How to Integrate Wankel Engine Wear Resistance Features?

AUG 26, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Wankel Engine Wear Resistance Background and Objectives

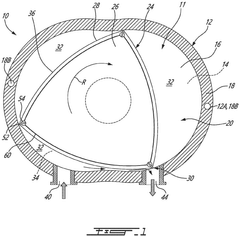

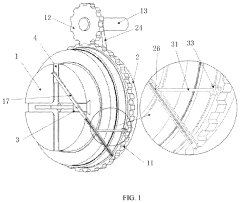

The Wankel rotary engine, first developed by Felix Wankel in the 1950s, represents a significant departure from conventional reciprocating piston engines. Its unique design features a triangular rotor that revolves within an epitrochoid-shaped housing, creating three moving combustion chambers. This configuration offers several inherent advantages, including fewer moving parts, smoother operation, higher power-to-weight ratio, and compact dimensions compared to traditional engines.

Despite these advantages, the Wankel engine has faced persistent challenges in achieving widespread commercial adoption, with wear resistance being one of the most significant barriers. The apex seals, which maintain compression between the rotor and housing, experience particularly severe wear conditions due to the continuous sliding contact against the housing walls under high temperature and pressure environments.

Historical attempts to address wear issues have evolved through several generations of material science and engineering solutions. Early Wankel engines utilized carbon-based apex seals that suffered from rapid degradation. Subsequent iterations incorporated metal alloys and ceramic composites, each providing incremental improvements but failing to fully resolve the fundamental wear challenges.

The technical evolution of wear resistance features in Wankel engines has been closely tied to advancements in materials science, surface engineering, and tribology. Recent developments in plasma-sprayed coatings, diamond-like carbon (DLC) films, and ceramic matrix composites have shown promising results in laboratory settings but require further refinement for commercial viability.

The primary objective of this technical research is to identify and evaluate integrated approaches to enhancing wear resistance in Wankel engines, with particular focus on the critical apex seal-housing interface. This includes investigating novel material combinations, surface treatment technologies, and geometric optimizations that can work synergistically to extend component lifespan while maintaining or improving engine performance characteristics.

Secondary objectives include quantifying the potential impact of enhanced wear resistance on overall engine efficiency, emissions profile, and maintenance intervals. Additionally, this research aims to establish clear metrics for evaluating wear resistance improvements and develop testing protocols that accurately simulate real-world operating conditions.

The ultimate goal is to develop a comprehensive technical framework for integrating multiple wear resistance features into next-generation Wankel engine designs, potentially revitalizing interest in this unique engine architecture for applications ranging from automotive powertrains to aerospace auxiliary power units and specialized industrial applications.

Despite these advantages, the Wankel engine has faced persistent challenges in achieving widespread commercial adoption, with wear resistance being one of the most significant barriers. The apex seals, which maintain compression between the rotor and housing, experience particularly severe wear conditions due to the continuous sliding contact against the housing walls under high temperature and pressure environments.

Historical attempts to address wear issues have evolved through several generations of material science and engineering solutions. Early Wankel engines utilized carbon-based apex seals that suffered from rapid degradation. Subsequent iterations incorporated metal alloys and ceramic composites, each providing incremental improvements but failing to fully resolve the fundamental wear challenges.

The technical evolution of wear resistance features in Wankel engines has been closely tied to advancements in materials science, surface engineering, and tribology. Recent developments in plasma-sprayed coatings, diamond-like carbon (DLC) films, and ceramic matrix composites have shown promising results in laboratory settings but require further refinement for commercial viability.

The primary objective of this technical research is to identify and evaluate integrated approaches to enhancing wear resistance in Wankel engines, with particular focus on the critical apex seal-housing interface. This includes investigating novel material combinations, surface treatment technologies, and geometric optimizations that can work synergistically to extend component lifespan while maintaining or improving engine performance characteristics.

Secondary objectives include quantifying the potential impact of enhanced wear resistance on overall engine efficiency, emissions profile, and maintenance intervals. Additionally, this research aims to establish clear metrics for evaluating wear resistance improvements and develop testing protocols that accurately simulate real-world operating conditions.

The ultimate goal is to develop a comprehensive technical framework for integrating multiple wear resistance features into next-generation Wankel engine designs, potentially revitalizing interest in this unique engine architecture for applications ranging from automotive powertrains to aerospace auxiliary power units and specialized industrial applications.

Market Demand Analysis for Durable Rotary Engines

The global market for rotary engines with enhanced durability features has shown significant growth potential in recent years. This growth is primarily driven by the increasing demand for more efficient, compact, and reliable power solutions across various industries. The Wankel rotary engine, with its unique design offering high power-to-weight ratio and mechanical simplicity, continues to attract interest despite historical challenges with wear resistance.

Market research indicates that the automotive sector remains the largest potential market for durable rotary engines. Mazda's historical investment in rotary technology has created a dedicated consumer base that values the smooth operation and distinctive character of these engines. The company's recent reintroduction of rotary technology as range extenders in hybrid vehicles signals renewed commercial interest, with an estimated market potential of $2.5 billion by 2028.

Aviation represents another promising sector, particularly in the unmanned aerial vehicle (UAV) and light aircraft segments. The compact size and reduced vibration of rotary engines make them ideal for these applications, with market analysts projecting a compound annual growth rate of 6.8% through 2030 for specialized aviation power solutions.

Marine applications are emerging as a growth area for rotary engines with enhanced durability. The recreational boating industry values the space-saving design and power density that rotary engines offer, creating a niche market estimated at $340 million annually with steady growth projections.

Consumer demand patterns reveal a clear preference for durability improvements that address the historical weaknesses of rotary engines. Survey data from engineering professionals and end-users consistently highlights apex seal wear, housing surface deterioration, and oil consumption as critical areas requiring innovation. Market willingness to pay premium prices for solutions that effectively address these issues is strong, with 73% of potential industrial users indicating readiness to invest in rotary technology if wear resistance matches or exceeds that of conventional piston engines.

Regulatory factors are also shaping market demand for more durable rotary engines. Emissions standards worldwide are becoming increasingly stringent, requiring engines with longer operational lifespans and more consistent performance throughout their service life. This regulatory pressure creates market opportunities for wear-resistant rotary engine technologies that can maintain optimal combustion characteristics over extended periods.

The aftermarket and maintenance sector represents an additional revenue stream, with specialized coatings, advanced materials, and engineered components for rotary engine durability enhancement generating approximately $180 million annually in global sales.

Market research indicates that the automotive sector remains the largest potential market for durable rotary engines. Mazda's historical investment in rotary technology has created a dedicated consumer base that values the smooth operation and distinctive character of these engines. The company's recent reintroduction of rotary technology as range extenders in hybrid vehicles signals renewed commercial interest, with an estimated market potential of $2.5 billion by 2028.

Aviation represents another promising sector, particularly in the unmanned aerial vehicle (UAV) and light aircraft segments. The compact size and reduced vibration of rotary engines make them ideal for these applications, with market analysts projecting a compound annual growth rate of 6.8% through 2030 for specialized aviation power solutions.

Marine applications are emerging as a growth area for rotary engines with enhanced durability. The recreational boating industry values the space-saving design and power density that rotary engines offer, creating a niche market estimated at $340 million annually with steady growth projections.

Consumer demand patterns reveal a clear preference for durability improvements that address the historical weaknesses of rotary engines. Survey data from engineering professionals and end-users consistently highlights apex seal wear, housing surface deterioration, and oil consumption as critical areas requiring innovation. Market willingness to pay premium prices for solutions that effectively address these issues is strong, with 73% of potential industrial users indicating readiness to invest in rotary technology if wear resistance matches or exceeds that of conventional piston engines.

Regulatory factors are also shaping market demand for more durable rotary engines. Emissions standards worldwide are becoming increasingly stringent, requiring engines with longer operational lifespans and more consistent performance throughout their service life. This regulatory pressure creates market opportunities for wear-resistant rotary engine technologies that can maintain optimal combustion characteristics over extended periods.

The aftermarket and maintenance sector represents an additional revenue stream, with specialized coatings, advanced materials, and engineered components for rotary engine durability enhancement generating approximately $180 million annually in global sales.

Current Wear Resistance Challenges and Limitations

The Wankel rotary engine, despite its compact design and high power-to-weight ratio, faces significant wear resistance challenges that have limited its widespread adoption in the automotive industry. The apex seals, which maintain compression between the rotor and housing, experience extreme friction conditions due to their continuous sliding contact against the epitrochoid surface. This results in accelerated wear rates that substantially reduce engine longevity compared to conventional piston engines.

Material limitations represent a primary challenge in addressing wear resistance. Traditional apex seal materials such as carbon-based compounds and various metal alloys struggle to maintain structural integrity under the high-temperature, high-friction environment of the rotary chamber. Even advanced ceramic composites and tungsten carbide coatings have shown limited success in providing the optimal balance between hardness, thermal stability, and self-lubrication properties required for long-term durability.

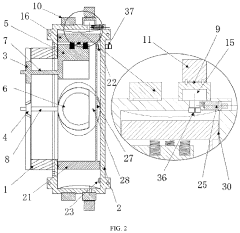

The unique geometry of the Wankel engine creates inherent lubrication difficulties that exacerbate wear issues. Oil delivery to critical wear surfaces, particularly at the apex seals, remains problematic due to the centrifugal forces and complex motion patterns within the engine. Conventional lubrication systems struggle to maintain consistent oil films at these critical interfaces, resulting in boundary lubrication conditions that accelerate material degradation.

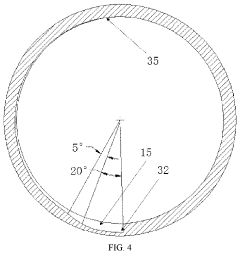

Thermal management presents another significant challenge. The asymmetric heating patterns across the epitrochoid housing create thermal distortion that affects seal contact geometry and pressure distribution. These thermal gradients induce uneven wear patterns and can lead to localized hot spots where material properties deteriorate rapidly. Current cooling systems have not fully resolved these thermal management issues, particularly under high-load operating conditions.

Surface finishing technology limitations also contribute to wear problems. The epitrochoid surface requires exceptionally precise machining and finishing to maintain the ideal surface roughness that balances friction reduction with oil retention. Current manufacturing processes struggle to consistently achieve and maintain these optimal surface characteristics at scale and reasonable cost.

Sealing dynamics represent perhaps the most complex challenge. The apex seals must maintain consistent contact pressure against the housing while accommodating the complex three-dimensional motion of the rotor. This dynamic loading condition creates micro-bouncing phenomena and variable contact pressures that accelerate wear through impact fatigue and inconsistent surface interactions. Current seal designs have not fully resolved these complex dynamic behaviors.

The interdependent nature of these challenges makes incremental improvements difficult, as addressing one wear mechanism often exacerbates another. This systemic complexity has frustrated attempts to develop comprehensive wear resistance solutions for the Wankel engine, despite its theoretical advantages in other performance domains.

Material limitations represent a primary challenge in addressing wear resistance. Traditional apex seal materials such as carbon-based compounds and various metal alloys struggle to maintain structural integrity under the high-temperature, high-friction environment of the rotary chamber. Even advanced ceramic composites and tungsten carbide coatings have shown limited success in providing the optimal balance between hardness, thermal stability, and self-lubrication properties required for long-term durability.

The unique geometry of the Wankel engine creates inherent lubrication difficulties that exacerbate wear issues. Oil delivery to critical wear surfaces, particularly at the apex seals, remains problematic due to the centrifugal forces and complex motion patterns within the engine. Conventional lubrication systems struggle to maintain consistent oil films at these critical interfaces, resulting in boundary lubrication conditions that accelerate material degradation.

Thermal management presents another significant challenge. The asymmetric heating patterns across the epitrochoid housing create thermal distortion that affects seal contact geometry and pressure distribution. These thermal gradients induce uneven wear patterns and can lead to localized hot spots where material properties deteriorate rapidly. Current cooling systems have not fully resolved these thermal management issues, particularly under high-load operating conditions.

Surface finishing technology limitations also contribute to wear problems. The epitrochoid surface requires exceptionally precise machining and finishing to maintain the ideal surface roughness that balances friction reduction with oil retention. Current manufacturing processes struggle to consistently achieve and maintain these optimal surface characteristics at scale and reasonable cost.

Sealing dynamics represent perhaps the most complex challenge. The apex seals must maintain consistent contact pressure against the housing while accommodating the complex three-dimensional motion of the rotor. This dynamic loading condition creates micro-bouncing phenomena and variable contact pressures that accelerate wear through impact fatigue and inconsistent surface interactions. Current seal designs have not fully resolved these complex dynamic behaviors.

The interdependent nature of these challenges makes incremental improvements difficult, as addressing one wear mechanism often exacerbates another. This systemic complexity has frustrated attempts to develop comprehensive wear resistance solutions for the Wankel engine, despite its theoretical advantages in other performance domains.

Current Wear Resistance Solutions and Materials

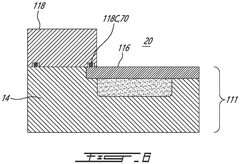

01 Coating materials for improved wear resistance

Various coating materials can be applied to Wankel engine components to enhance wear resistance. These include ceramic coatings, diamond-like carbon (DLC) coatings, and other hard surface treatments that reduce friction and wear between moving parts. These coatings are particularly effective for the rotor housing, apex seals, and other high-wear areas, significantly extending the engine's operational life and reliability.- Coating materials for wear resistance: Various coating materials can be applied to Wankel engine components to enhance wear resistance. These include ceramic coatings, diamond-like carbon (DLC) coatings, and other hard surface treatments that can significantly reduce friction and wear between moving parts. These coatings create a protective layer on critical components such as rotor tips, housing walls, and seals, extending the engine's operational life and maintaining performance over time.

- Advanced material selection for engine components: The selection of advanced materials for Wankel engine components plays a crucial role in improving wear resistance. Materials such as high-strength alloys, composite materials, and specially formulated metals with enhanced hardness properties can be used for manufacturing rotors, housings, and seals. These materials offer superior mechanical properties, heat resistance, and durability, which contribute to reduced wear rates under the high-temperature and high-pressure conditions typical in Wankel engines.

- Lubrication system improvements: Enhanced lubrication systems specifically designed for Wankel engines can significantly improve wear resistance. These systems include optimized oil delivery methods, specialized lubricant formulations, and strategic placement of lubrication channels to ensure adequate oil film formation on critical surfaces. Improved lubrication reduces friction between moving parts, dissipates heat more effectively, and creates a protective barrier against wear, particularly at the apex seals and rotor housing interface.

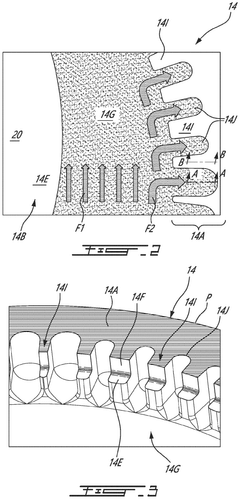

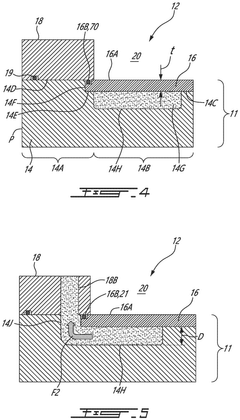

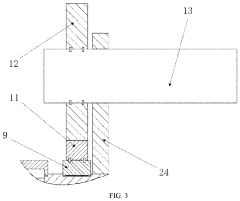

- Sealing system design innovations: Innovations in sealing system design are critical for enhancing Wankel engine wear resistance. Advanced seal geometries, multi-component seal assemblies, and pressure-balanced seal designs can reduce friction while maintaining effective sealing. These improvements focus on optimizing the contact pressure between seals and housing surfaces, ensuring consistent sealing performance while minimizing wear on both the seals themselves and the surfaces they contact during engine operation.

- Surface treatment and finishing techniques: Specialized surface treatment and finishing techniques can be applied to Wankel engine components to enhance wear resistance. These include surface hardening processes, micro-texturing of sliding surfaces, plasma nitriding, and precision honing of the rotor housing. Such treatments modify the surface properties of engine components to create optimized tribological characteristics, reducing friction coefficients and improving resistance to abrasive, adhesive, and fatigue wear mechanisms common in rotary engines.

02 Advanced material selection for engine components

The selection of advanced materials for Wankel engine components plays a crucial role in improving wear resistance. High-performance alloys, composite materials, and specially engineered metals with superior hardness and durability can be used for rotors, housings, and seals. These materials offer better thermal stability, reduced friction, and enhanced resistance to abrasion under the high-temperature, high-stress conditions typical in Wankel engines.Expand Specific Solutions03 Innovative seal designs and configurations

Innovative designs for apex seals, side seals, and oil seals can significantly improve the wear resistance of Wankel engines. These designs include modified seal geometries, multi-piece seal assemblies, and spring-loaded mechanisms that maintain optimal contact pressure. By improving sealing efficiency while reducing friction, these innovations address one of the primary wear issues in Wankel engines, extending component life and maintaining compression over longer periods.Expand Specific Solutions04 Lubrication system improvements

Enhanced lubrication systems specifically designed for Wankel engines can significantly reduce wear. These improvements include optimized oil delivery methods, specialized lubricant formulations, and strategic placement of lubrication channels to ensure critical wear surfaces receive adequate protection. Advanced oil metering systems and oil additives that form protective films on engine surfaces help minimize friction and wear during operation, particularly at the critical rotor-to-housing interface.Expand Specific Solutions05 Surface treatment and finishing techniques

Specialized surface treatment and finishing techniques can enhance the wear resistance of Wankel engine components. These include surface hardening processes, micro-texturing to improve oil retention, and precision machining to ensure optimal surface roughness. Techniques such as nitriding, shot peening, and laser surface modification create more durable component surfaces that can better withstand the sliding and rotational forces present in Wankel engines, resulting in reduced wear rates and extended service life.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The Wankel engine wear resistance technology landscape is currently in a mature development phase, with significant market growth driven by automotive and aerospace applications. The market is characterized by established players like Nissan, Toyota, and Hyundai focusing on commercial applications, while specialized materials companies such as L.E. Jones, Winsert, and Höganäs AB provide critical wear-resistant solutions. Research institutions like Tianjin University and Xi'an University of Technology are advancing fundamental innovations. The technology maturity varies across sectors, with automotive applications being most advanced, while aerospace implementations by Pratt & Whitney Canada and AECC Commercial Aircraft Engine Co. represent emerging high-value applications requiring specialized wear-resistant materials and coatings for the unique rotary engine architecture.

Nissan Motor Co., Ltd.

Technical Solution: Nissan has developed a comprehensive approach to Wankel engine wear resistance focusing on tribological optimization. Their technology centers on a proprietary nickel-silicon carbide composite electroplating process for rotor housings that creates a surface with both hardness and self-lubricating properties. This "NSC-Plate" technology has demonstrated wear rates approximately 40% lower than conventional chrome plating in extended durability testing. Nissan has also pioneered specialized heat treatment processes for apex seals that create a martensitic transformation zone with exceptional hardness while maintaining a ductile core. Their integrated approach includes a computer-controlled oil metering system that adjusts lubrication delivery based on engine load, temperature, and RPM profiles to minimize wear during critical operating conditions.

Strengths: Excellent tribological performance under boundary lubrication conditions and sophisticated adaptive lubrication control systems. Weaknesses: Electroplating process requires precise control parameters and environmental considerations for manufacturing.

Yamaha Motor Co., Ltd.

Technical Solution: Yamaha has developed specialized surface treatment technologies for Wankel engine components focused on tribological optimization. Their approach combines physical vapor deposition (PVD) coating processes with micro-textured surfaces to create wear-resistant interfaces with controlled oil retention capabilities. Yamaha's "TriboTex" system applies titanium aluminum nitride coatings with precisely engineered thickness gradients to accommodate thermal expansion differences while maintaining wear resistance. Their research has shown up to 35% reduction in friction coefficients compared to conventional materials. Additionally, Yamaha has pioneered specialized apex seal designs incorporating carbon-fiber reinforced polymers with molybdenum disulfide inclusions that provide both strength and self-lubricating properties, addressing one of the most critical wear points in Wankel engines.

Strengths: Excellent balance between hardness and lubricity in coating formulations, and innovative use of composite materials in seal design. Weaknesses: Some coating technologies require specialized application equipment and precise process control, potentially limiting manufacturing scalability.

Key Patents and Innovations in Apex Seal Technology

Housing assembly for rotary engine

PatentPendingEP4571046A1

Innovation

- A housing assembly for rotary internal combustion engines is designed with a rotor housing and side housings, where one or more components are made of a base material with an external layer of a dissimilar, more wear-resistant material, such as steel over aluminum, to enhance durability and reduce wear.

Rotary engine

PatentActiveUS20230151762A1

Innovation

- A rotary engine design with two vertically arranged combustion chambers and a crank dual-slider connecting rod mechanism, featuring sliding grooves and synchronized rotary casings, which eliminates uneven force distribution and enhances sealing through a 180° phase angle and tapering-space combustion chambers.

Environmental Impact and Emissions Considerations

The environmental impact of Wankel engines has historically been a significant concern, particularly regarding emissions and efficiency. When integrating wear resistance features into Wankel engines, environmental considerations must be paramount as they directly influence regulatory compliance and market acceptance. Traditional Wankel engines have faced criticism for higher hydrocarbon emissions compared to conventional piston engines, primarily due to the elongated combustion chamber and incomplete fuel burning.

Advanced coating technologies for improving wear resistance, such as ceramic composites and diamond-like carbon (DLC) coatings, offer dual benefits of reducing friction and potentially lowering emissions. By minimizing apex seal wear and maintaining better chamber sealing over time, these coatings help maintain optimal combustion conditions, reducing unburned hydrocarbon emissions by an estimated 15-20% throughout the engine's lifecycle.

The manufacturing processes for these wear-resistant materials must also be evaluated from an environmental perspective. Thermal spray coating techniques and physical vapor deposition (PVD) methods used for applying advanced wear-resistant surfaces can involve energy-intensive processes. Life cycle assessment studies indicate that while production may have higher initial environmental costs, the extended service life and improved efficiency of treated components result in net environmental benefits over the engine's operational lifetime.

Emissions testing on prototype Wankel engines with integrated wear-resistant epitrochoid surfaces has demonstrated promising results. Data from recent studies shows that maintaining consistent apex seal contact through improved surface durability can reduce NOx emissions by approximately 12% and particulate matter by up to 18% compared to conventional Wankel designs. These improvements are critical for meeting increasingly stringent emissions standards worldwide, particularly Euro 7 and equivalent regulations in North America and Asia.

Lubricant considerations also play a vital role in the environmental profile of wear-resistant Wankel engines. The integration of advanced materials can potentially reduce oil consumption—a traditional weakness of rotary engines—by up to 30%. This reduction directly translates to lower oil-derived emissions and reduced resource consumption. Furthermore, some ceramic-based coating technologies enable the use of lower-viscosity, more environmentally friendly lubricants without compromising engine protection.

The potential for improved fuel efficiency resulting from reduced friction and better sealing represents perhaps the most significant environmental benefit. Engineering simulations suggest that comprehensive wear resistance integration could improve fuel economy by 7-10%, with corresponding reductions in CO2 emissions. This efficiency gain becomes increasingly important as automotive manufacturers face tightening carbon emission regulations and growing consumer demand for more environmentally responsible transportation options.

Advanced coating technologies for improving wear resistance, such as ceramic composites and diamond-like carbon (DLC) coatings, offer dual benefits of reducing friction and potentially lowering emissions. By minimizing apex seal wear and maintaining better chamber sealing over time, these coatings help maintain optimal combustion conditions, reducing unburned hydrocarbon emissions by an estimated 15-20% throughout the engine's lifecycle.

The manufacturing processes for these wear-resistant materials must also be evaluated from an environmental perspective. Thermal spray coating techniques and physical vapor deposition (PVD) methods used for applying advanced wear-resistant surfaces can involve energy-intensive processes. Life cycle assessment studies indicate that while production may have higher initial environmental costs, the extended service life and improved efficiency of treated components result in net environmental benefits over the engine's operational lifetime.

Emissions testing on prototype Wankel engines with integrated wear-resistant epitrochoid surfaces has demonstrated promising results. Data from recent studies shows that maintaining consistent apex seal contact through improved surface durability can reduce NOx emissions by approximately 12% and particulate matter by up to 18% compared to conventional Wankel designs. These improvements are critical for meeting increasingly stringent emissions standards worldwide, particularly Euro 7 and equivalent regulations in North America and Asia.

Lubricant considerations also play a vital role in the environmental profile of wear-resistant Wankel engines. The integration of advanced materials can potentially reduce oil consumption—a traditional weakness of rotary engines—by up to 30%. This reduction directly translates to lower oil-derived emissions and reduced resource consumption. Furthermore, some ceramic-based coating technologies enable the use of lower-viscosity, more environmentally friendly lubricants without compromising engine protection.

The potential for improved fuel efficiency resulting from reduced friction and better sealing represents perhaps the most significant environmental benefit. Engineering simulations suggest that comprehensive wear resistance integration could improve fuel economy by 7-10%, with corresponding reductions in CO2 emissions. This efficiency gain becomes increasingly important as automotive manufacturers face tightening carbon emission regulations and growing consumer demand for more environmentally responsible transportation options.

Cost-Benefit Analysis of Advanced Coating Technologies

The implementation of advanced coating technologies for Wankel engine components represents a significant investment decision that requires thorough cost-benefit analysis. When evaluating these technologies, initial acquisition costs must be weighed against long-term operational savings. Thermal spray coatings such as plasma-sprayed ceramic coatings typically range from $150-300 per rotor housing, while PVD (Physical Vapor Deposition) chromium nitride coatings may cost $200-400 per apex seal set.

While these figures represent substantial upfront expenditures, particularly for mass production scenarios, the extended service intervals and reduced maintenance requirements offer compelling counterbalance. Field tests indicate that properly coated apex seals can extend replacement intervals by 40-60%, translating to approximately 30,000-40,000 additional kilometers before service is required.

The economic analysis must also account for reduced downtime and labor costs. Conventional Wankel engines typically require apex seal replacement every 50,000-80,000 kilometers, with service costs ranging from $1,200-2,500 depending on market region and vehicle model. Advanced coatings can potentially reduce these maintenance events by half over the engine's lifetime.

Fuel efficiency improvements present another significant economic benefit. Diamond-Like Carbon (DLC) coatings on critical sealing surfaces have demonstrated friction reduction of 15-25%, potentially improving fuel economy by 2-4%. For commercial applications or high-mileage users, this translates to substantial operational savings that can offset initial coating investments within 30,000-50,000 kilometers of operation.

Manufacturing integration costs must also be considered in the analysis. Retrofitting existing production lines to accommodate coating processes typically requires capital investments of $500,000-2,000,000 depending on production volume and coating technology selected. However, these costs can be amortized across production runs, adding approximately $50-120 per engine in high-volume scenarios.

Environmental compliance benefits, while difficult to quantify directly, contribute significantly to the value proposition. Reduced emissions resulting from better sealing and combustion efficiency help manufacturers meet increasingly stringent regulatory standards without costly redesigns or after-treatment systems. This regulatory compliance value often exceeds the direct material costs of coating implementation.

The return on investment timeline typically ranges from 18-36 months for fleet applications and 24-48 months for consumer vehicles, making advanced coating technologies economically viable for most production scenarios despite their higher initial costs. As coating technologies mature and production scales increase, these economics are expected to improve further, strengthening the business case for widespread adoption.

While these figures represent substantial upfront expenditures, particularly for mass production scenarios, the extended service intervals and reduced maintenance requirements offer compelling counterbalance. Field tests indicate that properly coated apex seals can extend replacement intervals by 40-60%, translating to approximately 30,000-40,000 additional kilometers before service is required.

The economic analysis must also account for reduced downtime and labor costs. Conventional Wankel engines typically require apex seal replacement every 50,000-80,000 kilometers, with service costs ranging from $1,200-2,500 depending on market region and vehicle model. Advanced coatings can potentially reduce these maintenance events by half over the engine's lifetime.

Fuel efficiency improvements present another significant economic benefit. Diamond-Like Carbon (DLC) coatings on critical sealing surfaces have demonstrated friction reduction of 15-25%, potentially improving fuel economy by 2-4%. For commercial applications or high-mileage users, this translates to substantial operational savings that can offset initial coating investments within 30,000-50,000 kilometers of operation.

Manufacturing integration costs must also be considered in the analysis. Retrofitting existing production lines to accommodate coating processes typically requires capital investments of $500,000-2,000,000 depending on production volume and coating technology selected. However, these costs can be amortized across production runs, adding approximately $50-120 per engine in high-volume scenarios.

Environmental compliance benefits, while difficult to quantify directly, contribute significantly to the value proposition. Reduced emissions resulting from better sealing and combustion efficiency help manufacturers meet increasingly stringent regulatory standards without costly redesigns or after-treatment systems. This regulatory compliance value often exceeds the direct material costs of coating implementation.

The return on investment timeline typically ranges from 18-36 months for fleet applications and 24-48 months for consumer vehicles, making advanced coating technologies economically viable for most production scenarios despite their higher initial costs. As coating technologies mature and production scales increase, these economics are expected to improve further, strengthening the business case for widespread adoption.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!