How to Secure Column Performance in HPLC Analyses

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HPLC Column Technology Background and Objectives

High-performance liquid chromatography (HPLC) has evolved significantly since its inception in the late 1960s, becoming an indispensable analytical technique in pharmaceutical, environmental, food safety, and clinical research sectors. The column, as the heart of HPLC systems, has undergone continuous refinement to meet increasingly demanding analytical requirements. The evolution of HPLC column technology has progressed from conventional silica-based particles to advanced core-shell particles, monolithic columns, and ultra-high-performance materials.

The historical trajectory of HPLC column development reveals a consistent focus on improving separation efficiency, reducing analysis time, and enhancing detection sensitivity. Early columns featured particle sizes of 10μm or larger, while modern columns utilize sub-2μm particles that dramatically improve chromatographic performance. This miniaturization trend has been accompanied by innovations in particle morphology, pore structure, and surface chemistry to address specific analytical challenges.

Current market trends indicate a growing demand for columns that maintain consistent performance over extended usage periods, particularly in high-throughput environments where column longevity directly impacts operational efficiency and cost-effectiveness. The ability to secure reliable column performance has become a critical factor in analytical laboratories facing increasing sample loads and regulatory scrutiny.

The primary technical objectives in securing HPLC column performance include: developing robust methods for column qualification and performance verification; establishing effective protocols for column maintenance and regeneration; identifying and mitigating factors that contribute to column degradation; and designing predictive models for column lifetime under various operational conditions.

Emerging technologies such as artificial intelligence and machine learning are beginning to play significant roles in predicting column performance and optimizing chromatographic methods. These computational approaches complement traditional empirical methods by identifying subtle patterns in system behavior that may indicate impending column failure or performance degradation.

The convergence of advanced materials science, surface chemistry, and data analytics presents unprecedented opportunities for enhancing column performance security. Research efforts are increasingly focused on developing self-diagnosing columns with integrated sensors, smart column technologies that adapt to changing sample matrices, and automated systems for column performance monitoring and maintenance.

As analytical demands continue to evolve, particularly in emerging fields such as biopharmaceuticals, personalized medicine, and environmental microcontaminant analysis, securing consistent HPLC column performance remains a fundamental challenge that requires multidisciplinary approaches combining chemistry, materials science, engineering, and informatics.

The historical trajectory of HPLC column development reveals a consistent focus on improving separation efficiency, reducing analysis time, and enhancing detection sensitivity. Early columns featured particle sizes of 10μm or larger, while modern columns utilize sub-2μm particles that dramatically improve chromatographic performance. This miniaturization trend has been accompanied by innovations in particle morphology, pore structure, and surface chemistry to address specific analytical challenges.

Current market trends indicate a growing demand for columns that maintain consistent performance over extended usage periods, particularly in high-throughput environments where column longevity directly impacts operational efficiency and cost-effectiveness. The ability to secure reliable column performance has become a critical factor in analytical laboratories facing increasing sample loads and regulatory scrutiny.

The primary technical objectives in securing HPLC column performance include: developing robust methods for column qualification and performance verification; establishing effective protocols for column maintenance and regeneration; identifying and mitigating factors that contribute to column degradation; and designing predictive models for column lifetime under various operational conditions.

Emerging technologies such as artificial intelligence and machine learning are beginning to play significant roles in predicting column performance and optimizing chromatographic methods. These computational approaches complement traditional empirical methods by identifying subtle patterns in system behavior that may indicate impending column failure or performance degradation.

The convergence of advanced materials science, surface chemistry, and data analytics presents unprecedented opportunities for enhancing column performance security. Research efforts are increasingly focused on developing self-diagnosing columns with integrated sensors, smart column technologies that adapt to changing sample matrices, and automated systems for column performance monitoring and maintenance.

As analytical demands continue to evolve, particularly in emerging fields such as biopharmaceuticals, personalized medicine, and environmental microcontaminant analysis, securing consistent HPLC column performance remains a fundamental challenge that requires multidisciplinary approaches combining chemistry, materials science, engineering, and informatics.

Market Demand Analysis for High-Performance HPLC Columns

The global market for high-performance liquid chromatography (HPLC) columns continues to expand significantly, driven by increasing applications across pharmaceutical, biotechnology, food safety, environmental monitoring, and clinical diagnostics sectors. Current market valuations place the HPLC column segment at approximately 3.2 billion USD, with projections indicating a compound annual growth rate of 5.7% through 2028.

Pharmaceutical and biopharmaceutical industries remain the dominant consumers of high-performance HPLC columns, accounting for nearly 65% of market demand. This dominance stems from stringent regulatory requirements for drug development and quality control processes, where column performance directly impacts analytical reliability and compliance outcomes. The rising complexity of biological drugs and biosimilars has further intensified demand for specialized columns capable of handling challenging separations.

Academic and research institutions constitute the second-largest market segment, representing approximately 18% of total demand. These institutions prioritize columns offering superior resolution and reproducibility for cutting-edge research applications, particularly in proteomics, metabolomics, and other emerging fields requiring precise molecular characterization.

Regional analysis reveals North America as the leading market for high-performance HPLC columns, followed closely by Europe and Asia-Pacific. However, the Asia-Pacific region demonstrates the highest growth rate, attributed to expanding pharmaceutical manufacturing capabilities, increasing research investments, and strengthening regulatory frameworks in countries like China, India, and South Korea.

Customer surveys indicate evolving priorities among HPLC column users. While separation efficiency remains paramount, longevity and consistency between manufacturing batches have emerged as critical selection factors. Users increasingly demand columns that maintain performance over extended usage periods, reducing frequency of replacement and recalibration requirements. This shift reflects broader industry trends toward operational efficiency and cost reduction in analytical laboratories.

Environmental sustainability has emerged as a notable market driver, with growing demand for columns compatible with green chromatography approaches. These include columns designed for use with reduced solvent volumes, compatibility with aqueous mobile phases, and manufacturing processes that minimize environmental impact.

The market exhibits increasing segmentation based on specific application requirements. Specialized columns for chiral separations, hydrophilic interaction chromatography (HILIC), and size-exclusion applications command premium pricing due to their technical sophistication and targeted performance characteristics. This specialization trend is expected to continue as analytical challenges become more complex across industries.

Pharmaceutical and biopharmaceutical industries remain the dominant consumers of high-performance HPLC columns, accounting for nearly 65% of market demand. This dominance stems from stringent regulatory requirements for drug development and quality control processes, where column performance directly impacts analytical reliability and compliance outcomes. The rising complexity of biological drugs and biosimilars has further intensified demand for specialized columns capable of handling challenging separations.

Academic and research institutions constitute the second-largest market segment, representing approximately 18% of total demand. These institutions prioritize columns offering superior resolution and reproducibility for cutting-edge research applications, particularly in proteomics, metabolomics, and other emerging fields requiring precise molecular characterization.

Regional analysis reveals North America as the leading market for high-performance HPLC columns, followed closely by Europe and Asia-Pacific. However, the Asia-Pacific region demonstrates the highest growth rate, attributed to expanding pharmaceutical manufacturing capabilities, increasing research investments, and strengthening regulatory frameworks in countries like China, India, and South Korea.

Customer surveys indicate evolving priorities among HPLC column users. While separation efficiency remains paramount, longevity and consistency between manufacturing batches have emerged as critical selection factors. Users increasingly demand columns that maintain performance over extended usage periods, reducing frequency of replacement and recalibration requirements. This shift reflects broader industry trends toward operational efficiency and cost reduction in analytical laboratories.

Environmental sustainability has emerged as a notable market driver, with growing demand for columns compatible with green chromatography approaches. These include columns designed for use with reduced solvent volumes, compatibility with aqueous mobile phases, and manufacturing processes that minimize environmental impact.

The market exhibits increasing segmentation based on specific application requirements. Specialized columns for chiral separations, hydrophilic interaction chromatography (HILIC), and size-exclusion applications command premium pricing due to their technical sophistication and targeted performance characteristics. This specialization trend is expected to continue as analytical challenges become more complex across industries.

Current Challenges in HPLC Column Performance

Despite significant advancements in HPLC technology, column performance remains a critical challenge that affects analytical reliability and efficiency. The primary issues revolve around column degradation over time, which manifests as peak broadening, decreased resolution, and increased backpressure. These performance issues are often attributed to particulate contamination from samples, mobile phases, or system components that gradually accumulate at the column inlet, creating a physical barrier to efficient separation.

Chemical degradation presents another significant challenge, particularly when columns are exposed to extreme pH conditions, aggressive mobile phases, or incompatible solvents. Silica-based columns, which dominate the market, are especially vulnerable to dissolution under high pH conditions (>8), leading to shortened column lifespans and inconsistent results. Conversely, at low pH, bonded phases may be hydrolyzed, compromising selectivity and retention characteristics.

Temperature fluctuations during analysis represent a frequently overlooked challenge. Inconsistent temperature control can alter selectivity, retention times, and peak shapes, making method transfer between instruments problematic. Modern HPLC systems incorporate column ovens, but temperature gradients within columns can still occur, especially during high-throughput analyses where equilibration time is limited.

The phenomenon of column bleeding—where stationary phase components gradually elute from the column—poses challenges for sensitive detection methods, particularly mass spectrometry. This issue is exacerbated by newer column technologies with complex bonded phases designed for specialized separations, as these may exhibit unique degradation patterns not observed in traditional C18 columns.

Reproducibility between columns, even those from the same manufacturer and lot, remains problematic. Minor variations in packing density, surface coverage, and end-capping efficiency can lead to significant differences in selectivity and efficiency. This variability complicates method development and transfer, especially in regulated environments where consistent performance is mandatory.

Emerging challenges include the adaptation of traditional HPLC columns to ultra-high-pressure liquid chromatography (UHPLC) conditions. While sub-2μm particles offer enhanced efficiency, they generate substantially higher backpressure and are more susceptible to fouling due to their smaller interstitial spaces. Additionally, the mechanical stress from high-pressure operation can cause particle fracture and bed collapse over time.

Bioanalytical applications present unique challenges, as biomolecules can irreversibly adsorb to column surfaces, gradually altering selectivity and reducing column lifetime. This is particularly problematic with protein and peptide analyses, where secondary interactions with residual silanol groups can cause peak tailing and poor recovery of analytes.

Chemical degradation presents another significant challenge, particularly when columns are exposed to extreme pH conditions, aggressive mobile phases, or incompatible solvents. Silica-based columns, which dominate the market, are especially vulnerable to dissolution under high pH conditions (>8), leading to shortened column lifespans and inconsistent results. Conversely, at low pH, bonded phases may be hydrolyzed, compromising selectivity and retention characteristics.

Temperature fluctuations during analysis represent a frequently overlooked challenge. Inconsistent temperature control can alter selectivity, retention times, and peak shapes, making method transfer between instruments problematic. Modern HPLC systems incorporate column ovens, but temperature gradients within columns can still occur, especially during high-throughput analyses where equilibration time is limited.

The phenomenon of column bleeding—where stationary phase components gradually elute from the column—poses challenges for sensitive detection methods, particularly mass spectrometry. This issue is exacerbated by newer column technologies with complex bonded phases designed for specialized separations, as these may exhibit unique degradation patterns not observed in traditional C18 columns.

Reproducibility between columns, even those from the same manufacturer and lot, remains problematic. Minor variations in packing density, surface coverage, and end-capping efficiency can lead to significant differences in selectivity and efficiency. This variability complicates method development and transfer, especially in regulated environments where consistent performance is mandatory.

Emerging challenges include the adaptation of traditional HPLC columns to ultra-high-pressure liquid chromatography (UHPLC) conditions. While sub-2μm particles offer enhanced efficiency, they generate substantially higher backpressure and are more susceptible to fouling due to their smaller interstitial spaces. Additionally, the mechanical stress from high-pressure operation can cause particle fracture and bed collapse over time.

Bioanalytical applications present unique challenges, as biomolecules can irreversibly adsorb to column surfaces, gradually altering selectivity and reducing column lifetime. This is particularly problematic with protein and peptide analyses, where secondary interactions with residual silanol groups can cause peak tailing and poor recovery of analytes.

Current Solutions for HPLC Column Performance Optimization

01 Column packing materials and stationary phases

Different packing materials and stationary phases significantly impact HPLC column performance. These include silica-based materials, polymer-based materials, and hybrid materials with various surface modifications. The choice of stationary phase affects separation efficiency, selectivity, and resolution. Modifications such as C18, C8, phenyl, or amino functionalities provide different interaction mechanisms with analytes, allowing for optimized separations based on the target compounds.- Column packing materials and stationary phases: Different packing materials and stationary phases significantly impact HPLC column performance. These include silica-based materials, polymer-based materials, and hybrid materials with various surface modifications. The choice of stationary phase affects separation efficiency, selectivity, and resolution. Modifications such as C18, C8, phenyl, and amino groups provide different interaction mechanisms with analytes, allowing for customized separations based on the target compounds.

- Column design and structural improvements: Innovations in column design enhance chromatographic performance through improved flow dynamics and reduced band broadening. These include optimized column dimensions (length, internal diameter), end-fitting designs, and column hardware that minimizes dead volume. Advanced column structures incorporate uniform packing density, improved pressure resistance, and thermal stability features that contribute to better peak shapes, higher plate counts, and extended column lifetimes.

- Performance evaluation and testing methods: Standardized methods for evaluating HPLC column performance include testing for efficiency (theoretical plate count), selectivity, resolution, peak symmetry, and pressure drop. These tests often use specific probe compounds to assess column characteristics under controlled conditions. Advanced evaluation techniques incorporate multiple parameters to provide comprehensive performance profiles, enabling better column selection for specific applications and monitoring of column degradation over time.

- Column regeneration and lifetime extension: Techniques to maintain and extend HPLC column performance include cleaning protocols, regeneration procedures, and preventive maintenance. These methods address common issues like contamination, stationary phase degradation, and void formation. Specialized washing sequences using different solvents can remove accumulated contaminants, while proper storage conditions and handling procedures help preserve column integrity and maintain separation efficiency over extended periods of use.

- Specialized columns for specific applications: Purpose-designed HPLC columns address specific analytical challenges through tailored selectivity and enhanced performance for particular compound classes. These include columns for chiral separations, biomolecule analysis, high-temperature applications, and ultra-fast separations. Specialized columns may incorporate unique particle technologies, pore structures, or surface chemistries optimized for specific sample types, providing improved resolution, sensitivity, and throughput for challenging analytical problems.

02 Column design and structural improvements

Innovations in column design enhance HPLC performance through improved flow dynamics and mechanical stability. These include developments in column hardware, frit designs, connection systems, and column dimensions. Structural improvements such as monolithic columns, core-shell particles, and specialized geometries reduce backpressure, improve mass transfer, and increase separation efficiency. Advanced manufacturing techniques ensure uniform packing and reduce eddy diffusion, leading to sharper peaks and better resolution.Expand Specific Solutions03 Performance evaluation and testing methods

Standardized methods for evaluating HPLC column performance include testing protocols for efficiency, selectivity, resolution, and reproducibility. These methods measure parameters such as theoretical plate count, peak asymmetry, tailing factor, and pressure drop. Quality control procedures ensure consistent column performance across manufacturing batches. Advanced testing approaches use specific test mixtures designed to challenge different aspects of column performance under various operating conditions.Expand Specific Solutions04 Column conditioning and maintenance techniques

Proper conditioning and maintenance procedures significantly extend HPLC column life and maintain performance. These include appropriate equilibration protocols, cleaning methods for removing contaminants, storage recommendations, and regeneration techniques. Regular maintenance practices help prevent issues such as increased backpressure, reduced efficiency, and peak tailing. Specialized washing sequences and solvent combinations can restore performance of columns affected by sample matrix buildup or phase degradation.Expand Specific Solutions05 Application-specific column technologies

Specialized column technologies designed for specific applications offer enhanced performance for particular analytical challenges. These include columns optimized for biomolecule analysis, chiral separations, high-temperature operations, ultra-high pressure applications, and rapid analysis. Application-specific columns feature tailored selectivity, improved stability under extreme conditions, and enhanced compatibility with complex matrices. These specialized designs enable improved resolution of closely related compounds and detection of trace components in complex samples.Expand Specific Solutions

Major Manufacturers and Competitors in HPLC Column Market

The HPLC column performance security market is in a mature growth phase, with an estimated global market size exceeding $1 billion. Major players like Agilent Technologies, Waters Technology, and Shimadzu dominate with comprehensive solutions, while specialized companies such as IDEX Health & Science and Junkosha focus on niche innovations. The technology has reached high maturity levels, with established players (Merck, Hitachi High-Tech) offering standardized solutions, while emerging competitors differentiate through advanced materials and AI-driven analytics. Academic institutions (Max Planck Society, IIT Delhi) continue pushing boundaries in column chemistry and separation techniques, creating a competitive landscape balanced between established protocols and innovative approaches.

Agilent Technologies, Inc.

Technical Solution: Agilent has developed a comprehensive approach to securing HPLC column performance through their InfinityLab Column Technology. Their solution incorporates advanced end-fitting designs that minimize dead volume and reduce peak dispersion. The company's proprietary A-Line Quick Connect fittings enable consistent, zero-dead-volume connections that maintain column efficiency even after multiple reconnections. Agilent's columns feature optimized particle technology with narrow particle size distribution and specialized surface treatments that enhance separation reproducibility and column longevity. Their InfinityLab Poroshell 120 columns utilize superficially porous particles with a solid core and porous outer layer, providing faster analysis while maintaining resolution comparable to fully porous particles. Additionally, Agilent has implemented rigorous quality control protocols including individual column testing with performance documentation and batch-to-batch consistency verification to ensure reliable column performance across applications.

Strengths: Superior connection technology minimizing dead volume; comprehensive quality control ensuring batch-to-batch consistency; wide range of selectivity options for method development. Weaknesses: Premium pricing compared to some competitors; proprietary fittings may require specific hardware compatibility; some specialized applications may require custom solutions beyond standard offerings.

IDEX Health & Science LLC

Technical Solution: IDEX Health & Science has focused on connection technology as a critical factor in securing HPLC column performance. Their MarvelX™ UHPLC connection system addresses one of the primary causes of column performance degradation - improper connections causing dead volume and leaks. The system features finger-tight fittings capable of withstanding pressures up to 19,000 psi without tools, while maintaining zero-dead-volume connections. IDEX's proprietary biocompatible polymer blends in their fittings resist deformation under high pressure and temperature cycling, maintaining seal integrity throughout column lifetime. Their VHP-320 column hardware incorporates precision-machined components with specialized internal flow paths designed to minimize pre-column dispersion and maintain peak efficiency. IDEX has also developed the MarvelXACT™ system with audible and tactile feedback to confirm proper connection, preventing the common user error of under-tightening or over-tightening fittings. Their column protection solutions include advanced in-line filters with precisely controlled porosity and large surface area to trap particulates without introducing band broadening, extending column lifetime while preserving chromatographic performance.

Strengths: Superior connection technology preventing common causes of column failure; tool-free operation improving laboratory workflow; compatibility with multiple vendor systems. Weaknesses: Primary focus on connection technology rather than comprehensive column solutions; requires proper user training despite ease-of-use features; premium pricing for specialized connection systems.

Key Innovations in Column Chemistry and Design

Chromatography beads, production and use thereof

PatentWO2020002300A1

Innovation

- Development of small, rigid, and non-permeable agarose beads with diameters of 1-25 μm, produced through a method involving emulsification, cross-linking, and surface grafting to create polymer tentacles for functionalization, which can withstand high pressures and exclude compounds as small as 100 g/mol, enabling efficient mass transfer and sharper peaks.

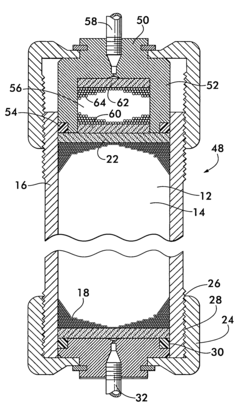

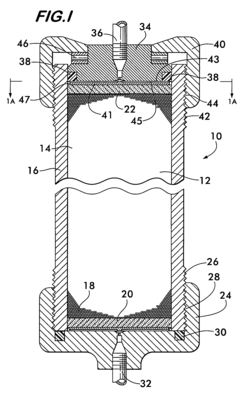

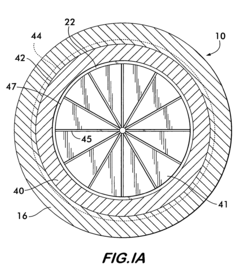

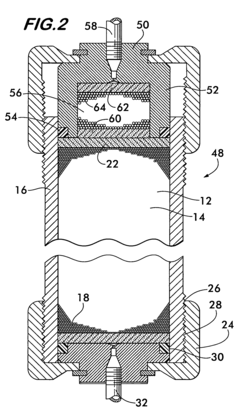

Column for liquid chromatography with adjustable compression

PatentActiveUS7588683B2

Innovation

- A column design featuring movable porous plugs and a piston for precise compression of the packing medium, maintaining hydraulic orientation and uniformity even after pressure removal, using an interference fit and adjustable fittings to ensure consistent flow and prevent leakage.

Quality Control Standards for HPLC Column Manufacturing

Quality control standards in HPLC column manufacturing represent a critical framework that ensures consistent performance and reliability in analytical separations. These standards encompass multiple dimensions of quality assurance, beginning with raw material specifications for silica particles, bonding chemistries, and end-capping reagents. Manufacturers must implement rigorous testing protocols to verify particle size distribution, pore diameter, surface area, and chemical purity of base materials before column production begins.

The manufacturing process itself requires strict environmental controls, including clean room facilities with regulated temperature, humidity, and particulate levels. Column packing procedures must follow validated protocols with precise pressure ramping, slurry concentration control, and mechanical stability testing. Each production batch undergoes comprehensive documentation through detailed batch records that track all materials, equipment, personnel, and process parameters.

Performance testing constitutes the cornerstone of quality control, with each column subjected to chromatographic evaluation using standardized test mixtures. Key performance indicators include theoretical plate count, asymmetry factor, retention time reproducibility, and resolution of critical pairs. Statistical process control methods are employed to monitor trends and detect deviations before they impact product quality.

Stability testing protocols ensure columns maintain performance throughout their expected shelf life, with accelerated aging studies and real-time monitoring of reference columns from each production lot. Manufacturers increasingly implement automated inspection systems utilizing machine vision and sensor technologies to detect physical defects such as voids, channeling, or irregular packing density.

Regulatory compliance forms another essential dimension, with manufacturers adhering to ISO 9001 standards, Good Manufacturing Practices (GMP), and industry-specific guidelines from organizations like USP and ASTM. Documentation requirements include certificates of analysis, validation reports, and traceability records for all components and processes.

Advanced quality metrics now incorporate customer-centric performance indicators such as batch-to-batch reproducibility, column-to-column consistency, and long-term robustness under various mobile phase conditions. Leading manufacturers implement Six Sigma methodologies to drive continuous improvement in manufacturing processes, targeting defect rates below 3.4 parts per million.

The industry continues to evolve toward more stringent standards, with recent developments including implementation of Process Analytical Technology (PAT) for real-time monitoring and automated quality decisions during manufacturing, reducing reliance on end-product testing alone.

The manufacturing process itself requires strict environmental controls, including clean room facilities with regulated temperature, humidity, and particulate levels. Column packing procedures must follow validated protocols with precise pressure ramping, slurry concentration control, and mechanical stability testing. Each production batch undergoes comprehensive documentation through detailed batch records that track all materials, equipment, personnel, and process parameters.

Performance testing constitutes the cornerstone of quality control, with each column subjected to chromatographic evaluation using standardized test mixtures. Key performance indicators include theoretical plate count, asymmetry factor, retention time reproducibility, and resolution of critical pairs. Statistical process control methods are employed to monitor trends and detect deviations before they impact product quality.

Stability testing protocols ensure columns maintain performance throughout their expected shelf life, with accelerated aging studies and real-time monitoring of reference columns from each production lot. Manufacturers increasingly implement automated inspection systems utilizing machine vision and sensor technologies to detect physical defects such as voids, channeling, or irregular packing density.

Regulatory compliance forms another essential dimension, with manufacturers adhering to ISO 9001 standards, Good Manufacturing Practices (GMP), and industry-specific guidelines from organizations like USP and ASTM. Documentation requirements include certificates of analysis, validation reports, and traceability records for all components and processes.

Advanced quality metrics now incorporate customer-centric performance indicators such as batch-to-batch reproducibility, column-to-column consistency, and long-term robustness under various mobile phase conditions. Leading manufacturers implement Six Sigma methodologies to drive continuous improvement in manufacturing processes, targeting defect rates below 3.4 parts per million.

The industry continues to evolve toward more stringent standards, with recent developments including implementation of Process Analytical Technology (PAT) for real-time monitoring and automated quality decisions during manufacturing, reducing reliance on end-product testing alone.

Environmental Considerations in HPLC Analysis

Environmental considerations in HPLC analysis have become increasingly important as laboratories worldwide face growing pressure to adopt more sustainable practices. The environmental impact of HPLC operations stems from multiple sources, including solvent consumption, waste generation, energy usage, and the carbon footprint associated with instrument manufacturing and operation. Traditional HPLC methods often rely on hazardous organic solvents such as acetonitrile, methanol, and tetrahydrofuran, which pose significant environmental and health risks.

Solvent usage represents one of the most substantial environmental concerns in HPLC analysis. A typical HPLC system operating at 1 mL/min generates approximately 1.5 liters of waste per day, translating to over 500 liters annually for a single instrument. This waste stream contains not only organic solvents but also analytes, buffers, and other additives that may require specialized disposal procedures. The environmental burden extends beyond waste management to include the ecological costs of solvent production and transportation.

Recent advances in green chromatography have introduced several approaches to mitigate these environmental impacts while maintaining column performance. Miniaturization technologies, including micro-HPLC and nano-HPLC, significantly reduce solvent consumption by operating at flow rates of 1-100 μL/min and <1 μL/min respectively. These techniques can decrease solvent usage by 90-99% compared to conventional methods while often improving sensitivity and reducing sample volume requirements.

The adoption of greener mobile phases represents another significant trend in environmentally conscious HPLC. Water-based mobile phases, supercritical CO2, and bio-derived solvents like ethyl lactate and 2-methyltetrahydrofuran offer promising alternatives to traditional toxic solvents. These alternatives not only reduce environmental impact but can also extend column lifetime by minimizing chemical degradation of stationary phases.

Temperature optimization provides an additional strategy for enhancing environmental sustainability in HPLC. Elevated temperature chromatography can decrease mobile phase viscosity, allowing for faster analyses and reduced solvent consumption. Studies indicate that increasing column temperature from ambient to 60°C can reduce analysis time by 50-75% while maintaining separation efficiency, thereby significantly decreasing the environmental footprint per analysis.

Laboratory waste management practices also play a crucial role in minimizing the environmental impact of HPLC operations. Implementing solvent recycling systems, proper waste segregation protocols, and treatment technologies such as advanced oxidation processes can substantially reduce the environmental burden of analytical laboratories. Some facilities have reported up to 80% reduction in hazardous waste through comprehensive management programs.

Solvent usage represents one of the most substantial environmental concerns in HPLC analysis. A typical HPLC system operating at 1 mL/min generates approximately 1.5 liters of waste per day, translating to over 500 liters annually for a single instrument. This waste stream contains not only organic solvents but also analytes, buffers, and other additives that may require specialized disposal procedures. The environmental burden extends beyond waste management to include the ecological costs of solvent production and transportation.

Recent advances in green chromatography have introduced several approaches to mitigate these environmental impacts while maintaining column performance. Miniaturization technologies, including micro-HPLC and nano-HPLC, significantly reduce solvent consumption by operating at flow rates of 1-100 μL/min and <1 μL/min respectively. These techniques can decrease solvent usage by 90-99% compared to conventional methods while often improving sensitivity and reducing sample volume requirements.

The adoption of greener mobile phases represents another significant trend in environmentally conscious HPLC. Water-based mobile phases, supercritical CO2, and bio-derived solvents like ethyl lactate and 2-methyltetrahydrofuran offer promising alternatives to traditional toxic solvents. These alternatives not only reduce environmental impact but can also extend column lifetime by minimizing chemical degradation of stationary phases.

Temperature optimization provides an additional strategy for enhancing environmental sustainability in HPLC. Elevated temperature chromatography can decrease mobile phase viscosity, allowing for faster analyses and reduced solvent consumption. Studies indicate that increasing column temperature from ambient to 60°C can reduce analysis time by 50-75% while maintaining separation efficiency, thereby significantly decreasing the environmental footprint per analysis.

Laboratory waste management practices also play a crucial role in minimizing the environmental impact of HPLC operations. Implementing solvent recycling systems, proper waste segregation protocols, and treatment technologies such as advanced oxidation processes can substantially reduce the environmental burden of analytical laboratories. Some facilities have reported up to 80% reduction in hazardous waste through comprehensive management programs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!