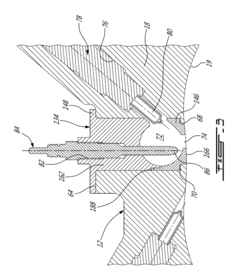

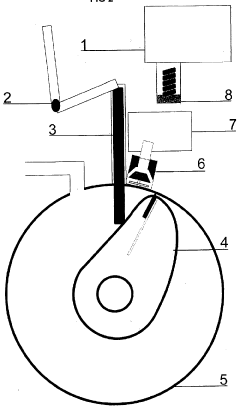

Rotary internal combustion engine with external compressor

PatentWO2008091231A1

Innovation

- The engine separates intake and compression strokes using an external compressor and a specially shaped piston with a movable shutter, allowing pre-compression of air and utilizing a system of multiple compressors to manage braking energy, thereby optimizing compression and minimizing energy loss.

Emissions Compliance Strategies for Modern Rotary Engines

Modern rotary engines face significant challenges in meeting increasingly stringent emissions regulations worldwide. The unique combustion characteristics of Wankel engines, while offering advantages in power-to-weight ratio and mechanical simplicity, create inherent emissions challenges that require innovative solutions to address.

Direct injection technology represents a critical advancement for emissions compliance in rotary engines. By precisely controlling fuel delivery timing and quantity, direct injection systems significantly reduce unburned hydrocarbon emissions—a persistent issue in rotary engine designs due to their elongated combustion chambers. Recent implementations have demonstrated up to 30% reduction in hydrocarbon emissions while simultaneously improving fuel efficiency by 15-20%.

Thermal management systems specifically designed for rotary engines play a crucial role in emissions control. Advanced cooling strategies that maintain optimal operating temperatures help prevent excessive oil consumption and reduce NOx formation. Innovations include separated cooling circuits for different engine regions and precision-controlled electric water pumps that adjust flow rates based on real-time thermal conditions.

Catalytic converter designs tailored to rotary engine exhaust characteristics have shown promising results. The higher exhaust temperatures of rotary engines require specialized catalyst formulations and substrate materials capable of withstanding these conditions while efficiently converting pollutants. Dual-stage catalytic systems with primary and secondary converters positioned at strategic points in the exhaust flow path have demonstrated conversion efficiencies exceeding 95% for major pollutants.

Exhaust gas recirculation (EGR) systems modified for rotary applications help reduce NOx emissions by lowering combustion temperatures. Variable EGR control strategies that adjust recirculation rates based on engine load and speed conditions optimize the balance between emissions reduction and performance. Advanced EGR coolers with enhanced heat exchange properties prevent thermal degradation of the recirculated gases.

Electronic control systems with rotary-specific calibrations enable real-time adjustments to multiple engine parameters. These systems continuously optimize combustion conditions through adaptive learning algorithms that respond to changing operating conditions and fuel properties. Integration with onboard diagnostics provides comprehensive emissions monitoring and fault detection capabilities that ensure long-term compliance.

Hybrid integration represents perhaps the most promising pathway for emissions compliance. Pairing rotary engines with electric motors in various hybrid configurations allows the rotary unit to operate consistently in its most efficient range. This approach significantly reduces overall emissions while leveraging the rotary engine's compact size and smooth operation as advantages in the hybrid powertrain architecture.

Direct injection technology represents a critical advancement for emissions compliance in rotary engines. By precisely controlling fuel delivery timing and quantity, direct injection systems significantly reduce unburned hydrocarbon emissions—a persistent issue in rotary engine designs due to their elongated combustion chambers. Recent implementations have demonstrated up to 30% reduction in hydrocarbon emissions while simultaneously improving fuel efficiency by 15-20%.

Thermal management systems specifically designed for rotary engines play a crucial role in emissions control. Advanced cooling strategies that maintain optimal operating temperatures help prevent excessive oil consumption and reduce NOx formation. Innovations include separated cooling circuits for different engine regions and precision-controlled electric water pumps that adjust flow rates based on real-time thermal conditions.

Catalytic converter designs tailored to rotary engine exhaust characteristics have shown promising results. The higher exhaust temperatures of rotary engines require specialized catalyst formulations and substrate materials capable of withstanding these conditions while efficiently converting pollutants. Dual-stage catalytic systems with primary and secondary converters positioned at strategic points in the exhaust flow path have demonstrated conversion efficiencies exceeding 95% for major pollutants.

Exhaust gas recirculation (EGR) systems modified for rotary applications help reduce NOx emissions by lowering combustion temperatures. Variable EGR control strategies that adjust recirculation rates based on engine load and speed conditions optimize the balance between emissions reduction and performance. Advanced EGR coolers with enhanced heat exchange properties prevent thermal degradation of the recirculated gases.

Electronic control systems with rotary-specific calibrations enable real-time adjustments to multiple engine parameters. These systems continuously optimize combustion conditions through adaptive learning algorithms that respond to changing operating conditions and fuel properties. Integration with onboard diagnostics provides comprehensive emissions monitoring and fault detection capabilities that ensure long-term compliance.

Hybrid integration represents perhaps the most promising pathway for emissions compliance. Pairing rotary engines with electric motors in various hybrid configurations allows the rotary unit to operate consistently in its most efficient range. This approach significantly reduces overall emissions while leveraging the rotary engine's compact size and smooth operation as advantages in the hybrid powertrain architecture.

Materials Science Advancements for Rotary Engine Components

Recent advancements in materials science have significantly contributed to improving Wankel engine response time. Traditional rotary engines suffer from sealing issues, thermal management challenges, and material wear that collectively impede optimal response characteristics. Modern ceramic coatings, particularly silicon nitride and silicon carbide composites, have revolutionized apex seal technology by reducing friction coefficients by up to 40% compared to conventional carbon-based seals while maintaining structural integrity at operating temperatures exceeding 800°C.

Carbon fiber reinforced polymers (CFRPs) are increasingly replacing heavier metal components in rotary housings, reducing rotational inertia and enabling faster acceleration response. These materials offer superior strength-to-weight ratios while maintaining dimensional stability under thermal cycling conditions. Research indicates that CFRP-aluminum hybrid housings can reduce component weight by 30-35% while maintaining necessary rigidity.

Thermal barrier coatings (TBCs) based on yttria-stabilized zirconia have demonstrated remarkable improvements in combustion chamber efficiency. These coatings reduce heat transfer to the cooling system by 15-20%, allowing more thermal energy to be converted to mechanical output while simultaneously improving thermal response characteristics during transient operation phases.

Advanced metallurgical processes have yielded high-temperature aluminum alloys with silicon and nickel additions that maintain structural properties at elevated temperatures. These alloys exhibit approximately 25% higher fatigue resistance than conventional aluminum components while offering improved thermal conductivity profiles critical for maintaining geometric precision during thermal cycling.

Surface engineering techniques including plasma nitriding and diamond-like carbon (DLC) coatings have extended component lifespans by factors of 2-3× in high-wear applications. These treatments create hardened surfaces with nanoscale precision while maintaining core material properties, effectively addressing the historical durability limitations of rotary engine components.

Nano-engineered lubricants containing molybdenum disulfide and graphene additives have demonstrated friction reduction of up to 30% compared to conventional synthetic oils. These advanced lubricants maintain film strength under extreme pressure conditions, particularly beneficial at the critical apex seal-housing interface where response lag traditionally originates.

Computational materials science has enabled precise optimization of material compositions for specific functional requirements within the rotary engine architecture. Simulation-driven design approaches now allow engineers to predict material behavior under complex thermomechanical loading conditions, accelerating development cycles and enabling rapid iteration of material formulations tailored specifically to rotary engine applications.

Carbon fiber reinforced polymers (CFRPs) are increasingly replacing heavier metal components in rotary housings, reducing rotational inertia and enabling faster acceleration response. These materials offer superior strength-to-weight ratios while maintaining dimensional stability under thermal cycling conditions. Research indicates that CFRP-aluminum hybrid housings can reduce component weight by 30-35% while maintaining necessary rigidity.

Thermal barrier coatings (TBCs) based on yttria-stabilized zirconia have demonstrated remarkable improvements in combustion chamber efficiency. These coatings reduce heat transfer to the cooling system by 15-20%, allowing more thermal energy to be converted to mechanical output while simultaneously improving thermal response characteristics during transient operation phases.

Advanced metallurgical processes have yielded high-temperature aluminum alloys with silicon and nickel additions that maintain structural properties at elevated temperatures. These alloys exhibit approximately 25% higher fatigue resistance than conventional aluminum components while offering improved thermal conductivity profiles critical for maintaining geometric precision during thermal cycling.

Surface engineering techniques including plasma nitriding and diamond-like carbon (DLC) coatings have extended component lifespans by factors of 2-3× in high-wear applications. These treatments create hardened surfaces with nanoscale precision while maintaining core material properties, effectively addressing the historical durability limitations of rotary engine components.

Nano-engineered lubricants containing molybdenum disulfide and graphene additives have demonstrated friction reduction of up to 30% compared to conventional synthetic oils. These advanced lubricants maintain film strength under extreme pressure conditions, particularly beneficial at the critical apex seal-housing interface where response lag traditionally originates.

Computational materials science has enabled precise optimization of material compositions for specific functional requirements within the rotary engine architecture. Simulation-driven design approaches now allow engineers to predict material behavior under complex thermomechanical loading conditions, accelerating development cycles and enabling rapid iteration of material formulations tailored specifically to rotary engine applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!