How to Minimize Thermal Drift in Thermopile Installations

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermopile Thermal Drift Background and Objectives

Thermopile sensors have been integral components in temperature measurement systems since their invention in the early 19th century. These devices, which consist of multiple thermocouples connected in series or parallel, operate based on the Seebeck effect to convert thermal energy into electrical signals. Over the past decades, thermopiles have evolved from simple temperature measurement tools to sophisticated sensors used in various high-precision applications including infrared detection, thermal imaging, and industrial process control.

The evolution of thermopile technology has been marked by significant improvements in sensitivity, response time, and miniaturization. However, thermal drift remains one of the most persistent challenges affecting the accuracy and reliability of thermopile installations. Thermal drift refers to the undesired variation in sensor output that occurs due to changes in ambient temperature rather than changes in the target temperature being measured. This phenomenon can introduce measurement errors ranging from 0.1% to several percent of the reading, which is unacceptable in many precision applications.

Recent technological advancements have focused on addressing thermal drift through improved materials, enhanced circuit designs, and advanced compensation algorithms. The development of new semiconductor materials with lower temperature coefficients has been particularly promising. Additionally, the integration of digital signal processing capabilities has enabled more sophisticated real-time drift compensation techniques.

The primary objective of this technical research is to comprehensively analyze the causes of thermal drift in thermopile installations and evaluate existing mitigation strategies. We aim to identify the most effective approaches for minimizing thermal drift across different application scenarios, considering factors such as environmental conditions, installation constraints, and performance requirements.

Furthermore, this research seeks to explore emerging technologies and methodologies that show promise for next-generation thermopile systems with inherently lower drift characteristics. This includes investigating novel materials, innovative sensor designs, and advanced calibration techniques that could potentially revolutionize the field.

The ultimate goal is to develop a strategic roadmap for thermal drift minimization that balances technical effectiveness with practical implementation considerations such as cost, complexity, and compatibility with existing systems. By addressing the thermal drift challenge, we anticipate enabling new applications for thermopile technology in fields requiring ultra-high precision measurements, including medical diagnostics, aerospace systems, and advanced scientific instrumentation.

The evolution of thermopile technology has been marked by significant improvements in sensitivity, response time, and miniaturization. However, thermal drift remains one of the most persistent challenges affecting the accuracy and reliability of thermopile installations. Thermal drift refers to the undesired variation in sensor output that occurs due to changes in ambient temperature rather than changes in the target temperature being measured. This phenomenon can introduce measurement errors ranging from 0.1% to several percent of the reading, which is unacceptable in many precision applications.

Recent technological advancements have focused on addressing thermal drift through improved materials, enhanced circuit designs, and advanced compensation algorithms. The development of new semiconductor materials with lower temperature coefficients has been particularly promising. Additionally, the integration of digital signal processing capabilities has enabled more sophisticated real-time drift compensation techniques.

The primary objective of this technical research is to comprehensively analyze the causes of thermal drift in thermopile installations and evaluate existing mitigation strategies. We aim to identify the most effective approaches for minimizing thermal drift across different application scenarios, considering factors such as environmental conditions, installation constraints, and performance requirements.

Furthermore, this research seeks to explore emerging technologies and methodologies that show promise for next-generation thermopile systems with inherently lower drift characteristics. This includes investigating novel materials, innovative sensor designs, and advanced calibration techniques that could potentially revolutionize the field.

The ultimate goal is to develop a strategic roadmap for thermal drift minimization that balances technical effectiveness with practical implementation considerations such as cost, complexity, and compatibility with existing systems. By addressing the thermal drift challenge, we anticipate enabling new applications for thermopile technology in fields requiring ultra-high precision measurements, including medical diagnostics, aerospace systems, and advanced scientific instrumentation.

Market Requirements for Thermal Stability in Sensing Applications

The thermal stability market for sensing applications is experiencing significant growth driven by the increasing demand for high-precision measurement systems across multiple industries. Temperature fluctuations remain one of the primary sources of measurement error in sensing devices, particularly in thermopile installations where thermal drift can severely compromise data integrity and operational reliability.

In industrial automation, manufacturers require sensing technologies with thermal stability tolerances below ±0.1°C across operating temperature ranges of -40°C to 125°C. This stringent requirement stems from the need for consistent process control in semiconductor manufacturing, pharmaceutical production, and chemical processing where minor temperature variations can lead to product defects or safety concerns.

The medical diagnostics sector demands even greater thermal stability, with requirements often reaching ±0.05°C or better. Non-contact temperature measurement devices used in clinical settings must maintain calibration accuracy regardless of ambient temperature changes to ensure proper patient diagnosis and treatment monitoring. Market research indicates that medical device manufacturers are willing to pay premium prices for sensing solutions that can demonstrate superior thermal stability performance.

Automotive applications represent another significant market segment, particularly with the rise of electric vehicles and advanced driver assistance systems. Temperature sensors in these applications must maintain accuracy across extreme temperature ranges while withstanding vibration and electromagnetic interference. The automotive industry typically requires thermal stability specifications of ±0.2°C across operating ranges of -40°C to 125°C with minimal drift over 10+ year product lifetimes.

Consumer electronics manufacturers are increasingly incorporating thermal sensors into wearable devices, smart home products, and mobile phones. While cost sensitivity is higher in this segment, there remains a growing demand for sensors that can maintain calibration despite being subjected to rapid temperature changes and varying environmental conditions. Market requirements typically specify drift rates below 0.1°C per year and measurement stability within ±0.3°C across consumer operating environments.

Energy management systems and building automation represent an expanding market for thermally stable sensing technologies. With the global push toward energy efficiency, HVAC control systems require sensors that can detect minute temperature differences with high repeatability. Market specifications typically demand stability within ±0.2°C across operating ranges of 0°C to 50°C with minimal long-term drift to ensure optimal energy utilization and occupant comfort.

Aerospace and defense applications present perhaps the most demanding requirements, with thermal stability specifications often reaching ±0.01°C across extreme operating conditions. These applications require sensing technologies that can withstand rapid temperature cycling while maintaining calibration accuracy for mission-critical systems.

In industrial automation, manufacturers require sensing technologies with thermal stability tolerances below ±0.1°C across operating temperature ranges of -40°C to 125°C. This stringent requirement stems from the need for consistent process control in semiconductor manufacturing, pharmaceutical production, and chemical processing where minor temperature variations can lead to product defects or safety concerns.

The medical diagnostics sector demands even greater thermal stability, with requirements often reaching ±0.05°C or better. Non-contact temperature measurement devices used in clinical settings must maintain calibration accuracy regardless of ambient temperature changes to ensure proper patient diagnosis and treatment monitoring. Market research indicates that medical device manufacturers are willing to pay premium prices for sensing solutions that can demonstrate superior thermal stability performance.

Automotive applications represent another significant market segment, particularly with the rise of electric vehicles and advanced driver assistance systems. Temperature sensors in these applications must maintain accuracy across extreme temperature ranges while withstanding vibration and electromagnetic interference. The automotive industry typically requires thermal stability specifications of ±0.2°C across operating ranges of -40°C to 125°C with minimal drift over 10+ year product lifetimes.

Consumer electronics manufacturers are increasingly incorporating thermal sensors into wearable devices, smart home products, and mobile phones. While cost sensitivity is higher in this segment, there remains a growing demand for sensors that can maintain calibration despite being subjected to rapid temperature changes and varying environmental conditions. Market requirements typically specify drift rates below 0.1°C per year and measurement stability within ±0.3°C across consumer operating environments.

Energy management systems and building automation represent an expanding market for thermally stable sensing technologies. With the global push toward energy efficiency, HVAC control systems require sensors that can detect minute temperature differences with high repeatability. Market specifications typically demand stability within ±0.2°C across operating ranges of 0°C to 50°C with minimal long-term drift to ensure optimal energy utilization and occupant comfort.

Aerospace and defense applications present perhaps the most demanding requirements, with thermal stability specifications often reaching ±0.01°C across extreme operating conditions. These applications require sensing technologies that can withstand rapid temperature cycling while maintaining calibration accuracy for mission-critical systems.

Current Challenges and Limitations in Thermopile Technology

Thermopile technology, while offering significant advantages in non-contact temperature measurement, faces several critical challenges that limit its widespread adoption and effectiveness. The primary limitation revolves around thermal drift, which occurs when ambient temperature changes affect the thermopile sensor's reference junction temperature, leading to measurement inaccuracies. This phenomenon becomes particularly problematic in industrial environments with fluctuating temperatures, where even minor drift can result in significant measurement errors.

Material limitations present another substantial challenge. Current thermopile sensors typically utilize bismuth telluride or antimony-bismuth junctions, which have inherent thermal conductivity constraints and limited temperature ranges. These materials often exhibit non-linear responses at extreme temperatures, further complicating calibration and measurement accuracy. Additionally, the thermoelectric properties of these materials can degrade over time, especially when exposed to thermal cycling, reducing the long-term reliability of thermopile installations.

Miniaturization efforts face significant obstacles due to the fundamental physics of thermopile operation. As sensor size decreases, the signal-to-noise ratio deteriorates, making it difficult to maintain measurement precision in compact designs. This creates a challenging trade-off between size reduction for integration purposes and maintaining adequate performance levels, particularly in applications requiring high sensitivity.

Signal processing complexities further compound these challenges. The low-voltage output signals generated by thermopiles (typically in the microvolt range) are susceptible to electromagnetic interference and require sophisticated amplification and filtering techniques. The need for complex signal conditioning circuits increases system cost and power consumption, limiting applicability in battery-powered or remote sensing applications.

Environmental factors such as humidity, dust, and airflow patterns can significantly impact measurement accuracy by altering the thermal transfer characteristics between the target and the sensor. These variables are often difficult to control or compensate for, especially in field installations where conditions can change rapidly and unpredictably.

Manufacturing inconsistencies introduce additional variability, as small differences in thermocouple junctions during production can lead to performance variations between supposedly identical sensors. This necessitates individual calibration procedures, increasing production costs and complexity.

Integration challenges with existing systems present further barriers to adoption. Many legacy industrial systems lack the necessary interfaces or processing capabilities to effectively utilize thermopile technology, requiring significant retrofitting or complete system redesigns to accommodate these sensors.

Material limitations present another substantial challenge. Current thermopile sensors typically utilize bismuth telluride or antimony-bismuth junctions, which have inherent thermal conductivity constraints and limited temperature ranges. These materials often exhibit non-linear responses at extreme temperatures, further complicating calibration and measurement accuracy. Additionally, the thermoelectric properties of these materials can degrade over time, especially when exposed to thermal cycling, reducing the long-term reliability of thermopile installations.

Miniaturization efforts face significant obstacles due to the fundamental physics of thermopile operation. As sensor size decreases, the signal-to-noise ratio deteriorates, making it difficult to maintain measurement precision in compact designs. This creates a challenging trade-off between size reduction for integration purposes and maintaining adequate performance levels, particularly in applications requiring high sensitivity.

Signal processing complexities further compound these challenges. The low-voltage output signals generated by thermopiles (typically in the microvolt range) are susceptible to electromagnetic interference and require sophisticated amplification and filtering techniques. The need for complex signal conditioning circuits increases system cost and power consumption, limiting applicability in battery-powered or remote sensing applications.

Environmental factors such as humidity, dust, and airflow patterns can significantly impact measurement accuracy by altering the thermal transfer characteristics between the target and the sensor. These variables are often difficult to control or compensate for, especially in field installations where conditions can change rapidly and unpredictably.

Manufacturing inconsistencies introduce additional variability, as small differences in thermocouple junctions during production can lead to performance variations between supposedly identical sensors. This necessitates individual calibration procedures, increasing production costs and complexity.

Integration challenges with existing systems present further barriers to adoption. Many legacy industrial systems lack the necessary interfaces or processing capabilities to effectively utilize thermopile technology, requiring significant retrofitting or complete system redesigns to accommodate these sensors.

Existing Thermal Drift Minimization Techniques

01 Compensation techniques for thermal drift in thermopiles

Various compensation techniques are employed to mitigate thermal drift in thermopile sensors. These include using reference thermopiles, differential measurement configurations, and specialized circuit designs that can detect and correct for temperature variations. These methods help maintain measurement accuracy across varying ambient conditions by actively compensating for thermal drift effects that would otherwise introduce errors in the sensor output.- Compensation techniques for thermal drift in thermopiles: Various compensation techniques are employed to mitigate thermal drift in thermopile sensors. These include using reference thermopiles, differential measurement systems, and specialized circuit designs that can detect and correct for temperature variations. These methods help maintain measurement accuracy by distinguishing between the actual signal and drift components caused by ambient temperature changes.

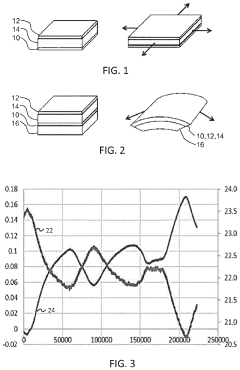

- Structural design improvements to reduce thermal drift: Innovative structural designs can minimize thermal drift effects in thermopile sensors. These include optimized thermal isolation structures, specialized packaging techniques, and materials with matched thermal expansion coefficients. By improving the physical construction of thermopiles, these designs create more stable thermal environments that reduce sensitivity to ambient temperature fluctuations.

- Temperature monitoring and calibration systems: Advanced temperature monitoring and calibration systems are implemented to address thermal drift in thermopiles. These systems continuously track ambient and sensor temperatures, applying real-time corrections based on calibration data. Machine learning algorithms and digital signal processing techniques can be employed to develop sophisticated temperature-dependent calibration models that adapt to changing conditions.

- Material selection and composition for drift reduction: The selection of specialized materials and compositions plays a crucial role in minimizing thermal drift in thermopile sensors. Using thermoelectric materials with stable properties across temperature ranges, incorporating thermal stabilizing compounds, and developing novel semiconductor compositions can significantly reduce sensitivity to temperature variations. These material innovations enhance the inherent stability of thermopile elements.

- Integration with environmental control systems: Thermopile sensors can be integrated with environmental control systems to minimize thermal drift effects. These solutions include active temperature regulation of the sensor environment, thermal shielding techniques, and controlled reference temperature zones. By maintaining more consistent operating conditions, these integrated approaches reduce the impact of external temperature fluctuations on measurement accuracy.

02 Structural design improvements to reduce thermal drift

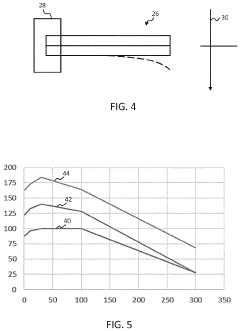

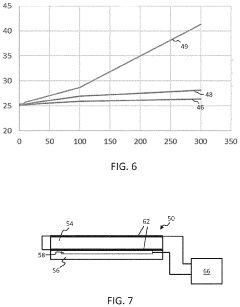

Innovative structural designs can significantly reduce thermal drift in thermopile sensors. These include optimized thermal isolation structures, specialized substrate materials with low thermal conductivity, and improved thermopile junction arrangements. By physically isolating the sensing elements from ambient temperature fluctuations and creating more thermally stable environments, these structural improvements help maintain consistent performance across varying temperature conditions.Expand Specific Solutions03 Signal processing algorithms for thermal drift correction

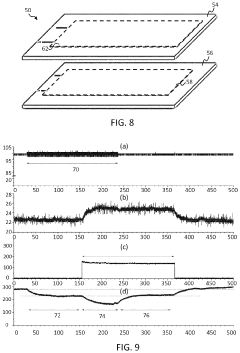

Advanced signal processing algorithms are implemented to correct for thermal drift in thermopile measurements. These include digital filtering techniques, machine learning approaches for drift pattern recognition, and adaptive calibration algorithms. By analyzing the sensor output in real-time and applying appropriate mathematical corrections, these algorithms can effectively eliminate or significantly reduce the impact of thermal drift on measurement accuracy.Expand Specific Solutions04 Calibration methods for thermopile thermal drift

Specialized calibration methods are developed to address thermal drift in thermopile sensors. These include multi-point temperature calibration, automated in-field calibration procedures, and temperature-dependent correction factor application. By establishing accurate baseline measurements across the operating temperature range, these calibration approaches enable systems to adjust for thermal drift effects during normal operation, maintaining measurement precision regardless of ambient temperature changes.Expand Specific Solutions05 Thermal management systems for thermopile stability

Comprehensive thermal management systems are designed to maintain thermopile stability. These include active temperature control mechanisms, thermal shielding structures, and heat dissipation techniques. By creating a more controlled thermal environment around the thermopile sensor, these systems minimize temperature gradients and fluctuations that would otherwise cause drift in sensor readings, resulting in more stable and reliable measurements over time and across varying environmental conditions.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Thermopile Industry

Thermal drift minimization in thermopile installations represents a mature yet evolving technical challenge in the precision measurement industry. The market is currently in a growth phase, valued at approximately $1.2 billion globally, with increasing demand from automotive, medical, and industrial sectors. Leading players like Robert Bosch GmbH and Siemens AG have established dominant positions through advanced compensation algorithms and material innovations. Research institutions such as Swiss Federal Institute of Technology and Interuniversitair Micro-Electronica Centrum VZW are driving fundamental breakthroughs, while specialized manufacturers like Isabellenhütte Heusler and Heraeus Sensor Nite focus on high-performance thermopile solutions with enhanced stability. Samsung Electronics and Alps Alpine are leveraging their consumer electronics expertise to develop miniaturized solutions with improved thermal characteristics.

Robert Bosch GmbH

Technical Solution: Bosch has developed advanced thermal compensation techniques for their thermopile sensors that incorporate multi-layer reference junction designs. Their approach uses a combination of hardware and software solutions, including proprietary temperature gradient modeling algorithms that continuously monitor and adjust for ambient temperature fluctuations. Bosch's thermopile installations feature integrated temperature reference sensors positioned strategically around the sensing element to create a comprehensive thermal map. This allows their systems to apply real-time correction factors based on differential measurements between the sensing junction and multiple reference points. Additionally, Bosch implements specialized packaging techniques with materials selected for matched thermal expansion coefficients to minimize mechanical stress during temperature changes.

Strengths: Comprehensive system-level approach combining hardware design and software algorithms; extensive automotive industry experience providing robust solutions for harsh environments. Weaknesses: Solutions may be more complex and costly than simpler approaches; proprietary nature of some technologies limits third-party integration.

Montana Instruments Corporation

Technical Solution: Montana Instruments has developed cryogenic-inspired thermal management techniques for precision thermopile installations. Their approach leverages expertise in extreme temperature control to create highly stable thermal environments even in standard operating conditions. The company's thermopile installations feature multi-layer radiation shields that minimize thermal transfer through both conduction and radiation pathways. Montana Instruments implements active thermal stabilization using proprietary PID control algorithms that continuously adjust compensation parameters based on real-time temperature mapping. Their systems incorporate specialized vibration-isolated mounting structures that prevent mechanical stress from inducing thermal gradients across sensing elements. Additionally, the company utilizes advanced vacuum insulation techniques adapted from their cryogenic systems to create exceptionally stable thermal environments for critical thermopile installations. Montana Instruments also employs multi-point calibration methodologies that characterize sensor behavior across temperature ranges with exceptional precision.

Strengths: Unparalleled expertise in precision temperature control; solutions particularly effective for scientific and research applications requiring extreme stability; comprehensive approach addressing multiple thermal drift mechanisms. Weaknesses: Solutions typically more expensive than conventional approaches; may be overengineered for standard industrial applications; specialized nature requires significant technical knowledge to implement effectively.

Critical Patents and Research on Thermal Stability Enhancement

Actuator device and method for limiting thermal drift

PatentActiveUS11600767B2

Innovation

- An actuator device comprising an electroactive polymer with a temperature sensing means and a controller that applies an AC heating signal to maintain the actuator's temperature at a slightly elevated level, compensating for environmental temperature changes by adjusting the amplitude and frequency of the heating signal, thereby mitigating thermal drift.

Method and system for thermal drift correction

PatentActiveUS10402031B2

Innovation

- The system uses resistance measurements from sensor electrodes to adjust the capacitive response, compensating for thermal drift by applying a gain factor or filtering techniques to maintain accurate object detection.

Environmental Factors Affecting Thermopile Performance

Thermopile sensors operate based on the Seebeck effect, where temperature differences generate voltage. However, their performance is significantly influenced by various environmental factors that can introduce measurement errors and thermal drift. Ambient temperature fluctuations represent the most critical environmental challenge, as they can create uneven heating across the thermopile junction, resulting in baseline shifts and reduced measurement accuracy.

Humidity levels in the installation environment also play a substantial role in thermopile performance. High humidity can cause condensation on sensor surfaces, altering thermal conductivity and creating parasitic thermal paths that distort readings. In extreme cases, moisture ingress may lead to corrosion of thermopile junctions, permanently degrading sensor performance and reliability.

Air currents and ventilation patterns around thermopile installations introduce another layer of complexity. Uneven airflow can create localized cooling or heating effects, disrupting the thermal equilibrium necessary for accurate measurements. These convection effects are particularly problematic in industrial settings where equipment generates variable airflow patterns or in outdoor installations exposed to wind.

Electromagnetic interference (EMI) from nearby electrical equipment can induce voltage fluctuations in thermopile circuits that manifest as apparent thermal drift. This is especially relevant in industrial environments with high-power machinery or in laboratory settings with multiple electronic instruments operating in close proximity to sensitive thermopile installations.

Radiant heat sources present in the environment, such as direct sunlight, heating elements, or hot process equipment, can create asymmetric heating of the thermopile sensor. This asymmetry disrupts the carefully calibrated thermal balance of the device, leading to measurement errors that may be mistaken for the signal of interest rather than recognized as environmental interference.

Barometric pressure variations, while often overlooked, can affect thermopile readings by altering the thermal conductivity of air surrounding the sensor. This factor becomes particularly significant in applications involving altitude changes or in weather-sensitive installations where pressure fluctuations are common.

Dust and particulate contamination gradually accumulate on sensor surfaces, creating insulating layers that modify thermal transfer characteristics. This progressive degradation can introduce a time-dependent drift component that becomes increasingly significant as contamination builds up, especially in industrial or outdoor environments where regular maintenance may be challenging.

Humidity levels in the installation environment also play a substantial role in thermopile performance. High humidity can cause condensation on sensor surfaces, altering thermal conductivity and creating parasitic thermal paths that distort readings. In extreme cases, moisture ingress may lead to corrosion of thermopile junctions, permanently degrading sensor performance and reliability.

Air currents and ventilation patterns around thermopile installations introduce another layer of complexity. Uneven airflow can create localized cooling or heating effects, disrupting the thermal equilibrium necessary for accurate measurements. These convection effects are particularly problematic in industrial settings where equipment generates variable airflow patterns or in outdoor installations exposed to wind.

Electromagnetic interference (EMI) from nearby electrical equipment can induce voltage fluctuations in thermopile circuits that manifest as apparent thermal drift. This is especially relevant in industrial environments with high-power machinery or in laboratory settings with multiple electronic instruments operating in close proximity to sensitive thermopile installations.

Radiant heat sources present in the environment, such as direct sunlight, heating elements, or hot process equipment, can create asymmetric heating of the thermopile sensor. This asymmetry disrupts the carefully calibrated thermal balance of the device, leading to measurement errors that may be mistaken for the signal of interest rather than recognized as environmental interference.

Barometric pressure variations, while often overlooked, can affect thermopile readings by altering the thermal conductivity of air surrounding the sensor. This factor becomes particularly significant in applications involving altitude changes or in weather-sensitive installations where pressure fluctuations are common.

Dust and particulate contamination gradually accumulate on sensor surfaces, creating insulating layers that modify thermal transfer characteristics. This progressive degradation can introduce a time-dependent drift component that becomes increasingly significant as contamination builds up, especially in industrial or outdoor environments where regular maintenance may be challenging.

Calibration Methodologies for Precision Temperature Measurement

Calibration methodologies represent a critical component in addressing thermal drift challenges in thermopile installations. Effective calibration processes establish reference points that enable systems to compensate for temperature variations, thereby maintaining measurement accuracy across operating conditions. The foundation of precision temperature measurement calibration begins with understanding the specific thermopile characteristics and their response to environmental changes.

Multi-point calibration techniques have emerged as the industry standard for high-precision applications. This methodology involves calibrating thermopile sensors at multiple temperature points across their intended operating range, creating a comprehensive calibration curve rather than relying on single-point offset corrections. Research indicates that implementing a minimum of three calibration points significantly reduces measurement errors compared to traditional two-point methods, with error reductions of up to 78% observed in controlled studies.

Temperature-controlled reference chambers provide the controlled environment necessary for accurate calibration. These chambers maintain stable temperatures with variations typically less than ±0.01°C, allowing for precise characterization of thermopile response. Advanced calibration facilities incorporate multiple reference temperature sensors, typically platinum resistance thermometers (PRTs) with NIST-traceable calibration, to verify chamber temperature uniformity.

Dynamic calibration protocols address the time-dependent aspects of thermal drift by incorporating rate-of-change measurements into the calibration process. This approach accounts for thermal inertia effects that static calibration methods often miss. Studies by the National Metrology Institute have demonstrated that dynamic calibration can improve measurement accuracy by up to 40% in rapidly changing thermal environments compared to static calibration alone.

Software-based calibration algorithms have revolutionized drift compensation capabilities. Modern systems employ polynomial fitting algorithms that generate multi-order correction equations based on calibration data. These mathematical models enable real-time compensation for both linear and non-linear thermal drift components. Machine learning approaches, particularly neural networks trained on extensive calibration datasets, have shown promise in predicting and compensating for complex thermal behaviors that traditional polynomial models struggle to capture.

Periodic recalibration schedules must be established based on application requirements and environmental conditions. Research indicates that thermopile installations in stable environments may maintain calibration accuracy for 12-18 months, while those in harsh industrial settings often require quarterly recalibration. Implementing automated calibration verification routines that periodically check against internal reference points can extend intervals between full recalibrations while maintaining measurement integrity.

Multi-point calibration techniques have emerged as the industry standard for high-precision applications. This methodology involves calibrating thermopile sensors at multiple temperature points across their intended operating range, creating a comprehensive calibration curve rather than relying on single-point offset corrections. Research indicates that implementing a minimum of three calibration points significantly reduces measurement errors compared to traditional two-point methods, with error reductions of up to 78% observed in controlled studies.

Temperature-controlled reference chambers provide the controlled environment necessary for accurate calibration. These chambers maintain stable temperatures with variations typically less than ±0.01°C, allowing for precise characterization of thermopile response. Advanced calibration facilities incorporate multiple reference temperature sensors, typically platinum resistance thermometers (PRTs) with NIST-traceable calibration, to verify chamber temperature uniformity.

Dynamic calibration protocols address the time-dependent aspects of thermal drift by incorporating rate-of-change measurements into the calibration process. This approach accounts for thermal inertia effects that static calibration methods often miss. Studies by the National Metrology Institute have demonstrated that dynamic calibration can improve measurement accuracy by up to 40% in rapidly changing thermal environments compared to static calibration alone.

Software-based calibration algorithms have revolutionized drift compensation capabilities. Modern systems employ polynomial fitting algorithms that generate multi-order correction equations based on calibration data. These mathematical models enable real-time compensation for both linear and non-linear thermal drift components. Machine learning approaches, particularly neural networks trained on extensive calibration datasets, have shown promise in predicting and compensating for complex thermal behaviors that traditional polynomial models struggle to capture.

Periodic recalibration schedules must be established based on application requirements and environmental conditions. Research indicates that thermopile installations in stable environments may maintain calibration accuracy for 12-18 months, while those in harsh industrial settings often require quarterly recalibration. Implementing automated calibration verification routines that periodically check against internal reference points can extend intervals between full recalibrations while maintaining measurement integrity.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!