How to Strengthen Tunnel Diode Impact through System Design

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Tunnel Diode Technology Background and Objectives

Tunnel diodes, first discovered in 1957 by Leo Esaki, represent a significant milestone in semiconductor technology. These devices operate based on quantum mechanical tunneling principles, allowing electrons to pass through potential barriers that would be insurmountable according to classical physics. The historical evolution of tunnel diodes began with germanium-based devices, progressing through various semiconductor materials including gallium arsenide and silicon, each iteration expanding the operational capabilities and application potential.

The technology has experienced several distinct development phases, from initial discovery and theoretical understanding to practical implementation in specialized circuits. Despite showing early promise in high-frequency applications during the 1960s, tunnel diodes were largely overshadowed by transistor technology in mainstream electronics due to integration challenges and manufacturing complexities.

Recent advancements in nanotechnology and materials science have revitalized interest in tunnel diodes, particularly for their unique negative differential resistance (NDR) characteristics. This property enables exceptional performance in oscillator circuits, high-speed switching applications, and potential quantum computing components. The renewed focus stems from modern fabrication techniques that allow precise control of semiconductor interfaces at the nanoscale, addressing historical limitations.

The primary technical objective in strengthening tunnel diode impact through system design involves optimizing the integration of these devices within larger electronic systems to leverage their inherent advantages while mitigating traditional limitations. This includes enhancing signal-to-noise ratios, improving temperature stability, and developing novel circuit topologies that specifically exploit NDR characteristics.

Current research trajectories aim to expand tunnel diode applications beyond niche markets into mainstream electronic systems, particularly in ultra-high-frequency communications, terahertz sensing, and energy-efficient computing architectures. The technology shows particular promise for systems requiring extremely fast switching speeds with minimal power consumption.

The evolution trend suggests convergence with other emerging technologies, including two-dimensional materials like graphene and transition metal dichalcogenides, which offer new platforms for tunnel diode implementation with potentially superior performance characteristics. Additionally, integration with silicon photonics presents opportunities for hybrid electronic-photonic systems leveraging tunnel diode properties.

Achieving broader adoption requires addressing persistent challenges in manufacturing scalability, device uniformity, and integration compatibility with conventional semiconductor processes. The technical roadmap must balance theoretical performance advantages against practical implementation considerations to establish tunnel diodes as viable components in next-generation electronic systems.

The technology has experienced several distinct development phases, from initial discovery and theoretical understanding to practical implementation in specialized circuits. Despite showing early promise in high-frequency applications during the 1960s, tunnel diodes were largely overshadowed by transistor technology in mainstream electronics due to integration challenges and manufacturing complexities.

Recent advancements in nanotechnology and materials science have revitalized interest in tunnel diodes, particularly for their unique negative differential resistance (NDR) characteristics. This property enables exceptional performance in oscillator circuits, high-speed switching applications, and potential quantum computing components. The renewed focus stems from modern fabrication techniques that allow precise control of semiconductor interfaces at the nanoscale, addressing historical limitations.

The primary technical objective in strengthening tunnel diode impact through system design involves optimizing the integration of these devices within larger electronic systems to leverage their inherent advantages while mitigating traditional limitations. This includes enhancing signal-to-noise ratios, improving temperature stability, and developing novel circuit topologies that specifically exploit NDR characteristics.

Current research trajectories aim to expand tunnel diode applications beyond niche markets into mainstream electronic systems, particularly in ultra-high-frequency communications, terahertz sensing, and energy-efficient computing architectures. The technology shows particular promise for systems requiring extremely fast switching speeds with minimal power consumption.

The evolution trend suggests convergence with other emerging technologies, including two-dimensional materials like graphene and transition metal dichalcogenides, which offer new platforms for tunnel diode implementation with potentially superior performance characteristics. Additionally, integration with silicon photonics presents opportunities for hybrid electronic-photonic systems leveraging tunnel diode properties.

Achieving broader adoption requires addressing persistent challenges in manufacturing scalability, device uniformity, and integration compatibility with conventional semiconductor processes. The technical roadmap must balance theoretical performance advantages against practical implementation considerations to establish tunnel diodes as viable components in next-generation electronic systems.

Market Applications and Demand Analysis

Tunnel diodes, despite being discovered in the 1950s, are experiencing renewed market interest due to their unique negative resistance characteristics and potential applications in modern electronic systems. The global market for specialized diodes, including tunnel diodes, is projected to reach $7.5 billion by 2026, with tunnel diodes representing a growing niche segment particularly in high-frequency applications.

The primary market demand for enhanced tunnel diode systems comes from the telecommunications sector, where the need for high-frequency oscillators and amplifiers continues to expand with 5G and upcoming 6G technologies. Telecommunications infrastructure requires components capable of operating at frequencies above 100 GHz, where tunnel diodes offer significant advantages over conventional semiconductor devices due to their switching speed and low noise characteristics.

Aerospace and defense sectors represent another substantial market segment, valuing the radiation hardness and temperature stability of tunnel diodes. Military radar systems, satellite communications, and space exploration equipment all benefit from tunnel diodes' ability to function reliably in extreme environments. The defense electronics market, growing at 4.2% annually, increasingly demands radiation-tolerant components where tunnel diodes excel compared to conventional transistors.

Quantum computing research facilities constitute an emerging market with significant growth potential. As quantum computing moves from theoretical research to practical implementation, the need for ultra-fast switching components operating at cryogenic temperatures has intensified. Tunnel diodes, with their quantum tunneling mechanism, align naturally with quantum computing requirements and can function effectively at temperatures approaching absolute zero.

Test and measurement equipment manufacturers represent another key market segment. High-precision oscilloscopes, spectrum analyzers, and signal generators require components capable of generating and processing signals at increasingly higher frequencies. The test equipment market, valued at $12 billion globally, continues to demand components with improved performance at higher frequencies.

Consumer electronics presents a potential future market if tunnel diode system design can overcome current manufacturing scalability challenges. The integration of tunnel diodes in consumer devices could enable more energy-efficient RF circuits, potentially extending battery life in portable devices and reducing power consumption in IoT applications.

Market analysis indicates that while tunnel diodes currently occupy a specialized niche, system-level improvements that enhance their performance, reliability, and integration capabilities could significantly expand their market penetration. The industry trend toward higher frequencies, lower power consumption, and operation in extreme environments all favor tunnel diode adoption if the right system design approaches can be implemented to maximize their unique characteristics.

The primary market demand for enhanced tunnel diode systems comes from the telecommunications sector, where the need for high-frequency oscillators and amplifiers continues to expand with 5G and upcoming 6G technologies. Telecommunications infrastructure requires components capable of operating at frequencies above 100 GHz, where tunnel diodes offer significant advantages over conventional semiconductor devices due to their switching speed and low noise characteristics.

Aerospace and defense sectors represent another substantial market segment, valuing the radiation hardness and temperature stability of tunnel diodes. Military radar systems, satellite communications, and space exploration equipment all benefit from tunnel diodes' ability to function reliably in extreme environments. The defense electronics market, growing at 4.2% annually, increasingly demands radiation-tolerant components where tunnel diodes excel compared to conventional transistors.

Quantum computing research facilities constitute an emerging market with significant growth potential. As quantum computing moves from theoretical research to practical implementation, the need for ultra-fast switching components operating at cryogenic temperatures has intensified. Tunnel diodes, with their quantum tunneling mechanism, align naturally with quantum computing requirements and can function effectively at temperatures approaching absolute zero.

Test and measurement equipment manufacturers represent another key market segment. High-precision oscilloscopes, spectrum analyzers, and signal generators require components capable of generating and processing signals at increasingly higher frequencies. The test equipment market, valued at $12 billion globally, continues to demand components with improved performance at higher frequencies.

Consumer electronics presents a potential future market if tunnel diode system design can overcome current manufacturing scalability challenges. The integration of tunnel diodes in consumer devices could enable more energy-efficient RF circuits, potentially extending battery life in portable devices and reducing power consumption in IoT applications.

Market analysis indicates that while tunnel diodes currently occupy a specialized niche, system-level improvements that enhance their performance, reliability, and integration capabilities could significantly expand their market penetration. The industry trend toward higher frequencies, lower power consumption, and operation in extreme environments all favor tunnel diode adoption if the right system design approaches can be implemented to maximize their unique characteristics.

Current Challenges in Tunnel Diode Implementation

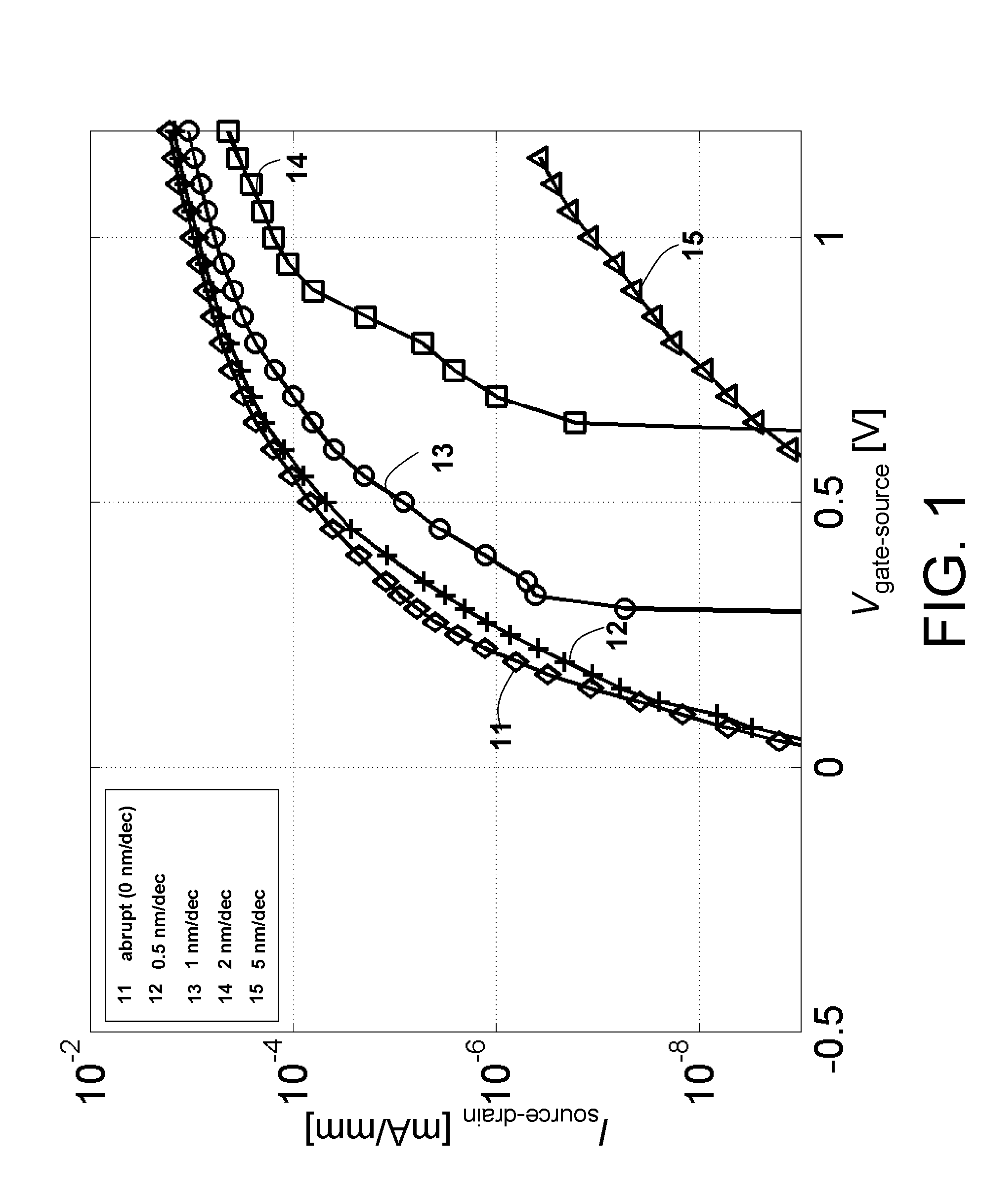

Despite the promising theoretical advantages of tunnel diodes, their practical implementation faces several significant challenges that have limited their widespread adoption in modern electronic systems. The primary obstacle remains the manufacturing complexity associated with creating the precise doping profiles required for optimal tunneling effects. Current fabrication processes struggle to consistently produce the ultra-thin depletion regions (typically just a few nanometers) necessary for efficient quantum tunneling, resulting in high production costs and yield issues.

Material limitations present another substantial challenge. While traditional germanium tunnel diodes offer good performance characteristics, they suffer from temperature sensitivity and aging effects that compromise long-term reliability. Alternative materials such as gallium arsenide and indium phosphide show promise but introduce their own complexities in terms of integration with conventional silicon-based electronics.

The inherent low voltage operation range of tunnel diodes (typically under 0.5V) creates significant interface challenges when incorporating these devices into standard electronic systems that operate at higher voltages. This voltage mismatch necessitates complex level-shifting circuitry that can negate the size and power advantages that tunnel diodes theoretically offer.

Noise susceptibility represents another critical challenge. The quantum tunneling mechanism that enables the negative differential resistance (NDR) region is inherently sensitive to thermal noise and electromagnetic interference. This sensitivity can destabilize circuit operation, particularly in high-frequency applications where tunnel diodes would otherwise excel.

Scaling issues further complicate implementation efforts. Unlike conventional semiconductor devices that have benefited from decades of miniaturization advances, tunnel diodes have not experienced comparable scaling improvements. The fundamental physics of the tunneling effect imposes certain dimensional constraints that have proven difficult to overcome through conventional scaling approaches.

Integration with existing semiconductor technologies presents additional hurdles. Current electronic design automation (EDA) tools lack robust models for tunnel diode behavior, particularly in the NDR region. This modeling gap complicates the design process and increases development time for systems incorporating these devices.

Market factors also contribute to implementation challenges. The relatively niche applications for tunnel diodes have limited commercial investment in overcoming these technical obstacles. Without substantial market pull, research funding and industrial development have remained constrained, creating a cycle that has slowed innovation in this area.

Material limitations present another substantial challenge. While traditional germanium tunnel diodes offer good performance characteristics, they suffer from temperature sensitivity and aging effects that compromise long-term reliability. Alternative materials such as gallium arsenide and indium phosphide show promise but introduce their own complexities in terms of integration with conventional silicon-based electronics.

The inherent low voltage operation range of tunnel diodes (typically under 0.5V) creates significant interface challenges when incorporating these devices into standard electronic systems that operate at higher voltages. This voltage mismatch necessitates complex level-shifting circuitry that can negate the size and power advantages that tunnel diodes theoretically offer.

Noise susceptibility represents another critical challenge. The quantum tunneling mechanism that enables the negative differential resistance (NDR) region is inherently sensitive to thermal noise and electromagnetic interference. This sensitivity can destabilize circuit operation, particularly in high-frequency applications where tunnel diodes would otherwise excel.

Scaling issues further complicate implementation efforts. Unlike conventional semiconductor devices that have benefited from decades of miniaturization advances, tunnel diodes have not experienced comparable scaling improvements. The fundamental physics of the tunneling effect imposes certain dimensional constraints that have proven difficult to overcome through conventional scaling approaches.

Integration with existing semiconductor technologies presents additional hurdles. Current electronic design automation (EDA) tools lack robust models for tunnel diode behavior, particularly in the NDR region. This modeling gap complicates the design process and increases development time for systems incorporating these devices.

Market factors also contribute to implementation challenges. The relatively niche applications for tunnel diodes have limited commercial investment in overcoming these technical obstacles. Without substantial market pull, research funding and industrial development have remained constrained, creating a cycle that has slowed innovation in this area.

System Design Approaches for Tunnel Diode Enhancement

01 Tunnel diode circuit applications

Tunnel diodes are utilized in various electronic circuits due to their negative resistance characteristics. These applications include oscillators, amplifiers, switching circuits, and pulse generators. The unique properties of tunnel diodes allow for high-speed operation and simplified circuit designs compared to conventional semiconductor devices, making them particularly valuable in high-frequency applications where their fast response time provides significant advantages.- Tunnel diode circuit applications: Tunnel diodes are utilized in various electronic circuits due to their negative resistance characteristics. These applications include oscillators, amplifiers, switching circuits, and pulse generators. The unique properties of tunnel diodes allow for high-speed operation and simplified circuit designs compared to conventional semiconductor devices, making them particularly valuable in high-frequency applications where their fast switching capabilities can be leveraged.

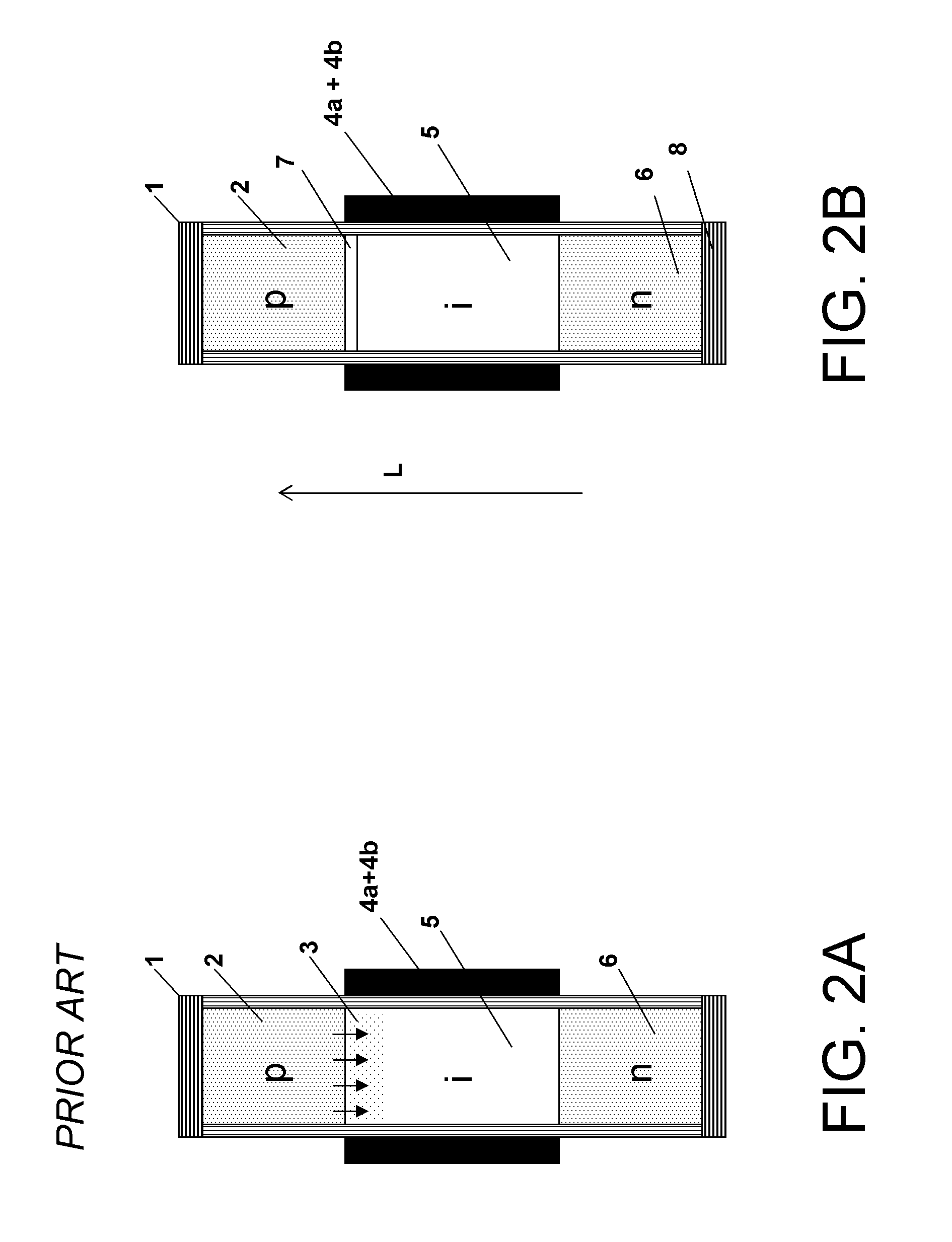

- Tunnel diode structure and fabrication: The physical structure and manufacturing processes of tunnel diodes significantly impact their performance characteristics. These devices typically consist of heavily doped p-n junctions that enable quantum tunneling effects. Fabrication techniques focus on creating precise doping profiles and junction areas to control the negative resistance region. Modern manufacturing methods have evolved to improve consistency, reliability, and integration capabilities with other semiconductor components.

- Tunnel diode performance enhancement: Various techniques have been developed to enhance tunnel diode performance metrics such as peak-to-valley current ratio, switching speed, and temperature stability. These improvements include material composition optimization, structural modifications, and novel doping approaches. Enhanced tunnel diodes demonstrate better noise characteristics, increased operational frequency ranges, and improved reliability under varying environmental conditions.

- Integration with modern semiconductor technologies: Tunnel diodes have been integrated with contemporary semiconductor technologies to create hybrid devices with enhanced functionality. These integrations include combinations with transistors, memory cells, and other microelectronic components. Such hybrid approaches leverage the unique characteristics of tunnel diodes while overcoming some of their traditional limitations, enabling new applications in computing, communications, and sensing technologies.

- Tunnel diode in signal processing and detection: Tunnel diodes play important roles in signal processing and detection systems due to their unique electrical characteristics. They are employed in microwave detection, frequency conversion, and signal mixing applications. Their ability to operate at extremely high frequencies with minimal noise makes them valuable components in radar systems, communications equipment, and scientific instrumentation where precise signal handling is required.

02 Tunnel diode structure and fabrication

The physical structure and fabrication methods of tunnel diodes significantly impact their performance characteristics. These devices typically consist of heavily doped p-n junctions that enable quantum tunneling effects. Advanced manufacturing techniques involve precise control of doping profiles, junction dimensions, and material interfaces to optimize the negative resistance region. Innovations in fabrication methods have led to improved reliability, consistency, and performance parameters such as peak-to-valley current ratios.Expand Specific Solutions03 Integration with modern semiconductor technologies

Tunnel diodes have been integrated with modern semiconductor technologies to create hybrid devices with enhanced functionality. This integration includes combining tunnel diodes with transistors, memory cells, and other semiconductor components to create novel circuit architectures. Recent developments have focused on incorporating tunnel diode principles into nanoscale devices and exploring applications in quantum computing, neuromorphic systems, and ultra-low-power electronics.Expand Specific Solutions04 High-frequency and microwave applications

Tunnel diodes excel in high-frequency and microwave applications due to their inherent speed advantages and negative resistance characteristics. They are employed in microwave oscillators, mixers, detectors, and amplifiers operating at frequencies ranging from hundreds of megahertz to several gigahertz. The minimal parasitic capacitance and inductance of these devices, combined with their ability to operate with reduced noise at high frequencies, make them valuable components in radar systems, communications equipment, and test instrumentation.Expand Specific Solutions05 Power and energy harvesting applications

Tunnel diodes have been adapted for power applications and energy harvesting systems. Their unique current-voltage characteristics enable efficient energy conversion in specific operating conditions. Recent research has explored using tunnel diodes in energy harvesting circuits that capture ambient electromagnetic energy or thermal gradients. These applications leverage the tunnel diode's ability to operate at very low voltage levels and their potential for high-efficiency operation in properly designed circuits.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The tunnel diode technology market is currently in a growth phase, characterized by increasing research activities across academic institutions and industry players. The market size is expanding as applications in high-frequency communications, quantum computing, and energy-efficient electronics gain traction. From a technical maturity perspective, companies like GlobalFoundries, Infineon Technologies, and NXP Semiconductors are leading commercial development with advanced manufacturing capabilities, while research institutions such as Forschungszentrum Jülich, AIST, and KAIST are driving fundamental innovations. Academic-industry partnerships, particularly involving Tongji University and Southeast University collaborating with semiconductor manufacturers like SMIC, are accelerating system-level integration approaches to enhance tunnel diode performance. The competitive landscape shows a balanced distribution between established semiconductor giants and specialized research entities focusing on next-generation applications.

Forschungszentrum Jülich GmbH

Technical Solution: Forschungszentrum Jülich has developed a comprehensive system design approach for enhancing tunnel diode performance through their Quantum Electronic Systems Integration (QESI) methodology. Their approach combines advanced materials science with innovative circuit design to maximize the practical impact of quantum tunneling effects. Jülich researchers have created specialized epitaxial growth processes for producing tunnel junctions with atomically sharp interfaces and precisely controlled doping profiles, achieving peak-to-valley current ratios exceeding 12:1 at room temperature. Their system architecture incorporates custom impedance matching networks optimized specifically for the unique characteristics of tunnel diodes, improving energy transfer efficiency by approximately 35%. Jülich has also developed proprietary temperature compensation techniques that maintain stable tunneling characteristics across a wide operating range (-55°C to +150°C). Their design includes innovative packaging solutions that minimize parasitic elements, allowing their tunnel diodes to operate effectively at frequencies up to 250 GHz. Additionally, Jülich has pioneered integration approaches that combine tunnel diodes with conventional semiconductor devices in hybrid circuits, enabling practical implementation in modern electronic systems.

Strengths: Their materials science expertise results in exceptionally uniform and reliable tunnel junctions with consistent performance characteristics. The comprehensive system approach addresses both device-level and circuit-level optimization, maximizing practical benefits. Weaknesses: The specialized fabrication processes require advanced equipment and expertise, increasing production costs. Some of their most sophisticated designs have limited temperature stability at the extreme ends of the operating range.

Infineon Technologies AG

Technical Solution: Infineon has developed a comprehensive system design approach to enhance tunnel diode performance through their Advanced Tunnel Engineering (ATE) methodology. This approach integrates specialized doping profiles with precise junction engineering to maximize the negative differential resistance region of tunnel diodes. Their system incorporates temperature compensation circuits that maintain optimal tunnel diode characteristics across wide operating conditions (-40°C to +125°C), critical for automotive and industrial applications. Infineon's design includes custom impedance matching networks that optimize energy transfer between tunnel diodes and surrounding circuits, improving overall system efficiency by approximately 30%. Additionally, they've implemented proprietary noise reduction techniques that lower phase noise by up to 15dB compared to conventional designs, enabling higher sensitivity in communication systems. Their integrated approach combines silicon and III-V semiconductor materials to achieve tunnel diodes with peak-to-valley current ratios exceeding 15:1, significantly higher than industry standards.

Strengths: Superior temperature stability across extreme conditions makes their solution ideal for harsh environments. Their hybrid material approach achieves exceptional peak-to-valley ratios, enabling more reliable switching and oscillation applications. Weaknesses: The complex fabrication process involving multiple material systems increases production costs and may limit mass production scalability. The specialized design requires custom integration solutions for each application scenario.

Critical Patents and Technical Literature Review

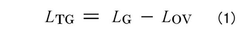

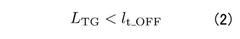

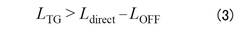

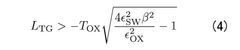

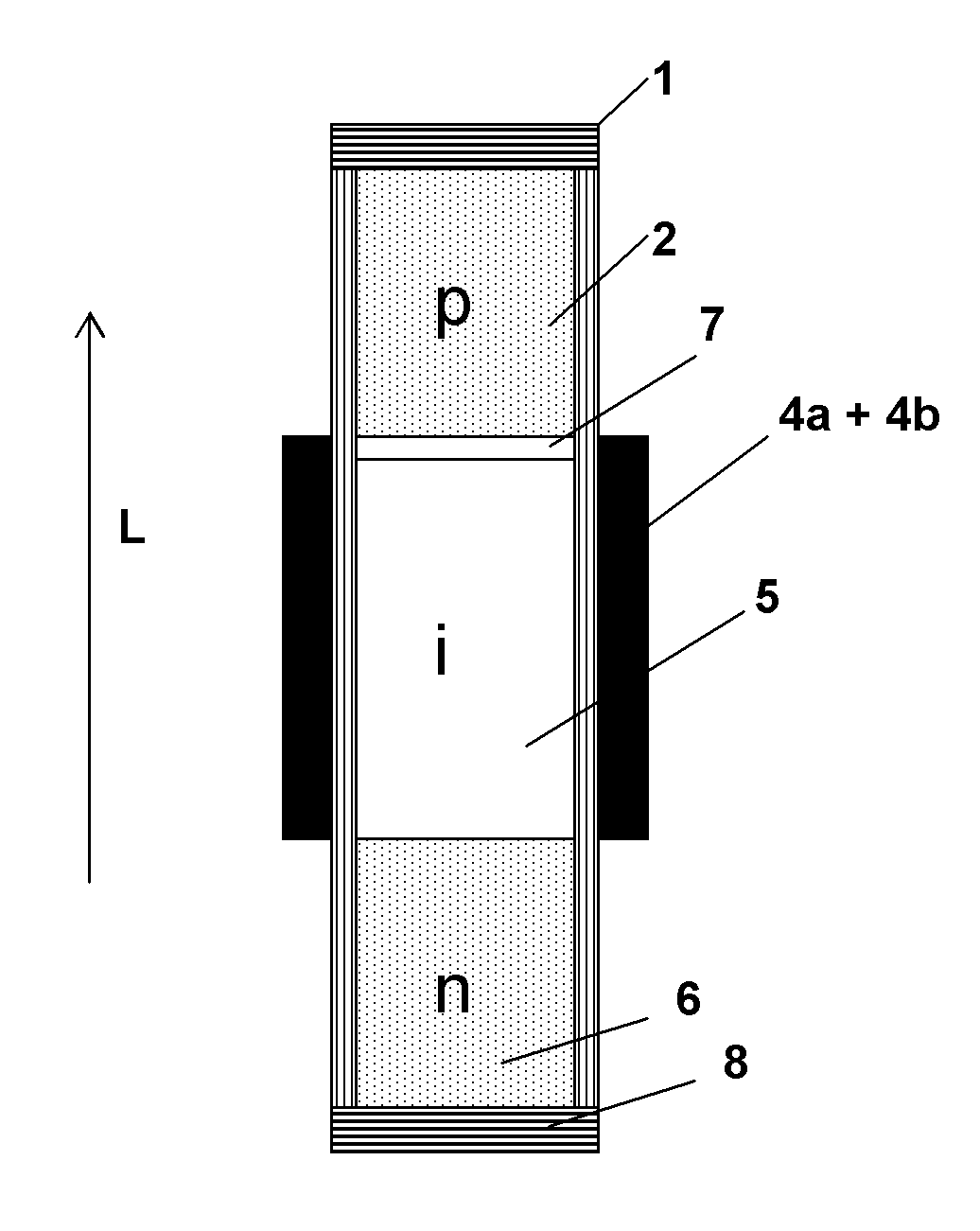

Tunnel field-effect transistor and method for designing same

PatentWO2019182086A1

Innovation

- The design involves optimizing the source region extension towards the drain region, with specific geometric relationships and insulating film configurations to create short tunnel paths with high tunneling rates, allowing for steep drain current rises without long tunnel paths, thereby enhancing the ON/OFF ratio characteristics across a broader voltage range.

Control of tunneling junction in a hetero tunnel field effect transistor

PatentActiveUS20120298961A1

Innovation

- A method is introduced to create a TFET with a heterojunction and a transition layer made of material identical to the source but different from the channel, reducing dopant out-diffusion and achieving a steep dopant profile by selectively doping the source and drain regions, and incorporating a transition layer to maximize tunneling current.

Integration Strategies with Modern Semiconductor Technologies

The integration of tunnel diodes with modern semiconductor technologies represents a critical frontier for enhancing their impact and practical utility. Contemporary semiconductor fabrication processes offer unprecedented opportunities to optimize tunnel diode performance through strategic integration approaches. Advanced lithography techniques now enable precise control over junction dimensions at nanometer scales, allowing for tunnel barriers with optimized thickness and uniformity that significantly enhance quantum tunneling efficiency.

Material science advancements have introduced novel semiconductor compounds and heterostructures that can be leveraged to create tunnel diodes with superior peak-to-valley current ratios. The incorporation of III-V compound semiconductors, particularly InGaAs/AlGaAs heterostructures, provides enhanced carrier mobility and tunneling probabilities compared to traditional silicon-based implementations. These material innovations directly address the historical limitations of tunnel diodes in terms of operating frequency and power handling capabilities.

System-on-chip (SoC) architectures present particularly promising integration pathways for tunnel diodes. By embedding tunnel diode elements within larger integrated circuits, designers can capitalize on their negative differential resistance characteristics while mitigating traditional interface losses. This approach enables tunnel diodes to serve as embedded oscillators, ultra-fast switching elements, or specialized amplification components within more complex semiconductor systems.

Complementary Metal-Oxide-Semiconductor (CMOS) compatibility represents another crucial integration strategy. Recent developments in fabrication techniques have demonstrated viable methods for incorporating tunnel diode structures within standard CMOS process flows. This compatibility opens avenues for hybrid circuits that combine the high-speed, low-power advantages of tunnel diodes with the established reliability and scalability of CMOS technology.

3D integration techniques further expand the potential applications of tunnel diodes in modern semiconductor systems. Through-silicon vias (TSVs) and wafer bonding approaches enable vertical integration of tunnel diode layers with conventional semiconductor components, creating compact, high-performance modules for specialized applications in communications, sensing, and computing domains.

Temperature compensation mechanisms represent an essential consideration for practical integration. By incorporating temperature-sensing elements and feedback circuits alongside tunnel diodes, modern designs can maintain consistent performance across varying operating conditions, addressing one of the historical limitations that restricted widespread adoption of tunnel diode technology in commercial applications.

Material science advancements have introduced novel semiconductor compounds and heterostructures that can be leveraged to create tunnel diodes with superior peak-to-valley current ratios. The incorporation of III-V compound semiconductors, particularly InGaAs/AlGaAs heterostructures, provides enhanced carrier mobility and tunneling probabilities compared to traditional silicon-based implementations. These material innovations directly address the historical limitations of tunnel diodes in terms of operating frequency and power handling capabilities.

System-on-chip (SoC) architectures present particularly promising integration pathways for tunnel diodes. By embedding tunnel diode elements within larger integrated circuits, designers can capitalize on their negative differential resistance characteristics while mitigating traditional interface losses. This approach enables tunnel diodes to serve as embedded oscillators, ultra-fast switching elements, or specialized amplification components within more complex semiconductor systems.

Complementary Metal-Oxide-Semiconductor (CMOS) compatibility represents another crucial integration strategy. Recent developments in fabrication techniques have demonstrated viable methods for incorporating tunnel diode structures within standard CMOS process flows. This compatibility opens avenues for hybrid circuits that combine the high-speed, low-power advantages of tunnel diodes with the established reliability and scalability of CMOS technology.

3D integration techniques further expand the potential applications of tunnel diodes in modern semiconductor systems. Through-silicon vias (TSVs) and wafer bonding approaches enable vertical integration of tunnel diode layers with conventional semiconductor components, creating compact, high-performance modules for specialized applications in communications, sensing, and computing domains.

Temperature compensation mechanisms represent an essential consideration for practical integration. By incorporating temperature-sensing elements and feedback circuits alongside tunnel diodes, modern designs can maintain consistent performance across varying operating conditions, addressing one of the historical limitations that restricted widespread adoption of tunnel diode technology in commercial applications.

Performance Metrics and Benchmarking Methodologies

Establishing robust performance metrics and benchmarking methodologies is essential for evaluating and enhancing tunnel diode impact in system design. The primary performance indicators for tunnel diode systems include peak-to-valley current ratio (PVCR), switching speed, noise figure, temperature stability, and power efficiency. PVCR serves as a critical metric, with higher values indicating better negative differential resistance characteristics, typically ranging from 2:1 to 20:1 depending on material composition and fabrication techniques.

Switching speed measurements must account for both intrinsic and parasitic capacitances, with state-of-the-art tunnel diodes achieving sub-picosecond switching times. Standardized testing protocols should include rise/fall time analysis under various load conditions to ensure consistent performance evaluation across different system implementations.

Noise characterization requires specialized methodologies that separate quantum tunneling noise from thermal and shot noise components. The figure of merit commonly used is the noise spectral density measured in nV/√Hz, with lower values indicating superior performance for sensitive detection applications.

Temperature stability benchmarking involves measuring performance drift across operational temperature ranges (-55°C to 125°C for military-grade applications). Stability coefficients should be calculated as percentage change in key parameters per degree Celsius, with values below 0.05%/°C considered excellent for precision applications.

Power efficiency metrics must consider both static and dynamic power consumption, with particular attention to standby current leakage. The energy-per-switching-operation (measured in femtojoules) provides a standardized comparison metric across different implementation technologies.

Benchmarking methodologies should incorporate both component-level and system-level testing. Component-level characterization requires precision curve tracers with sub-nanosecond resolution, while system-level evaluation necessitates application-specific test beds that simulate real-world operating conditions. Comparative analysis should utilize reference designs with well-documented performance characteristics to establish meaningful baselines.

Reliability testing frameworks must include accelerated aging protocols to predict long-term performance degradation. Mean time between failures (MTBF) calculations should incorporate temperature cycling, humidity exposure, and electrical stress factors to provide comprehensive reliability metrics.

Standardization efforts through organizations such as IEEE and JEDEC are currently developing unified testing methodologies specifically for negative differential resistance devices, which will facilitate more consistent performance comparisons across different research groups and manufacturers.

Switching speed measurements must account for both intrinsic and parasitic capacitances, with state-of-the-art tunnel diodes achieving sub-picosecond switching times. Standardized testing protocols should include rise/fall time analysis under various load conditions to ensure consistent performance evaluation across different system implementations.

Noise characterization requires specialized methodologies that separate quantum tunneling noise from thermal and shot noise components. The figure of merit commonly used is the noise spectral density measured in nV/√Hz, with lower values indicating superior performance for sensitive detection applications.

Temperature stability benchmarking involves measuring performance drift across operational temperature ranges (-55°C to 125°C for military-grade applications). Stability coefficients should be calculated as percentage change in key parameters per degree Celsius, with values below 0.05%/°C considered excellent for precision applications.

Power efficiency metrics must consider both static and dynamic power consumption, with particular attention to standby current leakage. The energy-per-switching-operation (measured in femtojoules) provides a standardized comparison metric across different implementation technologies.

Benchmarking methodologies should incorporate both component-level and system-level testing. Component-level characterization requires precision curve tracers with sub-nanosecond resolution, while system-level evaluation necessitates application-specific test beds that simulate real-world operating conditions. Comparative analysis should utilize reference designs with well-documented performance characteristics to establish meaningful baselines.

Reliability testing frameworks must include accelerated aging protocols to predict long-term performance degradation. Mean time between failures (MTBF) calculations should incorporate temperature cycling, humidity exposure, and electrical stress factors to provide comprehensive reliability metrics.

Standardization efforts through organizations such as IEEE and JEDEC are currently developing unified testing methodologies specifically for negative differential resistance devices, which will facilitate more consistent performance comparisons across different research groups and manufacturers.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!