How to Optimize Layout of Thermopiles for maximum Detection

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermopile Layout Optimization Background and Objectives

Thermopiles have emerged as critical components in various sensing applications, particularly in infrared detection systems, temperature measurement devices, and motion sensors. The history of thermopile technology dates back to the early 19th century with the discovery of the thermoelectric effect by Thomas Johann Seebeck. However, significant advancements in miniaturization and integration have transformed these devices into sophisticated sensing elements capable of detecting minute temperature variations with remarkable precision.

The evolution of thermopile technology has been characterized by continuous improvements in sensitivity, response time, and form factor. Early thermopiles consisted of discrete thermocouple junctions arranged in series, while modern implementations leverage microfabrication techniques to create dense arrays of thermocouples on semiconductor substrates. This miniaturization has enabled the integration of thermopiles into compact consumer electronics, medical devices, and industrial monitoring systems.

Current technological trends in thermopile development focus on enhancing detection capabilities through optimized layout designs. The spatial arrangement of thermocouple junctions, the geometry of hot and cold junctions, and the overall array configuration significantly impact the performance metrics of thermopile sensors. Researchers and manufacturers are increasingly exploring novel layout strategies to maximize signal-to-noise ratio, improve thermal isolation, and enhance detection sensitivity.

The primary objective of thermopile layout optimization is to achieve maximum detection efficiency while considering practical constraints such as power consumption, manufacturing feasibility, and integration requirements. This involves a multidisciplinary approach combining principles from materials science, thermal physics, electrical engineering, and microfabrication technology. Specific goals include enhancing the temperature coefficient of resistance, minimizing thermal crosstalk between adjacent elements, and optimizing the thermal mass of sensing elements.

Another critical objective is to develop layout designs that can be efficiently manufactured at scale while maintaining consistent performance characteristics. This requires careful consideration of fabrication tolerances, material properties, and process variations. Additionally, there is growing interest in creating reconfigurable thermopile layouts that can adapt to different sensing scenarios or environmental conditions.

The optimization of thermopile layouts also aims to address emerging application requirements, such as multi-spectral detection capabilities, directional sensitivity, and operation in harsh environments. These advanced functionalities necessitate innovative approaches to thermopile design, including three-dimensional structures, novel materials integration, and hybrid sensing architectures.

As we look toward future developments, the optimization of thermopile layouts will likely incorporate machine learning algorithms for design automation, quantum effects for enhanced sensitivity, and biomimetic principles inspired by natural thermal sensing systems. These advancements promise to expand the application scope of thermopile sensors and enable new capabilities in fields ranging from autonomous vehicles to environmental monitoring and healthcare diagnostics.

The evolution of thermopile technology has been characterized by continuous improvements in sensitivity, response time, and form factor. Early thermopiles consisted of discrete thermocouple junctions arranged in series, while modern implementations leverage microfabrication techniques to create dense arrays of thermocouples on semiconductor substrates. This miniaturization has enabled the integration of thermopiles into compact consumer electronics, medical devices, and industrial monitoring systems.

Current technological trends in thermopile development focus on enhancing detection capabilities through optimized layout designs. The spatial arrangement of thermocouple junctions, the geometry of hot and cold junctions, and the overall array configuration significantly impact the performance metrics of thermopile sensors. Researchers and manufacturers are increasingly exploring novel layout strategies to maximize signal-to-noise ratio, improve thermal isolation, and enhance detection sensitivity.

The primary objective of thermopile layout optimization is to achieve maximum detection efficiency while considering practical constraints such as power consumption, manufacturing feasibility, and integration requirements. This involves a multidisciplinary approach combining principles from materials science, thermal physics, electrical engineering, and microfabrication technology. Specific goals include enhancing the temperature coefficient of resistance, minimizing thermal crosstalk between adjacent elements, and optimizing the thermal mass of sensing elements.

Another critical objective is to develop layout designs that can be efficiently manufactured at scale while maintaining consistent performance characteristics. This requires careful consideration of fabrication tolerances, material properties, and process variations. Additionally, there is growing interest in creating reconfigurable thermopile layouts that can adapt to different sensing scenarios or environmental conditions.

The optimization of thermopile layouts also aims to address emerging application requirements, such as multi-spectral detection capabilities, directional sensitivity, and operation in harsh environments. These advanced functionalities necessitate innovative approaches to thermopile design, including three-dimensional structures, novel materials integration, and hybrid sensing architectures.

As we look toward future developments, the optimization of thermopile layouts will likely incorporate machine learning algorithms for design automation, quantum effects for enhanced sensitivity, and biomimetic principles inspired by natural thermal sensing systems. These advancements promise to expand the application scope of thermopile sensors and enable new capabilities in fields ranging from autonomous vehicles to environmental monitoring and healthcare diagnostics.

Market Analysis for High-Performance Thermal Detection Systems

The global market for high-performance thermal detection systems has experienced significant growth in recent years, driven by increasing demand across multiple sectors including industrial automation, healthcare, automotive, and consumer electronics. The thermopile sensor market specifically is projected to reach $2.3 billion by 2027, growing at a CAGR of 8.7% from 2022. This growth is primarily fueled by the expanding applications of thermal sensing technology in emerging fields such as IoT devices, smart buildings, and advanced driver assistance systems.

In the industrial sector, optimized thermopile layouts are increasingly sought after for their ability to enhance precision in temperature monitoring and control systems. Manufacturing facilities are adopting these advanced thermal detection systems to improve quality control processes and reduce operational costs through predictive maintenance. The industrial automation segment currently represents approximately 32% of the total market share for high-performance thermal detection systems.

The healthcare and medical diagnostics sector has emerged as another significant market driver, particularly following the global pandemic which highlighted the importance of non-contact temperature measurement. Medical-grade thermal detection systems with optimized thermopile layouts are being integrated into a wide range of diagnostic equipment, patient monitoring systems, and telehealth devices. Market analysis indicates this sector is growing at 11.3% annually, outpacing the overall market growth rate.

Consumer electronics manufacturers are increasingly incorporating thermal sensors into smartphones, wearables, and smart home devices, creating substantial market opportunities for miniaturized, energy-efficient thermopile arrays. This segment is characterized by high volume but intense price pressure, requiring continuous innovation in thermopile layout optimization to reduce costs while maintaining performance.

Regional analysis reveals that North America currently leads the market with 38% share, followed by Europe (27%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to witness the fastest growth over the next five years due to rapid industrialization, increasing healthcare expenditure, and the expanding consumer electronics manufacturing base in countries like China, South Korea, and India.

Key market challenges include price sensitivity in consumer applications, technical limitations in extreme environmental conditions, and increasing competition from alternative thermal sensing technologies such as microbolometers and pyroelectric sensors. Despite these challenges, the market outlook remains positive as continuous advancements in thermopile layout optimization are enabling higher detection sensitivity, improved spatial resolution, and reduced power consumption, thereby expanding the application scope and market potential of these systems.

In the industrial sector, optimized thermopile layouts are increasingly sought after for their ability to enhance precision in temperature monitoring and control systems. Manufacturing facilities are adopting these advanced thermal detection systems to improve quality control processes and reduce operational costs through predictive maintenance. The industrial automation segment currently represents approximately 32% of the total market share for high-performance thermal detection systems.

The healthcare and medical diagnostics sector has emerged as another significant market driver, particularly following the global pandemic which highlighted the importance of non-contact temperature measurement. Medical-grade thermal detection systems with optimized thermopile layouts are being integrated into a wide range of diagnostic equipment, patient monitoring systems, and telehealth devices. Market analysis indicates this sector is growing at 11.3% annually, outpacing the overall market growth rate.

Consumer electronics manufacturers are increasingly incorporating thermal sensors into smartphones, wearables, and smart home devices, creating substantial market opportunities for miniaturized, energy-efficient thermopile arrays. This segment is characterized by high volume but intense price pressure, requiring continuous innovation in thermopile layout optimization to reduce costs while maintaining performance.

Regional analysis reveals that North America currently leads the market with 38% share, followed by Europe (27%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to witness the fastest growth over the next five years due to rapid industrialization, increasing healthcare expenditure, and the expanding consumer electronics manufacturing base in countries like China, South Korea, and India.

Key market challenges include price sensitivity in consumer applications, technical limitations in extreme environmental conditions, and increasing competition from alternative thermal sensing technologies such as microbolometers and pyroelectric sensors. Despite these challenges, the market outlook remains positive as continuous advancements in thermopile layout optimization are enabling higher detection sensitivity, improved spatial resolution, and reduced power consumption, thereby expanding the application scope and market potential of these systems.

Current Thermopile Layout Techniques and Limitations

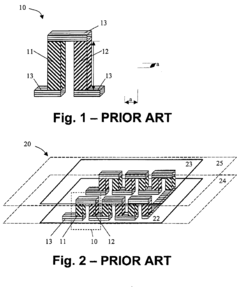

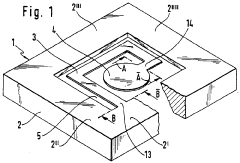

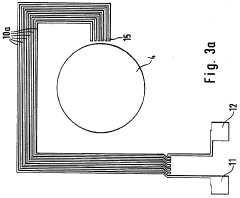

Current thermopile layout techniques predominantly rely on traditional geometric arrangements that have been established over decades of thermal sensor development. The most common configuration involves a series connection of thermocouples arranged in a radial pattern around a central absorber area. This design aims to maximize the temperature gradient between the hot and cold junctions, thereby enhancing the Seebeck effect for improved signal generation.

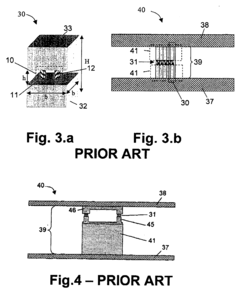

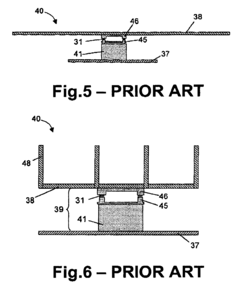

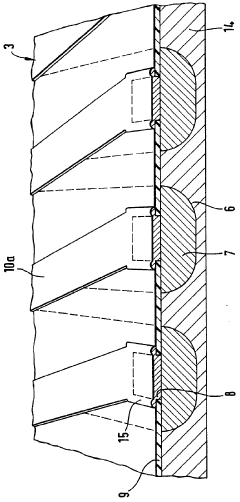

Conventional layouts typically feature thermopiles with 20-100 thermocouples arranged in concentric rings or linear arrays. The absorber region, usually positioned centrally, is designed with high thermal isolation from the substrate through suspended membrane structures. This isolation is critical for maintaining temperature differentials but creates significant manufacturing challenges related to mechanical stability.

Material selection represents another crucial aspect of current thermopile layouts. Traditional implementations utilize bismuth-antimony or polysilicon-aluminum thermocouple pairs, offering reasonable thermoelectric coefficients but limited optimization potential. More advanced designs have begun incorporating thin-film materials such as bismuth telluride or antimony telluride to improve thermoelectric performance, though integration complexities often limit widespread adoption.

A significant limitation in existing layouts stems from the inherent trade-off between thermal isolation and response time. Highly isolated structures that maximize temperature differentials typically suffer from slower thermal response characteristics, limiting their effectiveness in applications requiring rapid detection. This fundamental constraint has driven various compromise solutions rather than truly optimized designs.

Current manufacturing techniques also impose substantial limitations on thermopile layout optimization. Standard CMOS-compatible processes restrict material choices and geometric configurations, while specialized MEMS fabrication approaches increase production costs and complexity. These manufacturing constraints often force designers to prioritize producibility over theoretical performance optimization.

Thermal crosstalk between adjacent thermocouples represents another critical limitation in dense array configurations. As designers attempt to maximize thermocouple density for improved sensitivity, parasitic thermal pathways increasingly undermine performance gains. Current mitigation strategies typically involve spacing compromises that reduce overall detection efficiency.

Signal-to-noise ratio (SNR) optimization remains particularly challenging in existing layouts. Electrical noise from interconnections and thermal noise from supporting structures significantly impact detection thresholds, especially for low-level signals. Contemporary designs employ various shielding and isolation techniques, but fundamental layout-based solutions remain elusive.

Conventional layouts typically feature thermopiles with 20-100 thermocouples arranged in concentric rings or linear arrays. The absorber region, usually positioned centrally, is designed with high thermal isolation from the substrate through suspended membrane structures. This isolation is critical for maintaining temperature differentials but creates significant manufacturing challenges related to mechanical stability.

Material selection represents another crucial aspect of current thermopile layouts. Traditional implementations utilize bismuth-antimony or polysilicon-aluminum thermocouple pairs, offering reasonable thermoelectric coefficients but limited optimization potential. More advanced designs have begun incorporating thin-film materials such as bismuth telluride or antimony telluride to improve thermoelectric performance, though integration complexities often limit widespread adoption.

A significant limitation in existing layouts stems from the inherent trade-off between thermal isolation and response time. Highly isolated structures that maximize temperature differentials typically suffer from slower thermal response characteristics, limiting their effectiveness in applications requiring rapid detection. This fundamental constraint has driven various compromise solutions rather than truly optimized designs.

Current manufacturing techniques also impose substantial limitations on thermopile layout optimization. Standard CMOS-compatible processes restrict material choices and geometric configurations, while specialized MEMS fabrication approaches increase production costs and complexity. These manufacturing constraints often force designers to prioritize producibility over theoretical performance optimization.

Thermal crosstalk between adjacent thermocouples represents another critical limitation in dense array configurations. As designers attempt to maximize thermocouple density for improved sensitivity, parasitic thermal pathways increasingly undermine performance gains. Current mitigation strategies typically involve spacing compromises that reduce overall detection efficiency.

Signal-to-noise ratio (SNR) optimization remains particularly challenging in existing layouts. Electrical noise from interconnections and thermal noise from supporting structures significantly impact detection thresholds, especially for low-level signals. Contemporary designs employ various shielding and isolation techniques, but fundamental layout-based solutions remain elusive.

State-of-the-Art Thermopile Layout Solutions

01 Thermopile sensor design and structure

Thermopile sensors are designed with specific structural elements to enhance detection capabilities. These designs include specialized junction arrangements, substrate materials, and packaging configurations that optimize thermal response. Advanced thermopile structures incorporate multiple thermocouples connected in series to increase sensitivity to temperature gradients, allowing for more precise detection of thermal radiation.- Thermopile sensor design and structure: Thermopile sensors are designed with specific structural elements to enhance detection capabilities. These designs include specialized junction arrangements, membrane structures, and material selections that optimize thermal sensitivity. Advanced fabrication techniques allow for miniaturization while maintaining detection performance. The structural design directly impacts the sensor's ability to detect thermal radiation accurately.

- Thermal radiation detection methods: Various methods are employed for detecting thermal radiation using thermopiles. These include differential measurement techniques, signal amplification, and specialized filtering to improve signal-to-noise ratio. Advanced algorithms process the thermopile output signals to enhance detection accuracy and reduce false readings. These methods enable thermopiles to detect even small temperature variations in the target environment.

- Integration with electronic systems: Thermopiles are integrated into larger electronic systems for enhanced functionality. This integration includes connection with processing units, display systems, and communication modules. Circuit designs accommodate the specific electrical characteristics of thermopile sensors, including impedance matching and signal conditioning. The integration enables real-time monitoring and automated response to detected thermal changes.

- Application-specific thermopile configurations: Thermopiles are configured differently based on their intended applications. Configurations vary for applications such as motion detection, temperature measurement, gas analysis, and infrared imaging. Each configuration optimizes specific parameters like response time, detection range, or spectral sensitivity. Special housing and optical elements may be incorporated to enhance performance in particular environments or use cases.

- Calibration and error compensation techniques: Various techniques are employed to calibrate thermopile detectors and compensate for potential errors. These include temperature compensation circuits, reference measurement systems, and self-calibration mechanisms. Advanced algorithms correct for ambient temperature variations, aging effects, and other environmental factors that might affect measurement accuracy. These techniques ensure reliable and consistent detection performance over time and across different operating conditions.

02 Infrared radiation detection applications

Thermopiles are widely used for non-contact temperature measurement and infrared radiation detection. These applications include thermal imaging, motion detection, gas analysis, and medical diagnostics. The sensors convert thermal radiation into electrical signals through the Seebeck effect, enabling the detection of objects and temperature variations without physical contact, which is particularly valuable in environments where contact measurements are impractical.Expand Specific Solutions03 Signal processing and noise reduction techniques

Advanced signal processing methods are employed to enhance thermopile detection accuracy. These techniques include filtering algorithms, amplification circuits, and compensation mechanisms to reduce noise and improve signal-to-noise ratios. Temperature drift compensation and calibration methods are implemented to maintain measurement accuracy across varying ambient conditions, ensuring reliable detection performance in challenging environments.Expand Specific Solutions04 Integration with electronic systems

Thermopile detectors are integrated into larger electronic systems for various applications. This integration involves interface circuitry, microcontrollers, and communication protocols that enable thermopile sensors to work within complex detection systems. Miniaturization techniques allow thermopiles to be incorporated into portable devices, wearable technology, and IoT applications, expanding their utility in consumer and industrial products.Expand Specific Solutions05 Historical development and manufacturing methods

The evolution of thermopile technology spans decades, with significant advancements in manufacturing processes and materials. Early designs have evolved into sophisticated sensors through improvements in fabrication techniques, including thin-film deposition, micromachining, and semiconductor processing. Modern manufacturing methods enable mass production of thermopiles with consistent performance characteristics, reduced size, and lower costs, facilitating their widespread adoption across industries.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Thermopile Technology

The thermopile layout optimization market is currently in a growth phase, with increasing applications in thermal sensing and infrared detection technologies. The global market size for thermal sensors is expanding rapidly, driven by demand in automotive, consumer electronics, and medical sectors. Key players in this technological landscape include Hamamatsu Photonics and Excelitas Technologies, who lead in thermopile sensor development, while research institutions like IMEC Nederland and Shandong University contribute significant academic advancements. Companies like Robert Bosch, DENSO, and Nissan are integrating optimized thermopile technologies into automotive applications. The technology is approaching maturity in traditional applications but remains in development for emerging use cases, with companies like X-FAB and Elmos Semiconductor working on miniaturization and sensitivity improvements for next-generation thermal detection systems.

Robert Bosch GmbH

Technical Solution: Bosch has developed a sophisticated approach to thermopile layout optimization focusing on automotive and industrial applications. Their technology employs a multi-zone thermopile architecture with differential sensing elements arranged in concentric rings to maximize detection area while maintaining thermal isolation between zones. This design enables simultaneous wide-field and spot detection capabilities. Bosch's manufacturing process utilizes advanced silicon micromachining techniques to create suspended membrane structures with precisely controlled thermal mass and conductivity properties. Their thermopile layouts incorporate specialized compensation elements that actively mitigate ambient temperature fluctuations, achieving temperature stability of ±0.1°C across an operating range of -40°C to +125°C. The company has also pioneered the integration of application-specific signal processing directly within the sensor package, implementing proprietary algorithms that enhance detection performance in challenging environmental conditions such as high humidity or rapid temperature changes, resulting in up to 30% improvement in detection reliability compared to conventional designs.

Strengths: Exceptional thermal stability across wide temperature ranges; robust design optimized for harsh environmental conditions; advanced integration with signal processing capabilities. Weaknesses: Higher power consumption compared to simpler thermopile designs; more complex calibration requirements; primarily optimized for automotive and industrial applications rather than scientific instrumentation.

Excelitas Technologies Singapore Pte Ltd.

Technical Solution: Excelitas Technologies has pioneered thermopile optimization through their DigiPile™ technology platform, which employs a systematic approach to thermopile layout design. Their solution features a hexagonal arrangement of thermocouples with optimized hot junction placement to maximize the temperature differential across the sensing element. The company utilizes advanced thin-film deposition techniques to create precisely controlled thermocouple layers with thickness variations under 0.1μm, enabling consistent performance across production batches. Their proprietary vacuum-sealed packaging technology maintains an internal cavity pressure below 10^-2 mbar, significantly reducing thermal conductivity losses through air and improving sensitivity by up to 65% compared to non-evacuated designs. Excelitas has also developed specialized optical concentrators and filters integrated directly with the thermopile layout to enhance wavelength-specific detection capabilities, particularly valuable in gas sensing and temperature measurement applications where precise spectral response is critical.

Strengths: Comprehensive thermopile optimization approach addressing both material and geometric factors; industry-leading vacuum packaging technology; extensive application-specific customization capabilities. Weaknesses: Higher unit cost compared to standard thermopile sensors; more complex manufacturing process requiring specialized equipment; longer lead times for custom configurations.

Critical Patents and Research on Thermopile Geometry Optimization

Method for thermal matching of a thermoelectric generator with a heat source having high thermal resistance and thermoelectric generator thus obtained

PatentInactiveEP1970973A1

Innovation

- A method for thermal matching of TEGs with heat sources and sinks is developed, involving a thermopile unit with a specific number of thermocouples and thermal resistance configuration, along with the use of spacers and radiators to optimize heat transfer, ensuring the thermal resistance of the TEG matches the ambient thermal resistance within a certain percentage, thereby enhancing power output.

Thermopile radiation detector

PatentWO1991002229A1

Innovation

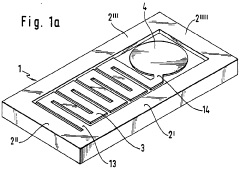

- A thermopile radiation detector design featuring a radiation-receiving surface on the free end of a spiral or meandering thin band with low thermal conductivity, combined with doped silicon and metal thermoelectric materials, and a compact, rotationally symmetrical structure that reduces chip area and enhances thermal efficiency, along with insulating layers and strategically placed conductor tracks to minimize thermal conductivity and material costs.

Thermal Simulation and Modeling Methodologies

Thermal simulation and modeling methodologies represent critical tools for optimizing thermopile layouts to achieve maximum detection capabilities. These methodologies employ sophisticated computational techniques to predict thermal behavior, heat transfer mechanisms, and temperature gradients across thermopile structures under various operating conditions.

Finite Element Analysis (FEA) stands as the predominant simulation approach, allowing engineers to divide complex thermopile geometries into smaller elements for detailed thermal analysis. This method enables precise modeling of heat conduction pathways, thermal resistance networks, and temperature distribution patterns that directly impact detection sensitivity. Modern FEA software packages incorporate multiphysics capabilities that can simultaneously model thermal, electrical, and mechanical behaviors, providing comprehensive insights into thermopile performance.

Computational Fluid Dynamics (CFD) complements FEA by modeling convective heat transfer mechanisms that affect thermopile operation, particularly in applications involving fluid flow or air currents. CFD simulations help identify potential thermal interference sources and optimize thermopile positioning to minimize unwanted thermal noise while maximizing signal detection.

Thermal transient analysis represents another crucial modeling methodology, focusing on the dynamic response of thermopiles to rapidly changing thermal conditions. This approach enables engineers to evaluate response times, thermal time constants, and recovery periods—all critical parameters for applications requiring high-speed thermal detection.

Monte Carlo simulations provide probabilistic insights by modeling random thermal fluctuations and their impact on thermopile performance. These simulations help establish statistical confidence intervals for detection thresholds and signal-to-noise ratios across different layout configurations.

Emerging methodologies incorporate machine learning algorithms to optimize thermopile layouts based on vast simulation datasets. These AI-driven approaches can rapidly evaluate thousands of potential configurations to identify optimal geometric arrangements, spacing parameters, and material combinations that maximize detection sensitivity.

Validation protocols form an essential component of thermal modeling methodologies, comparing simulation results with experimental measurements to ensure model accuracy. This typically involves infrared thermography, micro-thermocouple measurements, and electrical characterization under controlled thermal conditions to refine simulation parameters and boundary conditions.

Finite Element Analysis (FEA) stands as the predominant simulation approach, allowing engineers to divide complex thermopile geometries into smaller elements for detailed thermal analysis. This method enables precise modeling of heat conduction pathways, thermal resistance networks, and temperature distribution patterns that directly impact detection sensitivity. Modern FEA software packages incorporate multiphysics capabilities that can simultaneously model thermal, electrical, and mechanical behaviors, providing comprehensive insights into thermopile performance.

Computational Fluid Dynamics (CFD) complements FEA by modeling convective heat transfer mechanisms that affect thermopile operation, particularly in applications involving fluid flow or air currents. CFD simulations help identify potential thermal interference sources and optimize thermopile positioning to minimize unwanted thermal noise while maximizing signal detection.

Thermal transient analysis represents another crucial modeling methodology, focusing on the dynamic response of thermopiles to rapidly changing thermal conditions. This approach enables engineers to evaluate response times, thermal time constants, and recovery periods—all critical parameters for applications requiring high-speed thermal detection.

Monte Carlo simulations provide probabilistic insights by modeling random thermal fluctuations and their impact on thermopile performance. These simulations help establish statistical confidence intervals for detection thresholds and signal-to-noise ratios across different layout configurations.

Emerging methodologies incorporate machine learning algorithms to optimize thermopile layouts based on vast simulation datasets. These AI-driven approaches can rapidly evaluate thousands of potential configurations to identify optimal geometric arrangements, spacing parameters, and material combinations that maximize detection sensitivity.

Validation protocols form an essential component of thermal modeling methodologies, comparing simulation results with experimental measurements to ensure model accuracy. This typically involves infrared thermography, micro-thermocouple measurements, and electrical characterization under controlled thermal conditions to refine simulation parameters and boundary conditions.

Manufacturing Constraints and Cost-Performance Tradeoffs

The optimization of thermopile layouts for maximum detection capability is significantly constrained by manufacturing limitations and economic considerations. Current semiconductor fabrication processes impose strict dimensional constraints on thermopile elements, with minimum feature sizes typically ranging from 0.5 to 2 microns depending on the manufacturing technology employed. These constraints directly impact the density and arrangement possibilities of thermocouples within a given area, limiting the theoretical maximum number of junctions achievable.

Material selection represents another critical manufacturing constraint, as compatibility with standard CMOS or MEMS processes is essential for cost-effective production. While exotic materials might offer superior thermoelectric properties, their integration often requires specialized processing steps that exponentially increase manufacturing complexity and cost. Most commercially viable thermopile designs therefore utilize materials such as polysilicon, aluminum, or bismuth telluride that balance performance with processability.

Yield considerations further restrict design options, particularly for high-density layouts. As thermopile density increases, manufacturing defect rates typically rise non-linearly, creating a practical ceiling for junction density beyond which production becomes economically unfeasible. Industry data suggests that defect rates increase by approximately 15-20% when junction density doubles beyond certain technology-specific thresholds.

The cost-performance relationship in thermopile design follows a distinct non-linear curve. Initial improvements in detection capability can be achieved with relatively modest cost increases, but performance gains become increasingly expensive beyond certain optimization points. Analysis of current market offerings reveals that doubling detection sensitivity typically requires a 2.5-3x increase in manufacturing cost when approaching the limits of a given technology node.

Package-level constraints also influence layout optimization decisions. Vacuum packaging, which significantly enhances thermal isolation and therefore detection sensitivity, adds substantial cost—typically 30-40% of the total device cost. This creates a critical design decision point where manufacturers must choose between optimizing layout for maximum performance in standard packaging or designing for adequate performance in premium packaging.

Production volume considerations ultimately shape many design decisions, as certain advanced layout techniques become economically viable only at high volumes. For instance, wafer-level packaging and advanced lithography approaches that enable ultra-dense thermopile arrangements require substantial non-recurring engineering costs that can only be amortized across large production runs exceeding 100,000 units annually.

Material selection represents another critical manufacturing constraint, as compatibility with standard CMOS or MEMS processes is essential for cost-effective production. While exotic materials might offer superior thermoelectric properties, their integration often requires specialized processing steps that exponentially increase manufacturing complexity and cost. Most commercially viable thermopile designs therefore utilize materials such as polysilicon, aluminum, or bismuth telluride that balance performance with processability.

Yield considerations further restrict design options, particularly for high-density layouts. As thermopile density increases, manufacturing defect rates typically rise non-linearly, creating a practical ceiling for junction density beyond which production becomes economically unfeasible. Industry data suggests that defect rates increase by approximately 15-20% when junction density doubles beyond certain technology-specific thresholds.

The cost-performance relationship in thermopile design follows a distinct non-linear curve. Initial improvements in detection capability can be achieved with relatively modest cost increases, but performance gains become increasingly expensive beyond certain optimization points. Analysis of current market offerings reveals that doubling detection sensitivity typically requires a 2.5-3x increase in manufacturing cost when approaching the limits of a given technology node.

Package-level constraints also influence layout optimization decisions. Vacuum packaging, which significantly enhances thermal isolation and therefore detection sensitivity, adds substantial cost—typically 30-40% of the total device cost. This creates a critical design decision point where manufacturers must choose between optimizing layout for maximum performance in standard packaging or designing for adequate performance in premium packaging.

Production volume considerations ultimately shape many design decisions, as certain advanced layout techniques become economically viable only at high volumes. For instance, wafer-level packaging and advanced lithography approaches that enable ultra-dense thermopile arrangements require substantial non-recurring engineering costs that can only be amortized across large production runs exceeding 100,000 units annually.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!