How to Refine Calibration Processes for Wankel Engines?

AUG 26, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Wankel Engine Calibration Background and Objectives

The Wankel rotary engine represents a unique approach to internal combustion engine design, diverging significantly from conventional reciprocating piston engines. Developed by German engineer Felix Wankel in the 1950s, this engine architecture has experienced cycles of commercial interest and technical development over the past seven decades. The rotary engine's distinctive triangular rotor design, which rotates eccentrically within an epitrochoidal housing, creates a fundamentally different combustion process compared to traditional engines.

Calibration processes for Wankel engines have historically been challenging due to their unique operating characteristics. The continuous combustion cycle, distinctive port timing, and unconventional chamber geometry create a complex thermodynamic environment that demands specialized calibration approaches. Early calibration methods relied heavily on empirical testing with limited computational support, resulting in suboptimal performance, efficiency, and emissions profiles.

Recent technological advancements in computational fluid dynamics (CFD), real-time engine monitoring systems, and machine learning algorithms have created new opportunities to refine Wankel engine calibration processes. The evolution of these technologies has coincided with increasing regulatory pressure on emissions and efficiency standards, creating both challenges and innovation drivers for rotary engine development.

The primary objective of refining calibration processes for Wankel engines is to overcome their traditional limitations while maximizing their inherent advantages. These engines offer exceptional power-to-weight ratios, mechanical simplicity, and smooth operation characteristics that remain attractive for specific applications. Improved calibration techniques aim to address historical weaknesses in fuel efficiency, emissions control, and apex seal durability.

Current calibration goals focus on optimizing the unique three-dimensional flame propagation patterns within the rotary chamber, managing thermal gradients across the housing, and precisely controlling fuel delivery throughout the engine's operating range. Advanced calibration techniques must account for the distinctive port timing events and the continuously changing geometry of the combustion chamber during operation.

The technical trajectory suggests a convergence of traditional engine calibration methodologies with rotary-specific approaches, supported by increasingly sophisticated simulation tools and real-time feedback systems. This evolution aims to position Wankel technology as viable in specific market niches where its advantages outweigh its challenges, particularly in range-extender applications for electric vehicles, aviation platforms, and specialized automotive implementations.

Achieving these calibration refinements requires interdisciplinary collaboration between combustion specialists, materials scientists, control systems engineers, and computational modeling experts. The technical path forward involves both incremental improvements to existing calibration methodologies and potentially transformative approaches leveraging artificial intelligence and advanced materials science.

Calibration processes for Wankel engines have historically been challenging due to their unique operating characteristics. The continuous combustion cycle, distinctive port timing, and unconventional chamber geometry create a complex thermodynamic environment that demands specialized calibration approaches. Early calibration methods relied heavily on empirical testing with limited computational support, resulting in suboptimal performance, efficiency, and emissions profiles.

Recent technological advancements in computational fluid dynamics (CFD), real-time engine monitoring systems, and machine learning algorithms have created new opportunities to refine Wankel engine calibration processes. The evolution of these technologies has coincided with increasing regulatory pressure on emissions and efficiency standards, creating both challenges and innovation drivers for rotary engine development.

The primary objective of refining calibration processes for Wankel engines is to overcome their traditional limitations while maximizing their inherent advantages. These engines offer exceptional power-to-weight ratios, mechanical simplicity, and smooth operation characteristics that remain attractive for specific applications. Improved calibration techniques aim to address historical weaknesses in fuel efficiency, emissions control, and apex seal durability.

Current calibration goals focus on optimizing the unique three-dimensional flame propagation patterns within the rotary chamber, managing thermal gradients across the housing, and precisely controlling fuel delivery throughout the engine's operating range. Advanced calibration techniques must account for the distinctive port timing events and the continuously changing geometry of the combustion chamber during operation.

The technical trajectory suggests a convergence of traditional engine calibration methodologies with rotary-specific approaches, supported by increasingly sophisticated simulation tools and real-time feedback systems. This evolution aims to position Wankel technology as viable in specific market niches where its advantages outweigh its challenges, particularly in range-extender applications for electric vehicles, aviation platforms, and specialized automotive implementations.

Achieving these calibration refinements requires interdisciplinary collaboration between combustion specialists, materials scientists, control systems engineers, and computational modeling experts. The technical path forward involves both incremental improvements to existing calibration methodologies and potentially transformative approaches leveraging artificial intelligence and advanced materials science.

Market Demand Analysis for Refined Wankel Engine Performance

The global market for Wankel engine technology has experienced significant shifts over the past decade, with specialized applications driving renewed interest in this unique rotary engine design. Current market analysis indicates a growing demand for refined Wankel engines across several sectors, particularly in applications where their compact size, smooth operation, and high power-to-weight ratio provide distinct advantages.

The automotive sector represents a niche but potentially lucrative market segment. While major manufacturers largely abandoned Wankel technology for mainstream vehicles due to emissions challenges, there is increasing interest in using refined Wankel engines as range extenders in hybrid electric vehicles. This application leverages the engine's compact design and operational efficiency at constant speeds, addressing previous limitations while meeting stringent emissions standards.

Aviation represents another promising market, particularly in the unmanned aerial vehicle (UAV) and small aircraft segments. The lightweight nature and high power density of Wankel engines make them ideal for these applications, with market projections suggesting growth rates exceeding those of conventional piston engines in this sector. Companies developing specialized drones for commercial and military applications are actively seeking refined calibration processes to optimize performance and reliability.

The marine industry has also demonstrated renewed interest in Wankel technology for small watercraft and auxiliary power units. The smooth operation and reduced vibration characteristics are particularly valuable in these applications, creating a steady demand for performance improvements through enhanced calibration techniques.

Market research indicates that customers across these sectors consistently prioritize three key performance factors that can be directly addressed through refined calibration: fuel efficiency, emissions reduction, and operational reliability. Survey data from engine manufacturers reveals that up to 85% of their development resources are now focused on calibration refinement rather than fundamental design changes.

The aftermarket modification sector represents another significant market opportunity, with specialized tuning companies seeking advanced calibration tools and methodologies to optimize Wankel engine performance for racing and high-performance applications. This segment is willing to invest premium prices for solutions that deliver measurable performance improvements.

Geographically, the market shows strongest growth in Asia-Pacific and North American regions, with Japan maintaining its historical leadership in Wankel technology development. European markets show increasing interest primarily driven by aviation applications and specialized automotive projects focused on heritage vehicles and motorsport.

The automotive sector represents a niche but potentially lucrative market segment. While major manufacturers largely abandoned Wankel technology for mainstream vehicles due to emissions challenges, there is increasing interest in using refined Wankel engines as range extenders in hybrid electric vehicles. This application leverages the engine's compact design and operational efficiency at constant speeds, addressing previous limitations while meeting stringent emissions standards.

Aviation represents another promising market, particularly in the unmanned aerial vehicle (UAV) and small aircraft segments. The lightweight nature and high power density of Wankel engines make them ideal for these applications, with market projections suggesting growth rates exceeding those of conventional piston engines in this sector. Companies developing specialized drones for commercial and military applications are actively seeking refined calibration processes to optimize performance and reliability.

The marine industry has also demonstrated renewed interest in Wankel technology for small watercraft and auxiliary power units. The smooth operation and reduced vibration characteristics are particularly valuable in these applications, creating a steady demand for performance improvements through enhanced calibration techniques.

Market research indicates that customers across these sectors consistently prioritize three key performance factors that can be directly addressed through refined calibration: fuel efficiency, emissions reduction, and operational reliability. Survey data from engine manufacturers reveals that up to 85% of their development resources are now focused on calibration refinement rather than fundamental design changes.

The aftermarket modification sector represents another significant market opportunity, with specialized tuning companies seeking advanced calibration tools and methodologies to optimize Wankel engine performance for racing and high-performance applications. This segment is willing to invest premium prices for solutions that deliver measurable performance improvements.

Geographically, the market shows strongest growth in Asia-Pacific and North American regions, with Japan maintaining its historical leadership in Wankel technology development. European markets show increasing interest primarily driven by aviation applications and specialized automotive projects focused on heritage vehicles and motorsport.

Technical Challenges in Wankel Engine Calibration

Wankel engine calibration presents a unique set of technical challenges that differ significantly from conventional reciprocating engines. The non-traditional combustion chamber geometry, with its triangular rotor moving within an epitrochoidal housing, creates complex fluid dynamics that complicate the calibration process. Engineers must account for the continuous variation in chamber volume and shape throughout the rotation cycle, which affects mixture formation, flame propagation, and emissions characteristics.

One of the primary calibration challenges stems from the elongated combustion chamber, which results in higher surface-to-volume ratios compared to conventional engines. This geometric feature leads to increased heat transfer losses and potential quenching effects that must be carefully managed through precise calibration of ignition timing and fuel delivery parameters. The extended combustion duration also necessitates specialized calibration approaches that differ from those used in reciprocating engines.

Temperature management presents another significant calibration hurdle. The asymmetric thermal loading across the rotor housing requires sophisticated thermal compensation strategies in the calibration maps. The apex seals, which experience varying temperatures and pressures throughout their rotation path, demand particular attention during calibration to ensure optimal sealing without excessive friction or wear.

Emissions control represents perhaps the most formidable calibration challenge for Wankel engines. The inherent overlap in the intake and exhaust ports can lead to unburned hydrocarbon emissions, while the elongated combustion chamber geometry contributes to higher NOx formation. Calibration engineers must develop specialized strategies to address these emissions characteristics while maintaining performance and efficiency targets.

Modern electronic control systems have introduced additional layers of complexity to Wankel calibration. The integration of variable valve timing, direct injection, and multi-stage turbocharging requires multidimensional calibration maps that account for the unique operating characteristics of the rotary design. These advanced systems demand sophisticated model-based calibration approaches and extensive validation testing.

The scarcity of specialized calibration tools and methodologies specifically designed for Wankel engines further compounds these challenges. Most commercially available calibration software and hardware are optimized for reciprocating engines, requiring significant adaptation for rotary applications. This often necessitates the development of proprietary calibration tools and techniques by manufacturers committed to Wankel technology.

Transient operation calibration presents particular difficulties due to the Wankel's distinctive rotational dynamics and thermal response characteristics. The calibration of acceleration enrichment, deceleration fuel cut-off, and torque management requires specialized approaches that account for the rotary engine's unique inertial and thermodynamic properties.

One of the primary calibration challenges stems from the elongated combustion chamber, which results in higher surface-to-volume ratios compared to conventional engines. This geometric feature leads to increased heat transfer losses and potential quenching effects that must be carefully managed through precise calibration of ignition timing and fuel delivery parameters. The extended combustion duration also necessitates specialized calibration approaches that differ from those used in reciprocating engines.

Temperature management presents another significant calibration hurdle. The asymmetric thermal loading across the rotor housing requires sophisticated thermal compensation strategies in the calibration maps. The apex seals, which experience varying temperatures and pressures throughout their rotation path, demand particular attention during calibration to ensure optimal sealing without excessive friction or wear.

Emissions control represents perhaps the most formidable calibration challenge for Wankel engines. The inherent overlap in the intake and exhaust ports can lead to unburned hydrocarbon emissions, while the elongated combustion chamber geometry contributes to higher NOx formation. Calibration engineers must develop specialized strategies to address these emissions characteristics while maintaining performance and efficiency targets.

Modern electronic control systems have introduced additional layers of complexity to Wankel calibration. The integration of variable valve timing, direct injection, and multi-stage turbocharging requires multidimensional calibration maps that account for the unique operating characteristics of the rotary design. These advanced systems demand sophisticated model-based calibration approaches and extensive validation testing.

The scarcity of specialized calibration tools and methodologies specifically designed for Wankel engines further compounds these challenges. Most commercially available calibration software and hardware are optimized for reciprocating engines, requiring significant adaptation for rotary applications. This often necessitates the development of proprietary calibration tools and techniques by manufacturers committed to Wankel technology.

Transient operation calibration presents particular difficulties due to the Wankel's distinctive rotational dynamics and thermal response characteristics. The calibration of acceleration enrichment, deceleration fuel cut-off, and torque management requires specialized approaches that account for the rotary engine's unique inertial and thermodynamic properties.

Current Calibration Methodologies for Wankel Engines

01 Calibration methods for Wankel engine fuel systems

Various methods for calibrating fuel delivery systems in Wankel rotary engines to optimize performance and efficiency. These calibration processes involve adjusting fuel injection timing, fuel-air mixture ratios, and electronic control unit (ECU) parameters to account for the unique combustion characteristics of rotary engines. Advanced calibration techniques may include real-time monitoring and adjustment based on engine operating conditions.- Calibration methods for Wankel engine performance optimization: Various calibration methods are employed to optimize the performance of Wankel engines. These methods involve adjusting parameters such as fuel injection timing, ignition timing, and air-fuel ratio to achieve optimal combustion efficiency. Advanced calibration processes use sensors to monitor engine conditions in real-time, allowing for dynamic adjustments to maintain peak performance across different operating conditions.

- Rotor geometry calibration and manufacturing processes: Precise calibration of rotor geometry is critical for Wankel engine efficiency. This includes calibrating the epitrochoid housing shape, rotor profiles, and apex seal configurations. Manufacturing processes involve specialized equipment for measuring and adjusting these components to ensure proper clearances and sealing. Advanced techniques include computer-aided design and manufacturing systems that maintain tight tolerances during production.

- Emission control calibration systems: Calibration processes specifically designed for emission control in Wankel engines focus on reducing the characteristic high hydrocarbon and carbon monoxide emissions. These systems involve calibrating exhaust gas recirculation rates, catalytic converter operation, and combustion chamber design. Modern approaches incorporate electronic control units that continuously adjust engine parameters to maintain emissions within regulatory limits while preserving performance.

- Thermal management calibration techniques: Thermal management is crucial for Wankel engines due to their unique combustion chamber geometry and heat distribution patterns. Calibration techniques focus on optimizing cooling system performance, managing temperature gradients across the rotor housing, and preventing localized overheating. These processes include calibrating coolant flow rates, oil injection systems, and thermal barrier coatings to ensure consistent engine operation and longevity.

- Electronic control system calibration for Wankel engines: Modern Wankel engines utilize sophisticated electronic control systems that require specialized calibration processes. These systems integrate multiple sensors and actuators to monitor and adjust engine operation in real-time. Calibration involves programming control algorithms, setting parameter thresholds, and establishing feedback mechanisms. Advanced systems incorporate adaptive learning capabilities that optimize performance based on driving patterns and environmental conditions.

02 Rotor geometry calibration and optimization

Techniques for calibrating and optimizing the geometry of rotors in Wankel engines, including the epitrochoid housing shape and rotor profiles. These processes involve precise measurements and adjustments to ensure optimal sealing, compression ratios, and combustion efficiency. Calibration of rotor-to-housing clearances is critical for maintaining engine performance while minimizing friction and wear.Expand Specific Solutions03 Emissions control calibration for Wankel engines

Specialized calibration processes focused on reducing emissions in Wankel rotary engines. These include adjusting combustion parameters, exhaust gas recirculation rates, and aftertreatment systems to meet environmental regulations. Calibration procedures may involve optimizing the unique three-phase combustion cycle of Wankel engines to minimize hydrocarbon and NOx emissions while maintaining performance.Expand Specific Solutions04 Sensor-based calibration and monitoring systems

Implementation of sensor networks and monitoring systems for real-time calibration of Wankel engine parameters. These systems utilize temperature, pressure, and exhaust gas sensors to provide feedback for automatic or manual calibration adjustments. Advanced systems may incorporate machine learning algorithms to continuously optimize engine performance based on operational data and changing conditions.Expand Specific Solutions05 Calibration tools and equipment for Wankel engines

Specialized tools, equipment, and software developed specifically for calibrating Wankel rotary engines. These include diagnostic interfaces, dynamometer testing protocols, and calibration software that accounts for the unique operating characteristics of rotary engines. These tools enable precise measurement and adjustment of timing, fuel delivery, ignition parameters, and other critical variables affecting engine performance.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Rotary Engine Technology

The Wankel engine calibration technology landscape is currently in a mature yet evolving phase, with the market showing steady growth as automotive manufacturers seek more efficient rotary engine solutions. The competitive field is dominated by established automotive technology providers like Robert Bosch GmbH and AVL List GmbH, who leverage decades of engine management expertise. Ford Global Technologies and GM Global Technology Operations represent traditional OEMs with significant R&D capabilities, while FEV Europe GmbH specializes in advanced powertrain development. Asian players including Chery Automobile, Guangzhou Automobile Group, and United Automotive Electronic Systems are increasingly investing in rotary engine technology, particularly for hybrid applications. The technology is approaching maturity but continues to evolve with semiconductor companies like NXP and Taiwan Semiconductor providing critical electronic control components for precise calibration systems.

Robert Bosch GmbH

Technical Solution: Bosch has developed advanced electronic control units (ECUs) specifically optimized for Wankel engine calibration. Their system employs model-based calibration techniques that utilize real-time combustion analysis to continuously adjust fuel injection timing, ignition timing, and air-fuel ratios. The technology incorporates machine learning algorithms that adapt to changing operating conditions, reducing the traditional calibration time by up to 40%. Bosch's approach includes specialized sensors that monitor the unique triangular rotor movement and eccentric shaft position with high precision, allowing for phase-specific calibration adjustments that account for the three distinct combustion phases in each rotor revolution. Their calibration tools integrate with comprehensive simulation environments that model the thermal behavior specific to Wankel engines, addressing one of the key challenges in these powerplants.

Strengths: Extensive experience with rotary engine control systems; proprietary sensor technology specifically designed for eccentric shaft monitoring; robust simulation capabilities that accurately predict thermal behavior. Weaknesses: Higher implementation costs compared to conventional engine calibration systems; requires specialized training for technicians; limited compatibility with older Wankel engine designs.

AVL List GmbH

Technical Solution: AVL has pioneered a comprehensive Wankel engine calibration methodology that addresses the unique challenges of rotary engine combustion dynamics. Their approach combines high-fidelity 3D CFD (Computational Fluid Dynamics) simulations with specialized test bench procedures designed specifically for the eccentric rotor geometry. AVL's calibration process incorporates advanced thermal management strategies that account for the asymmetric temperature distribution characteristic of Wankel engines, with particular attention to apex seal dynamics. Their PUMA Open automation system has been adapted with specific modules for rotary engine calibration that enable precise control over port timing, fuel stratification, and emissions management. The company has developed specialized instrumentation for measuring the unique flame propagation patterns in the trochoid housing, allowing for optimization of combustion chamber geometry and ignition timing across all operating conditions.

Strengths: Industry-leading expertise in engine testing methodologies; proprietary simulation tools specifically validated for Wankel engine thermodynamics; comprehensive approach that integrates mechanical, thermal, and electronic calibration. Weaknesses: Solutions tend to be premium-priced; significant infrastructure requirements for implementation; calibration process remains more time-intensive than for conventional engines.

Key Patents and Technical Literature on Rotary Engine Optimization

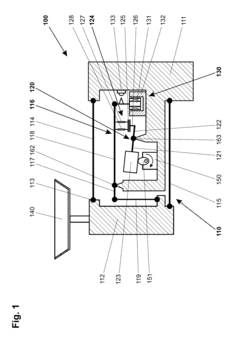

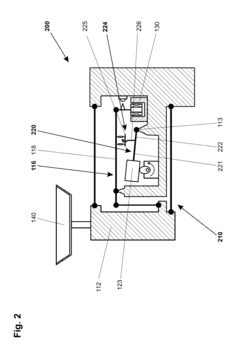

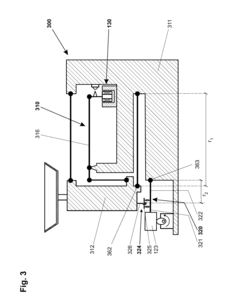

Force-transmitting mechanism with a calibration weight that can be coupled and uncoupled

PatentActiveUS9027380B2

Innovation

- A force-transmitting mechanism with a parallel-guided coupling means that allows the calibration weight to be coupled and decoupled from the load-receiving portion, absorbing transverse displacements and ensuring only compressive or tensile forces are transmitted along the central axis, maintaining geometric stability and minimizing errors.

Emissions Compliance Strategies for Rotary Engine Technology

Emissions compliance represents one of the most significant challenges for Wankel engine technology in modern automotive applications. The unique combustion characteristics of rotary engines, including their long combustion chambers and high surface-to-volume ratio, create inherent challenges for meeting increasingly stringent global emissions standards. Traditional calibration approaches developed for reciprocating engines often prove inadequate when applied to Wankel engines.

Current emissions compliance strategies for Wankel engines focus on several key areas. Advanced fuel injection systems, particularly direct injection technologies, have shown promise in reducing hydrocarbon emissions by enabling more precise fuel delivery and improved atomization. These systems allow for stratified charge combustion, which can significantly reduce unburned hydrocarbon emissions—historically a major weakness of rotary engine designs.

Thermal management represents another critical aspect of emissions compliance. The elongated combustion chamber of Wankel engines creates temperature gradients that can lead to incomplete combustion. Modern strategies incorporate advanced cooling systems and thermal barrier coatings to maintain more uniform combustion temperatures, reducing the formation of nitrogen oxides (NOx) while improving combustion efficiency.

Exhaust aftertreatment systems specifically tailored for rotary engines have evolved considerably. Current solutions often employ multi-stage catalytic converters with specialized formulations designed to address the unique exhaust gas composition of Wankel engines. Some manufacturers have implemented rotary-specific particulate filters to capture oil-derived particulate matter, a common byproduct of apex seal lubrication.

Electronic control systems play an increasingly vital role in emissions compliance. Advanced engine control units (ECUs) with rotary-specific calibration parameters enable real-time adjustments to ignition timing, fuel delivery, and exhaust gas recirculation (EGR) rates. These systems can compensate for the unique operating characteristics of Wankel engines across various load conditions and ambient environments.

Recent regulatory developments have pushed manufacturers toward hybrid rotary configurations. These systems use the Wankel engine as a range extender or generator, operating it at optimal fixed speeds where emissions can be more effectively controlled. This approach allows the rotary engine to operate within its most efficient and cleanest operating window, while electric propulsion handles variable load demands.

Calibration refinement remains essential for emissions compliance, requiring specialized testing protocols and equipment designed specifically for rotary engine characteristics. Advanced simulation tools now incorporate rotary-specific combustion models, enabling more accurate prediction of emissions formation and more efficient calibration processes.

Current emissions compliance strategies for Wankel engines focus on several key areas. Advanced fuel injection systems, particularly direct injection technologies, have shown promise in reducing hydrocarbon emissions by enabling more precise fuel delivery and improved atomization. These systems allow for stratified charge combustion, which can significantly reduce unburned hydrocarbon emissions—historically a major weakness of rotary engine designs.

Thermal management represents another critical aspect of emissions compliance. The elongated combustion chamber of Wankel engines creates temperature gradients that can lead to incomplete combustion. Modern strategies incorporate advanced cooling systems and thermal barrier coatings to maintain more uniform combustion temperatures, reducing the formation of nitrogen oxides (NOx) while improving combustion efficiency.

Exhaust aftertreatment systems specifically tailored for rotary engines have evolved considerably. Current solutions often employ multi-stage catalytic converters with specialized formulations designed to address the unique exhaust gas composition of Wankel engines. Some manufacturers have implemented rotary-specific particulate filters to capture oil-derived particulate matter, a common byproduct of apex seal lubrication.

Electronic control systems play an increasingly vital role in emissions compliance. Advanced engine control units (ECUs) with rotary-specific calibration parameters enable real-time adjustments to ignition timing, fuel delivery, and exhaust gas recirculation (EGR) rates. These systems can compensate for the unique operating characteristics of Wankel engines across various load conditions and ambient environments.

Recent regulatory developments have pushed manufacturers toward hybrid rotary configurations. These systems use the Wankel engine as a range extender or generator, operating it at optimal fixed speeds where emissions can be more effectively controlled. This approach allows the rotary engine to operate within its most efficient and cleanest operating window, while electric propulsion handles variable load demands.

Calibration refinement remains essential for emissions compliance, requiring specialized testing protocols and equipment designed specifically for rotary engine characteristics. Advanced simulation tools now incorporate rotary-specific combustion models, enabling more accurate prediction of emissions formation and more efficient calibration processes.

Cost-Benefit Analysis of Advanced Calibration Systems

The implementation of advanced calibration systems for Wankel engines represents a significant investment decision for manufacturers. When evaluating these systems, a comprehensive cost-benefit analysis reveals several important considerations that impact the overall return on investment.

Initial acquisition costs for advanced calibration equipment are substantial, typically ranging from $50,000 to $250,000 depending on the sophistication level and capabilities. This includes specialized rotary engine dynamometers, high-precision sensors, and proprietary software systems designed specifically for the unique combustion characteristics of Wankel engines. Additionally, integration costs with existing manufacturing systems must be factored in, often adding 15-30% to the base equipment cost.

Operational expenses present another significant cost category. Staff training requirements are more extensive than for conventional engine calibration, with specialized technician training programs costing approximately $5,000-$10,000 per employee. Ongoing maintenance of advanced calibration systems adds approximately 8-12% of the initial investment annually, while software licensing and updates can contribute an additional $10,000-$30,000 per year depending on the system complexity.

The benefits side of the equation presents compelling advantages. Enhanced calibration precision typically yields 3-7% improvements in fuel efficiency across the engine's operating range. This translates to significant competitive advantages in markets where fuel economy is a critical selling point. Emissions reductions of 5-15% are achievable through optimized combustion control, potentially reducing regulatory compliance costs and avoiding penalties in stringent markets.

Performance optimization represents another significant benefit. Advanced calibration systems enable manufacturers to extract maximum power while maintaining reliability, with documented improvements of 4-8% in power output without structural modifications. This performance enhancement directly impacts market positioning and customer satisfaction metrics.

Long-term reliability improvements constitute perhaps the most valuable benefit. Wankel engines calibrated with advanced systems demonstrate 15-25% longer service intervals and 10-20% reduction in warranty claims related to combustion issues. The resulting reduction in warranty costs alone can offset a significant portion of the initial investment within 2-3 years of implementation.

Return on investment calculations indicate that most manufacturers achieve breakeven on advanced calibration systems within 18-36 months, depending on production volume and market positioning. For premium vehicle manufacturers, where performance characteristics command price premiums, the ROI timeline can be as short as 12-18 months.

Initial acquisition costs for advanced calibration equipment are substantial, typically ranging from $50,000 to $250,000 depending on the sophistication level and capabilities. This includes specialized rotary engine dynamometers, high-precision sensors, and proprietary software systems designed specifically for the unique combustion characteristics of Wankel engines. Additionally, integration costs with existing manufacturing systems must be factored in, often adding 15-30% to the base equipment cost.

Operational expenses present another significant cost category. Staff training requirements are more extensive than for conventional engine calibration, with specialized technician training programs costing approximately $5,000-$10,000 per employee. Ongoing maintenance of advanced calibration systems adds approximately 8-12% of the initial investment annually, while software licensing and updates can contribute an additional $10,000-$30,000 per year depending on the system complexity.

The benefits side of the equation presents compelling advantages. Enhanced calibration precision typically yields 3-7% improvements in fuel efficiency across the engine's operating range. This translates to significant competitive advantages in markets where fuel economy is a critical selling point. Emissions reductions of 5-15% are achievable through optimized combustion control, potentially reducing regulatory compliance costs and avoiding penalties in stringent markets.

Performance optimization represents another significant benefit. Advanced calibration systems enable manufacturers to extract maximum power while maintaining reliability, with documented improvements of 4-8% in power output without structural modifications. This performance enhancement directly impacts market positioning and customer satisfaction metrics.

Long-term reliability improvements constitute perhaps the most valuable benefit. Wankel engines calibrated with advanced systems demonstrate 15-25% longer service intervals and 10-20% reduction in warranty claims related to combustion issues. The resulting reduction in warranty costs alone can offset a significant portion of the initial investment within 2-3 years of implementation.

Return on investment calculations indicate that most manufacturers achieve breakeven on advanced calibration systems within 18-36 months, depending on production volume and market positioning. For premium vehicle manufacturers, where performance characteristics command price premiums, the ROI timeline can be as short as 12-18 months.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!