How to Investigate Solid-State Relay Failure Modes

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SSR Failure Analysis Background and Objectives

Solid-State Relays (SSRs) have evolved significantly since their introduction in the 1970s as alternatives to electromechanical relays. These semiconductor-based switching devices have gained prominence across various industries due to their reliability, longevity, and absence of moving parts. Despite these advantages, SSRs are not immune to failures, which can lead to significant operational disruptions, safety hazards, and financial losses in critical applications.

The investigation of SSR failure modes has become increasingly important as these components are deployed in more sophisticated and mission-critical systems. Historical data indicates that while SSRs generally offer longer operational lifespans than their mechanical counterparts, their failure mechanisms are often more complex and can be challenging to diagnose without specialized knowledge and equipment.

The technological evolution of SSRs has introduced various designs including AC, DC, and hybrid variants, each with unique failure characteristics. Modern SSRs incorporate advanced features such as zero-crossing detection, integrated heat sinks, and enhanced isolation barriers, all of which influence potential failure modes and diagnostic approaches.

Current industry statistics suggest that approximately 60% of SSR failures are attributable to thermal stress, 25% to electrical overstress, and the remainder to manufacturing defects or environmental factors. Understanding these patterns is crucial for developing effective investigation methodologies and preventive measures.

The primary objective of this technical research is to establish a comprehensive framework for investigating SSR failure modes that encompasses both reactive diagnostics and proactive prevention strategies. This framework aims to enable engineers and technicians to accurately identify failure causes, implement appropriate corrective actions, and enhance system reliability through improved design and maintenance practices.

Secondary objectives include developing standardized testing protocols for SSR failure analysis, creating a taxonomy of failure signatures that facilitates rapid diagnosis, and identifying emerging trends in SSR technology that may introduce new failure mechanisms or mitigate existing ones.

This research will address the technical gaps in current literature regarding SSR failure analysis, particularly in high-power applications and harsh environmental conditions where traditional investigation methods may prove inadequate. By synthesizing theoretical knowledge with practical field experience, we aim to advance the understanding of SSR reliability and contribute to the development of more robust industrial control systems.

The scope encompasses both catastrophic failures and degradation mechanisms, recognizing that the latter often precede the former and present opportunities for preventive intervention if properly identified and understood.

The investigation of SSR failure modes has become increasingly important as these components are deployed in more sophisticated and mission-critical systems. Historical data indicates that while SSRs generally offer longer operational lifespans than their mechanical counterparts, their failure mechanisms are often more complex and can be challenging to diagnose without specialized knowledge and equipment.

The technological evolution of SSRs has introduced various designs including AC, DC, and hybrid variants, each with unique failure characteristics. Modern SSRs incorporate advanced features such as zero-crossing detection, integrated heat sinks, and enhanced isolation barriers, all of which influence potential failure modes and diagnostic approaches.

Current industry statistics suggest that approximately 60% of SSR failures are attributable to thermal stress, 25% to electrical overstress, and the remainder to manufacturing defects or environmental factors. Understanding these patterns is crucial for developing effective investigation methodologies and preventive measures.

The primary objective of this technical research is to establish a comprehensive framework for investigating SSR failure modes that encompasses both reactive diagnostics and proactive prevention strategies. This framework aims to enable engineers and technicians to accurately identify failure causes, implement appropriate corrective actions, and enhance system reliability through improved design and maintenance practices.

Secondary objectives include developing standardized testing protocols for SSR failure analysis, creating a taxonomy of failure signatures that facilitates rapid diagnosis, and identifying emerging trends in SSR technology that may introduce new failure mechanisms or mitigate existing ones.

This research will address the technical gaps in current literature regarding SSR failure analysis, particularly in high-power applications and harsh environmental conditions where traditional investigation methods may prove inadequate. By synthesizing theoretical knowledge with practical field experience, we aim to advance the understanding of SSR reliability and contribute to the development of more robust industrial control systems.

The scope encompasses both catastrophic failures and degradation mechanisms, recognizing that the latter often precede the former and present opportunities for preventive intervention if properly identified and understood.

Market Demand for Reliable Solid-State Relays

The global market for solid-state relays (SSRs) has been experiencing robust growth, driven primarily by increasing automation across various industries. The demand for reliable SSRs has been particularly strong in manufacturing, energy management, and building automation sectors where system uptime and operational continuity are critical factors. Current market valuations indicate that the global solid-state relay market is expanding at a compound annual growth rate of approximately 6% and is expected to continue this trajectory through 2028.

Industrial automation represents the largest market segment for reliable SSRs, accounting for nearly 40% of total demand. Manufacturing facilities are increasingly replacing traditional electromechanical relays with solid-state alternatives to reduce maintenance requirements and improve system reliability. The automotive industry has also emerged as a significant consumer of high-reliability SSRs, particularly with the growth of electric vehicles and advanced driver-assistance systems that require precise power management.

Market research indicates that customers are willing to pay premium prices for SSRs with demonstrated reliability and comprehensive failure mode documentation. A recent industry survey revealed that 78% of procurement managers consider documented failure mode analysis as "very important" or "critical" when selecting relay components for mission-critical applications. This represents a significant shift from previous purchasing patterns that were more heavily weighted toward cost considerations.

The healthcare and medical device sectors have shown the fastest-growing demand for ultra-reliable SSRs, with particular emphasis on failure mode understanding and predictability. Medical equipment manufacturers require components with well-characterized failure behaviors to ensure patient safety and regulatory compliance. This segment is projected to grow at nearly twice the rate of the overall market over the next five years.

Geographically, North America and Europe currently lead in demand for high-reliability SSRs with comprehensive failure mode documentation, though Asia-Pacific markets are showing the most rapid growth. China and India, in particular, are experiencing surging demand as their manufacturing sectors modernize and adopt more sophisticated quality control standards.

Energy efficiency has emerged as another key market driver, with customers increasingly seeking SSRs that minimize power losses while maintaining reliability. The renewable energy sector, especially solar inverter manufacturers, represents a growing market segment with stringent requirements for relay reliability under variable load conditions.

Customer feedback indicates growing interest in predictive maintenance capabilities, with 65% of industrial users expressing willingness to invest in SSRs with integrated diagnostics that can predict potential failures before they occur. This represents a significant market opportunity for manufacturers who can effectively characterize and monitor failure modes in their solid-state relay products.

Industrial automation represents the largest market segment for reliable SSRs, accounting for nearly 40% of total demand. Manufacturing facilities are increasingly replacing traditional electromechanical relays with solid-state alternatives to reduce maintenance requirements and improve system reliability. The automotive industry has also emerged as a significant consumer of high-reliability SSRs, particularly with the growth of electric vehicles and advanced driver-assistance systems that require precise power management.

Market research indicates that customers are willing to pay premium prices for SSRs with demonstrated reliability and comprehensive failure mode documentation. A recent industry survey revealed that 78% of procurement managers consider documented failure mode analysis as "very important" or "critical" when selecting relay components for mission-critical applications. This represents a significant shift from previous purchasing patterns that were more heavily weighted toward cost considerations.

The healthcare and medical device sectors have shown the fastest-growing demand for ultra-reliable SSRs, with particular emphasis on failure mode understanding and predictability. Medical equipment manufacturers require components with well-characterized failure behaviors to ensure patient safety and regulatory compliance. This segment is projected to grow at nearly twice the rate of the overall market over the next five years.

Geographically, North America and Europe currently lead in demand for high-reliability SSRs with comprehensive failure mode documentation, though Asia-Pacific markets are showing the most rapid growth. China and India, in particular, are experiencing surging demand as their manufacturing sectors modernize and adopt more sophisticated quality control standards.

Energy efficiency has emerged as another key market driver, with customers increasingly seeking SSRs that minimize power losses while maintaining reliability. The renewable energy sector, especially solar inverter manufacturers, represents a growing market segment with stringent requirements for relay reliability under variable load conditions.

Customer feedback indicates growing interest in predictive maintenance capabilities, with 65% of industrial users expressing willingness to invest in SSRs with integrated diagnostics that can predict potential failures before they occur. This represents a significant market opportunity for manufacturers who can effectively characterize and monitor failure modes in their solid-state relay products.

Current Challenges in SSR Reliability

Despite significant advancements in solid-state relay (SSR) technology, several persistent reliability challenges continue to plague these devices in industrial applications. The absence of moving parts, which initially promised enhanced reliability compared to electromechanical relays, has not eliminated failure concerns but rather transformed them into different manifestations requiring specialized investigation approaches.

Thermal management remains perhaps the most critical challenge in SSR reliability. Unlike mechanical relays that can physically separate contacts during overheating, SSRs lack this self-protective mechanism. The semiconductor junction temperature in SSRs must be carefully controlled, as exceeding thermal limits can trigger catastrophic failure modes. Current thermal design limitations often result in derating requirements that significantly reduce the practical current handling capacity compared to theoretical specifications.

Voltage transient susceptibility presents another significant reliability hurdle. Modern industrial environments contain numerous sources of electrical noise and voltage spikes that can compromise SSR functionality. Despite improvements in internal protection circuits, SSRs remain vulnerable to damage from voltage transients that exceed their rated impulse withstand voltage, particularly in applications with inductive loads or near high-power switching equipment.

The semiconductor aging process introduces reliability concerns unique to solid-state technology. Gradual parameter drift occurs as semiconductor materials degrade over time, affecting critical specifications such as leakage current, on-state voltage drop, and switching characteristics. This progressive degradation can lead to subtle performance issues that may go undetected until complete failure occurs, complicating predictive maintenance efforts.

Environmental factors pose substantial challenges to SSR reliability. While SSRs generally outperform mechanical relays in harsh environments, they remain susceptible to humidity-induced failures through moisture ingress, particularly at the interface between different materials in the package. Chemical contamination can accelerate corrosion of internal components, while mechanical stress from vibration or thermal cycling can compromise internal connections and solder joints.

The detection and diagnosis of incipient SSR failures represent a significant technical challenge. Unlike mechanical relays where contact wear is often visible or audible, SSR failure modes frequently manifest without obvious external indicators. Current monitoring technologies struggle to differentiate between normal parameter variations and early warning signs of impending failure, limiting the effectiveness of condition-based maintenance strategies for SSR-dependent systems.

Thermal management remains perhaps the most critical challenge in SSR reliability. Unlike mechanical relays that can physically separate contacts during overheating, SSRs lack this self-protective mechanism. The semiconductor junction temperature in SSRs must be carefully controlled, as exceeding thermal limits can trigger catastrophic failure modes. Current thermal design limitations often result in derating requirements that significantly reduce the practical current handling capacity compared to theoretical specifications.

Voltage transient susceptibility presents another significant reliability hurdle. Modern industrial environments contain numerous sources of electrical noise and voltage spikes that can compromise SSR functionality. Despite improvements in internal protection circuits, SSRs remain vulnerable to damage from voltage transients that exceed their rated impulse withstand voltage, particularly in applications with inductive loads or near high-power switching equipment.

The semiconductor aging process introduces reliability concerns unique to solid-state technology. Gradual parameter drift occurs as semiconductor materials degrade over time, affecting critical specifications such as leakage current, on-state voltage drop, and switching characteristics. This progressive degradation can lead to subtle performance issues that may go undetected until complete failure occurs, complicating predictive maintenance efforts.

Environmental factors pose substantial challenges to SSR reliability. While SSRs generally outperform mechanical relays in harsh environments, they remain susceptible to humidity-induced failures through moisture ingress, particularly at the interface between different materials in the package. Chemical contamination can accelerate corrosion of internal components, while mechanical stress from vibration or thermal cycling can compromise internal connections and solder joints.

The detection and diagnosis of incipient SSR failures represent a significant technical challenge. Unlike mechanical relays where contact wear is often visible or audible, SSR failure modes frequently manifest without obvious external indicators. Current monitoring technologies struggle to differentiate between normal parameter variations and early warning signs of impending failure, limiting the effectiveness of condition-based maintenance strategies for SSR-dependent systems.

Methodologies for SSR Failure Investigation

01 Thermal failure modes in solid-state relays

Solid-state relays can fail due to thermal issues, including overheating of semiconductor components. Excessive heat can cause degradation of the internal semiconductor junctions, leading to permanent damage. Thermal runaway can occur when increased temperature causes increased current flow, which further increases temperature in a destructive cycle. Proper heat dissipation through heat sinks and thermal management systems is critical to prevent these failure modes.- Thermal failure modes in solid-state relays: Solid-state relays can fail due to thermal issues, including overheating of semiconductor components. When operating beyond temperature specifications, thermal runaway can occur, leading to permanent damage. Heat dissipation problems in confined spaces exacerbate these issues. Proper heat sinking and thermal management are essential to prevent junction temperature rise beyond critical thresholds. Thermal cycling can also cause mechanical stress on internal connections, leading to eventual failure.

- Overvoltage and surge protection failures: Solid-state relays are susceptible to damage from voltage transients and surges that exceed their rated breakdown voltage. These events can cause immediate catastrophic failure or create latent defects that lead to premature failure. Protection mechanisms such as varistors, TVS diodes, or RC snubber circuits are often implemented to absorb transient energy. Failure of these protection components themselves can leave the relay vulnerable to subsequent overvoltage events, creating a secondary failure mode.

- Input circuit and isolation failures: The input control circuit of solid-state relays can fail due to degradation of optocouplers or other isolation components. This may result in either permanent on or off states regardless of control signals. Isolation breakdown between input and output circuits compromises safety and can lead to unpredictable relay behavior. Aging of LED components in optoisolators reduces light output over time, potentially causing triggering failures. Contamination or manufacturing defects in the isolation barrier can also lead to premature failure.

- Output semiconductor degradation and failure: The output switching elements, typically triacs, thyristors, or MOSFETs, can degrade over time due to repeated switching operations. This degradation manifests as increased leakage current, higher on-state resistance, or inability to block voltage in the off state. Semiconductor junction damage from overcurrent events may not cause immediate failure but can reduce operational lifetime. Partial or intermittent switching failures may occur before complete failure, making diagnosis challenging. Semiconductor aging effects accelerate at elevated temperatures.

- Environmental and mechanical stress failures: Solid-state relays can fail due to environmental factors such as humidity, corrosive atmospheres, or vibration. Moisture ingress can cause corrosion of internal components and conductive paths, leading to short circuits or open circuits. Mechanical stress from thermal cycling or vibration can cause solder joint fatigue or internal connection failures. Dust accumulation can impede heat dissipation, indirectly causing thermal failure. Encapsulation material degradation over time may compromise environmental protection, allowing contaminants to affect internal components.

02 Overvoltage and surge protection failures

Solid-state relays are susceptible to damage from voltage spikes and surges that exceed their rated voltage capabilities. These overvoltage events can cause breakdown of the semiconductor material, leading to short circuits or open circuits. Protection mechanisms such as varistors, transient voltage suppressors, and snubber circuits can be implemented to mitigate these failure modes, but may themselves fail under extreme conditions, leaving the relay vulnerable.Expand Specific Solutions03 Semiconductor junction degradation and aging

Over time, the semiconductor junctions within solid-state relays can degrade due to normal aging processes. This degradation can manifest as increased leakage current, reduced switching capability, or complete failure to switch. Factors that accelerate aging include thermal cycling, high operating temperatures, and switching high inductive loads. The gradual nature of this failure mode makes it difficult to detect before complete failure occurs.Expand Specific Solutions04 Control circuit and isolation failures

The control circuit and isolation components in solid-state relays can fail, leading to improper operation or complete relay failure. Optocouplers used for isolation between input and output circuits may degrade over time, reducing isolation effectiveness. Control circuit failures can result in the relay remaining permanently on or off, regardless of control signals. These failures can be particularly dangerous as they may not be immediately apparent and can lead to unexpected equipment operation.Expand Specific Solutions05 Environmental and contamination-related failures

Environmental factors such as humidity, dust, and corrosive atmospheres can contribute to solid-state relay failures. Moisture ingress can cause corrosion of internal components and conductive paths, while dust accumulation can impede heat dissipation. Chemical contaminants can degrade the semiconductor materials and packaging. Inadequate protection against these environmental factors can significantly reduce the operational life of solid-state relays and lead to premature failure.Expand Specific Solutions

Major SSR Manufacturers and Market Landscape

The solid-state relay (SSR) failure modes investigation market is in a growth phase, with increasing adoption across industrial automation, power distribution, and consumer electronics sectors. The global market size for SSR technology is expanding rapidly due to the transition toward smart grid infrastructure and industrial IoT applications. From a technical maturity perspective, the landscape shows varying degrees of advancement. State Grid Corporation of China and its research institutes lead in power grid applications, while companies like Midea Group and Renault focus on consumer and automotive implementations respectively. Contemporary Amperex Technology and LG Energy Solution are advancing SSR technology for energy storage systems. Specialized players such as Viking Protection Systems and Wieland Electric offer niche expertise in failure analysis methodologies. The competitive environment is characterized by regional strengths, with Asian manufacturers focusing on high-volume production while Western companies emphasize reliability engineering and specialized applications.

Cisco Technology, Inc.

Technical Solution: Cisco has developed a sophisticated approach to investigating SSR failures in their networking and data center equipment, focusing on reliability in mission-critical applications. Their methodology employs automated test equipment capable of characterizing SSR performance across multiple parameters simultaneously, including turn-on/turn-off times, leakage current, and voltage drop[1]. Cisco utilizes advanced data analytics to correlate environmental conditions with failure incidents, identifying patterns that may not be apparent through conventional analysis. Their investigation protocol includes detailed power quality monitoring to detect anomalies in the power supply that might stress SSRs beyond their rated capabilities. Cisco engineers have developed specialized firmware diagnostic tools that can detect abnormal switching patterns indicative of impending SSR failure, enabling proactive replacement before system downtime occurs[3]. Their approach incorporates accelerated aging tests under controlled conditions to validate failure hypotheses and verify corrective actions. Additionally, Cisco maintains a comprehensive database of component failures across their global installed base, allowing them to quickly identify systemic issues with specific SSR manufacturers or production batches.

Strengths: Extensive experience with high-reliability applications where downtime is extremely costly. Their data-driven approach leverages information from millions of deployed devices to identify failure patterns. Weaknesses: Their methodology is primarily focused on telecommunications and data center environments, which may limit applicability to industrial or automotive applications with different operating conditions.

International Business Machines Corp.

Technical Solution: IBM has developed a comprehensive SSR failure investigation methodology that combines hardware analysis with advanced diagnostic software. Their approach begins with automated electrical characterization of failed components using custom-designed test fixtures that can detect subtle parametric shifts indicative of degradation mechanisms[2]. IBM employs high-resolution imaging techniques including acoustic microscopy and X-ray tomography to identify internal structural defects without destructive analysis. Their investigation protocol includes detailed analysis of the semiconductor die using focused ion beam (FIB) techniques to create cross-sections at specific points of interest, revealing failure mechanisms at the microscopic level. IBM has developed specialized thermal modeling software that can simulate heat distribution within SSR packages under various operating conditions, identifying potential design weaknesses[4]. Their methodology incorporates extensive environmental testing including temperature cycling, humidity exposure, and mechanical stress to reproduce field failures under controlled conditions. Additionally, IBM maintains a sophisticated materials analysis laboratory capable of identifying contamination issues and material degradation that can contribute to SSR failure, particularly in hermetically sealed components where internal atmosphere changes can affect long-term reliability.

Strengths: World-class failure analysis facilities with advanced equipment for semiconductor device investigation. Their multidisciplinary approach combines electrical engineering, materials science, and thermal analysis for comprehensive failure mode identification. Weaknesses: Their investigation methods are resource-intensive and may be economically justified only for high-value systems or when developing new SSR technologies rather than routine maintenance.

Critical Failure Mechanisms and Root Causes

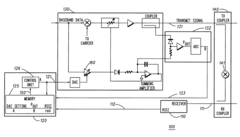

Method and apparatus for determining failure modes of a transceiver

PatentInactiveUS6311044B1

Innovation

- A method that applies a control signal to the transmitter's power control input, detecting the power level of the transmit signal and coupling it to the receiver to determine failure modes by comparing voltage levels, allowing for characterization of failure conditions, including soft failure modes, and storing diagnostic data for remote analysis.

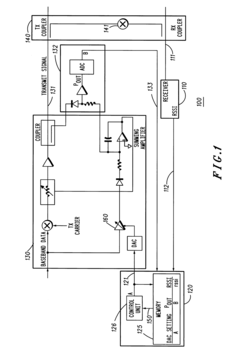

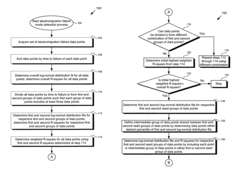

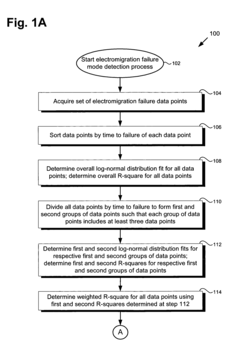

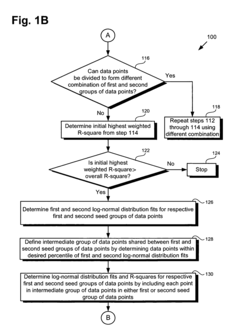

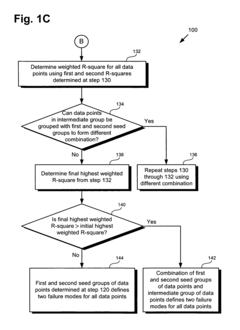

Method for quantitative detection of multiple electromigration failure modes

PatentActiveUS7818655B1

Innovation

- A computer-implemented method that sorts data points by time to failure, determines overall and group-specific log-normal distribution fits, and calculates weighted R-squares to identify and separate multiple failure modes through iterative grouping and recombination of data points.

Environmental Factors Affecting SSR Performance

Environmental conditions significantly impact the performance and reliability of Solid-State Relays (SSRs), often leading to premature failures when operating outside specified parameters. Temperature represents the most critical environmental factor affecting SSRs. These devices generate heat during operation, and when ambient temperatures exceed recommended thresholds, thermal stress accelerates component degradation. High temperatures can cause semiconductor junction breakdown, while thermal cycling induces mechanical stress through expansion and contraction, potentially leading to solder joint fatigue and internal connection failures.

Humidity presents another substantial challenge for SSR reliability. Excessive moisture can penetrate non-hermetically sealed SSRs, causing corrosion of internal components and conductive paths. In extreme cases, condensation may form on circuit boards, creating leakage paths that compromise isolation integrity. This is particularly problematic in industrial environments with significant temperature fluctuations that promote condensation cycles.

Atmospheric contaminants, including dust, chemicals, and corrosive gases, constitute a third category of environmental stressors. Industrial settings often contain airborne particulates that can accumulate on SSR surfaces, impeding heat dissipation and exacerbating thermal issues. Chemical vapors and gases like hydrogen sulfide or chlorine compounds can penetrate SSR packaging and corrode internal components, particularly affecting metal contacts and wire bonds.

Electromagnetic interference (EMI) and voltage fluctuations represent electrical environmental factors that impact SSR performance. Strong electromagnetic fields can induce unwanted triggering in SSRs with insufficient shielding. Power quality issues such as voltage spikes, surges, and transients can damage input circuitry or output semiconductors, especially in installations lacking adequate surge protection.

Mechanical factors, including vibration and shock, can physically damage SSR components over time. Continuous vibration may weaken solder joints and internal connections, while sudden mechanical shocks can cause immediate component failure. These issues are particularly relevant in applications involving heavy machinery or transportation equipment.

Understanding these environmental factors is essential when investigating SSR failures. Comprehensive failure analysis should include environmental condition assessment at the installation site, comparing actual conditions against manufacturer specifications. Implementing appropriate environmental controls—such as temperature management systems, conformal coatings for humidity protection, filtration for contaminants, EMI shielding, and vibration dampening—can significantly extend SSR operational life and improve system reliability.

Humidity presents another substantial challenge for SSR reliability. Excessive moisture can penetrate non-hermetically sealed SSRs, causing corrosion of internal components and conductive paths. In extreme cases, condensation may form on circuit boards, creating leakage paths that compromise isolation integrity. This is particularly problematic in industrial environments with significant temperature fluctuations that promote condensation cycles.

Atmospheric contaminants, including dust, chemicals, and corrosive gases, constitute a third category of environmental stressors. Industrial settings often contain airborne particulates that can accumulate on SSR surfaces, impeding heat dissipation and exacerbating thermal issues. Chemical vapors and gases like hydrogen sulfide or chlorine compounds can penetrate SSR packaging and corrode internal components, particularly affecting metal contacts and wire bonds.

Electromagnetic interference (EMI) and voltage fluctuations represent electrical environmental factors that impact SSR performance. Strong electromagnetic fields can induce unwanted triggering in SSRs with insufficient shielding. Power quality issues such as voltage spikes, surges, and transients can damage input circuitry or output semiconductors, especially in installations lacking adequate surge protection.

Mechanical factors, including vibration and shock, can physically damage SSR components over time. Continuous vibration may weaken solder joints and internal connections, while sudden mechanical shocks can cause immediate component failure. These issues are particularly relevant in applications involving heavy machinery or transportation equipment.

Understanding these environmental factors is essential when investigating SSR failures. Comprehensive failure analysis should include environmental condition assessment at the installation site, comparing actual conditions against manufacturer specifications. Implementing appropriate environmental controls—such as temperature management systems, conformal coatings for humidity protection, filtration for contaminants, EMI shielding, and vibration dampening—can significantly extend SSR operational life and improve system reliability.

Predictive Maintenance Strategies for SSRs

Predictive maintenance strategies for Solid-State Relays (SSRs) represent a critical advancement in preventing unexpected failures and optimizing operational efficiency. By implementing condition monitoring systems, organizations can continuously track key parameters such as junction temperature, switching patterns, and load characteristics to identify early warning signs of potential failures.

Data-driven predictive models form the cornerstone of effective SSR maintenance strategies. These models utilize machine learning algorithms to analyze historical failure data, operational patterns, and environmental conditions to predict when an SSR might approach failure. Advanced analytics can detect subtle changes in switching behavior or thermal characteristics that precede common failure modes such as thermal runaway or input circuit degradation.

Thermal imaging has emerged as a particularly valuable technique for SSR predictive maintenance. Regular thermal scans can identify hotspots or abnormal temperature distributions that often indicate impending failure. When integrated with automated monitoring systems, these thermal signatures can trigger alerts before catastrophic failure occurs, allowing for planned replacement during scheduled downtime rather than emergency maintenance.

Electrical parameter monitoring provides another layer of predictive capability. Tracking changes in forward voltage drop, leakage current, or switching characteristics over time enables maintenance teams to establish baseline performance metrics and detect gradual degradation. Sophisticated monitoring systems can now differentiate between normal operational variations and concerning trends that require intervention.

Implementation of IoT sensors and connectivity has revolutionized SSR maintenance approaches. Modern industrial systems can incorporate networked sensors that continuously monitor SSR performance and transmit data to centralized maintenance management systems. This real-time monitoring capability enables immediate response to developing issues and facilitates data collection for ongoing refinement of predictive models.

Cost-benefit analysis demonstrates that predictive maintenance strategies for SSRs typically deliver substantial return on investment. While the initial implementation costs may exceed traditional reactive maintenance approaches, the prevention of unplanned downtime, reduction in catastrophic failures, and extension of component lifespan generally result in significant operational savings. Organizations implementing comprehensive SSR predictive maintenance programs commonly report 30-50% reductions in relay-related downtime and 20-40% increases in SSR operational lifespan.

Integration of predictive maintenance strategies into broader asset management systems represents the most mature implementation approach. By connecting SSR health monitoring with enterprise resource planning and maintenance scheduling systems, organizations can optimize maintenance activities across their entire operation, balancing resource allocation while minimizing production disruptions.

Data-driven predictive models form the cornerstone of effective SSR maintenance strategies. These models utilize machine learning algorithms to analyze historical failure data, operational patterns, and environmental conditions to predict when an SSR might approach failure. Advanced analytics can detect subtle changes in switching behavior or thermal characteristics that precede common failure modes such as thermal runaway or input circuit degradation.

Thermal imaging has emerged as a particularly valuable technique for SSR predictive maintenance. Regular thermal scans can identify hotspots or abnormal temperature distributions that often indicate impending failure. When integrated with automated monitoring systems, these thermal signatures can trigger alerts before catastrophic failure occurs, allowing for planned replacement during scheduled downtime rather than emergency maintenance.

Electrical parameter monitoring provides another layer of predictive capability. Tracking changes in forward voltage drop, leakage current, or switching characteristics over time enables maintenance teams to establish baseline performance metrics and detect gradual degradation. Sophisticated monitoring systems can now differentiate between normal operational variations and concerning trends that require intervention.

Implementation of IoT sensors and connectivity has revolutionized SSR maintenance approaches. Modern industrial systems can incorporate networked sensors that continuously monitor SSR performance and transmit data to centralized maintenance management systems. This real-time monitoring capability enables immediate response to developing issues and facilitates data collection for ongoing refinement of predictive models.

Cost-benefit analysis demonstrates that predictive maintenance strategies for SSRs typically deliver substantial return on investment. While the initial implementation costs may exceed traditional reactive maintenance approaches, the prevention of unplanned downtime, reduction in catastrophic failures, and extension of component lifespan generally result in significant operational savings. Organizations implementing comprehensive SSR predictive maintenance programs commonly report 30-50% reductions in relay-related downtime and 20-40% increases in SSR operational lifespan.

Integration of predictive maintenance strategies into broader asset management systems represents the most mature implementation approach. By connecting SSR health monitoring with enterprise resource planning and maintenance scheduling systems, organizations can optimize maintenance activities across their entire operation, balancing resource allocation while minimizing production disruptions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!