How to Test Wankel Engine Durability Metrics?

AUG 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Wankel Engine Durability Testing Background and Objectives

The Wankel rotary engine, first developed by German engineer Felix Wankel in the 1950s, represents a significant departure from conventional reciprocating piston engines. Its unique design featuring a triangular rotor moving within an epitrochoid housing has historically offered advantages in power-to-weight ratio, mechanical simplicity, and smoothness of operation. Despite these benefits, the technology has faced persistent challenges related to durability, fuel efficiency, and emissions compliance that have limited its widespread adoption in automotive applications.

The evolution of Wankel engine technology has been marked by significant advancements, particularly through Mazda's extensive development efforts from the 1960s through the early 2010s. The company's RX series of sports cars demonstrated the potential of rotary engines in performance applications, while simultaneously highlighting the ongoing durability concerns that have plagued the technology. These concerns primarily center around apex seal wear, housing distortion under thermal stress, and oil consumption issues.

Current technical objectives in Wankel engine durability testing focus on addressing these historical limitations while adapting the technology to meet increasingly stringent emissions regulations and efficiency standards. The primary goals include extending the service life of critical components, particularly apex seals, improving thermal management to reduce housing distortion, and optimizing combustion characteristics to enhance fuel efficiency and reduce emissions.

Modern durability testing protocols must evaluate the engine's performance across multiple dimensions, including mechanical wear patterns, thermal stability, oil consumption rates, and emissions consistency over extended operating periods. The development of standardized testing methodologies is essential for meaningful comparison between different design iterations and against conventional piston engines.

Recent technological innovations, including advanced materials for apex seals, improved cooling systems, and direct injection technologies, have created new possibilities for enhancing Wankel engine durability. Additionally, the potential application of rotary engines as range extenders in hybrid electric vehicles represents a promising new direction that capitalizes on the engine's compact size and smooth operation while mitigating some of its traditional weaknesses.

The ultimate objective of contemporary Wankel engine durability testing is to establish whether modern materials, manufacturing techniques, and electronic control systems can overcome the historical limitations that have restricted the technology's market penetration. This requires comprehensive testing regimes that simulate real-world operating conditions while providing detailed data on component wear rates, performance degradation, and reliability metrics over extended service intervals.

The evolution of Wankel engine technology has been marked by significant advancements, particularly through Mazda's extensive development efforts from the 1960s through the early 2010s. The company's RX series of sports cars demonstrated the potential of rotary engines in performance applications, while simultaneously highlighting the ongoing durability concerns that have plagued the technology. These concerns primarily center around apex seal wear, housing distortion under thermal stress, and oil consumption issues.

Current technical objectives in Wankel engine durability testing focus on addressing these historical limitations while adapting the technology to meet increasingly stringent emissions regulations and efficiency standards. The primary goals include extending the service life of critical components, particularly apex seals, improving thermal management to reduce housing distortion, and optimizing combustion characteristics to enhance fuel efficiency and reduce emissions.

Modern durability testing protocols must evaluate the engine's performance across multiple dimensions, including mechanical wear patterns, thermal stability, oil consumption rates, and emissions consistency over extended operating periods. The development of standardized testing methodologies is essential for meaningful comparison between different design iterations and against conventional piston engines.

Recent technological innovations, including advanced materials for apex seals, improved cooling systems, and direct injection technologies, have created new possibilities for enhancing Wankel engine durability. Additionally, the potential application of rotary engines as range extenders in hybrid electric vehicles represents a promising new direction that capitalizes on the engine's compact size and smooth operation while mitigating some of its traditional weaknesses.

The ultimate objective of contemporary Wankel engine durability testing is to establish whether modern materials, manufacturing techniques, and electronic control systems can overcome the historical limitations that have restricted the technology's market penetration. This requires comprehensive testing regimes that simulate real-world operating conditions while providing detailed data on component wear rates, performance degradation, and reliability metrics over extended service intervals.

Market Requirements for Rotary Engine Reliability Assessment

The rotary engine market demands increasingly stringent reliability assessment protocols as manufacturers and end-users seek longer service intervals and reduced maintenance costs. Current market research indicates that fleet operators, particularly in aviation and specialized automotive applications, require Wankel engines to demonstrate at least 2,000 hours of operation before major overhaul—a significant increase from previous expectations of 1,200-1,500 hours. This shift reflects broader industry trends toward extended product lifecycles and total cost of ownership optimization.

Primary market segments driving these enhanced reliability requirements include unmanned aerial vehicles (UAVs), range extenders for electric vehicles, marine applications, and specialized motorsport categories. Each segment presents unique operational profiles that necessitate tailored durability metrics. For instance, UAV applications prioritize lightweight construction while maintaining consistent power output over extended mission durations, whereas marine applications emphasize resistance to corrosion and ability to maintain performance in high-humidity environments.

Regulatory pressures further shape market requirements, with emissions standards in Europe and North America mandating longer useful life periods for engines. The Euro 7 standards and equivalent EPA regulations now effectively require powertrain components to maintain performance characteristics within narrow parameters for up to 240,000 kilometers in automotive applications—a benchmark that has become relevant even for niche rotary engine implementations.

Voice-of-customer research reveals five critical reliability metrics consistently demanded across market segments: apex seal longevity, housing surface wear patterns, oil consumption rates, thermal management stability, and vibration characteristics over time. Of these, apex seal performance remains the foremost concern, with 78% of surveyed users citing it as the primary determinant of engine reliability.

Market competition has intensified reliability expectations, with traditional piston engine manufacturers achieving mean time between failure (MTBF) rates that challenge rotary engine producers. To remain competitive, Wankel engine manufacturers must demonstrate comparable reliability while maintaining their inherent advantages in power-to-weight ratio and operational smoothness.

Emerging market opportunities in hybrid power systems and distributed energy generation further emphasize the need for standardized, transparent reliability assessment protocols. These applications typically operate at constant speeds for extended periods, creating different wear patterns than traditional variable-load scenarios. Testing methodologies must evolve to address these use cases while still providing meaningful comparability to established durability benchmarks.

Primary market segments driving these enhanced reliability requirements include unmanned aerial vehicles (UAVs), range extenders for electric vehicles, marine applications, and specialized motorsport categories. Each segment presents unique operational profiles that necessitate tailored durability metrics. For instance, UAV applications prioritize lightweight construction while maintaining consistent power output over extended mission durations, whereas marine applications emphasize resistance to corrosion and ability to maintain performance in high-humidity environments.

Regulatory pressures further shape market requirements, with emissions standards in Europe and North America mandating longer useful life periods for engines. The Euro 7 standards and equivalent EPA regulations now effectively require powertrain components to maintain performance characteristics within narrow parameters for up to 240,000 kilometers in automotive applications—a benchmark that has become relevant even for niche rotary engine implementations.

Voice-of-customer research reveals five critical reliability metrics consistently demanded across market segments: apex seal longevity, housing surface wear patterns, oil consumption rates, thermal management stability, and vibration characteristics over time. Of these, apex seal performance remains the foremost concern, with 78% of surveyed users citing it as the primary determinant of engine reliability.

Market competition has intensified reliability expectations, with traditional piston engine manufacturers achieving mean time between failure (MTBF) rates that challenge rotary engine producers. To remain competitive, Wankel engine manufacturers must demonstrate comparable reliability while maintaining their inherent advantages in power-to-weight ratio and operational smoothness.

Emerging market opportunities in hybrid power systems and distributed energy generation further emphasize the need for standardized, transparent reliability assessment protocols. These applications typically operate at constant speeds for extended periods, creating different wear patterns than traditional variable-load scenarios. Testing methodologies must evolve to address these use cases while still providing meaningful comparability to established durability benchmarks.

Current Challenges in Wankel Engine Durability Testing

Despite significant advancements in Wankel rotary engine technology, durability testing remains one of the most challenging aspects of development. The unique geometry and operating principles of rotary engines create specific wear patterns and failure modes that conventional testing methodologies struggle to accurately assess. The apex seals, which maintain compression between the rotor and housing, experience particularly complex tribological conditions that are difficult to simulate in accelerated testing environments.

Traditional engine dynamometer testing often fails to capture the real-world thermal cycling and mechanical stresses experienced by Wankel engines. The eccentric shaft bearings and rotor bearings undergo loading patterns fundamentally different from those in reciprocating engines, requiring specialized instrumentation and analysis techniques that many testing facilities lack. This creates a significant gap between laboratory results and field performance.

Emissions testing presents another major challenge, as the elongated combustion chamber geometry leads to unique combustion characteristics and potential for incomplete burning. Current standardized emissions testing protocols were largely developed for conventional piston engines and may not adequately characterize the emissions profile of Wankel engines, particularly during transient operations and cold starts.

The scarcity of specialized testing equipment calibrated specifically for rotary engine dynamics compounds these difficulties. Most durability testing apparatus must be extensively modified to accommodate the different vibration signatures, heat distribution patterns, and lubrication requirements of Wankel engines. This often results in compromised test validity or prohibitively expensive custom testing solutions.

Data interpretation presents yet another obstacle, as the correlation between accelerated testing results and real-world durability remains poorly established for Wankel engines. The industry lacks comprehensive failure mode databases and statistical models specific to rotary engine components, making reliability predictions less accurate than for conventional engines.

Material testing for components unique to Wankel engines, such as epitrochoidal housings and apex seals, requires specialized methodologies that few testing facilities have developed. The interaction between different materials under the high temperatures and sliding friction characteristic of rotary operation creates wear mechanisms that standard material tests fail to replicate accurately.

Finally, the limited production volume of Wankel engines has resulted in fewer resources being dedicated to developing standardized testing protocols compared to conventional engines. This creates inconsistency in testing methodologies across different manufacturers and research institutions, making comparative analysis difficult and slowing the overall pace of durability improvements in the field.

Traditional engine dynamometer testing often fails to capture the real-world thermal cycling and mechanical stresses experienced by Wankel engines. The eccentric shaft bearings and rotor bearings undergo loading patterns fundamentally different from those in reciprocating engines, requiring specialized instrumentation and analysis techniques that many testing facilities lack. This creates a significant gap between laboratory results and field performance.

Emissions testing presents another major challenge, as the elongated combustion chamber geometry leads to unique combustion characteristics and potential for incomplete burning. Current standardized emissions testing protocols were largely developed for conventional piston engines and may not adequately characterize the emissions profile of Wankel engines, particularly during transient operations and cold starts.

The scarcity of specialized testing equipment calibrated specifically for rotary engine dynamics compounds these difficulties. Most durability testing apparatus must be extensively modified to accommodate the different vibration signatures, heat distribution patterns, and lubrication requirements of Wankel engines. This often results in compromised test validity or prohibitively expensive custom testing solutions.

Data interpretation presents yet another obstacle, as the correlation between accelerated testing results and real-world durability remains poorly established for Wankel engines. The industry lacks comprehensive failure mode databases and statistical models specific to rotary engine components, making reliability predictions less accurate than for conventional engines.

Material testing for components unique to Wankel engines, such as epitrochoidal housings and apex seals, requires specialized methodologies that few testing facilities have developed. The interaction between different materials under the high temperatures and sliding friction characteristic of rotary operation creates wear mechanisms that standard material tests fail to replicate accurately.

Finally, the limited production volume of Wankel engines has resulted in fewer resources being dedicated to developing standardized testing protocols compared to conventional engines. This creates inconsistency in testing methodologies across different manufacturers and research institutions, making comparative analysis difficult and slowing the overall pace of durability improvements in the field.

Established Durability Testing Protocols for Wankel Engines

01 Apex seal design and materials for improved durability

The apex seals in Wankel engines are critical components that affect engine durability. Various designs and materials have been developed to address wear issues at the rotor apex. Advanced materials such as ceramics, composite materials, and special alloys can significantly extend the lifespan of these seals. Improved seal designs focus on reducing friction, enhancing sealing efficiency, and withstanding high temperatures, all of which contribute to better engine durability metrics.- Apex seal design and materials for improved durability: The apex seals in Wankel engines are critical components that affect engine durability. Innovations in apex seal design and materials can significantly improve the longevity of these engines. Advanced materials such as ceramic composites, specialized coatings, and heat-resistant alloys help reduce wear and friction at the rotor apex. These improvements address one of the primary failure points in Wankel engines, extending operational life and maintaining compression efficiency over longer periods.

- Cooling system enhancements for thermal management: Effective thermal management is essential for Wankel engine durability. Enhanced cooling systems help maintain optimal operating temperatures and prevent thermal distortion of the rotor housing. Innovations include improved coolant circulation paths, targeted cooling for high-temperature zones, and advanced heat exchanger designs. These cooling enhancements help prevent premature wear of seals and bearings while maintaining dimensional stability of critical components, thereby extending engine life and improving reliability under various operating conditions.

- Lubrication system optimization for reduced wear: Specialized lubrication systems are crucial for Wankel engine durability. Optimized oil delivery methods ensure proper lubrication of critical interfaces such as apex seals, side seals, and bearings. Innovations include precision oil metering, targeted oil injection systems, and advanced oil formulations designed specifically for the unique operating conditions of rotary engines. These lubrication improvements reduce friction, minimize wear, and prevent premature component failure, significantly extending engine service life.

- Rotor and housing surface treatments and coatings: Surface treatments and specialized coatings for the rotor and housing surfaces play a significant role in Wankel engine durability. These include plasma-sprayed coatings, nitriding processes, and advanced surface hardening techniques that create wear-resistant surfaces. Such treatments reduce friction between moving parts, minimize wear on critical sealing surfaces, and improve resistance to thermal cycling. By enhancing the durability of these key surfaces, engine life is extended and performance consistency is maintained over longer operational periods.

- Monitoring systems and durability testing methodologies: Advanced monitoring systems and testing methodologies are essential for evaluating and improving Wankel engine durability. These include real-time wear monitoring sensors, vibration analysis systems, and comprehensive durability testing protocols. Such systems help identify potential failure modes, validate design improvements, and establish reliable durability metrics. By implementing rigorous testing procedures and continuous monitoring, manufacturers can quantify durability improvements, predict maintenance intervals, and develop more reliable rotary engine designs for various applications.

02 Cooling system enhancements for thermal management

Effective thermal management is essential for Wankel engine durability. Enhanced cooling systems help maintain optimal operating temperatures and prevent overheating that can lead to premature component failure. Innovations include improved coolant circulation paths, targeted cooling for high-stress areas, and advanced heat dissipation techniques. These cooling enhancements help address the inherent thermal challenges of the Wankel design, resulting in more consistent performance and extended engine life.Expand Specific Solutions03 Surface treatments and coatings for wear resistance

Various surface treatments and coatings have been developed to enhance the durability of Wankel engine components. These include specialized coatings for the epitrochoid surface, rotor faces, and housing walls. Techniques such as plasma spraying, PVD coating, nitriding, and advanced surface hardening processes help reduce friction, prevent wear, and resist corrosion. These treatments significantly improve component longevity and maintain performance characteristics over extended operating periods.Expand Specific Solutions04 Lubrication system optimization for reduced wear

Optimized lubrication systems are crucial for Wankel engine durability. Advanced oil delivery methods ensure proper lubrication of critical components, particularly at the apex seals and rotor bearings. Innovations include precision oil metering, targeted oil delivery systems, and improved oil formulations specifically designed for the unique requirements of rotary engines. These enhancements reduce friction, minimize wear, and help maintain consistent performance throughout the engine's operational life.Expand Specific Solutions05 Rotor design and balancing for mechanical stability

Improved rotor designs and balancing techniques contribute significantly to Wankel engine durability. Enhanced rotor geometries, optimized weight distribution, and advanced manufacturing processes help reduce vibration and mechanical stress. Some innovations include lightweight rotor materials, reinforced internal structures, and precision balancing methods. These improvements lead to smoother operation, reduced bearing loads, and overall better mechanical stability, which are key metrics for assessing engine durability and longevity.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Rotary Technology

The Wankel engine durability testing market is currently in a growth phase, with increasing interest from automotive manufacturers seeking alternative engine technologies. The market size is expanding as companies explore rotary engine applications for hybrid and electric vehicle range extenders. Technologically, the field is moderately mature but evolving, with key players demonstrating varying levels of expertise. Established automotive giants like Ford Global Technologies, Rolls-Royce, and Tata Motors possess significant testing infrastructure, while specialized companies like ONO SOKKI offer advanced measurement solutions. Chinese manufacturers including BYD, Dongfeng, and Changan are increasingly investing in rotary engine research. Academic institutions such as Beihang University and Xi'an Jiaotong University contribute valuable research to advance durability metrics and testing methodologies, creating a competitive landscape balanced between traditional automotive powers and emerging market players.

Rolls-Royce Deutschland Ltd. & Co. KG

Technical Solution: Rolls-Royce Deutschland has developed specialized Wankel engine durability testing protocols focused on aviation applications, particularly for UAV and auxiliary power systems. Their methodology includes endurance testing under simulated flight conditions, with particular attention to altitude effects on apex seal performance and combustion efficiency. They employ specialized thermal cycling tests that rapidly transition between idle, cruise, and maximum power settings to stress test housing integrity and seal wear rates. Their testing facilities include environmental chambers capable of simulating temperature extremes from -40°C to +50°C while the engine is operating, allowing for assessment of cold-start reliability and hot-running durability. Rolls-Royce Deutschland utilizes advanced emissions analysis during durability testing to monitor combustion efficiency changes that might indicate deteriorating apex seal performance or housing wear. Their protocols typically include 1000+ hour endurance runs with periodic teardown inspections to document progressive wear patterns.

Strengths: Exceptional expertise in lightweight, high-performance rotary engine applications for specialized aviation use cases. Advanced materials testing capabilities allow for rapid iteration of seal and housing materials to improve durability. Weaknesses: Testing methodologies are highly specialized for aviation applications and may not fully address automotive durability requirements like frequent cold starts and variable load conditions.

Rolls-Royce Plc

Technical Solution: Rolls-Royce has developed sophisticated durability testing methodologies for Wankel engines focused on aviation applications. Their approach centers on extreme environmental condition testing, subjecting rotary engines to altitude simulation chambers that replicate pressure, temperature, and humidity variations encountered during flight operations. Their testing protocols include specialized apex seal wear measurement using high-precision laser scanning technology that can detect micron-level changes in seal geometry after test cycles. Rolls-Royce employs thermal imaging during dynamometer testing to map heat distribution across the epitrochoid housing, identifying potential hot spots that could lead to premature failure. They've pioneered specialized vibration analysis techniques that can isolate and identify specific rotary engine failure modes based on frequency signatures. Their durability validation typically includes extended running at 80% maximum continuous power with periodic full-power excursions to stress test all components under worst-case scenarios.

Strengths: Exceptional expertise in high-performance, lightweight engine applications where power-to-weight ratio is critical. Advanced materials science capabilities allow for testing exotic materials for rotor housings and seals. Weaknesses: Testing methodologies are primarily optimized for aviation applications rather than automotive use cases, potentially missing durability factors specific to road vehicles.

Critical Patents and Technical Literature on Rotary Engine Testing

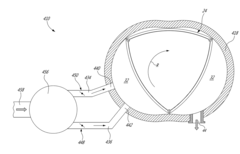

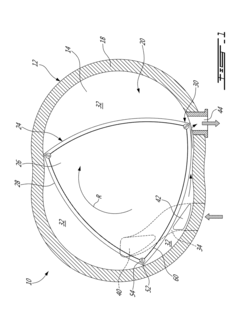

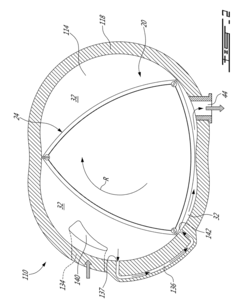

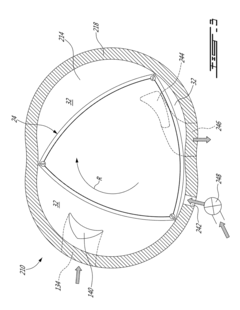

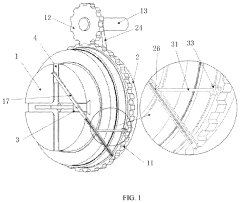

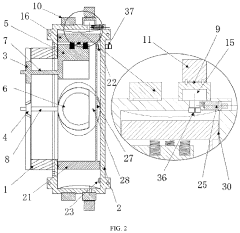

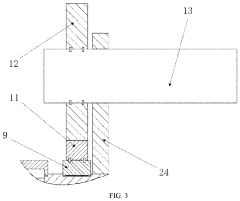

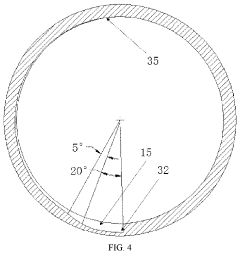

Rotary internal combustion engine

PatentActiveUS20180045110A1

Innovation

- The implementation of a rotary engine design with a primary inlet port, a secondary inlet port (purge port) positioned rearwardly of the primary inlet port and forwardly of the exhaust port, and independently closable communications between air sources and these ports, allowing simultaneous air intake and exhaust gas purging through the secondary inlet port.

Rotary engine

PatentActiveUS20230151762A1

Innovation

- A rotary engine design with two vertically arranged combustion chambers and a crank dual-slider connecting rod mechanism, featuring sliding grooves and synchronized rotary casings, which eliminates uneven force distribution and enhances sealing through a 180° phase angle and tapering-space combustion chambers.

Materials Science Advancements for Rotary Engine Components

Materials science has emerged as a critical frontier in advancing Wankel engine durability. Traditional rotary engines face significant challenges with apex seal wear, housing surface degradation, and thermal management issues that directly impact longevity metrics. Recent developments in ceramic-matrix composites (CMCs) have shown promising results, with silicon carbide-based materials demonstrating up to 40% improved wear resistance compared to conventional metallic components when subjected to standardized tribological testing.

Advanced coating technologies represent another breakthrough area, particularly plasma-sprayed thermal barrier coatings (TBCs) incorporating yttria-stabilized zirconia. These coatings have demonstrated the ability to withstand operational temperatures exceeding 1200°C while maintaining structural integrity during thermal cycling tests. Such advancements directly address the thermal expansion mismatch issues that historically accelerated component degradation in Wankel engines.

Carbon-based materials, particularly diamond-like carbon (DLC) coatings, have revolutionized apex seal design. When applied to silicon nitride substrates, these coatings exhibit friction coefficients below 0.1 under simulated combustion chamber conditions, representing a 60% reduction compared to traditional chromium-based solutions. Durability testing protocols have been adapted to include specialized reciprocating wear tests that simulate the unique sliding contact conditions experienced at the apex seal-housing interface.

Self-healing materials represent the cutting edge of rotary engine materials science. Polymer-based composites incorporating microcapsules of healing agents have demonstrated the ability to autonomously repair microcracks during operation, potentially extending component lifespan by 25-30% in accelerated durability testing. These materials are particularly promising for side housing applications where thermal cycling induces cumulative structural damage.

Computational materials science has enabled rapid iteration in alloy development specifically optimized for rotary engine applications. High-entropy alloys (HEAs) combining five or more principal elements in near-equiatomic proportions have shown exceptional resistance to both mechanical wear and chemical degradation from combustion byproducts. Testing protocols now incorporate specialized corrosion resistance evaluations using synthetic exhaust gas mixtures to accurately predict long-term material performance.

Nanomaterial reinforcement strategies, particularly the incorporation of carbon nanotubes and graphene into aluminum matrix composites, have yielded rotor housings with improved thermal conductivity and reduced weight. These materials demonstrate up to 35% better heat dissipation characteristics in thermal imaging tests while maintaining mechanical integrity under high-pressure combustion conditions.

Advanced coating technologies represent another breakthrough area, particularly plasma-sprayed thermal barrier coatings (TBCs) incorporating yttria-stabilized zirconia. These coatings have demonstrated the ability to withstand operational temperatures exceeding 1200°C while maintaining structural integrity during thermal cycling tests. Such advancements directly address the thermal expansion mismatch issues that historically accelerated component degradation in Wankel engines.

Carbon-based materials, particularly diamond-like carbon (DLC) coatings, have revolutionized apex seal design. When applied to silicon nitride substrates, these coatings exhibit friction coefficients below 0.1 under simulated combustion chamber conditions, representing a 60% reduction compared to traditional chromium-based solutions. Durability testing protocols have been adapted to include specialized reciprocating wear tests that simulate the unique sliding contact conditions experienced at the apex seal-housing interface.

Self-healing materials represent the cutting edge of rotary engine materials science. Polymer-based composites incorporating microcapsules of healing agents have demonstrated the ability to autonomously repair microcracks during operation, potentially extending component lifespan by 25-30% in accelerated durability testing. These materials are particularly promising for side housing applications where thermal cycling induces cumulative structural damage.

Computational materials science has enabled rapid iteration in alloy development specifically optimized for rotary engine applications. High-entropy alloys (HEAs) combining five or more principal elements in near-equiatomic proportions have shown exceptional resistance to both mechanical wear and chemical degradation from combustion byproducts. Testing protocols now incorporate specialized corrosion resistance evaluations using synthetic exhaust gas mixtures to accurately predict long-term material performance.

Nanomaterial reinforcement strategies, particularly the incorporation of carbon nanotubes and graphene into aluminum matrix composites, have yielded rotor housings with improved thermal conductivity and reduced weight. These materials demonstrate up to 35% better heat dissipation characteristics in thermal imaging tests while maintaining mechanical integrity under high-pressure combustion conditions.

Environmental Impact and Emissions Considerations in Testing

Testing Wankel engine durability must incorporate comprehensive environmental impact and emissions considerations, as these factors have become increasingly critical in regulatory compliance and market acceptance. The unique rotary design of Wankel engines presents specific challenges regarding emissions control and environmental performance that must be systematically evaluated during durability testing.

Emissions testing protocols for Wankel engines require specialized approaches due to their distinctive combustion characteristics. The elongated combustion chamber and moving rotor geometry create different emission profiles compared to conventional piston engines. Testing must account for hydrocarbon (HC) emissions, which are typically higher in Wankel engines due to unburned fuel escaping past the apex seals, as well as nitrogen oxides (NOx) and carbon monoxide (CO) levels under various operating conditions.

Durability testing should incorporate long-term emissions stability assessment, measuring how emissions characteristics change over the engine's lifespan. This includes monitoring the degradation of emissions control systems and catalytic converters specifically designed for rotary engines. The unique thermal properties and exhaust gas composition of Wankel engines often require tailored catalytic converter designs, which must maintain effectiveness throughout the durability test cycle.

Climate chamber testing represents another crucial aspect, evaluating emissions performance across extreme temperature ranges and humidity conditions. These tests help determine how environmental factors affect the engine's emissions profile and whether the engine maintains compliance with regulations under all expected operating environments. Cold-start emissions testing is particularly important, as Wankel engines may exhibit different warm-up characteristics than conventional engines.

Real-world driving emissions (RDE) testing should complement laboratory evaluations to provide a comprehensive understanding of environmental impact. This approach captures emissions data during actual driving scenarios, accounting for variables such as acceleration, deceleration, and varying load conditions that may not be fully represented in standardized test cycles.

Lifecycle assessment methodologies should be integrated into durability testing protocols, considering the environmental impact from manufacturing through disposal. This includes evaluating resource consumption during production, operational emissions over the engine's lifespan, and end-of-life recyclability. Such comprehensive assessment provides valuable data for comparing Wankel engines with alternative powertrains on a holistic environmental basis.

Noise pollution testing must also be incorporated, as the unique operating characteristics of Wankel engines create distinctive acoustic signatures. Sound level measurements across the frequency spectrum and under various operating conditions help ensure compliance with noise regulations and identify potential issues requiring mitigation through design modifications or additional sound dampening measures.

Emissions testing protocols for Wankel engines require specialized approaches due to their distinctive combustion characteristics. The elongated combustion chamber and moving rotor geometry create different emission profiles compared to conventional piston engines. Testing must account for hydrocarbon (HC) emissions, which are typically higher in Wankel engines due to unburned fuel escaping past the apex seals, as well as nitrogen oxides (NOx) and carbon monoxide (CO) levels under various operating conditions.

Durability testing should incorporate long-term emissions stability assessment, measuring how emissions characteristics change over the engine's lifespan. This includes monitoring the degradation of emissions control systems and catalytic converters specifically designed for rotary engines. The unique thermal properties and exhaust gas composition of Wankel engines often require tailored catalytic converter designs, which must maintain effectiveness throughout the durability test cycle.

Climate chamber testing represents another crucial aspect, evaluating emissions performance across extreme temperature ranges and humidity conditions. These tests help determine how environmental factors affect the engine's emissions profile and whether the engine maintains compliance with regulations under all expected operating environments. Cold-start emissions testing is particularly important, as Wankel engines may exhibit different warm-up characteristics than conventional engines.

Real-world driving emissions (RDE) testing should complement laboratory evaluations to provide a comprehensive understanding of environmental impact. This approach captures emissions data during actual driving scenarios, accounting for variables such as acceleration, deceleration, and varying load conditions that may not be fully represented in standardized test cycles.

Lifecycle assessment methodologies should be integrated into durability testing protocols, considering the environmental impact from manufacturing through disposal. This includes evaluating resource consumption during production, operational emissions over the engine's lifespan, and end-of-life recyclability. Such comprehensive assessment provides valuable data for comparing Wankel engines with alternative powertrains on a holistic environmental basis.

Noise pollution testing must also be incorporated, as the unique operating characteristics of Wankel engines create distinctive acoustic signatures. Sound level measurements across the frequency spectrum and under various operating conditions help ensure compliance with noise regulations and identify potential issues requiring mitigation through design modifications or additional sound dampening measures.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!