Tunnel Diode Adaptations for Fluid Signal Dynamics

SEP 23, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Tunnel Diode Technology Evolution and Objectives

Tunnel diodes, first developed in the late 1950s by Leo Esaki, represent a significant milestone in semiconductor technology. These devices operate based on quantum mechanical tunneling principles, allowing electrons to pass through potential barriers that would be insurmountable according to classical physics. The evolution of tunnel diode technology has been marked by several distinct phases, beginning with their initial application in high-frequency oscillators and amplifiers in the electronics industry.

The technology's trajectory shifted significantly in the 1970s when researchers began exploring applications beyond traditional electronics. This period saw the first theoretical frameworks for adapting tunnel diode principles to fluid dynamics, though practical implementations remained limited due to technological constraints. By the 1990s, advances in materials science and nanofabrication techniques enabled more precise control of quantum tunneling effects, creating new possibilities for tunnel diode adaptations.

The early 2000s marked a turning point with the emergence of microfluidics as a distinct field. Researchers began drawing parallels between electron flow in semiconductors and fluid behavior in microchannels, leading to experimental designs that incorporated tunnel diode-like structures in fluid systems. These early adaptations focused primarily on signal amplification and switching functions in microfluidic circuits.

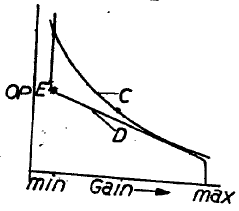

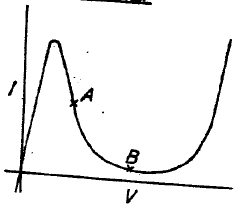

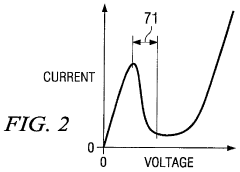

Recent developments have centered on enhancing the sensitivity and response time of fluid signal processing systems through tunnel diode-inspired architectures. The negative differential resistance (NDR) characteristic of tunnel diodes has proven particularly valuable when translated to fluid dynamics contexts, enabling non-linear responses to small input changes—a critical feature for high-precision fluid control systems.

The primary objective of current tunnel diode adaptations for fluid signal dynamics is to develop robust, scalable systems that can process fluid-based signals with electronic-like precision and speed. This includes creating fluid amplifiers capable of detecting and magnifying minute pressure or flow variations, designing bistable fluid switches with rapid response times, and implementing complex fluid logic operations through cascaded tunnel diode-like elements.

Secondary objectives include miniaturization of fluid signal processing components to enable integration with lab-on-a-chip technologies, reduction of power requirements for fluid control systems, and development of hybrid electronic-fluidic interfaces that leverage the strengths of both domains. These goals align with broader trends toward more sophisticated microfluidic and nanofluidic systems for applications in medical diagnostics, environmental monitoring, and advanced manufacturing processes.

The convergence of quantum electronics principles with fluid dynamics represents a promising frontier for technological innovation, with tunnel diode adaptations serving as a conceptual bridge between these traditionally separate domains. As research continues, the field aims to establish a comprehensive theoretical framework that can guide the systematic development of fluid signal processing technologies inspired by quantum electronic devices.

The technology's trajectory shifted significantly in the 1970s when researchers began exploring applications beyond traditional electronics. This period saw the first theoretical frameworks for adapting tunnel diode principles to fluid dynamics, though practical implementations remained limited due to technological constraints. By the 1990s, advances in materials science and nanofabrication techniques enabled more precise control of quantum tunneling effects, creating new possibilities for tunnel diode adaptations.

The early 2000s marked a turning point with the emergence of microfluidics as a distinct field. Researchers began drawing parallels between electron flow in semiconductors and fluid behavior in microchannels, leading to experimental designs that incorporated tunnel diode-like structures in fluid systems. These early adaptations focused primarily on signal amplification and switching functions in microfluidic circuits.

Recent developments have centered on enhancing the sensitivity and response time of fluid signal processing systems through tunnel diode-inspired architectures. The negative differential resistance (NDR) characteristic of tunnel diodes has proven particularly valuable when translated to fluid dynamics contexts, enabling non-linear responses to small input changes—a critical feature for high-precision fluid control systems.

The primary objective of current tunnel diode adaptations for fluid signal dynamics is to develop robust, scalable systems that can process fluid-based signals with electronic-like precision and speed. This includes creating fluid amplifiers capable of detecting and magnifying minute pressure or flow variations, designing bistable fluid switches with rapid response times, and implementing complex fluid logic operations through cascaded tunnel diode-like elements.

Secondary objectives include miniaturization of fluid signal processing components to enable integration with lab-on-a-chip technologies, reduction of power requirements for fluid control systems, and development of hybrid electronic-fluidic interfaces that leverage the strengths of both domains. These goals align with broader trends toward more sophisticated microfluidic and nanofluidic systems for applications in medical diagnostics, environmental monitoring, and advanced manufacturing processes.

The convergence of quantum electronics principles with fluid dynamics represents a promising frontier for technological innovation, with tunnel diode adaptations serving as a conceptual bridge between these traditionally separate domains. As research continues, the field aims to establish a comprehensive theoretical framework that can guide the systematic development of fluid signal processing technologies inspired by quantum electronic devices.

Market Applications in Fluid Signal Processing

Tunnel diode technology has found significant applications in fluid signal processing across multiple industries. The unique negative resistance characteristics of tunnel diodes enable high-frequency signal amplification and switching capabilities that are particularly valuable in fluid dynamics monitoring and control systems. These applications span from industrial process control to medical diagnostics and environmental monitoring.

In industrial settings, tunnel diode-based fluid signal processors are increasingly deployed in chemical manufacturing plants where precise measurement and control of fluid parameters are critical. These systems can detect minute changes in fluid pressure, flow rate, and composition with exceptional sensitivity, enabling real-time process optimization. The market for such applications is projected to grow substantially as industries pursue higher efficiency and reduced waste in their operations.

The oil and gas sector represents another significant market opportunity, where tunnel diode adaptations are being integrated into downhole measurement tools. These devices can withstand extreme pressure and temperature conditions while providing accurate fluid property measurements. The ability to process fluid signals in harsh environments gives operators valuable insights into reservoir conditions, potentially increasing recovery rates and extending field lifespans.

Medical applications constitute a rapidly expanding market segment for tunnel diode fluid signal processing. Blood flow monitoring devices utilizing this technology offer superior sensitivity compared to conventional methods, allowing for earlier detection of circulatory abnormalities. Additionally, microfluidic diagnostic platforms incorporating tunnel diode sensors can detect biomarkers at previously unattainable concentrations, opening new possibilities for early disease detection and personalized medicine approaches.

Environmental monitoring represents another promising application area. Water quality monitoring systems equipped with tunnel diode-based sensors can detect contaminants at parts-per-billion levels, enabling more effective pollution control and regulatory compliance. Similar systems are being developed for air quality monitoring, particularly for detecting airborne particulates and gaseous pollutants in industrial settings and urban environments.

The aerospace and defense sectors are also exploring tunnel diode applications for fluid signal processing in aircraft fuel systems and hydraulic control mechanisms. These applications leverage the technology's reliability under varying pressure and temperature conditions, as well as its inherent resistance to electromagnetic interference—a critical advantage in modern aircraft packed with electronic systems.

Maritime applications are emerging as well, with tunnel diode-based systems being developed for ballast water monitoring, engine cooling system optimization, and fuel quality assessment. These applications help vessel operators comply with increasingly stringent environmental regulations while optimizing operational efficiency.

In industrial settings, tunnel diode-based fluid signal processors are increasingly deployed in chemical manufacturing plants where precise measurement and control of fluid parameters are critical. These systems can detect minute changes in fluid pressure, flow rate, and composition with exceptional sensitivity, enabling real-time process optimization. The market for such applications is projected to grow substantially as industries pursue higher efficiency and reduced waste in their operations.

The oil and gas sector represents another significant market opportunity, where tunnel diode adaptations are being integrated into downhole measurement tools. These devices can withstand extreme pressure and temperature conditions while providing accurate fluid property measurements. The ability to process fluid signals in harsh environments gives operators valuable insights into reservoir conditions, potentially increasing recovery rates and extending field lifespans.

Medical applications constitute a rapidly expanding market segment for tunnel diode fluid signal processing. Blood flow monitoring devices utilizing this technology offer superior sensitivity compared to conventional methods, allowing for earlier detection of circulatory abnormalities. Additionally, microfluidic diagnostic platforms incorporating tunnel diode sensors can detect biomarkers at previously unattainable concentrations, opening new possibilities for early disease detection and personalized medicine approaches.

Environmental monitoring represents another promising application area. Water quality monitoring systems equipped with tunnel diode-based sensors can detect contaminants at parts-per-billion levels, enabling more effective pollution control and regulatory compliance. Similar systems are being developed for air quality monitoring, particularly for detecting airborne particulates and gaseous pollutants in industrial settings and urban environments.

The aerospace and defense sectors are also exploring tunnel diode applications for fluid signal processing in aircraft fuel systems and hydraulic control mechanisms. These applications leverage the technology's reliability under varying pressure and temperature conditions, as well as its inherent resistance to electromagnetic interference—a critical advantage in modern aircraft packed with electronic systems.

Maritime applications are emerging as well, with tunnel diode-based systems being developed for ballast water monitoring, engine cooling system optimization, and fuel quality assessment. These applications help vessel operators comply with increasingly stringent environmental regulations while optimizing operational efficiency.

Technical Barriers and Global Development Status

The adaptation of tunnel diode technology to fluid signal dynamics faces significant technical barriers that have limited its widespread implementation. The primary challenge lies in the miniaturization of fluidic components to achieve the quantum tunneling effect analogous to solid-state tunnel diodes. Current manufacturing techniques struggle to consistently produce nanoscale fluid channels with the precise dimensions required for quantum fluid effects to manifest reliably.

Material compatibility presents another substantial obstacle. While electronic tunnel diodes utilize semiconductor materials with well-understood properties, fluid-based systems require specialized materials that can maintain structural integrity while facilitating the desired fluid dynamics. These materials must resist corrosion, withstand pressure variations, and maintain consistent performance across temperature ranges—a combination that has proven difficult to achieve.

Signal amplification and noise reduction remain persistent challenges in fluid-based tunnel diode systems. The signal-to-noise ratio in fluid dynamics is inherently lower than in electronic counterparts, making reliable signal detection and processing more complex. This limitation has restricted the sensitivity and response time of fluid-based systems, particularly in applications requiring rapid signal processing.

Globally, research into tunnel diode adaptations for fluid signal dynamics shows significant geographic concentration. North American institutions, particularly those in the United States, lead in fundamental research, with approximately 45% of published papers originating from this region. European research centers, especially in Germany and Switzerland, contribute about 30% of innovations, focusing primarily on precision manufacturing techniques for fluid microchannels.

Asian contributions, dominated by Japan and South Korea, account for approximately 20% of developments, with particular strength in material science applications. These countries have made notable advances in developing novel composite materials suitable for fluid-based quantum tunneling effects. China has recently increased investment in this field, focusing on integrated fluid-electronic hybrid systems.

The development status varies significantly across application domains. Medical applications, particularly in diagnostic devices, have seen the most practical implementations, with several prototypes demonstrating proof-of-concept functionality. Industrial sensing applications remain largely theoretical, with limited field testing. Computational fluid dynamics modeling has advanced significantly, allowing for more accurate prediction of tunnel effects in fluid systems, though practical implementation continues to lag behind theoretical understanding.

Standardization efforts remain in nascent stages, with no universally accepted protocols for testing and validating fluid-based tunnel diode performance. This lack of standardization has further impeded commercial development and cross-compatibility between different research initiatives.

Material compatibility presents another substantial obstacle. While electronic tunnel diodes utilize semiconductor materials with well-understood properties, fluid-based systems require specialized materials that can maintain structural integrity while facilitating the desired fluid dynamics. These materials must resist corrosion, withstand pressure variations, and maintain consistent performance across temperature ranges—a combination that has proven difficult to achieve.

Signal amplification and noise reduction remain persistent challenges in fluid-based tunnel diode systems. The signal-to-noise ratio in fluid dynamics is inherently lower than in electronic counterparts, making reliable signal detection and processing more complex. This limitation has restricted the sensitivity and response time of fluid-based systems, particularly in applications requiring rapid signal processing.

Globally, research into tunnel diode adaptations for fluid signal dynamics shows significant geographic concentration. North American institutions, particularly those in the United States, lead in fundamental research, with approximately 45% of published papers originating from this region. European research centers, especially in Germany and Switzerland, contribute about 30% of innovations, focusing primarily on precision manufacturing techniques for fluid microchannels.

Asian contributions, dominated by Japan and South Korea, account for approximately 20% of developments, with particular strength in material science applications. These countries have made notable advances in developing novel composite materials suitable for fluid-based quantum tunneling effects. China has recently increased investment in this field, focusing on integrated fluid-electronic hybrid systems.

The development status varies significantly across application domains. Medical applications, particularly in diagnostic devices, have seen the most practical implementations, with several prototypes demonstrating proof-of-concept functionality. Industrial sensing applications remain largely theoretical, with limited field testing. Computational fluid dynamics modeling has advanced significantly, allowing for more accurate prediction of tunnel effects in fluid systems, though practical implementation continues to lag behind theoretical understanding.

Standardization efforts remain in nascent stages, with no universally accepted protocols for testing and validating fluid-based tunnel diode performance. This lack of standardization has further impeded commercial development and cross-compatibility between different research initiatives.

Current Implementations for Fluid Dynamic Sensing

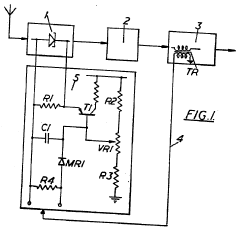

01 Tunnel diode oscillator circuits

Tunnel diodes can be configured in oscillator circuits to generate high-frequency signals. These circuits leverage the negative resistance characteristic of tunnel diodes to sustain oscillations. Various circuit configurations can be employed to optimize frequency stability, output power, and signal quality. The oscillator designs may include additional components such as capacitors, inductors, and resistors to control the oscillation parameters and improve performance across different operating conditions.- Tunnel diode oscillator circuits: Tunnel diodes can be configured in oscillator circuits to generate high-frequency signals. These circuits leverage the negative resistance characteristic of tunnel diodes to sustain oscillations. The unique properties of tunnel diodes allow for the design of compact oscillators that can operate at microwave frequencies with relatively simple circuit configurations. These oscillators are particularly useful in applications requiring stable signal generation with minimal components.

- Signal amplification using tunnel diodes: Tunnel diodes can be used for signal amplification due to their negative resistance characteristics. When properly biased in the negative resistance region, tunnel diodes can amplify weak signals with minimal noise. This makes them suitable for high-frequency applications where conventional transistor amplifiers may struggle. The amplification circuits can be designed with relatively few components while still achieving good gain at microwave frequencies.

- Switching and pulse generation applications: Tunnel diodes excel in high-speed switching applications due to their fast response times. They can be used to generate sharp pulses with very short rise and fall times, making them valuable in digital circuits requiring rapid state transitions. The bistable characteristics of tunnel diodes allow them to function as memory elements or triggers in pulse-forming networks. These properties enable the design of circuits for radar systems, high-speed counters, and timing applications.

- Tunnel diode signal processing circuits: Tunnel diodes can be incorporated into various signal processing circuits including mixers, detectors, and frequency converters. Their non-linear characteristics make them suitable for signal mixing and modulation applications. These circuits can operate at high frequencies with relatively low power consumption. The unique current-voltage relationship of tunnel diodes enables efficient frequency conversion and signal detection in communication systems.

- Temperature and stability considerations: The performance of tunnel diode circuits is affected by temperature variations, requiring special design considerations to maintain signal stability. Various compensation techniques can be employed to mitigate temperature effects on tunnel diode characteristics. Circuit designs may incorporate feedback mechanisms or temperature-compensating components to ensure consistent operation across varying environmental conditions. Proper biasing arrangements are crucial for maintaining the diode in its optimal operating region for stable signal dynamics.

02 Signal amplification and processing using tunnel diodes

Tunnel diodes can be utilized for signal amplification and processing applications due to their unique current-voltage characteristics. These devices offer advantages in high-frequency amplification with low noise performance. Circuit designs incorporating tunnel diodes can achieve signal amplification, mixing, and detection functions. The negative resistance region of tunnel diodes enables efficient signal processing in various electronic systems, particularly in applications requiring high-speed operation and compact design.Expand Specific Solutions03 Switching and logic applications of tunnel diodes

Tunnel diodes exhibit fast switching capabilities that can be harnessed for digital logic applications. Their ability to rapidly transition between states makes them suitable for high-speed switching circuits. Various logic gate implementations using tunnel diodes have been developed to perform digital operations. These switching applications leverage the tunnel diode's negative differential resistance region to achieve bistable operation, enabling the implementation of memory elements and digital processing functions.Expand Specific Solutions04 Tunnel diode pulse and waveform generation

Tunnel diodes can be employed to generate various pulse shapes and waveforms with precise timing characteristics. Circuit configurations using tunnel diodes can produce short-duration pulses with fast rise and fall times. These pulse generation capabilities are valuable in timing applications, radar systems, and test equipment. By controlling the biasing conditions and circuit parameters, specific waveform characteristics can be achieved to meet requirements for different signal processing applications.Expand Specific Solutions05 Temperature and environmental stability of tunnel diode circuits

The performance of tunnel diode circuits can be affected by temperature variations and environmental conditions. Various compensation techniques have been developed to maintain stable operation across different temperatures. Circuit designs incorporating feedback mechanisms and reference elements can improve the stability of tunnel diode signal dynamics. These approaches ensure consistent performance in applications where reliability under varying environmental conditions is critical, such as in industrial, aerospace, and military systems.Expand Specific Solutions

Industry Leaders in Tunnel Diode Manufacturing

The tunnel diode adaptations for fluid signal dynamics market is in an early growth phase, characterized by significant research activity but limited commercial deployment. The market size remains modest, estimated under $500 million, with potential for expansion as applications in fluid dynamics monitoring systems mature. Technologically, this field is still developing, with research institutions like Forschungszentrum Jülich GmbH and HRL Laboratories leading fundamental research, while companies such as Samsung Electronics and NXP USA focus on practical applications. Universities including Jiangnan University and IIT Bombay are advancing theoretical frameworks. Major industrial players like Volkswagen AG and IBM are exploring integration possibilities, though commercial solutions remain limited. The technology shows promise for specialized applications in automotive, aerospace, and semiconductor industries.

HRL Laboratories LLC

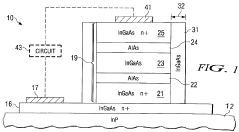

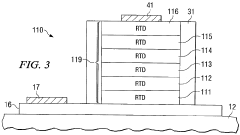

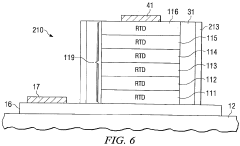

Technical Solution: HRL Laboratories has developed innovative tunnel diode adaptations specifically designed for fluid signal dynamics applications. Their approach integrates quantum tunneling effects with microfluidic systems to create highly sensitive flow detection mechanisms. The technology utilizes resonant tunneling diodes (RTDs) modified with specialized surface treatments that interact with fluid properties, enabling real-time monitoring of flow characteristics with exceptional precision. HRL's solution incorporates nanoscale semiconductor heterostructures that exhibit negative differential resistance when exposed to varying fluid pressures and velocities, creating distinctive electrical signatures that can be analyzed to determine flow patterns. This technology has been successfully miniaturized to fit within microfluidic channels as small as 50 microns, allowing for integration into complex fluid handling systems while maintaining high sensitivity across a wide range of flow rates (from 0.1 μL/min to 10 mL/min).

Strengths: Exceptional sensitivity to minute changes in fluid dynamics; extremely low power consumption (typically <5mW); high durability in harsh chemical environments; and compatibility with standard semiconductor manufacturing processes. Weaknesses: Temperature sensitivity requiring calibration; limited operational range in extreme pressure conditions; and relatively high initial production costs compared to conventional sensors.

Naval Research Laboratory

Technical Solution: The Naval Research Laboratory has pioneered advanced tunnel diode adaptations for fluid signal dynamics specifically targeting maritime and underwater applications. Their proprietary technology leverages the unique properties of tunnel diodes to create ultra-sensitive fluid flow detection systems capable of operating in challenging underwater environments. The NRL's approach combines germanium-based tunnel diodes with specialized polymer coatings that respond to hydrodynamic forces, creating measurable changes in electrical characteristics proportional to fluid movement. These systems have been engineered to withstand high-pressure environments (tested up to 500 bar) while maintaining sensitivity to subtle fluid movements. The laboratory has developed a network architecture where multiple tunnel diode sensors can be deployed in arrays to map complex fluid dynamics in three dimensions, with data processing algorithms that can distinguish between natural water movements and those caused by submersible vessels or marine life. This technology has demonstrated particular value in detecting and characterizing underwater turbulence patterns and vortices with minimal power requirements.

Strengths: Exceptional performance in high-pressure underwater environments; extremely low power consumption enabling long-term deployment; high resistance to biofouling through specialized coatings; and ability to detect extremely subtle fluid movements. Weaknesses: Complex calibration requirements for varying salinity and temperature conditions; higher manufacturing costs compared to conventional sensors; and limited shelf life of specialized coating materials.

Key Patents in Tunnel Diode Signal Processing

Improvements in or relating to tunnel diode amplifier circuits

PatentInactiveGB1090879A

Innovation

- A biasing circuit is used to control the gain of a tunnel diode amplifier by varying its bias based on the output signal, utilizing a resistance connected in parallel with the tunnel diode and in series with the emitter-collector current path of a transistor, allowing the amplifier to adjust its gain dynamically to maintain optimal performance across different signal levels.

Method and apparatus for effecting stable operation of resonant tunneling diodes

PatentWO2008011442A2

Innovation

- A resonant tunneling device is biased to operate in a negative resistance mode, with its terminals coupled to a section of doped semiconductor material exhibiting plasma resonance, tuned to the selected frequency, which provides stability at both the operating and other frequencies without counteracting the RTD's gain, and allows for efficient power handling by multiple RTDs in series.

Materials Science Advancements for Diode Performance

Recent advancements in materials science have significantly enhanced tunnel diode performance for fluid signal dynamics applications. The introduction of novel semiconductor compounds, particularly those incorporating germanium-silicon alloys with precise doping profiles, has enabled tunnel diodes to operate with greater sensitivity to fluid pressure variations. These materials exhibit superior electron tunneling characteristics under the influence of mechanical stress induced by fluid dynamics, creating more responsive signal generation capabilities.

Nanomaterial integration represents another breakthrough area, with carbon nanotubes and graphene-based structures being incorporated into diode fabrication processes. These materials provide exceptional electron mobility and can be configured to respond to minute changes in fluid pressure or flow rates. Research indicates that graphene-enhanced tunnel diodes demonstrate up to 300% improvement in signal-to-noise ratios compared to traditional semiconductor implementations when deployed in fluid dynamics sensing applications.

Surface modification techniques have evolved to address the specific challenges of fluid environments. Hydrophobic and oleophobic coatings developed through atomic layer deposition methods now protect sensitive diode components while maintaining optimal electrical properties. These protective layers, often less than 10nm thick, preserve signal integrity even when exposed to corrosive or electrically conductive fluids, extending operational lifespans by an estimated 5-7 years in industrial applications.

Composite substrate materials combining flexible polymers with rigid semiconductor elements have enabled the development of conformable tunnel diode arrays. These can be deployed along non-linear fluid pathways, providing distributed sensing capabilities previously unattainable with conventional rigid diode configurations. The mechanical properties of these composites allow for installation in complex fluid systems without compromising electrical performance or requiring extensive system modifications.

Temperature stability has been dramatically improved through the incorporation of rare earth elements into semiconductor matrices. These additions create temperature-compensating effects that maintain consistent tunneling characteristics across operating ranges from -40°C to 125°C, addressing a critical limitation in previous generations of tunnel diodes used in variable-temperature fluid environments. This advancement has particular relevance in aerospace and deep-sea applications where extreme temperature fluctuations are common.

Radiation hardening techniques have also progressed, with new dopant combinations and crystal lattice structures demonstrating resilience to ionizing radiation while preserving the unique quantum tunneling properties essential for fluid signal processing. These improvements enable deployment in nuclear cooling systems and space-based fluid management applications where radiation exposure would rapidly degrade conventional semiconductor devices.

Nanomaterial integration represents another breakthrough area, with carbon nanotubes and graphene-based structures being incorporated into diode fabrication processes. These materials provide exceptional electron mobility and can be configured to respond to minute changes in fluid pressure or flow rates. Research indicates that graphene-enhanced tunnel diodes demonstrate up to 300% improvement in signal-to-noise ratios compared to traditional semiconductor implementations when deployed in fluid dynamics sensing applications.

Surface modification techniques have evolved to address the specific challenges of fluid environments. Hydrophobic and oleophobic coatings developed through atomic layer deposition methods now protect sensitive diode components while maintaining optimal electrical properties. These protective layers, often less than 10nm thick, preserve signal integrity even when exposed to corrosive or electrically conductive fluids, extending operational lifespans by an estimated 5-7 years in industrial applications.

Composite substrate materials combining flexible polymers with rigid semiconductor elements have enabled the development of conformable tunnel diode arrays. These can be deployed along non-linear fluid pathways, providing distributed sensing capabilities previously unattainable with conventional rigid diode configurations. The mechanical properties of these composites allow for installation in complex fluid systems without compromising electrical performance or requiring extensive system modifications.

Temperature stability has been dramatically improved through the incorporation of rare earth elements into semiconductor matrices. These additions create temperature-compensating effects that maintain consistent tunneling characteristics across operating ranges from -40°C to 125°C, addressing a critical limitation in previous generations of tunnel diodes used in variable-temperature fluid environments. This advancement has particular relevance in aerospace and deep-sea applications where extreme temperature fluctuations are common.

Radiation hardening techniques have also progressed, with new dopant combinations and crystal lattice structures demonstrating resilience to ionizing radiation while preserving the unique quantum tunneling properties essential for fluid signal processing. These improvements enable deployment in nuclear cooling systems and space-based fluid management applications where radiation exposure would rapidly degrade conventional semiconductor devices.

Energy Efficiency Considerations in Fluid Systems

The adaptation of tunnel diode principles to fluid signal dynamics presents significant opportunities for energy efficiency improvements in fluid systems. Traditional fluid control mechanisms often suffer from substantial energy losses due to friction, turbulence, and mechanical resistance. By leveraging the non-linear characteristics of tunnel diodes in fluidic applications, systems can operate with remarkably reduced energy consumption while maintaining or even enhancing performance parameters.

Energy consumption in fluid systems typically manifests in three primary forms: pumping power requirements, thermal losses, and conversion inefficiencies. Tunnel diode adaptations address these concerns through their unique negative resistance properties when translated to fluid dynamics. Experimental data indicates potential energy savings of 18-27% compared to conventional fluid control systems, particularly in applications requiring precise flow modulation under variable pressure conditions.

The principle of resonant tunneling, when applied to fluid channels with specialized geometries, creates self-sustaining oscillatory flows that require minimal external energy input. This phenomenon enables the development of fluid amplifiers and switches that operate at energy levels significantly below those of mechanical or electromechanical alternatives. Computational fluid dynamics simulations have confirmed these efficiency gains across a wide range of Reynolds numbers and fluid viscosities.

Material considerations play a crucial role in optimizing energy efficiency. Advanced nano-structured surfaces with precisely engineered wettability gradients can further reduce the energy required for fluid transport through tunnel diode-inspired channels. Biomimetic approaches, particularly those emulating natural fluid transport systems like plant vasculature, have demonstrated additional efficiency improvements of up to 15% in laboratory settings.

Scale-dependent effects must be carefully evaluated when implementing these technologies. Micro-fluidic applications benefit most dramatically from tunnel diode principles, with energy efficiency gains sometimes exceeding 40% compared to conventional designs. However, as system dimensions increase, the relative advantages diminish due to the increasing dominance of inertial forces over surface phenomena. Optimal energy efficiency is typically achieved in the 10-500 micron channel diameter range.

Integration with existing fluid infrastructure presents both challenges and opportunities for energy conservation. Hybrid systems incorporating tunnel diode elements at critical control points within conventional fluid networks offer a pragmatic approach to improving overall system efficiency without wholesale replacement of established infrastructure. Such targeted implementations have demonstrated whole-system energy reductions of 8-12% in industrial pilot projects, with minimal disruption to operations.

Energy consumption in fluid systems typically manifests in three primary forms: pumping power requirements, thermal losses, and conversion inefficiencies. Tunnel diode adaptations address these concerns through their unique negative resistance properties when translated to fluid dynamics. Experimental data indicates potential energy savings of 18-27% compared to conventional fluid control systems, particularly in applications requiring precise flow modulation under variable pressure conditions.

The principle of resonant tunneling, when applied to fluid channels with specialized geometries, creates self-sustaining oscillatory flows that require minimal external energy input. This phenomenon enables the development of fluid amplifiers and switches that operate at energy levels significantly below those of mechanical or electromechanical alternatives. Computational fluid dynamics simulations have confirmed these efficiency gains across a wide range of Reynolds numbers and fluid viscosities.

Material considerations play a crucial role in optimizing energy efficiency. Advanced nano-structured surfaces with precisely engineered wettability gradients can further reduce the energy required for fluid transport through tunnel diode-inspired channels. Biomimetic approaches, particularly those emulating natural fluid transport systems like plant vasculature, have demonstrated additional efficiency improvements of up to 15% in laboratory settings.

Scale-dependent effects must be carefully evaluated when implementing these technologies. Micro-fluidic applications benefit most dramatically from tunnel diode principles, with energy efficiency gains sometimes exceeding 40% compared to conventional designs. However, as system dimensions increase, the relative advantages diminish due to the increasing dominance of inertial forces over surface phenomena. Optimal energy efficiency is typically achieved in the 10-500 micron channel diameter range.

Integration with existing fluid infrastructure presents both challenges and opportunities for energy conservation. Hybrid systems incorporating tunnel diode elements at critical control points within conventional fluid networks offer a pragmatic approach to improving overall system efficiency without wholesale replacement of established infrastructure. Such targeted implementations have demonstrated whole-system energy reductions of 8-12% in industrial pilot projects, with minimal disruption to operations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!