How to Monitor Radial Engine's Operating Temperatures

SEP 12, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Radial Engine Temperature Monitoring Background and Objectives

Radial engines, with their distinctive star-shaped cylinder arrangement, have been a cornerstone of aviation propulsion since their introduction in the early 20th century. These engines reached their zenith during World War II, powering iconic aircraft like the Boeing B-17 Flying Fortress and the Supermarine Spitfire. Despite being largely superseded by turbine engines in modern aviation, radial engines continue to serve in specialized applications including vintage aircraft restoration, aerobatic planes, and certain industrial applications where their unique characteristics remain valuable.

Temperature monitoring in radial engines presents unique challenges due to their distinctive architecture. Unlike inline or V-type engines, radial engines feature cylinders arranged in a circular pattern around the crankcase, creating uneven cooling patterns. The rear cylinders typically operate at higher temperatures than those at the front, necessitating sophisticated monitoring systems to ensure all cylinders maintain optimal operating temperatures.

The evolution of temperature monitoring technology for radial engines has progressed from basic mechanical gauges to advanced digital systems. Early monitoring relied on simple temperature indicators that provided limited information about engine thermal conditions. Modern systems incorporate multiple temperature sensors, digital displays, and predictive analytics to offer comprehensive thermal profiles across all engine components.

The primary objective of radial engine temperature monitoring is to maintain optimal operating temperatures across all cylinders to ensure engine longevity, performance, and safety. Excessive temperatures can lead to detonation, pre-ignition, and accelerated wear, while temperatures that are too low may cause incomplete combustion and carbon buildup. Effective monitoring systems must provide real-time data to pilots or operators, enabling timely adjustments to engine parameters.

Current technological trends in this field include the integration of wireless sensors, cloud-based data analytics, and predictive maintenance algorithms. These advancements aim to transform temperature monitoring from a reactive to a proactive process, identifying potential thermal issues before they manifest as operational problems. The development of retrofit solutions for vintage aircraft represents a significant focus area, balancing modern monitoring capabilities with the preservation of historical authenticity.

The ultimate goal of advancing radial engine temperature monitoring technology is to enhance operational safety, extend engine service life, optimize performance, and reduce maintenance costs. This requires systems that can accurately measure temperatures across multiple points, process this data intelligently, and present actionable information to operators in an intuitive format.

Temperature monitoring in radial engines presents unique challenges due to their distinctive architecture. Unlike inline or V-type engines, radial engines feature cylinders arranged in a circular pattern around the crankcase, creating uneven cooling patterns. The rear cylinders typically operate at higher temperatures than those at the front, necessitating sophisticated monitoring systems to ensure all cylinders maintain optimal operating temperatures.

The evolution of temperature monitoring technology for radial engines has progressed from basic mechanical gauges to advanced digital systems. Early monitoring relied on simple temperature indicators that provided limited information about engine thermal conditions. Modern systems incorporate multiple temperature sensors, digital displays, and predictive analytics to offer comprehensive thermal profiles across all engine components.

The primary objective of radial engine temperature monitoring is to maintain optimal operating temperatures across all cylinders to ensure engine longevity, performance, and safety. Excessive temperatures can lead to detonation, pre-ignition, and accelerated wear, while temperatures that are too low may cause incomplete combustion and carbon buildup. Effective monitoring systems must provide real-time data to pilots or operators, enabling timely adjustments to engine parameters.

Current technological trends in this field include the integration of wireless sensors, cloud-based data analytics, and predictive maintenance algorithms. These advancements aim to transform temperature monitoring from a reactive to a proactive process, identifying potential thermal issues before they manifest as operational problems. The development of retrofit solutions for vintage aircraft represents a significant focus area, balancing modern monitoring capabilities with the preservation of historical authenticity.

The ultimate goal of advancing radial engine temperature monitoring technology is to enhance operational safety, extend engine service life, optimize performance, and reduce maintenance costs. This requires systems that can accurately measure temperatures across multiple points, process this data intelligently, and present actionable information to operators in an intuitive format.

Market Requirements for Engine Temperature Monitoring Systems

The global market for engine temperature monitoring systems is experiencing significant growth, driven by increasing demands for operational efficiency, safety, and regulatory compliance across various industries. For radial engines specifically, which are predominantly used in vintage aircraft, agricultural applications, and certain specialized industrial equipment, the temperature monitoring requirements present unique challenges and opportunities.

Aviation industry stakeholders, including maintenance providers, operators, and regulatory bodies, consistently emphasize the need for reliable temperature monitoring solutions that can withstand extreme operating conditions while providing accurate, real-time data. Market research indicates that operators are willing to invest in premium monitoring systems that offer enhanced reliability and extended service intervals, recognizing the cost-benefit ratio when considering potential engine damage and downtime.

The agricultural sector, where radial engines power certain specialized equipment, demands monitoring systems with robust construction capable of withstanding dust, vibration, and temperature fluctuations. These systems must offer simple interfaces with clear warning indicators suitable for operation in bright outdoor environments.

Historical preservation organizations and vintage aircraft collectors represent a niche but significant market segment. These users require monitoring solutions that maintain period-appropriate aesthetics while incorporating modern sensing technology. The ability to retrofit these systems without extensive modification to original engine components commands premium pricing in this segment.

Industrial applications utilizing radial engines prioritize integration capabilities with existing control systems and remote monitoring functionality. The market increasingly demands solutions offering predictive maintenance capabilities through temperature trend analysis rather than simple threshold alerts.

Across all segments, there is growing demand for wireless monitoring solutions that eliminate the need for complex wiring harnesses, particularly in retrofit applications. Battery life, transmission reliability, and data security have emerged as critical evaluation factors for these wireless systems.

Regulatory requirements are becoming increasingly stringent regarding engine monitoring, particularly in aviation applications. Systems that facilitate compliance documentation and provide tamper-evident data logging capabilities are gaining market share. The ability to demonstrate regulatory compliance represents a significant value proposition for monitoring system manufacturers.

Cost sensitivity varies significantly across market segments, with commercial operators focusing on total cost of ownership including installation and maintenance, while hobbyist and preservation markets demonstrate greater willingness to pay premium prices for systems offering period-correct aesthetics combined with modern functionality.

Aviation industry stakeholders, including maintenance providers, operators, and regulatory bodies, consistently emphasize the need for reliable temperature monitoring solutions that can withstand extreme operating conditions while providing accurate, real-time data. Market research indicates that operators are willing to invest in premium monitoring systems that offer enhanced reliability and extended service intervals, recognizing the cost-benefit ratio when considering potential engine damage and downtime.

The agricultural sector, where radial engines power certain specialized equipment, demands monitoring systems with robust construction capable of withstanding dust, vibration, and temperature fluctuations. These systems must offer simple interfaces with clear warning indicators suitable for operation in bright outdoor environments.

Historical preservation organizations and vintage aircraft collectors represent a niche but significant market segment. These users require monitoring solutions that maintain period-appropriate aesthetics while incorporating modern sensing technology. The ability to retrofit these systems without extensive modification to original engine components commands premium pricing in this segment.

Industrial applications utilizing radial engines prioritize integration capabilities with existing control systems and remote monitoring functionality. The market increasingly demands solutions offering predictive maintenance capabilities through temperature trend analysis rather than simple threshold alerts.

Across all segments, there is growing demand for wireless monitoring solutions that eliminate the need for complex wiring harnesses, particularly in retrofit applications. Battery life, transmission reliability, and data security have emerged as critical evaluation factors for these wireless systems.

Regulatory requirements are becoming increasingly stringent regarding engine monitoring, particularly in aviation applications. Systems that facilitate compliance documentation and provide tamper-evident data logging capabilities are gaining market share. The ability to demonstrate regulatory compliance represents a significant value proposition for monitoring system manufacturers.

Cost sensitivity varies significantly across market segments, with commercial operators focusing on total cost of ownership including installation and maintenance, while hobbyist and preservation markets demonstrate greater willingness to pay premium prices for systems offering period-correct aesthetics combined with modern functionality.

Current Challenges in Radial Engine Temperature Sensing

Radial engine temperature monitoring faces significant technical challenges due to the unique architecture and operating conditions of these engines. The cylindrical arrangement around a central crankcase creates uneven heat distribution patterns that are difficult to accurately measure with conventional sensing technologies. Each cylinder experiences different thermal loads based on its position, airflow exposure, and combustion timing, resulting in temperature gradients that can vary by 50-100°F across the engine.

Current temperature sensing technologies struggle with the harsh vibration environment of radial engines, which can reach 10-20g during operation. This extreme mechanical stress frequently leads to sensor failure, connection issues, and calibration drift. Traditional thermocouples and RTDs (Resistance Temperature Detectors) demonstrate limited durability in these conditions, with mean time between failures often falling below industry standards for critical engine components.

The spatial constraints within radial engine compartments present another significant challenge. The compact design leaves minimal space for comprehensive sensor deployment, particularly in vintage aircraft where retrofitting modern monitoring systems must be accomplished without structural modifications. Engineers must balance measurement accuracy against practical installation considerations, often resulting in compromised sensor placement that fails to capture critical hotspots.

Data transmission from rotating components introduces additional complexity. Wireless technologies suffer from electromagnetic interference generated by ignition systems, while wired solutions must contend with the mechanical challenges of connecting from rotating to stationary components. Current slip ring technologies exhibit reliability issues under the high-temperature, high-vibration conditions typical of radial engine operation.

Power supply for sensing systems presents further complications. Battery-powered solutions face shortened lifespans due to elevated temperatures, while energy harvesting technologies have yet to demonstrate sufficient output under typical radial engine operating conditions. This often necessitates connections to aircraft electrical systems, adding complexity and potential points of failure.

Integration with existing aircraft instrumentation systems remains problematic. Many radial engines operate in vintage aircraft with limited panel space and basic electrical systems. Modern digital monitoring solutions often require significant modifications to accommodate displays, processing units, and warning systems. The resulting hybrid analog-digital systems frequently suffer from compatibility issues and increased maintenance requirements.

Regulatory compliance adds another layer of complexity, as modifications to engine monitoring systems typically require certification under aviation authorities' guidelines. The cost and time associated with this certification process often outweigh the perceived benefits of improved temperature monitoring, creating a significant barrier to technological advancement in this specialized field.

Current temperature sensing technologies struggle with the harsh vibration environment of radial engines, which can reach 10-20g during operation. This extreme mechanical stress frequently leads to sensor failure, connection issues, and calibration drift. Traditional thermocouples and RTDs (Resistance Temperature Detectors) demonstrate limited durability in these conditions, with mean time between failures often falling below industry standards for critical engine components.

The spatial constraints within radial engine compartments present another significant challenge. The compact design leaves minimal space for comprehensive sensor deployment, particularly in vintage aircraft where retrofitting modern monitoring systems must be accomplished without structural modifications. Engineers must balance measurement accuracy against practical installation considerations, often resulting in compromised sensor placement that fails to capture critical hotspots.

Data transmission from rotating components introduces additional complexity. Wireless technologies suffer from electromagnetic interference generated by ignition systems, while wired solutions must contend with the mechanical challenges of connecting from rotating to stationary components. Current slip ring technologies exhibit reliability issues under the high-temperature, high-vibration conditions typical of radial engine operation.

Power supply for sensing systems presents further complications. Battery-powered solutions face shortened lifespans due to elevated temperatures, while energy harvesting technologies have yet to demonstrate sufficient output under typical radial engine operating conditions. This often necessitates connections to aircraft electrical systems, adding complexity and potential points of failure.

Integration with existing aircraft instrumentation systems remains problematic. Many radial engines operate in vintage aircraft with limited panel space and basic electrical systems. Modern digital monitoring solutions often require significant modifications to accommodate displays, processing units, and warning systems. The resulting hybrid analog-digital systems frequently suffer from compatibility issues and increased maintenance requirements.

Regulatory compliance adds another layer of complexity, as modifications to engine monitoring systems typically require certification under aviation authorities' guidelines. The cost and time associated with this certification process often outweigh the perceived benefits of improved temperature monitoring, creating a significant barrier to technological advancement in this specialized field.

Existing Temperature Monitoring Solutions for Radial Engines

01 Temperature management systems for radial engines

Radial engines require specialized temperature management systems to maintain optimal operating temperatures. These systems include cooling fins, liquid cooling circuits, and temperature sensors that monitor and regulate engine heat. Effective temperature management prevents overheating, ensures efficient combustion, and extends engine life by maintaining components within their designed thermal operating ranges.- Temperature management systems for radial engines: Radial engines require effective temperature management systems to maintain optimal operating temperatures. These systems typically include cooling fins, oil coolers, and specialized cooling channels that help dissipate heat generated during operation. Advanced temperature control mechanisms monitor and regulate engine temperatures to prevent overheating, which can lead to reduced performance and potential engine damage. These systems are crucial for maintaining engine efficiency and longevity, especially during high-performance operations.

- Thermal monitoring and sensor technologies: Modern radial engines incorporate sophisticated thermal monitoring systems and sensor technologies to continuously track operating temperatures. These systems utilize temperature sensors strategically placed throughout the engine to provide real-time data on cylinder head temperatures, oil temperatures, and exhaust gas temperatures. The collected data enables precise temperature control and can trigger automatic adjustments or alerts when temperatures approach critical thresholds. Advanced diagnostic systems can analyze temperature patterns to predict potential issues before they cause engine failure.

- Materials and coatings for thermal management: Specialized materials and coatings play a significant role in managing operating temperatures in radial engines. Heat-resistant alloys and ceramic coatings are used for critical components exposed to extreme temperatures, such as cylinder heads and exhaust systems. These materials help maintain structural integrity while efficiently transferring or reflecting heat as needed. Thermal barrier coatings can reduce heat transfer to certain components, while thermally conductive materials facilitate heat dissipation in cooling systems. The selection of appropriate materials significantly impacts the engine's thermal performance and operational limits.

- Cooling system designs and innovations: Innovative cooling system designs are essential for maintaining optimal operating temperatures in radial engines. These include advanced air cooling arrangements with optimized fin designs, liquid cooling systems for high-performance applications, and hybrid cooling approaches that combine multiple methods. Oil cooling systems serve dual purposes of lubrication and heat management, with specialized oil passages and coolers. Some designs incorporate variable cooling systems that adjust based on operating conditions, providing efficient cooling during high-load operations while maintaining sufficient temperatures during startup and low-load conditions.

- Temperature-based performance optimization: Operating temperature significantly impacts radial engine performance, efficiency, and emissions. Temperature-based performance optimization involves adjusting various engine parameters based on thermal conditions to achieve optimal operation. This includes fuel mixture adjustments, ignition timing modifications, and power output management based on temperature readings. Electronic control systems can automatically implement these adjustments to maintain ideal operating temperatures across different flight phases or operating conditions. Proper temperature management ensures maximum power output while preventing detonation, pre-ignition, and excessive wear that can occur at extreme temperatures.

02 Thermal barrier coatings and materials for high-temperature operation

Advanced materials and thermal barrier coatings are used in radial engines to withstand high operating temperatures. These include ceramic coatings, heat-resistant alloys, and composite materials that provide thermal insulation and reduce heat transfer. Such materials protect critical engine components from thermal stress and degradation, allowing the engine to operate efficiently at elevated temperatures.Expand Specific Solutions03 Cooling system designs for temperature regulation

Specialized cooling system designs are implemented in radial engines to regulate operating temperatures. These include air cooling with optimized fin designs, liquid cooling circuits with precise flow control, and oil cooling systems that serve dual purposes of lubrication and heat dissipation. Effective cooling systems prevent hotspots and ensure uniform temperature distribution across engine cylinders.Expand Specific Solutions04 Temperature monitoring and control mechanisms

Radial engines employ sophisticated temperature monitoring and control mechanisms to maintain optimal operating conditions. These include thermocouples, infrared sensors, electronic control units, and automated cooling system adjustments based on real-time temperature data. Advanced monitoring systems can detect temperature anomalies before they cause damage and adjust engine parameters accordingly.Expand Specific Solutions05 Heat dissipation and thermal efficiency improvements

Innovations in heat dissipation and thermal efficiency have been developed specifically for radial engines. These include enhanced cylinder head designs, optimized combustion chamber geometries, exhaust heat recovery systems, and advanced cooling fin configurations. Improved thermal efficiency reduces fuel consumption, increases power output, and extends the operational lifespan of engine components exposed to high temperatures.Expand Specific Solutions

Leading Manufacturers and Suppliers in Engine Monitoring Industry

The radial engine temperature monitoring technology landscape is currently in a growth phase, with an estimated market size of $1.5-2 billion and expanding at 5-7% annually. The competitive field features established industrial giants like Siemens AG, Robert Bosch GmbH, and Rolls-Royce Plc offering comprehensive monitoring solutions with high integration capabilities. Aviation specialists including Boeing and United Technologies have developed proprietary systems with advanced predictive analytics. The technology maturity varies significantly, with companies like DENSO Corp. and Metrologics LLC focusing on sensor innovation, while GE and Siemens Energy lead in digital twin implementation for temperature monitoring. Japanese manufacturers (Japan Engine Corp., Mayekawa MFG) excel in specialized cooling system integration, creating a fragmented but innovation-driven competitive landscape.

The Boeing Co.

Technical Solution: Boeing has engineered a sophisticated temperature monitoring system for radial engines used in both commercial and military aircraft. Their approach utilizes a multi-tiered sensor network with primary high-precision thermocouples embedded at critical points including cylinder heads, crankcase, oil galleries, and exhaust manifolds. The system incorporates Boeing's proprietary ARINC 429 data bus architecture for reliable data transmission in aviation environments. Their solution features adaptive sampling rates that increase monitoring frequency during critical flight phases or when temperature anomalies are detected. Boeing's system includes comprehensive data logging capabilities that store both real-time and historical temperature profiles, enabling detailed post-flight analysis and maintenance planning. The monitoring solution integrates with Boeing's aircraft health management systems, providing pilots with simplified temperature status indicators while simultaneously transmitting detailed data to ground maintenance crews.

Strengths: Exceptional aviation-specific design optimized for flight conditions, seamless integration with aircraft avionics systems, and robust certification for aviation safety standards. Weaknesses: System is primarily designed for aviation applications and may require significant modification for other radial engine applications, higher cost structure reflecting aviation certification requirements.

Rolls-Royce North American Technologies, Inc.

Technical Solution: Rolls-Royce has developed an advanced thermal monitoring system for radial engines that utilizes a network of strategically placed thermocouples and infrared sensors. Their solution incorporates a dual-layer monitoring approach: primary sensors monitor critical components (cylinder heads, oil temperature, exhaust gas) while secondary sensors track ambient conditions affecting engine performance. The system features real-time data processing with proprietary algorithms that can detect thermal anomalies before they become critical failures. Their monitoring solution integrates with digital twin technology, allowing for predictive maintenance by comparing actual thermal signatures against expected performance models. The system includes wireless transmission capabilities for remote monitoring and automated alert systems that can trigger emergency protocols when temperatures exceed predetermined thresholds.

Strengths: Superior integration with aircraft systems, extensive historical performance data for accurate predictive analytics, and robust redundancy systems ensuring reliability in critical applications. Weaknesses: Higher implementation cost compared to simpler monitoring solutions, requires specialized training for maintenance personnel, and system complexity may present challenges in smaller aircraft applications.

Critical Technologies for Accurate Cylinder Temperature Measurement

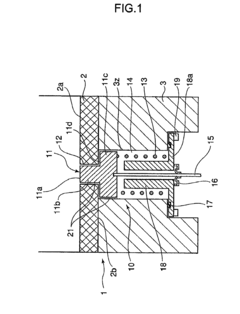

Bearing temperature-monitoring device and bearing device with the same

PatentInactiveEP2051054A1

Innovation

- A bearing temperature monitoring device with a cylindrical space in the back metal and a through hole in the bearing layer, using a bearing temperature carrying member with a higher thermal conductivity and a pushing member to prevent protrusion, ensuring the top end surface remains level with the bearing layer, and a temperature sensing member for accurate temperature detection.

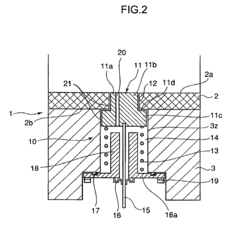

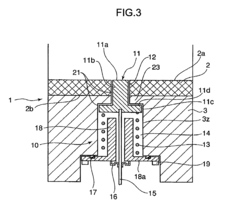

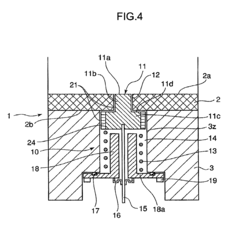

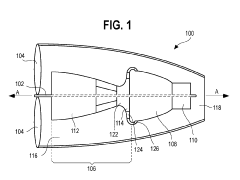

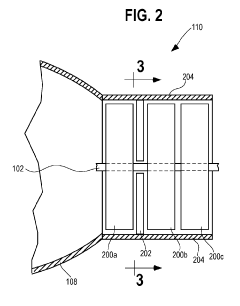

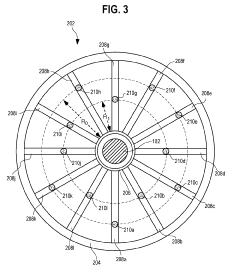

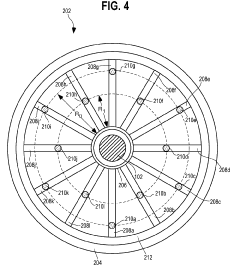

Apparatus and method for measuring turbine temperature

PatentActiveUS20190186283A1

Innovation

- A temperature sensing device with first and second sensor holders disposed between the rotatable shaft and outer casing, each holding only one temperature sensor at different radial distances, allowing for accurate temperature measurement and engine operation control.

Safety Standards and Certification Requirements

Monitoring radial engine operating temperatures must comply with a comprehensive framework of safety standards and certification requirements established by various aviation regulatory bodies. The Federal Aviation Administration (FAA) in the United States, through its Federal Aviation Regulations (FARs), particularly Parts 23, 25, 27, and 29, establishes specific requirements for temperature monitoring systems based on aircraft categories. These regulations mandate continuous monitoring capabilities, temperature limit indicators, and warning systems for critical engine components.

The European Union Aviation Safety Agency (EASA) maintains parallel certification specifications (CS) that align with but sometimes exceed FAA requirements, particularly regarding redundancy in monitoring systems and data recording capabilities. For radial engines specifically, EASA CS-E (Engine) regulations provide detailed specifications for temperature monitoring points and acceptable operating ranges.

Military specifications, such as MIL-STD-810 and MIL-E-5007, establish more stringent requirements for temperature monitoring in high-performance and combat aircraft applications. These standards focus on reliability under extreme conditions and electromagnetic interference resistance, which are critical for military operations.

International Civil Aviation Organization (ICAO) Annex 8 provides the overarching framework for airworthiness standards globally, ensuring consistency across national regulations. This framework requires temperature monitoring systems to demonstrate reliability through rigorous testing protocols, including environmental stress testing, vibration resistance, and long-term durability assessments.

Industry standards from organizations like SAE International and ASTM International complement regulatory requirements by providing detailed technical specifications for temperature sensors, monitoring equipment, and data processing systems. SAE AS478 specifically addresses temperature measurement in aircraft engines, while ASTM F2799 covers standards for engine monitoring systems.

Certification processes typically require manufacturers to demonstrate compliance through extensive testing, including environmental qualification testing, electromagnetic compatibility testing, and software verification and validation. Documentation requirements include detailed system safety assessments, failure mode and effects analyses (FMEA), and mean time between failure (MTBF) calculations.

Recent regulatory trends show increasing emphasis on integrated health monitoring systems that incorporate temperature data with other engine parameters for predictive maintenance capabilities. This shift is driving new certification pathways for advanced monitoring technologies, including wireless sensor networks and AI-based anomaly detection systems, which must still meet or exceed traditional safety standards while offering enhanced functionality.

The European Union Aviation Safety Agency (EASA) maintains parallel certification specifications (CS) that align with but sometimes exceed FAA requirements, particularly regarding redundancy in monitoring systems and data recording capabilities. For radial engines specifically, EASA CS-E (Engine) regulations provide detailed specifications for temperature monitoring points and acceptable operating ranges.

Military specifications, such as MIL-STD-810 and MIL-E-5007, establish more stringent requirements for temperature monitoring in high-performance and combat aircraft applications. These standards focus on reliability under extreme conditions and electromagnetic interference resistance, which are critical for military operations.

International Civil Aviation Organization (ICAO) Annex 8 provides the overarching framework for airworthiness standards globally, ensuring consistency across national regulations. This framework requires temperature monitoring systems to demonstrate reliability through rigorous testing protocols, including environmental stress testing, vibration resistance, and long-term durability assessments.

Industry standards from organizations like SAE International and ASTM International complement regulatory requirements by providing detailed technical specifications for temperature sensors, monitoring equipment, and data processing systems. SAE AS478 specifically addresses temperature measurement in aircraft engines, while ASTM F2799 covers standards for engine monitoring systems.

Certification processes typically require manufacturers to demonstrate compliance through extensive testing, including environmental qualification testing, electromagnetic compatibility testing, and software verification and validation. Documentation requirements include detailed system safety assessments, failure mode and effects analyses (FMEA), and mean time between failure (MTBF) calculations.

Recent regulatory trends show increasing emphasis on integrated health monitoring systems that incorporate temperature data with other engine parameters for predictive maintenance capabilities. This shift is driving new certification pathways for advanced monitoring technologies, including wireless sensor networks and AI-based anomaly detection systems, which must still meet or exceed traditional safety standards while offering enhanced functionality.

Integration with Aircraft Management Systems

The integration of radial engine temperature monitoring systems with broader aircraft management systems represents a critical advancement in aviation technology. Modern aircraft rely on comprehensive management systems that coordinate multiple subsystems for optimal performance and safety. Effective temperature monitoring of radial engines must be seamlessly incorporated into these larger systems to provide pilots and maintenance crews with consolidated information and automated responses.

Current integration approaches utilize standardized communication protocols such as ARINC 429, ARINC 664 (AFDX), or MIL-STD-1553 to ensure reliable data exchange between engine monitoring systems and central aircraft management computers. These protocols enable real-time temperature data from multiple engine sensors to be transmitted, processed, and displayed within integrated cockpit systems, reducing pilot workload and improving situational awareness.

Advanced aircraft management systems incorporate temperature data from radial engines into their health and usage monitoring systems (HUMS). This integration enables predictive maintenance capabilities by analyzing temperature patterns alongside other engine parameters. Machine learning algorithms can identify subtle deviations from normal operating conditions before they develop into critical issues, significantly enhancing safety margins and reducing maintenance costs.

Glass cockpit displays represent another crucial integration point, where temperature information is presented contextually alongside other flight parameters. Modern systems employ intuitive color-coding and graphical representations that allow pilots to quickly assess engine health without diverting attention from primary flight tasks. Customizable alert thresholds can be programmed based on specific aircraft configurations and mission profiles.

Wireless sensor networks are emerging as a promising technology for integrating temperature monitoring into aircraft management systems. These networks eliminate complex wiring harnesses, reducing weight and simplifying installation, particularly valuable for retrofitting older radial engine aircraft with modern monitoring capabilities. Secure wireless protocols ensure data integrity while providing flexibility in sensor placement.

Cloud-based integration solutions are increasingly being adopted, allowing temperature data to be transmitted to ground-based monitoring centers. This approach enables fleet-wide analysis and comparison of engine performance across multiple aircraft, identifying broader trends and potential design improvements. Maintenance teams can remotely access historical temperature data to prepare for scheduled inspections or troubleshoot reported issues.

Regulatory considerations remain paramount when integrating temperature monitoring systems. Any modifications to aircraft management systems must comply with applicable airworthiness directives and certification requirements. Manufacturers must demonstrate that integrated systems maintain appropriate redundancy and fail-safe characteristics to prevent cascading failures from compromising flight safety.

Current integration approaches utilize standardized communication protocols such as ARINC 429, ARINC 664 (AFDX), or MIL-STD-1553 to ensure reliable data exchange between engine monitoring systems and central aircraft management computers. These protocols enable real-time temperature data from multiple engine sensors to be transmitted, processed, and displayed within integrated cockpit systems, reducing pilot workload and improving situational awareness.

Advanced aircraft management systems incorporate temperature data from radial engines into their health and usage monitoring systems (HUMS). This integration enables predictive maintenance capabilities by analyzing temperature patterns alongside other engine parameters. Machine learning algorithms can identify subtle deviations from normal operating conditions before they develop into critical issues, significantly enhancing safety margins and reducing maintenance costs.

Glass cockpit displays represent another crucial integration point, where temperature information is presented contextually alongside other flight parameters. Modern systems employ intuitive color-coding and graphical representations that allow pilots to quickly assess engine health without diverting attention from primary flight tasks. Customizable alert thresholds can be programmed based on specific aircraft configurations and mission profiles.

Wireless sensor networks are emerging as a promising technology for integrating temperature monitoring into aircraft management systems. These networks eliminate complex wiring harnesses, reducing weight and simplifying installation, particularly valuable for retrofitting older radial engine aircraft with modern monitoring capabilities. Secure wireless protocols ensure data integrity while providing flexibility in sensor placement.

Cloud-based integration solutions are increasingly being adopted, allowing temperature data to be transmitted to ground-based monitoring centers. This approach enables fleet-wide analysis and comparison of engine performance across multiple aircraft, identifying broader trends and potential design improvements. Maintenance teams can remotely access historical temperature data to prepare for scheduled inspections or troubleshoot reported issues.

Regulatory considerations remain paramount when integrating temperature monitoring systems. Any modifications to aircraft management systems must comply with applicable airworthiness directives and certification requirements. Manufacturers must demonstrate that integrated systems maintain appropriate redundancy and fail-safe characteristics to prevent cascading failures from compromising flight safety.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!