How To Refine Tungsten-Polymer Blends?

Tungsten-Polymer Blend Refinement: Background and Objectives

Tungsten-polymer blends have emerged as a significant area of research and development in materials science, offering a unique combination of properties that are highly desirable in various industrial applications. The evolution of these blends can be traced back to the mid-20th century when researchers began exploring ways to combine the high density and thermal properties of tungsten with the flexibility and processability of polymers.

The primary objective of refining tungsten-polymer blends is to enhance their performance characteristics while addressing the challenges associated with their production and application. These blends have garnered attention due to their potential in radiation shielding, ballistic protection, and high-density applications in aerospace and automotive industries.

Over the years, the development of tungsten-polymer blends has been driven by the need for materials that can withstand extreme conditions while maintaining structural integrity. The progression of this technology has been marked by significant milestones, including improvements in dispersion techniques, advancements in polymer matrix selection, and innovations in processing methods.

The current technological landscape for tungsten-polymer blends is characterized by a focus on optimizing the interface between tungsten particles and the polymer matrix. This interface plays a crucial role in determining the overall properties of the composite material. Researchers are exploring various strategies to enhance the adhesion between tungsten and polymers, including surface modification of tungsten particles and the use of coupling agents.

Another key aspect of the refinement process is the development of novel polymer matrices that can effectively incorporate high loadings of tungsten while maintaining desirable mechanical properties. This involves investigating a wide range of thermoplastic and thermosetting polymers, as well as exploring the potential of hybrid matrix systems.

The refinement of tungsten-polymer blends also encompasses efforts to improve the homogeneity of particle distribution within the polymer matrix. Achieving uniform dispersion is critical for ensuring consistent properties throughout the material and maximizing its performance in various applications.

As we look towards the future, the refinement of tungsten-polymer blends is expected to focus on several key areas. These include the development of nanostructured tungsten particles to enhance the interface properties, the exploration of bio-based polymers for more sustainable composites, and the integration of smart materials to create multifunctional tungsten-polymer blends with adaptive properties.

Market Analysis for Advanced Composite Materials

The market for advanced composite materials, particularly tungsten-polymer blends, has been experiencing significant growth in recent years. This growth is driven by the increasing demand for high-performance materials in various industries, including aerospace, automotive, electronics, and defense. Tungsten-polymer blends offer a unique combination of properties, such as high density, excellent mechanical strength, and improved radiation shielding capabilities, making them attractive for specialized applications.

In the aerospace sector, tungsten-polymer composites are gaining traction due to their ability to provide weight reduction while maintaining structural integrity. This is crucial for improving fuel efficiency and overall performance of aircraft and spacecraft. The automotive industry is also showing interest in these materials for their potential use in electric vehicle battery components and structural reinforcements.

The electronics industry is another key market for tungsten-polymer blends, particularly in the production of heat sinks and electromagnetic interference (EMI) shielding components. As electronic devices become more compact and powerful, the need for efficient thermal management and EMI protection increases, driving the demand for advanced composite materials.

The defense sector represents a significant market opportunity for tungsten-polymer blends, especially in applications such as armor plating and ballistic protection. The superior density and strength of these composites make them ideal for developing lightweight yet highly effective protective gear and vehicle armor.

Market analysts project a compound annual growth rate (CAGR) for the advanced composite materials market, including tungsten-polymer blends, to be in the high single digits over the next five years. This growth is expected to be fueled by ongoing research and development efforts to refine and optimize the properties of these materials, as well as the expansion of their applications across various industries.

However, challenges remain in the widespread adoption of tungsten-polymer blends. These include the relatively high cost of production, limited availability of raw materials, and the need for specialized manufacturing processes. Overcoming these challenges through technological advancements and process improvements will be crucial for unlocking the full market potential of these advanced composite materials.

As industries continue to seek innovative solutions for improving performance and efficiency, the market for tungsten-polymer blends is expected to expand further. This growth will likely be supported by increasing investments in research and development, as well as collaborations between material scientists, manufacturers, and end-users to develop tailored solutions for specific applications.

Current Challenges in Tungsten-Polymer Blend Processing

The refinement of tungsten-polymer blends presents several significant challenges in current processing techniques. One of the primary issues is achieving uniform dispersion of tungsten particles within the polymer matrix. Due to the substantial density difference between tungsten and most polymers, there is a strong tendency for particle agglomeration and settling during processing. This non-uniform distribution can lead to inconsistent material properties and compromised performance in the final product.

Another major challenge lies in the interfacial adhesion between tungsten particles and the polymer matrix. Poor adhesion can result in weak mechanical properties and reduced overall performance of the composite. Improving the compatibility between these dissimilar materials often requires surface modification of tungsten particles or the use of coupling agents, which adds complexity and cost to the manufacturing process.

The high melting point of tungsten (approximately 3422°C) poses difficulties in conventional polymer processing methods. Most polymers degrade at temperatures well below tungsten's melting point, limiting the ability to fully integrate the metal into the polymer structure. This temperature mismatch necessitates innovative processing techniques that can effectively combine the two materials without compromising the integrity of the polymer.

Controlling the rheological properties of tungsten-polymer blends during processing is another significant challenge. The addition of tungsten particles can dramatically increase the viscosity of the mixture, making it difficult to process using standard polymer manufacturing equipment. This increased viscosity can lead to issues such as poor mold filling, increased wear on processing equipment, and difficulties in achieving desired part geometries.

The high density of tungsten also presents challenges in terms of equipment design and material handling. Processing equipment must be capable of withstanding the increased weight and abrasive nature of tungsten-loaded materials. This often requires specialized or reinforced equipment, adding to the overall cost and complexity of production.

Achieving consistent batch-to-batch quality in tungsten-polymer blends is an ongoing challenge. Variations in particle size distribution, morphology, and surface characteristics of tungsten powders can significantly impact the final properties of the composite. Developing robust quality control measures and standardized processing protocols is crucial for ensuring reproducible results in industrial applications.

Environmental and safety concerns also pose challenges in tungsten-polymer blend processing. Tungsten dust can be harmful if inhaled, necessitating stringent safety measures in handling and processing. Additionally, the recycling and disposal of tungsten-polymer composites at the end of their lifecycle present environmental challenges that need to be addressed for sustainable manufacturing practices.

Existing Refinement Techniques for Tungsten-Polymer Blends

01 Composition of tungsten-polymer blends

Tungsten-polymer blends typically consist of tungsten particles dispersed in a polymer matrix. These blends combine the high density and radiation shielding properties of tungsten with the processability and flexibility of polymers. The composition can be adjusted to achieve specific properties such as density, mechanical strength, and radiation attenuation.- Composition of tungsten-polymer blends: Tungsten-polymer blends are composite materials that combine tungsten particles with various polymer matrices. These blends are designed to leverage the high density of tungsten while maintaining the processability and flexibility of polymers. The composition can be adjusted to achieve specific properties such as radiation shielding, vibration damping, or enhanced mechanical strength.

- Manufacturing processes for tungsten-polymer blends: Various manufacturing processes are employed to produce tungsten-polymer blends, including injection molding, extrusion, and compression molding. These processes involve mixing tungsten particles with polymer resins, often requiring specialized equipment to handle the high density and abrasive nature of tungsten. The manufacturing methods are optimized to ensure uniform distribution of tungsten particles and to minimize porosity in the final product.

- Applications of tungsten-polymer blends: Tungsten-polymer blends find applications in diverse fields due to their unique combination of properties. They are used in radiation shielding for medical and nuclear industries, balance weights in automotive and aerospace sectors, vibration damping components, and high-density materials for sporting goods. The blends' ability to be molded into complex shapes while maintaining high density makes them versatile for various specialized applications.

- Surface modification of tungsten particles in polymer blends: Surface modification techniques are applied to tungsten particles to improve their compatibility with polymer matrices. These modifications can enhance the interfacial adhesion between tungsten and the polymer, leading to improved mechanical properties and more uniform dispersion. Common methods include chemical treatments, coating with coupling agents, or plasma modification of the tungsten surface.

- Characterization and testing of tungsten-polymer blends: Characterization and testing of tungsten-polymer blends involve various analytical techniques to assess their properties and performance. These may include density measurements, mechanical testing (tensile strength, impact resistance), thermal analysis, and radiation attenuation testing. Advanced imaging techniques such as electron microscopy are used to evaluate particle distribution and interface quality. These tests are crucial for quality control and optimizing blend formulations for specific applications.

02 Manufacturing methods for tungsten-polymer composites

Various manufacturing methods are employed to produce tungsten-polymer composites, including injection molding, extrusion, and compression molding. These processes involve mixing tungsten particles with polymer resins, followed by shaping and curing. Advanced techniques may be used to ensure uniform dispersion of tungsten particles and to minimize porosity in the final product.Expand Specific Solutions03 Applications of tungsten-polymer blends

Tungsten-polymer blends find applications in various industries due to their unique properties. They are used in radiation shielding for medical and nuclear applications, balance weights in aerospace and automotive industries, and vibration damping components. These materials are also employed in military applications for armor and projectiles.Expand Specific Solutions04 Enhancing properties of tungsten-polymer composites

Research focuses on improving the properties of tungsten-polymer composites through various methods. This includes surface modification of tungsten particles to enhance bonding with the polymer matrix, incorporation of additional reinforcing materials, and development of novel polymer formulations. These enhancements aim to improve mechanical strength, thermal stability, and overall performance of the composites.Expand Specific Solutions05 Environmental and recycling considerations

As the use of tungsten-polymer blends increases, attention is being given to environmental impacts and recycling possibilities. Research is ongoing to develop eco-friendly polymer matrices and to establish efficient recycling processes for these composites. This includes methods for separating tungsten from the polymer matrix and potential reuse of recovered materials.Expand Specific Solutions

Key Players in Tungsten-Polymer Blend Industry

The refinement of tungsten-polymer blends is a complex technological challenge in an evolving industry. The market is experiencing steady growth, driven by increasing demand in various sectors such as electronics, aerospace, and automotive. The technology is in a transitional phase, moving from early development to more advanced applications. Companies like ExxonMobil Chemical Patents, Inc. and Applied Materials, Inc. are at the forefront, leveraging their expertise in materials science. Research institutions such as Central South University and Henan University of Science & Technology are contributing to technological advancements. The involvement of specialized firms like Ganzhou Haichuang Tungsten Industry Co. Ltd. and Xian Huashan Tungsten Products Co., Ltd. indicates a maturing market with potential for further innovation and commercialization.

ExxonMobil Chemical Patents, Inc.

Applied Materials, Inc.

Innovative Approaches in Tungsten-Polymer Blend Refinement

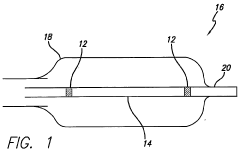

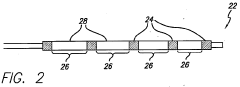

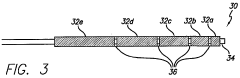

- A polymeric radiopaque marker with a higher fill ratio of radiopaque agents, achieved by using radiopaque materials with specific particle sizes and shapes, and additives like maleic anhydride graft polyolefin resin, allowing for increased ductility and flexibility while maintaining radiopacity, is developed. The process involves tumble mixing, twin-screw extrusion, and hot die necking to achieve the desired wall thickness and attachment to medical devices.

- A process combining acidification to a pH range of 7-10 for precipitation of impurities, followed by anion exchange using weakly to moderately basic ion exchangers to separate arsenic and molybdenum, and forming thiomolybdates for removal, which enhances the selectivity and capacity for molybdenum separation.

Environmental Impact of Tungsten-Polymer Blend Production

The production of tungsten-polymer blends has significant environmental implications that warrant careful consideration. The process involves the extraction of tungsten, a rare metal, which often requires extensive mining operations. These activities can lead to habitat destruction, soil erosion, and water pollution in the surrounding areas. Furthermore, the energy-intensive nature of tungsten extraction and processing contributes to increased carbon emissions and climate change concerns.

The polymer component of the blend also presents environmental challenges. Many polymers are derived from fossil fuels, and their production processes can release harmful chemicals and greenhouse gases. The manufacturing of tungsten-polymer blends often involves the use of solvents and other potentially hazardous materials, which may pose risks to both human health and the environment if not properly managed.

Waste management is another critical aspect of the environmental impact. The production process generates various waste streams, including solid waste, wastewater, and air emissions. Proper treatment and disposal of these wastes are essential to minimize environmental contamination and comply with regulatory standards. Additionally, the end-of-life disposal of tungsten-polymer blend products can be problematic, as the composite nature of the material may make recycling challenging.

Water usage is a significant concern in the production of tungsten-polymer blends. Both tungsten extraction and polymer manufacturing require substantial amounts of water, potentially straining local water resources in areas where these operations are located. This can lead to conflicts with other water users and impact aquatic ecosystems.

Energy consumption throughout the production chain is another environmental factor to consider. From mining and refining tungsten to synthesizing polymers and blending the materials, each step requires significant energy inputs. The source of this energy, whether from fossil fuels or renewable sources, greatly influences the overall carbon footprint of the production process.

To mitigate these environmental impacts, several strategies can be employed. Implementing cleaner production technologies, such as closed-loop systems and energy-efficient equipment, can reduce waste generation and energy consumption. Exploring alternative, more environmentally friendly polymer materials or recycled sources could decrease the reliance on virgin resources. Additionally, adopting sustainable mining practices for tungsten extraction and investing in habitat restoration can help minimize the ecological footprint of the industry.

Characterization Methods for Refined Tungsten-Polymer Blends

Characterization methods play a crucial role in understanding and optimizing the properties of refined tungsten-polymer blends. These methods provide essential insights into the material's structure, composition, and performance, enabling researchers and engineers to fine-tune the blending process and achieve desired outcomes.

One of the primary characterization techniques employed is scanning electron microscopy (SEM). SEM allows for high-resolution imaging of the blend's surface morphology, revealing the distribution and interaction of tungsten particles within the polymer matrix. This method is particularly useful for assessing the uniformity of particle dispersion and identifying any agglomeration issues that may affect the blend's properties.

X-ray diffraction (XRD) is another valuable tool for characterizing tungsten-polymer blends. XRD analysis provides information about the crystalline structure of the tungsten particles and can detect any phase changes or impurities present in the blend. This technique is essential for ensuring the purity and structural integrity of the tungsten component.

Thermal analysis methods, such as differential scanning calorimetry (DSC) and thermogravimetric analysis (TGA), are employed to investigate the thermal properties and stability of the blends. DSC reveals information about phase transitions, melting points, and crystallization behavior, while TGA helps determine the blend's thermal decomposition characteristics and tungsten content.

Mechanical testing is crucial for evaluating the performance of refined tungsten-polymer blends. Tensile testing, compression testing, and hardness measurements provide valuable data on the blend's strength, ductility, and overall mechanical behavior. These tests help assess how well the tungsten particles reinforce the polymer matrix and contribute to the material's overall properties.

Rheological characterization is essential for understanding the flow behavior of tungsten-polymer blends during processing. Techniques such as rotational rheometry and capillary rheometry provide insights into the blend's viscosity, shear thinning behavior, and processability. This information is crucial for optimizing manufacturing processes and ensuring consistent product quality.

Spectroscopic methods, including Fourier-transform infrared spectroscopy (FTIR) and Raman spectroscopy, are employed to analyze the chemical composition and bonding characteristics of the blends. These techniques can reveal information about polymer-tungsten interactions and help identify any chemical changes occurring during the blending process.

Particle size analysis is another critical aspect of characterizing tungsten-polymer blends. Laser diffraction and dynamic light scattering techniques are commonly used to determine the size distribution of tungsten particles within the blend. This information is vital for understanding how particle size affects the blend's properties and for optimizing the refinement process.