How to Minimize Drift in Thermopile Measurements

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermopile Drift Challenges and Objectives

Thermopile sensors have emerged as critical components in various precision measurement applications, from non-contact temperature sensing to infrared detection systems. The evolution of these devices traces back to the early 20th century, with significant advancements occurring in the 1960s and 1970s as semiconductor manufacturing techniques matured. Recent decades have witnessed remarkable improvements in sensitivity, response time, and integration capabilities, positioning thermopiles as essential elements in modern sensing technology.

Despite these advancements, drift remains a persistent challenge that undermines the reliability and accuracy of thermopile measurements. Drift manifests as unwanted variations in output signals over time, even when the measured parameter remains constant. This phenomenon significantly impacts applications requiring high precision and long-term stability, such as medical diagnostics, industrial process control, and environmental monitoring.

The primary objective of addressing thermopile drift is to enhance measurement stability across varying environmental conditions and extended operational periods. Specifically, this involves developing solutions that can maintain measurement accuracy within ±0.1°C over temperature ranges from -40°C to 125°C and operational lifespans exceeding 10 years. Such improvements would substantially expand the applicability of thermopile technology in critical fields requiring high reliability.

Current technical trends indicate a multidisciplinary approach to drift minimization, incorporating advancements in materials science, signal processing algorithms, and calibration methodologies. The integration of machine learning techniques for drift prediction and compensation represents a particularly promising direction, potentially enabling adaptive correction mechanisms that evolve throughout device lifetime.

Industry projections suggest that successful drift minimization could unlock new market opportunities worth an estimated $2.3 billion by 2028, particularly in emerging applications such as wearable health monitors, autonomous vehicle sensing systems, and smart building management. The growing demand for high-precision, maintenance-free sensing solutions across these sectors underscores the strategic importance of overcoming drift limitations.

From a competitive standpoint, achieving significant improvements in drift performance would provide substantial technological differentiation in a market increasingly characterized by commoditization. Organizations that successfully address this challenge stand to establish leadership positions in high-value application segments where measurement stability represents a critical performance parameter.

This technical investigation aims to comprehensively analyze drift mechanisms in thermopile sensors, evaluate current mitigation strategies, and identify promising research directions for developing next-generation solutions with dramatically improved stability characteristics.

Despite these advancements, drift remains a persistent challenge that undermines the reliability and accuracy of thermopile measurements. Drift manifests as unwanted variations in output signals over time, even when the measured parameter remains constant. This phenomenon significantly impacts applications requiring high precision and long-term stability, such as medical diagnostics, industrial process control, and environmental monitoring.

The primary objective of addressing thermopile drift is to enhance measurement stability across varying environmental conditions and extended operational periods. Specifically, this involves developing solutions that can maintain measurement accuracy within ±0.1°C over temperature ranges from -40°C to 125°C and operational lifespans exceeding 10 years. Such improvements would substantially expand the applicability of thermopile technology in critical fields requiring high reliability.

Current technical trends indicate a multidisciplinary approach to drift minimization, incorporating advancements in materials science, signal processing algorithms, and calibration methodologies. The integration of machine learning techniques for drift prediction and compensation represents a particularly promising direction, potentially enabling adaptive correction mechanisms that evolve throughout device lifetime.

Industry projections suggest that successful drift minimization could unlock new market opportunities worth an estimated $2.3 billion by 2028, particularly in emerging applications such as wearable health monitors, autonomous vehicle sensing systems, and smart building management. The growing demand for high-precision, maintenance-free sensing solutions across these sectors underscores the strategic importance of overcoming drift limitations.

From a competitive standpoint, achieving significant improvements in drift performance would provide substantial technological differentiation in a market increasingly characterized by commoditization. Organizations that successfully address this challenge stand to establish leadership positions in high-value application segments where measurement stability represents a critical performance parameter.

This technical investigation aims to comprehensively analyze drift mechanisms in thermopile sensors, evaluate current mitigation strategies, and identify promising research directions for developing next-generation solutions with dramatically improved stability characteristics.

Market Demand for High-Precision Temperature Sensing

The global market for high-precision temperature sensing technologies has experienced significant growth in recent years, driven by increasing demands across multiple industries for accurate, reliable, and stable temperature measurements. The thermopile sensor market specifically is projected to reach $2.3 billion by 2026, growing at a CAGR of 8.7% from 2021, highlighting the expanding commercial interest in these technologies.

Healthcare and medical diagnostics represent one of the largest market segments, where non-contact temperature measurement using thermopiles has become essential for applications ranging from clinical thermometers to advanced patient monitoring systems. The COVID-19 pandemic dramatically accelerated this trend, with a 300% increase in demand for high-precision infrared thermometers during 2020-2021.

Industrial process control constitutes another critical market segment, where even minor temperature measurement inaccuracies can result in significant production losses. Manufacturing facilities increasingly require temperature sensing solutions with drift rates below 0.01°C per year to maintain quality control in precision manufacturing processes.

The semiconductor industry presents particularly stringent requirements, demanding temperature measurement stability within ±0.005°C across extended operational periods. This level of precision is necessary for wafer processing, where thermal management directly impacts yield rates and device performance. Market research indicates that semiconductor manufacturers are willing to pay premium prices for sensing solutions that can demonstrate minimal drift characteristics.

Aerospace and defense applications represent a growing market segment with unique requirements. These applications often involve extreme environmental conditions where conventional temperature sensors exhibit accelerated drift. The demand for radiation-hardened thermopile sensors with enhanced stability has grown by approximately 12% annually since 2018.

Consumer electronics manufacturers are increasingly incorporating thermopile arrays into smartphones, wearables, and smart home devices, creating a high-volume market segment that values miniaturization and cost-effectiveness alongside measurement stability. This segment is expected to grow at 15% annually through 2025.

Research institutions and calibration laboratories form a specialized market segment requiring ultra-stable reference temperature sensors. These organizations typically seek measurement solutions with drift characteristics below 0.001°C per year and are willing to invest in premium technologies that can deliver this level of performance.

The geographical distribution of market demand shows particular strength in North America and Europe for medical and scientific applications, while Asia-Pacific leads in industrial and consumer electronics implementations. Emerging economies are showing accelerated adoption rates as their manufacturing sectors advance toward higher precision requirements.

Healthcare and medical diagnostics represent one of the largest market segments, where non-contact temperature measurement using thermopiles has become essential for applications ranging from clinical thermometers to advanced patient monitoring systems. The COVID-19 pandemic dramatically accelerated this trend, with a 300% increase in demand for high-precision infrared thermometers during 2020-2021.

Industrial process control constitutes another critical market segment, where even minor temperature measurement inaccuracies can result in significant production losses. Manufacturing facilities increasingly require temperature sensing solutions with drift rates below 0.01°C per year to maintain quality control in precision manufacturing processes.

The semiconductor industry presents particularly stringent requirements, demanding temperature measurement stability within ±0.005°C across extended operational periods. This level of precision is necessary for wafer processing, where thermal management directly impacts yield rates and device performance. Market research indicates that semiconductor manufacturers are willing to pay premium prices for sensing solutions that can demonstrate minimal drift characteristics.

Aerospace and defense applications represent a growing market segment with unique requirements. These applications often involve extreme environmental conditions where conventional temperature sensors exhibit accelerated drift. The demand for radiation-hardened thermopile sensors with enhanced stability has grown by approximately 12% annually since 2018.

Consumer electronics manufacturers are increasingly incorporating thermopile arrays into smartphones, wearables, and smart home devices, creating a high-volume market segment that values miniaturization and cost-effectiveness alongside measurement stability. This segment is expected to grow at 15% annually through 2025.

Research institutions and calibration laboratories form a specialized market segment requiring ultra-stable reference temperature sensors. These organizations typically seek measurement solutions with drift characteristics below 0.001°C per year and are willing to invest in premium technologies that can deliver this level of performance.

The geographical distribution of market demand shows particular strength in North America and Europe for medical and scientific applications, while Asia-Pacific leads in industrial and consumer electronics implementations. Emerging economies are showing accelerated adoption rates as their manufacturing sectors advance toward higher precision requirements.

Current Limitations in Thermopile Measurement Stability

Despite significant advancements in thermopile technology, several critical limitations continue to affect measurement stability and contribute to drift phenomena. The primary challenge remains thermal environmental fluctuations, which create temperature gradients across the sensor assembly. These gradients induce parasitic thermoelectric effects that manifest as measurement drift, particularly in applications requiring extended monitoring periods or high precision.

Material aging represents another significant limitation, as thermopile sensors typically employ dissimilar metals or semiconductor junctions that experience gradual degradation over time. This degradation alters the Seebeck coefficient characteristics, resulting in progressive calibration shifts that become increasingly pronounced with operational age. Even high-quality thermopile arrays exhibit this limitation, though at varying rates depending on material composition and manufacturing processes.

Electronic signal conditioning circuitry introduces additional stability challenges. Amplifier offset drift, gain variations with temperature, and analog-to-digital conversion errors compound the inherent sensor limitations. The extremely low-level signals generated by thermopiles (typically in the microvolt range) make them particularly susceptible to these electronic noise sources and amplification errors, necessitating sophisticated compensation techniques.

Packaging and mounting inconsistencies further exacerbate drift issues. Mechanical stresses from thermal expansion and contraction cycles create micromovements that affect the thermal coupling between the sensor and measured target. Additionally, contamination of optical elements in radiation-sensing thermopiles gradually alters their absorption characteristics, introducing long-term measurement bias that proves difficult to predict or compensate for algorithmically.

Current calibration methodologies also present limitations. Most thermopile systems employ single-point or two-point calibration procedures that inadequately address non-linear drift behaviors across wide temperature ranges. The calibration reference standards themselves may introduce uncertainties, particularly when traceability to primary standards is not maintained throughout the measurement chain.

Power supply variations, though often overlooked, significantly impact measurement stability. Fluctuations in supply voltage affect both the sensor biasing and signal conditioning circuits, introducing additional drift components that may not be adequately addressed by standard compensation techniques. This becomes particularly problematic in battery-powered or energy-harvesting applications where power management introduces variable operating conditions.

Finally, existing mathematical models for drift compensation typically rely on simplified assumptions about drift mechanisms, failing to capture the complex interactions between multiple drift sources. This modeling limitation hampers the development of effective predictive compensation algorithms, particularly for applications requiring sub-millikelvin resolution over extended periods.

Material aging represents another significant limitation, as thermopile sensors typically employ dissimilar metals or semiconductor junctions that experience gradual degradation over time. This degradation alters the Seebeck coefficient characteristics, resulting in progressive calibration shifts that become increasingly pronounced with operational age. Even high-quality thermopile arrays exhibit this limitation, though at varying rates depending on material composition and manufacturing processes.

Electronic signal conditioning circuitry introduces additional stability challenges. Amplifier offset drift, gain variations with temperature, and analog-to-digital conversion errors compound the inherent sensor limitations. The extremely low-level signals generated by thermopiles (typically in the microvolt range) make them particularly susceptible to these electronic noise sources and amplification errors, necessitating sophisticated compensation techniques.

Packaging and mounting inconsistencies further exacerbate drift issues. Mechanical stresses from thermal expansion and contraction cycles create micromovements that affect the thermal coupling between the sensor and measured target. Additionally, contamination of optical elements in radiation-sensing thermopiles gradually alters their absorption characteristics, introducing long-term measurement bias that proves difficult to predict or compensate for algorithmically.

Current calibration methodologies also present limitations. Most thermopile systems employ single-point or two-point calibration procedures that inadequately address non-linear drift behaviors across wide temperature ranges. The calibration reference standards themselves may introduce uncertainties, particularly when traceability to primary standards is not maintained throughout the measurement chain.

Power supply variations, though often overlooked, significantly impact measurement stability. Fluctuations in supply voltage affect both the sensor biasing and signal conditioning circuits, introducing additional drift components that may not be adequately addressed by standard compensation techniques. This becomes particularly problematic in battery-powered or energy-harvesting applications where power management introduces variable operating conditions.

Finally, existing mathematical models for drift compensation typically rely on simplified assumptions about drift mechanisms, failing to capture the complex interactions between multiple drift sources. This modeling limitation hampers the development of effective predictive compensation algorithms, particularly for applications requiring sub-millikelvin resolution over extended periods.

Existing Drift Compensation Techniques

01 Temperature compensation techniques for thermopile drift

Various temperature compensation techniques are employed to mitigate thermopile drift issues. These include using reference thermopiles, temperature sensors, and compensation circuits to adjust for ambient temperature changes. By implementing these compensation methods, the accuracy and stability of thermopile measurements can be significantly improved, reducing drift-related errors in applications requiring precise temperature sensing.- Temperature compensation techniques for thermopile drift: Various temperature compensation techniques are employed to mitigate thermopile drift caused by ambient temperature changes. These include using reference thermopiles, temperature sensors, and compensation circuits that adjust the output signal based on measured temperature differences. Advanced algorithms can process temperature data to calculate correction factors that maintain measurement accuracy despite environmental fluctuations.

- Structural design improvements to reduce drift: Specialized structural designs can minimize thermopile drift by improving thermal isolation and stability. These include optimized housing configurations, thermal barriers, and strategic placement of components to reduce temperature gradients. Some designs incorporate vacuum-sealed chambers or specialized materials with low thermal conductivity to isolate the thermopile from external thermal influences.

- Signal processing methods for drift correction: Advanced signal processing techniques can be implemented to correct thermopile drift in real-time. These methods include digital filtering, baseline correction algorithms, and adaptive calibration routines that continuously adjust for drift. Some systems employ machine learning algorithms to recognize drift patterns and automatically apply appropriate corrections based on historical performance data.

- Material selection for drift reduction: The choice of materials in thermopile construction significantly impacts drift characteristics. Specialized semiconductor materials, thermoelectric alloys with stable Seebeck coefficients, and materials with matched thermal expansion properties can minimize drift. Some designs incorporate novel composite materials or thin-film technologies that maintain consistent thermoelectric properties across temperature ranges.

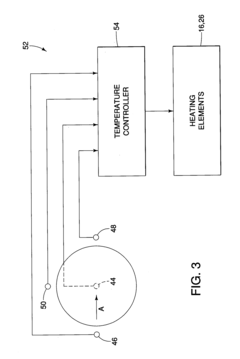

- Calibration systems for drift management: Automated calibration systems can periodically recalibrate thermopiles to compensate for drift over time. These systems may include reference heat sources, precision temperature control mechanisms, and calibration schedules based on usage patterns. Some advanced designs incorporate self-calibration features that automatically adjust readings based on internal reference measurements without interrupting normal operation.

02 Structural design improvements to reduce drift

Innovative structural designs help minimize thermopile drift by improving thermal isolation and stability. These designs include specialized housing structures, thermal barriers, and optimized thermopile junction arrangements. By enhancing the physical construction of thermopile sensors, thermal gradients that contribute to measurement drift can be reduced, resulting in more stable and reliable temperature readings over time.Expand Specific Solutions03 Signal processing algorithms for drift correction

Advanced signal processing algorithms are implemented to correct thermopile drift in real-time. These algorithms include digital filtering, baseline correction, and adaptive calibration techniques that continuously adjust for drift factors. By applying sophisticated computational methods to the raw thermopile output, long-term stability can be achieved even in challenging environmental conditions where drift would otherwise compromise measurement accuracy.Expand Specific Solutions04 Material innovations for drift reduction

Novel materials and fabrication techniques are developed to create thermopiles with inherently lower drift characteristics. These include specialized thermoelectric materials, improved junction materials, and advanced thin-film deposition methods. By selecting materials with better thermal stability and lower susceptibility to aging effects, the fundamental causes of thermopile drift can be addressed at the material level, extending sensor lifespan and reliability.Expand Specific Solutions05 Calibration systems for drift management

Automated calibration systems are implemented to periodically recalibrate thermopile sensors and compensate for drift over time. These systems include reference temperature sources, self-calibration mechanisms, and scheduled calibration routines. By establishing regular calibration procedures, the effects of long-term drift can be systematically corrected, maintaining measurement accuracy throughout the operational lifetime of thermopile-based sensing systems.Expand Specific Solutions

Leading Manufacturers and Research Institutions

Thermopile measurement drift minimization represents a mature yet evolving technical challenge in the precision measurement industry. The market is characterized by established players with specialized expertise operating in a steady-growth phase, estimated at approximately $1.2 billion globally. Companies like Watlow Electric Manufacturing, Honeywell International Technologies, and Robert Bosch GmbH lead with advanced temperature compensation algorithms and material innovations. Agilent Technologies and Koninklijke Philips contribute significant R&D in signal processing techniques, while specialized firms such as Yamari Industries and trinamiX GmbH focus on niche applications requiring extreme stability. The technology has reached commercial maturity but continues advancing through incremental innovations in materials science and digital calibration techniques to address persistent drift challenges in increasingly demanding applications.

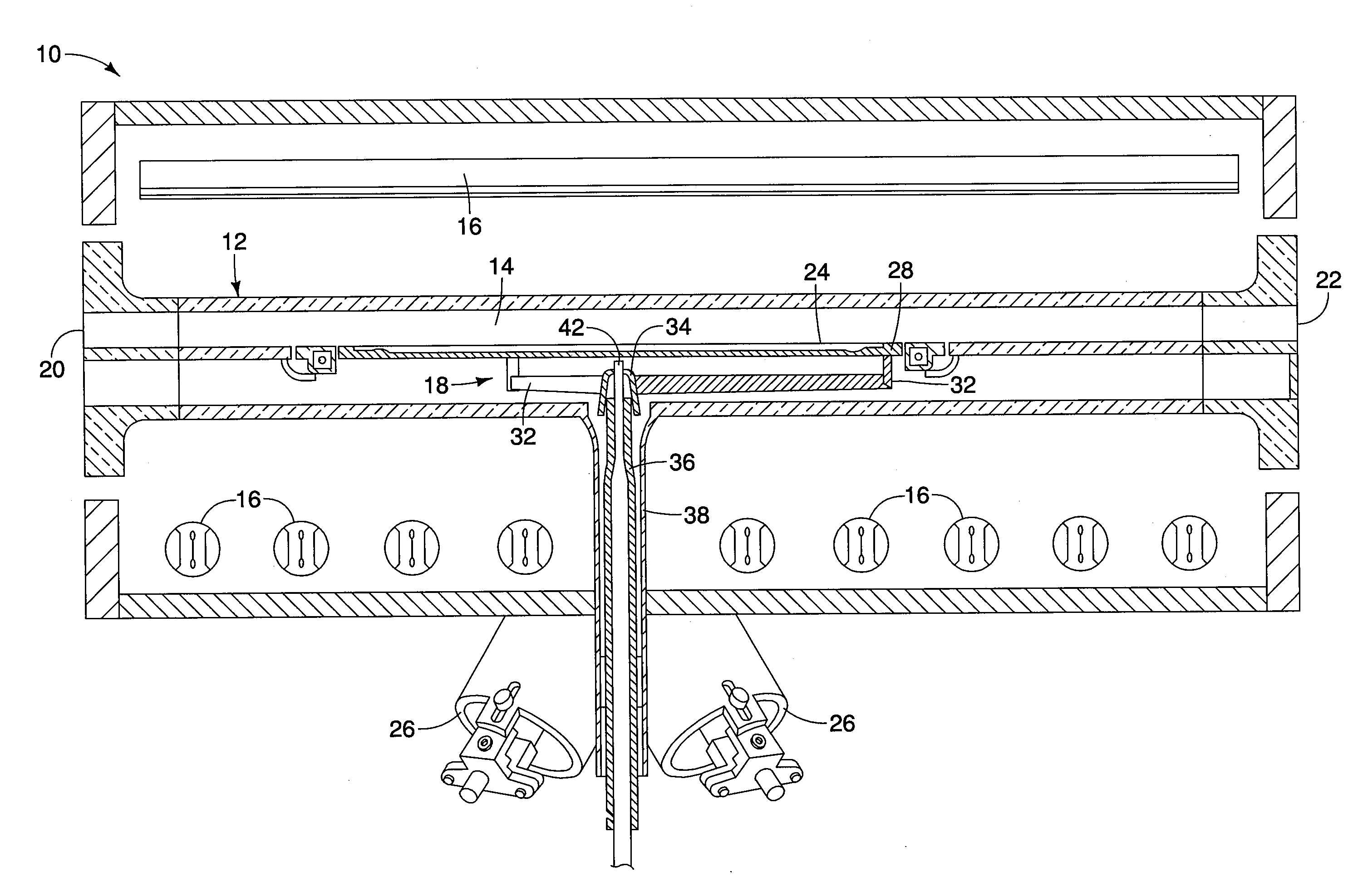

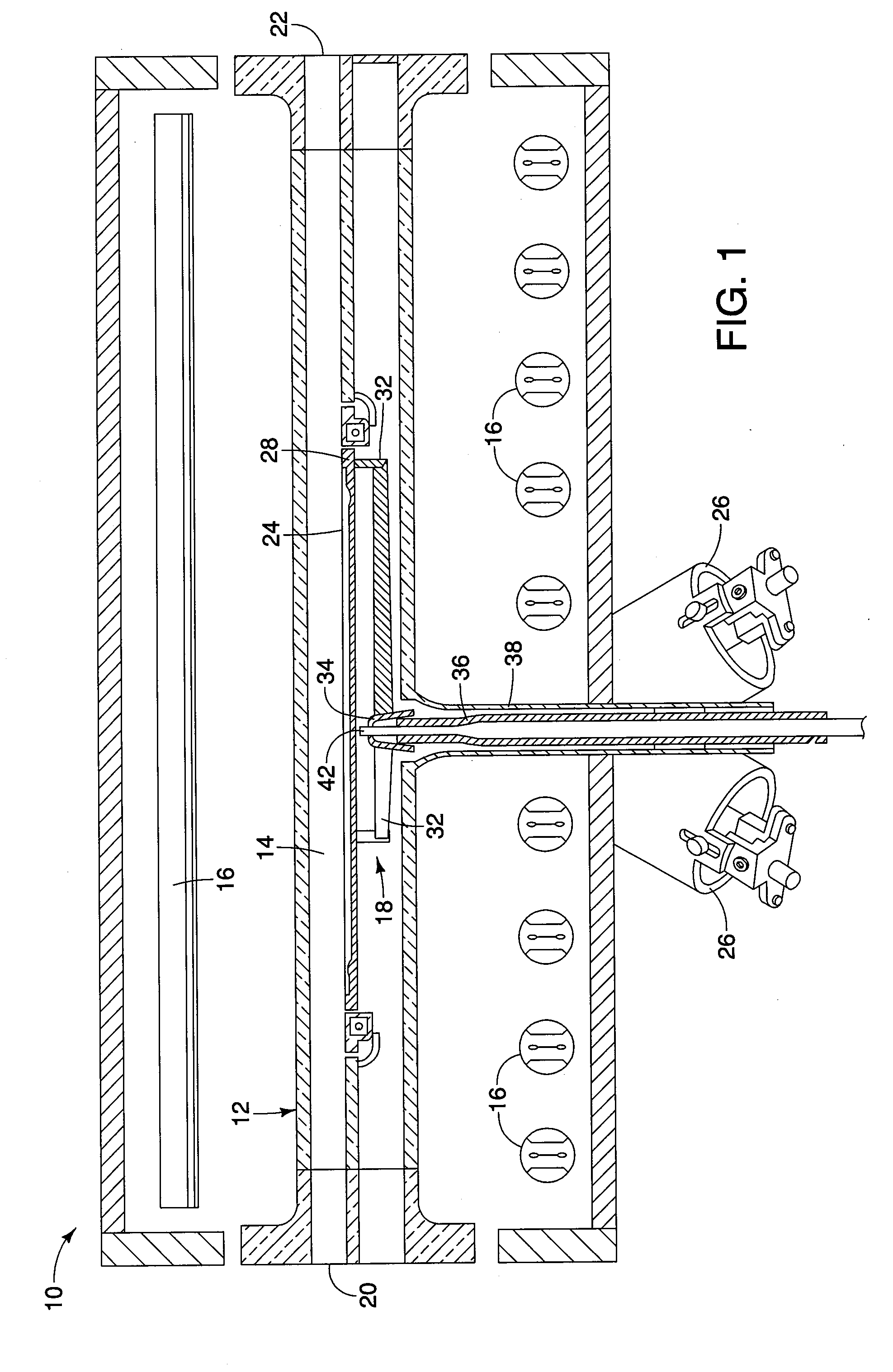

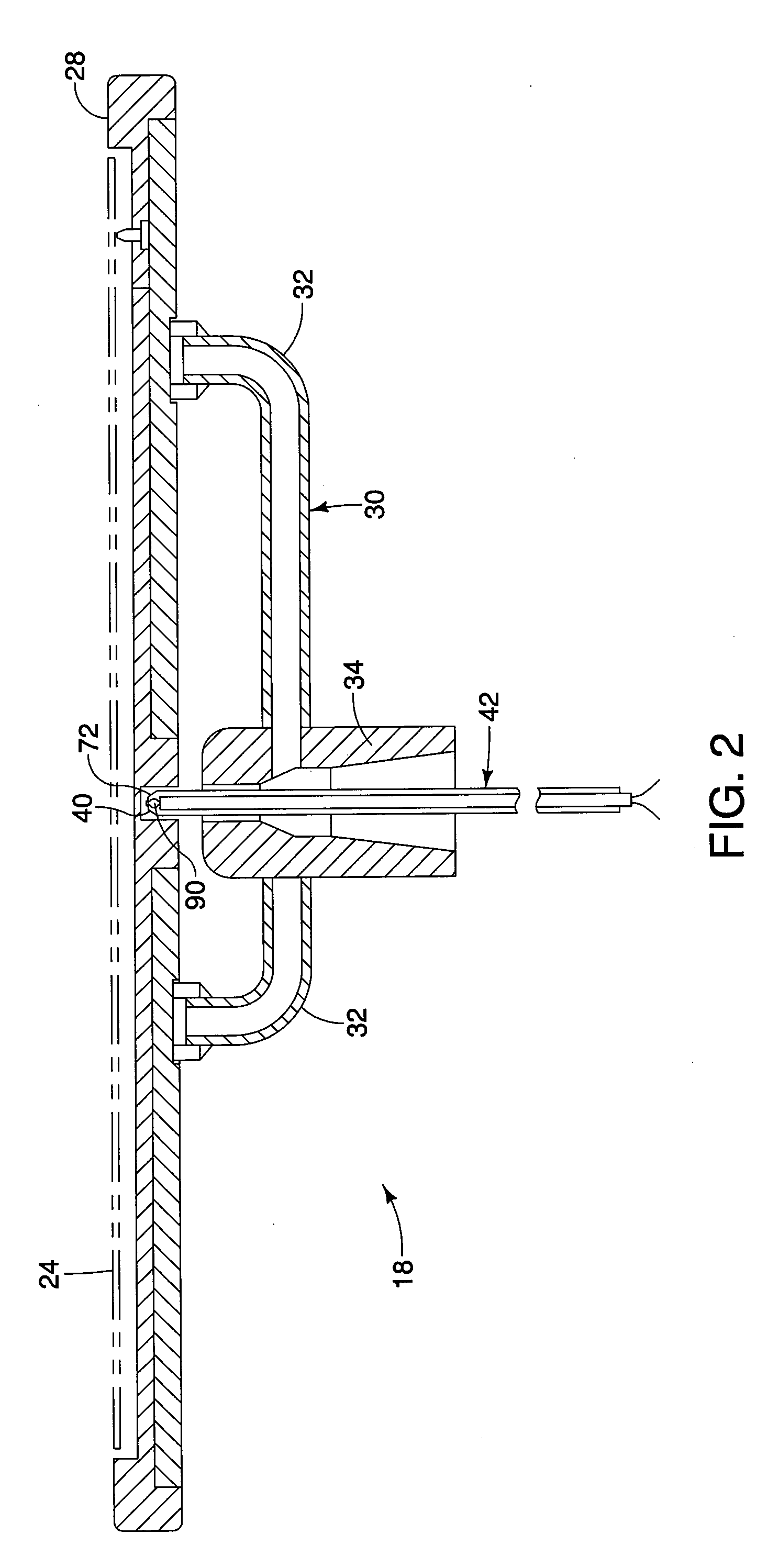

Robert Bosch GmbH

Technical Solution: Bosch has developed a comprehensive drift minimization system for thermopile sensors used in automotive and industrial applications. Their approach combines hardware design optimization with advanced signal processing techniques. At the hardware level, Bosch employs thermally balanced sensor designs with symmetrical thermal paths and specialized housing materials that minimize temperature gradients. Their thermopile sensors incorporate integrated reference temperature sensors for real-time temperature compensation. On the signal processing side, Bosch implements adaptive filtering algorithms that continuously adjust for changing environmental conditions, and utilizes proprietary calibration techniques that characterize individual sensor behavior across temperature ranges. Their system also features chopper-stabilized amplification circuits to reduce low-frequency noise and offset drift, complemented by digital correction algorithms that apply sensor-specific compensation factors stored in non-volatile memory.

Strengths: Robust solutions suitable for harsh automotive environments; integrated approach combining hardware and software solutions; extensive field testing and validation. Weaknesses: May prioritize reliability over absolute precision for some applications; solutions often tailored to specific use cases rather than general-purpose applications.

Watlow Electric Manufacturing Co.

Technical Solution: Watlow has developed specialized drift minimization techniques for thermopile sensors used in high-temperature industrial applications. Their approach focuses on material science innovations and thermal management expertise. Watlow's thermopile sensors utilize proprietary thermocouple materials with inherently lower drift characteristics and enhanced stability at elevated temperatures. Their design incorporates advanced ceramic substrates with carefully engineered thermal expansion properties to maintain sensor geometry across wide temperature ranges. Watlow's solution includes multi-layer radiation shields and thermal barriers that create stable thermal environments around the sensing elements. For signal conditioning, they employ precision instrumentation amplifiers with temperature-stabilized components and implement digital calibration techniques that store individual sensor characteristics in embedded memory. Their comprehensive approach also includes specialized mounting techniques that minimize thermal stress on sensor components and reduce mechanical strain-induced drift effects.

Strengths: Exceptional performance in high-temperature industrial environments; specialized materials science expertise; robust solutions for harsh conditions. Weaknesses: Solutions may be optimized for industrial rather than precision laboratory applications; potentially higher cost for specialized high-temperature capabilities.

Critical Patents in Thermopile Drift Reduction

thermocouple

PatentInactiveUS20090052498A1

Innovation

- A thermocouple design with a vertically oriented sheath, a support tube, and a junction between dissimilar metal wires, where a spring exerts a controlled force to maintain the junction in continuous contact with the measuring tip, minimizing deformation and drift in temperature measurements.

method

PatentWO2018046921A1

Innovation

- Doping platinum with yttrium, zirconium, or samarium to reduce rhodium drift and grain growth, thereby stabilizing the electrical properties of Pt vs. RhPt thermocouples in oxidizing environments.

Environmental Factors Affecting Thermopile Performance

Thermopile sensors are highly susceptible to environmental conditions that can significantly impact their measurement accuracy and stability. Temperature fluctuations represent the most critical environmental factor affecting thermopile performance. When ambient temperature changes rapidly or unevenly across the sensor assembly, it creates thermal gradients that directly contribute to measurement drift. These gradients disrupt the thermal equilibrium necessary for accurate readings, particularly in applications requiring high precision such as medical diagnostics or industrial process monitoring.

Humidity variations constitute another substantial environmental challenge. High humidity environments can lead to condensation on sensor surfaces, altering thermal conductivity characteristics and creating parasitic thermal paths. This effect is particularly pronounced in outdoor applications or industrial settings with variable moisture levels. Over time, repeated humidity cycling can also accelerate aging effects in sensor materials, further exacerbating drift issues.

Air currents and ventilation patterns around thermopile sensors create convective heat transfer that can dramatically affect measurement stability. Even subtle air movements can introduce noise and transient responses that manifest as apparent drift in output signals. This factor becomes especially problematic in open environments or improperly shielded installations where air flow patterns are unpredictable or constantly changing.

Electromagnetic interference (EMI) from nearby electronic equipment or power sources can induce voltage fluctuations in thermopile circuits that appear as measurement drift. The low-level signals generated by thermopiles make them particularly vulnerable to such interference, necessitating careful consideration of installation location and appropriate shielding measures.

Dust and particulate contamination gradually accumulate on sensor surfaces, altering their emissivity characteristics and thermal response profiles. This progressive degradation results in a slow but persistent drift that becomes more pronounced over extended operational periods. In industrial or outdoor environments where particulate levels are high, this effect can significantly reduce sensor lifespan and measurement reliability.

Barometric pressure changes, while often overlooked, can influence thermopile readings through alterations in the thermal conductivity of surrounding air. This factor becomes particularly relevant in applications involving altitude changes or pressurized environments, where pressure variations can introduce systematic measurement errors that manifest as apparent drift over time.

Humidity variations constitute another substantial environmental challenge. High humidity environments can lead to condensation on sensor surfaces, altering thermal conductivity characteristics and creating parasitic thermal paths. This effect is particularly pronounced in outdoor applications or industrial settings with variable moisture levels. Over time, repeated humidity cycling can also accelerate aging effects in sensor materials, further exacerbating drift issues.

Air currents and ventilation patterns around thermopile sensors create convective heat transfer that can dramatically affect measurement stability. Even subtle air movements can introduce noise and transient responses that manifest as apparent drift in output signals. This factor becomes especially problematic in open environments or improperly shielded installations where air flow patterns are unpredictable or constantly changing.

Electromagnetic interference (EMI) from nearby electronic equipment or power sources can induce voltage fluctuations in thermopile circuits that appear as measurement drift. The low-level signals generated by thermopiles make them particularly vulnerable to such interference, necessitating careful consideration of installation location and appropriate shielding measures.

Dust and particulate contamination gradually accumulate on sensor surfaces, altering their emissivity characteristics and thermal response profiles. This progressive degradation results in a slow but persistent drift that becomes more pronounced over extended operational periods. In industrial or outdoor environments where particulate levels are high, this effect can significantly reduce sensor lifespan and measurement reliability.

Barometric pressure changes, while often overlooked, can influence thermopile readings through alterations in the thermal conductivity of surrounding air. This factor becomes particularly relevant in applications involving altitude changes or pressurized environments, where pressure variations can introduce systematic measurement errors that manifest as apparent drift over time.

Calibration Methodologies for Long-term Accuracy

Calibration methodologies represent a critical component in maintaining long-term accuracy of thermopile measurement systems. The inherent drift characteristics of thermopile sensors necessitate robust calibration approaches that can compensate for both initial inaccuracies and time-dependent variations. Traditional single-point calibration methods have proven insufficient for applications requiring sustained precision over extended operational periods.

Multi-point calibration techniques have emerged as the industry standard for high-precision thermopile applications. These methodologies involve characterizing sensor response across the entire operational temperature range, typically using 3-5 reference points strategically distributed to capture non-linearities in the sensor response curve. The resulting calibration matrix enables dynamic compensation algorithms to adjust measurements based on both the measured value and ambient conditions.

Temperature cycling calibration represents an advanced methodology specifically designed to address thermal hysteresis effects in thermopile sensors. This approach subjects sensors to controlled temperature cycles that mimic expected operational conditions, allowing for the development of compensation models that account for the sensor's thermal memory effects. Research indicates this method can reduce drift by up to 68% compared to static calibration approaches.

Real-time reference comparison has gained significant traction in critical applications where continuous accuracy is paramount. This methodology incorporates a secondary high-stability reference sensor (typically a platinum resistance thermometer) within the measurement system. The thermopile readings are continuously compared against this reference, with correction factors dynamically updated. While increasing system complexity, this approach effectively transforms periodic calibration requirements into a continuous process.

Statistical drift prediction models represent the cutting edge of calibration methodologies. By analyzing the historical drift patterns of similar sensors and applying machine learning algorithms, these models can predict future drift behavior with increasing accuracy. The predicted drift can then be preemptively compensated for in the measurement system. Early implementations have demonstrated the ability to maintain measurement accuracy within ±0.1°C over operational periods exceeding 18 months.

Environmental factor compensation has proven essential for thermopile applications in variable conditions. Advanced calibration methodologies now incorporate multi-variable models that account for ambient temperature, humidity, pressure, and even electromagnetic interference. These comprehensive approaches utilize environmental sensors to provide contextual data that informs real-time calibration adjustments, significantly reducing environmentally-induced drift components.

Multi-point calibration techniques have emerged as the industry standard for high-precision thermopile applications. These methodologies involve characterizing sensor response across the entire operational temperature range, typically using 3-5 reference points strategically distributed to capture non-linearities in the sensor response curve. The resulting calibration matrix enables dynamic compensation algorithms to adjust measurements based on both the measured value and ambient conditions.

Temperature cycling calibration represents an advanced methodology specifically designed to address thermal hysteresis effects in thermopile sensors. This approach subjects sensors to controlled temperature cycles that mimic expected operational conditions, allowing for the development of compensation models that account for the sensor's thermal memory effects. Research indicates this method can reduce drift by up to 68% compared to static calibration approaches.

Real-time reference comparison has gained significant traction in critical applications where continuous accuracy is paramount. This methodology incorporates a secondary high-stability reference sensor (typically a platinum resistance thermometer) within the measurement system. The thermopile readings are continuously compared against this reference, with correction factors dynamically updated. While increasing system complexity, this approach effectively transforms periodic calibration requirements into a continuous process.

Statistical drift prediction models represent the cutting edge of calibration methodologies. By analyzing the historical drift patterns of similar sensors and applying machine learning algorithms, these models can predict future drift behavior with increasing accuracy. The predicted drift can then be preemptively compensated for in the measurement system. Early implementations have demonstrated the ability to maintain measurement accuracy within ±0.1°C over operational periods exceeding 18 months.

Environmental factor compensation has proven essential for thermopile applications in variable conditions. Advanced calibration methodologies now incorporate multi-variable models that account for ambient temperature, humidity, pressure, and even electromagnetic interference. These comprehensive approaches utilize environmental sensors to provide contextual data that informs real-time calibration adjustments, significantly reducing environmentally-induced drift components.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!