How to Minimize Emissions in Ethyl Acetate Processing?

JUN 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ethyl Acetate Emissions Background and Objectives

Ethyl acetate, a widely used solvent in various industries, has been a subject of growing environmental concern due to its volatile organic compound (VOC) emissions. The processing of ethyl acetate, particularly in manufacturing and industrial applications, has historically contributed to air pollution and potential health hazards. As global environmental regulations become more stringent, there is an increasing need to address and minimize these emissions.

The evolution of ethyl acetate processing technology has seen significant advancements over the past few decades. Initially, little attention was paid to emissions control, with open systems being common in many industrial settings. However, as awareness of environmental impacts grew, so did the focus on developing cleaner production methods and more efficient emission control technologies.

Current technological trends in ethyl acetate processing are moving towards closed-loop systems, improved catalysts for more efficient production, and advanced scrubbing technologies for capturing and treating emissions. The industry is also exploring alternative solvents and green chemistry approaches to reduce reliance on traditional ethyl acetate processing methods that generate high levels of emissions.

The primary objective in minimizing emissions in ethyl acetate processing is to develop and implement technologies that significantly reduce VOC releases while maintaining or improving production efficiency. This goal encompasses several key areas of focus, including process optimization, emission capture and treatment, and the development of alternative production methods that inherently produce fewer emissions.

Another critical objective is to meet and exceed increasingly stringent environmental regulations across different global markets. This requires not only technological innovation but also a comprehensive understanding of regulatory landscapes and the ability to adapt quickly to changing requirements.

Furthermore, there is a growing emphasis on lifecycle assessment and sustainability in ethyl acetate processing. The aim is to reduce emissions not just during the production phase but throughout the entire lifecycle of ethyl acetate-based products, from raw material extraction to end-of-life disposal or recycling.

Achieving these objectives requires a multidisciplinary approach, combining expertise in chemical engineering, environmental science, and process design. It also necessitates collaboration between industry, academia, and regulatory bodies to drive innovation and ensure that new technologies are both effective and compliant with environmental standards.

The evolution of ethyl acetate processing technology has seen significant advancements over the past few decades. Initially, little attention was paid to emissions control, with open systems being common in many industrial settings. However, as awareness of environmental impacts grew, so did the focus on developing cleaner production methods and more efficient emission control technologies.

Current technological trends in ethyl acetate processing are moving towards closed-loop systems, improved catalysts for more efficient production, and advanced scrubbing technologies for capturing and treating emissions. The industry is also exploring alternative solvents and green chemistry approaches to reduce reliance on traditional ethyl acetate processing methods that generate high levels of emissions.

The primary objective in minimizing emissions in ethyl acetate processing is to develop and implement technologies that significantly reduce VOC releases while maintaining or improving production efficiency. This goal encompasses several key areas of focus, including process optimization, emission capture and treatment, and the development of alternative production methods that inherently produce fewer emissions.

Another critical objective is to meet and exceed increasingly stringent environmental regulations across different global markets. This requires not only technological innovation but also a comprehensive understanding of regulatory landscapes and the ability to adapt quickly to changing requirements.

Furthermore, there is a growing emphasis on lifecycle assessment and sustainability in ethyl acetate processing. The aim is to reduce emissions not just during the production phase but throughout the entire lifecycle of ethyl acetate-based products, from raw material extraction to end-of-life disposal or recycling.

Achieving these objectives requires a multidisciplinary approach, combining expertise in chemical engineering, environmental science, and process design. It also necessitates collaboration between industry, academia, and regulatory bodies to drive innovation and ensure that new technologies are both effective and compliant with environmental standards.

Market Demand for Low-Emission Ethyl Acetate

The global market for low-emission ethyl acetate has been experiencing significant growth in recent years, driven by increasing environmental regulations and a growing awareness of sustainability among consumers and industries. This demand is particularly pronounced in sectors such as paints and coatings, adhesives, and pharmaceuticals, where ethyl acetate is widely used as a solvent.

In the paints and coatings industry, there is a strong push towards eco-friendly products with reduced volatile organic compound (VOC) emissions. This has led to a surge in demand for low-emission ethyl acetate, as manufacturers seek to comply with stringent environmental standards while maintaining product performance. The automotive and construction sectors, major consumers of paints and coatings, are key drivers of this trend.

The adhesives industry is another significant market for low-emission ethyl acetate. With the rise of green building practices and sustainable packaging solutions, there is a growing need for adhesives that minimize environmental impact. Low-emission ethyl acetate plays a crucial role in formulating these environmentally friendly adhesives, contributing to reduced overall emissions in various applications.

In the pharmaceutical sector, the demand for low-emission ethyl acetate is driven by the need for high-purity solvents in drug manufacturing processes. As regulatory bodies tighten controls on pharmaceutical production emissions, manufacturers are increasingly turning to low-emission alternatives to meet compliance requirements while ensuring product quality.

The electronics industry, particularly in the production of printed circuit boards and semiconductor cleaning, is also contributing to the market demand for low-emission ethyl acetate. As electronic devices become more compact and sophisticated, the need for cleaner, low-emission solvents in manufacturing processes has intensified.

Geographically, the Asia-Pacific region is expected to witness the highest growth in demand for low-emission ethyl acetate, primarily due to rapid industrialization, stringent environmental regulations, and increasing adoption of sustainable practices in countries like China and India. North America and Europe are also significant markets, driven by mature industries and strict environmental policies.

The market trend indicates a shift towards bio-based ethyl acetate as a sustainable alternative to petrochemical-derived products. This aligns with the broader industry movement towards renewable resources and circular economy principles, further stimulating the demand for low-emission variants.

As industries continue to prioritize sustainability and environmental responsibility, the market for low-emission ethyl acetate is projected to expand further. This growth is supported by ongoing research and development efforts to improve production processes and reduce emissions across the entire value chain of ethyl acetate manufacturing and usage.

In the paints and coatings industry, there is a strong push towards eco-friendly products with reduced volatile organic compound (VOC) emissions. This has led to a surge in demand for low-emission ethyl acetate, as manufacturers seek to comply with stringent environmental standards while maintaining product performance. The automotive and construction sectors, major consumers of paints and coatings, are key drivers of this trend.

The adhesives industry is another significant market for low-emission ethyl acetate. With the rise of green building practices and sustainable packaging solutions, there is a growing need for adhesives that minimize environmental impact. Low-emission ethyl acetate plays a crucial role in formulating these environmentally friendly adhesives, contributing to reduced overall emissions in various applications.

In the pharmaceutical sector, the demand for low-emission ethyl acetate is driven by the need for high-purity solvents in drug manufacturing processes. As regulatory bodies tighten controls on pharmaceutical production emissions, manufacturers are increasingly turning to low-emission alternatives to meet compliance requirements while ensuring product quality.

The electronics industry, particularly in the production of printed circuit boards and semiconductor cleaning, is also contributing to the market demand for low-emission ethyl acetate. As electronic devices become more compact and sophisticated, the need for cleaner, low-emission solvents in manufacturing processes has intensified.

Geographically, the Asia-Pacific region is expected to witness the highest growth in demand for low-emission ethyl acetate, primarily due to rapid industrialization, stringent environmental regulations, and increasing adoption of sustainable practices in countries like China and India. North America and Europe are also significant markets, driven by mature industries and strict environmental policies.

The market trend indicates a shift towards bio-based ethyl acetate as a sustainable alternative to petrochemical-derived products. This aligns with the broader industry movement towards renewable resources and circular economy principles, further stimulating the demand for low-emission variants.

As industries continue to prioritize sustainability and environmental responsibility, the market for low-emission ethyl acetate is projected to expand further. This growth is supported by ongoing research and development efforts to improve production processes and reduce emissions across the entire value chain of ethyl acetate manufacturing and usage.

Current Challenges in Ethyl Acetate Emission Control

Ethyl acetate processing faces significant challenges in emission control, primarily due to the volatile nature of the compound and its widespread use in various industries. The main sources of emissions include storage tanks, loading and unloading operations, and process vents. These emissions not only pose environmental concerns but also represent economic losses for manufacturers.

One of the primary challenges is the control of fugitive emissions from equipment leaks. Valves, pumps, and connectors in ethyl acetate processing plants are prone to leaks, which can be difficult to detect and quantify. Traditional leak detection and repair (LDAR) programs may not be sufficient to address the issue, especially in large-scale operations.

Another significant challenge is the management of vapor emissions during storage and transfer operations. Ethyl acetate's high vapor pressure makes it susceptible to evaporation, particularly during tank filling and emptying processes. Conventional fixed-roof tanks without proper vapor recovery systems can lead to substantial emissions, especially in regions with high ambient temperatures.

Process vent emissions present a unique set of challenges. Ethyl acetate production often involves distillation and purification steps, which can generate significant amounts of vapor. Capturing and treating these emissions efficiently without compromising the process efficiency or product quality is a complex task that requires careful engineering and control strategies.

The recovery and treatment of ethyl acetate emissions also pose technical difficulties. While various technologies such as adsorption, absorption, and condensation are available, each has its limitations in terms of efficiency, cost-effectiveness, and applicability to different emission sources. Selecting and optimizing the right combination of control technologies for a specific plant configuration remains a challenge for many operators.

Regulatory compliance adds another layer of complexity to emission control efforts. As environmental regulations become more stringent globally, manufacturers must continuously adapt their emission control strategies to meet evolving standards. This often requires significant investments in new technologies and process modifications, which can be financially challenging, especially for smaller operations.

Monitoring and quantification of emissions present ongoing challenges. Accurate measurement of ethyl acetate emissions, particularly from diffuse sources, is crucial for assessing the effectiveness of control measures and ensuring regulatory compliance. However, current monitoring technologies may not always provide the level of accuracy and reliability needed for comprehensive emission management.

Lastly, the integration of emission control measures with overall process optimization remains a significant challenge. Balancing the need for reduced emissions with production efficiency, product quality, and operational costs requires a holistic approach that is not always easy to achieve in practice. Manufacturers must navigate these competing priorities while striving for sustainable and economically viable operations.

One of the primary challenges is the control of fugitive emissions from equipment leaks. Valves, pumps, and connectors in ethyl acetate processing plants are prone to leaks, which can be difficult to detect and quantify. Traditional leak detection and repair (LDAR) programs may not be sufficient to address the issue, especially in large-scale operations.

Another significant challenge is the management of vapor emissions during storage and transfer operations. Ethyl acetate's high vapor pressure makes it susceptible to evaporation, particularly during tank filling and emptying processes. Conventional fixed-roof tanks without proper vapor recovery systems can lead to substantial emissions, especially in regions with high ambient temperatures.

Process vent emissions present a unique set of challenges. Ethyl acetate production often involves distillation and purification steps, which can generate significant amounts of vapor. Capturing and treating these emissions efficiently without compromising the process efficiency or product quality is a complex task that requires careful engineering and control strategies.

The recovery and treatment of ethyl acetate emissions also pose technical difficulties. While various technologies such as adsorption, absorption, and condensation are available, each has its limitations in terms of efficiency, cost-effectiveness, and applicability to different emission sources. Selecting and optimizing the right combination of control technologies for a specific plant configuration remains a challenge for many operators.

Regulatory compliance adds another layer of complexity to emission control efforts. As environmental regulations become more stringent globally, manufacturers must continuously adapt their emission control strategies to meet evolving standards. This often requires significant investments in new technologies and process modifications, which can be financially challenging, especially for smaller operations.

Monitoring and quantification of emissions present ongoing challenges. Accurate measurement of ethyl acetate emissions, particularly from diffuse sources, is crucial for assessing the effectiveness of control measures and ensuring regulatory compliance. However, current monitoring technologies may not always provide the level of accuracy and reliability needed for comprehensive emission management.

Lastly, the integration of emission control measures with overall process optimization remains a significant challenge. Balancing the need for reduced emissions with production efficiency, product quality, and operational costs requires a holistic approach that is not always easy to achieve in practice. Manufacturers must navigate these competing priorities while striving for sustainable and economically viable operations.

Existing Emission Control Solutions

01 Emission control in ethyl acetate production

Various methods are employed to control emissions during ethyl acetate production processes. These may include the use of scrubbers, catalytic oxidizers, or other abatement technologies to reduce volatile organic compound (VOC) emissions. Proper process design and optimization can also help minimize the release of harmful substances into the environment.- Emission control in ethyl acetate production: Various methods are employed to control emissions during ethyl acetate production. These include using advanced catalysts, optimizing reaction conditions, and implementing closed-loop systems to minimize the release of volatile organic compounds (VOCs) and other pollutants into the environment.

- Solvent recovery and recycling in ethyl acetate processing: Techniques for recovering and recycling ethyl acetate and other solvents used in industrial processes are developed to reduce emissions and improve efficiency. These may include distillation, membrane separation, and adsorption methods to capture and reuse solvents, minimizing waste and environmental impact.

- Monitoring and detection of ethyl acetate emissions: Advanced monitoring systems and detection technologies are utilized to measure and analyze ethyl acetate emissions in industrial settings. These may include gas chromatography, mass spectrometry, and real-time sensors to ensure compliance with environmental regulations and optimize process control.

- Treatment of ethyl acetate-containing waste streams: Various treatment methods are developed for handling waste streams containing ethyl acetate. These may include biological treatment, chemical oxidation, and advanced oxidation processes to break down or remove ethyl acetate from wastewater or gas streams before release into the environment.

- Green chemistry approaches for ethyl acetate synthesis: Environmentally friendly methods for synthesizing ethyl acetate are explored to reduce emissions and environmental impact. These may include using renewable feedstocks, developing low-temperature processes, and employing biocatalysts or green solvents to minimize the generation of harmful byproducts and emissions.

02 Solvent recovery and recycling systems

Implementing solvent recovery and recycling systems in ethyl acetate processing can significantly reduce emissions. These systems capture and purify used ethyl acetate, allowing it to be reused in the production process. This not only minimizes waste but also reduces the overall environmental impact of the manufacturing process.Expand Specific Solutions03 Advanced monitoring and detection techniques

Utilizing advanced monitoring and detection techniques helps in identifying and quantifying ethyl acetate emissions. This may include the use of gas chromatography, mass spectrometry, or other analytical methods to accurately measure emission levels. Real-time monitoring systems can also be employed to ensure compliance with environmental regulations.Expand Specific Solutions04 Process optimization and green chemistry approaches

Implementing process optimization techniques and green chemistry approaches can help reduce ethyl acetate emissions. This may involve using alternative, more environmentally friendly solvents, improving reaction efficiency, or developing novel catalysts that minimize byproduct formation. These strategies aim to reduce the overall environmental footprint of ethyl acetate processing.Expand Specific Solutions05 Waste heat recovery and energy efficiency

Incorporating waste heat recovery systems and improving energy efficiency in ethyl acetate processing can indirectly reduce emissions. By optimizing energy use and recovering waste heat, the overall carbon footprint of the production process is reduced. This may include the use of heat exchangers, cogeneration systems, or other energy-efficient technologies.Expand Specific Solutions

Key Players in Ethyl Acetate Production Industry

The ethyl acetate processing industry is in a mature stage, with a global market size expected to reach $4.3 billion by 2027. The technology for minimizing emissions in ethyl acetate processing is moderately mature, with ongoing research and development efforts. Key players like Celanese International Corp., Wacker Chemie AG, and Daicel Corp. are at the forefront of developing advanced emission reduction technologies. These companies are investing in process optimization, catalytic conversion, and closed-loop systems to minimize environmental impact. Emerging players such as LanzaTech NZ Ltd. are exploring innovative biotechnology approaches to further reduce emissions. The competitive landscape is characterized by a mix of established chemical companies and newer entrants focusing on sustainable solutions, driving continuous improvement in emission reduction techniques.

Celanese International Corp.

Technical Solution: Celanese has developed an innovative process for ethyl acetate production that significantly reduces emissions. Their approach involves using a reactive distillation technology, which combines reaction and separation in a single unit operation. This process achieves higher conversion rates and selectivity, resulting in reduced energy consumption and fewer byproducts[1]. The company has also implemented advanced catalysts that operate at lower temperatures, further minimizing energy requirements and associated emissions[2]. Additionally, Celanese utilizes a closed-loop system that captures and recycles unreacted raw materials, reducing waste and emissions from the overall process[3].

Strengths: High efficiency, reduced energy consumption, and minimized waste. Weaknesses: Potentially higher initial capital costs and complexity in process control.

Wacker Chemie AG

Technical Solution: Wacker Chemie has developed a sustainable approach to ethyl acetate production focusing on green chemistry principles. Their process utilizes bio-based feedstocks, specifically ethanol derived from renewable sources such as corn or sugarcane[4]. This shift to bio-based raw materials significantly reduces the carbon footprint of the production process. Wacker has also implemented an innovative catalytic system that operates at milder conditions, reducing energy requirements and associated emissions[5]. The company employs advanced process intensification techniques, including microreactor technology, which allows for better control of reaction parameters and minimizes side reactions, thereby reducing waste and emissions[6].

Strengths: Use of renewable feedstocks, reduced carbon footprint, and improved process control. Weaknesses: Potential supply chain challenges with bio-based feedstocks and higher production costs.

Innovative Approaches to Emission Minimization

Process for production of ethyl acetate

PatentWO2025072073A1

Innovation

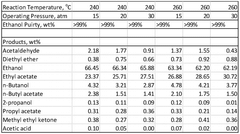

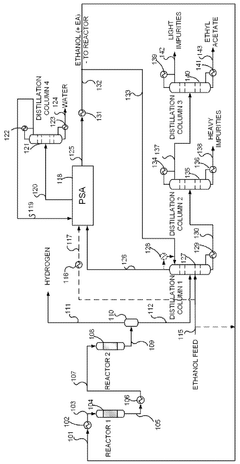

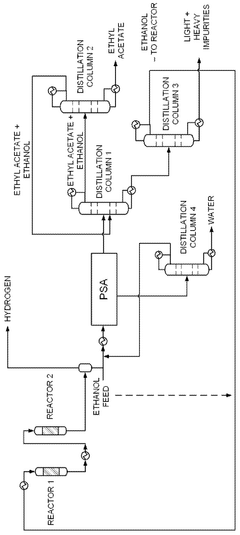

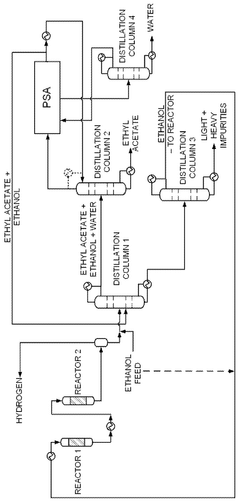

- A novel process that converts ethanol to ethyl acetate through dehydrogenation, followed by selective hydrogenation of byproducts to facilitate easier separation, and utilizes pressure swing adsorption to minimize water content and protect the catalyst.

Novel energy efficient method for ethanol production

PatentPendingIN202411044459A

Innovation

- A hybrid system integrating a fermenter with a freeze separation crystallizer utilizes the differential freezing points of ethanol and water to separate ethanol from water, employing ice as a cooling medium within a heat exchanger, eliminating the need for traditional distillation columns and cooling towers, and creating a closed-loop energy-efficient process.

Environmental Regulations and Compliance

Environmental regulations and compliance play a crucial role in minimizing emissions in ethyl acetate processing. The production of ethyl acetate is subject to stringent environmental laws and regulations at local, national, and international levels. These regulations aim to protect human health and the environment by setting limits on emissions of volatile organic compounds (VOCs) and other pollutants associated with the manufacturing process.

In the United States, the Environmental Protection Agency (EPA) enforces regulations under the Clean Air Act that directly impact ethyl acetate production. The National Emission Standards for Hazardous Air Pollutants (NESHAP) and New Source Performance Standards (NSPS) set specific emission limits for chemical manufacturing processes, including those involving ethyl acetate. Facilities must implement Maximum Achievable Control Technology (MACT) to reduce emissions to the greatest extent possible.

The European Union has implemented the Industrial Emissions Directive (IED) to control emissions from industrial activities. This directive requires facilities to obtain permits based on the application of Best Available Techniques (BAT). For ethyl acetate production, BAT includes the use of efficient catalysts, closed-loop systems, and advanced emission control technologies such as thermal oxidizers and scrubbers.

Compliance with these regulations often requires significant investment in emission control technologies and process improvements. Companies must regularly monitor and report their emissions to regulatory authorities. Failure to comply can result in hefty fines, legal action, and potential shutdown of operations.

Many countries have also implemented cap-and-trade systems or carbon taxes to incentivize emission reductions. These market-based mechanisms create financial incentives for companies to invest in cleaner technologies and processes. In the context of ethyl acetate production, this may encourage the adoption of more efficient catalysts, process optimization, and the use of renewable feedstocks.

As global concern over climate change intensifies, regulations are becoming increasingly stringent. The Paris Agreement and subsequent national commitments have led to more ambitious emission reduction targets. This trend is likely to continue, putting pressure on chemical manufacturers to innovate and adopt cleaner production methods.

To ensure compliance and minimize emissions, companies engaged in ethyl acetate processing must stay informed about evolving regulations, invest in best-in-class emission control technologies, and continuously improve their processes. This may involve regular audits, employee training, and collaboration with regulatory bodies and industry associations to develop and implement best practices.

In the United States, the Environmental Protection Agency (EPA) enforces regulations under the Clean Air Act that directly impact ethyl acetate production. The National Emission Standards for Hazardous Air Pollutants (NESHAP) and New Source Performance Standards (NSPS) set specific emission limits for chemical manufacturing processes, including those involving ethyl acetate. Facilities must implement Maximum Achievable Control Technology (MACT) to reduce emissions to the greatest extent possible.

The European Union has implemented the Industrial Emissions Directive (IED) to control emissions from industrial activities. This directive requires facilities to obtain permits based on the application of Best Available Techniques (BAT). For ethyl acetate production, BAT includes the use of efficient catalysts, closed-loop systems, and advanced emission control technologies such as thermal oxidizers and scrubbers.

Compliance with these regulations often requires significant investment in emission control technologies and process improvements. Companies must regularly monitor and report their emissions to regulatory authorities. Failure to comply can result in hefty fines, legal action, and potential shutdown of operations.

Many countries have also implemented cap-and-trade systems or carbon taxes to incentivize emission reductions. These market-based mechanisms create financial incentives for companies to invest in cleaner technologies and processes. In the context of ethyl acetate production, this may encourage the adoption of more efficient catalysts, process optimization, and the use of renewable feedstocks.

As global concern over climate change intensifies, regulations are becoming increasingly stringent. The Paris Agreement and subsequent national commitments have led to more ambitious emission reduction targets. This trend is likely to continue, putting pressure on chemical manufacturers to innovate and adopt cleaner production methods.

To ensure compliance and minimize emissions, companies engaged in ethyl acetate processing must stay informed about evolving regulations, invest in best-in-class emission control technologies, and continuously improve their processes. This may involve regular audits, employee training, and collaboration with regulatory bodies and industry associations to develop and implement best practices.

Life Cycle Assessment of Ethyl Acetate Production

Life Cycle Assessment (LCA) is a crucial tool for evaluating the environmental impacts of ethyl acetate production throughout its entire lifecycle. This comprehensive approach considers all stages, from raw material extraction to final disposal, providing valuable insights into potential emission reduction strategies.

The production of ethyl acetate typically involves the esterification of ethanol and acetic acid. The LCA begins with the sourcing of these raw materials, examining the environmental impacts associated with their extraction and transportation. For ethanol, this may include agricultural processes for biomass production or petrochemical routes. Acetic acid production often involves methanol carbonylation or ethylene oxidation, each with its own environmental implications.

The manufacturing process itself is a significant focus of the LCA. This stage encompasses the reaction conditions, catalysts used, and energy requirements for the esterification process. Modern production methods, such as reactive distillation, are analyzed for their potential to reduce energy consumption and improve overall efficiency. The assessment also considers the purification steps, including distillation and drying, which can be energy-intensive and contribute substantially to the carbon footprint.

Packaging and distribution of the final product are evaluated, taking into account transportation modes and distances. The use phase of ethyl acetate is examined, particularly in industrial applications where proper handling and containment can significantly impact emissions. End-of-life scenarios, including potential recycling or disposal methods, are also assessed to provide a complete picture of the product's environmental impact.

Throughout the LCA, key environmental indicators are quantified, such as global warming potential, acidification, eutrophication, and resource depletion. These metrics allow for a comparative analysis of different production routes and technologies, highlighting areas where emissions can be most effectively reduced.

The LCA also considers the potential for circular economy approaches in ethyl acetate production. This includes evaluating opportunities for using renewable feedstocks, implementing closed-loop recycling systems, and exploring bio-based alternatives that could lower the overall environmental footprint.

By conducting a thorough Life Cycle Assessment, manufacturers can identify hotspots in the production process where emissions are most significant. This information is invaluable for prioritizing improvement efforts and guiding research and development towards more sustainable production methods. The LCA results can also inform policy decisions and help companies meet increasingly stringent environmental regulations while improving their competitive position in a market that increasingly values sustainability.

The production of ethyl acetate typically involves the esterification of ethanol and acetic acid. The LCA begins with the sourcing of these raw materials, examining the environmental impacts associated with their extraction and transportation. For ethanol, this may include agricultural processes for biomass production or petrochemical routes. Acetic acid production often involves methanol carbonylation or ethylene oxidation, each with its own environmental implications.

The manufacturing process itself is a significant focus of the LCA. This stage encompasses the reaction conditions, catalysts used, and energy requirements for the esterification process. Modern production methods, such as reactive distillation, are analyzed for their potential to reduce energy consumption and improve overall efficiency. The assessment also considers the purification steps, including distillation and drying, which can be energy-intensive and contribute substantially to the carbon footprint.

Packaging and distribution of the final product are evaluated, taking into account transportation modes and distances. The use phase of ethyl acetate is examined, particularly in industrial applications where proper handling and containment can significantly impact emissions. End-of-life scenarios, including potential recycling or disposal methods, are also assessed to provide a complete picture of the product's environmental impact.

Throughout the LCA, key environmental indicators are quantified, such as global warming potential, acidification, eutrophication, and resource depletion. These metrics allow for a comparative analysis of different production routes and technologies, highlighting areas where emissions can be most effectively reduced.

The LCA also considers the potential for circular economy approaches in ethyl acetate production. This includes evaluating opportunities for using renewable feedstocks, implementing closed-loop recycling systems, and exploring bio-based alternatives that could lower the overall environmental footprint.

By conducting a thorough Life Cycle Assessment, manufacturers can identify hotspots in the production process where emissions are most significant. This information is invaluable for prioritizing improvement efforts and guiding research and development towards more sustainable production methods. The LCA results can also inform policy decisions and help companies meet increasingly stringent environmental regulations while improving their competitive position in a market that increasingly values sustainability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!