How To Utilize Tungsten For Radiation Shielding?

Tungsten Shielding Background and Objectives

Tungsten has emerged as a critical material in radiation shielding applications, owing to its unique properties and effectiveness in attenuating various forms of radiation. The evolution of tungsten-based shielding technologies has been driven by the growing need for enhanced protection in nuclear power plants, medical facilities, and aerospace industries. As radiation risks continue to pose significant challenges across multiple sectors, the development of advanced shielding solutions has become paramount.

The primary objective of utilizing tungsten for radiation shielding is to maximize protection against harmful ionizing radiation while minimizing the overall weight and volume of shielding structures. This goal aligns with the broader industry trends towards more efficient and compact radiation protection systems. Tungsten's high density, coupled with its excellent radiation absorption capabilities, makes it an ideal candidate for achieving these objectives.

Historically, lead has been the go-to material for radiation shielding. However, increasing environmental concerns and the quest for superior shielding performance have propelled tungsten to the forefront of shielding technology. The transition from lead to tungsten-based solutions represents a significant milestone in the field, marking a shift towards more sustainable and effective radiation protection strategies.

Recent technological advancements have focused on enhancing tungsten's shielding properties through innovative manufacturing processes and composite materials. These developments aim to overcome some of the inherent limitations of pure tungsten, such as its brittleness and high cost. Researchers are exploring various tungsten alloys and tungsten-based composites to strike an optimal balance between shielding effectiveness, mechanical properties, and economic viability.

The current trajectory of tungsten shielding technology points towards more sophisticated, multi-layered shielding designs that leverage tungsten's properties in combination with other materials. This approach seeks to create synergistic effects, potentially revolutionizing radiation protection across various applications. From medical imaging equipment to space exploration vehicles, the demand for advanced tungsten-based shielding solutions continues to grow.

As we look to the future, the objectives for tungsten shielding research and development are multifaceted. They include improving manufacturing techniques to reduce costs, developing new tungsten composites with enhanced properties, and expanding the range of applications where tungsten shielding can be effectively employed. Additionally, there is a strong focus on integrating tungsten-based solutions with smart materials and sensors to create adaptive shielding systems capable of responding dynamically to varying radiation levels.

Radiation Protection Market Analysis

The radiation protection market has experienced significant growth in recent years, driven by increasing awareness of radiation risks and the expanding applications of radiation technologies across various industries. The global market for radiation shielding materials and equipment is projected to continue its upward trajectory, with tungsten playing a crucial role in this sector.

Tungsten's high density and excellent radiation attenuation properties make it an ideal material for radiation shielding applications. The demand for tungsten-based radiation protection solutions is particularly strong in the healthcare sector, where it is used in medical imaging equipment, radiotherapy devices, and nuclear medicine facilities. The growing prevalence of cancer and the subsequent rise in radiotherapy treatments have been key factors driving the demand for tungsten shielding in medical applications.

In the industrial sector, tungsten shielding is increasingly utilized in nuclear power plants, research facilities, and manufacturing processes involving radioactive materials. The expansion of nuclear energy programs in several countries, coupled with stringent safety regulations, has contributed to the growing demand for high-performance radiation shielding materials like tungsten.

The aerospace and defense industries also represent significant market segments for tungsten-based radiation protection. As space exploration activities intensify and satellite technologies advance, the need for effective radiation shielding in spacecraft and satellites has grown. Similarly, military applications, including armor and protective equipment for personnel working in radiation-exposed environments, have bolstered the demand for tungsten shielding solutions.

Emerging technologies and innovative applications are expected to further expand the market for tungsten-based radiation protection. For instance, the development of compact and portable radiation detection devices for homeland security and environmental monitoring has created new opportunities for tungsten shielding materials.

Despite the positive market outlook, challenges such as the high cost of tungsten and the complexity of manufacturing tungsten-based shielding products may impact market growth. However, ongoing research and development efforts aimed at improving tungsten processing techniques and exploring new tungsten alloys are expected to address these challenges and enhance the material's competitiveness in the radiation protection market.

As environmental concerns and sustainability initiatives gain prominence, the radiation protection market is also witnessing a growing interest in recyclable and eco-friendly shielding materials. This trend presents both challenges and opportunities for tungsten-based solutions, driving innovation in material design and manufacturing processes to align with sustainability goals.

Tungsten Shielding Technology Status

Tungsten shielding technology has advanced significantly in recent years, driven by the growing demand for effective radiation protection in various industries. The current status of tungsten shielding technology reflects a mature field with ongoing innovations and improvements.

One of the primary advantages of tungsten as a shielding material is its high density, which allows for effective attenuation of gamma and X-ray radiation. Modern tungsten shielding solutions typically utilize tungsten alloys, which combine the excellent shielding properties of tungsten with improved mechanical characteristics. These alloys often contain small amounts of nickel, iron, or copper to enhance manufacturability and durability.

In the medical field, tungsten shielding technology has become increasingly sophisticated. Hospitals and imaging centers now employ tungsten-based collimators and beam shapers in radiotherapy equipment to precisely control radiation exposure. Additionally, tungsten-infused fabrics and flexible sheets have been developed for personal protective equipment, offering medical professionals enhanced protection during procedures involving ionizing radiation.

The nuclear industry has also embraced advanced tungsten shielding technologies. Tungsten heavy alloys are used in the construction of spent fuel casks and transportation containers, providing superior radiation attenuation while minimizing overall weight compared to traditional lead-based solutions. Furthermore, tungsten carbide composites have found applications in nuclear waste management, offering excellent resistance to both radiation and corrosion.

In the aerospace sector, tungsten shielding technology has been adapted to protect sensitive electronic components from cosmic radiation. Spacecraft and satellites now incorporate tungsten alloy shielding in critical areas to ensure the longevity and reliability of onboard systems during long-term space missions.

Recent advancements in manufacturing techniques have expanded the possibilities for tungsten shielding. Additive manufacturing, or 3D printing, has enabled the production of complex tungsten shield designs with optimized geometries for specific applications. This technology allows for the creation of lightweight yet highly effective shielding solutions, particularly beneficial in aerospace and portable medical equipment.

Nanotechnology has also made inroads in tungsten shielding, with researchers developing nanostructured tungsten composites that offer improved radiation attenuation properties. These materials show promise for next-generation shielding applications, potentially providing enhanced protection with reduced material thickness.

Despite these advancements, challenges remain in the field of tungsten shielding technology. The high cost of tungsten and its alloys continues to be a limiting factor for widespread adoption in some applications. Additionally, the weight of tungsten shields can be prohibitive in certain scenarios, driving ongoing research into lighter composite materials that maintain effective shielding properties.

Current Tungsten Shielding Solutions

01 Tungsten-based composite materials for radiation shielding

Composite materials incorporating tungsten are developed for effective radiation shielding. These materials combine tungsten's high density and atomic number with other components to enhance shielding properties while optimizing weight and manufacturability. The composites can be tailored for specific radiation types and energy levels, offering versatile protection in various applications.- Tungsten-based composite materials for radiation shielding: Composite materials incorporating tungsten are developed for effective radiation shielding. These materials combine tungsten's high density and atomic number with other elements or compounds to enhance shielding properties while potentially reducing weight or improving manufacturability. Such composites may include tungsten alloys, tungsten-polymer mixtures, or tungsten-ceramic combinations.

- Tungsten shielding in medical and industrial applications: Tungsten-based radiation shielding is utilized in various medical and industrial settings. This includes protection for X-ray equipment, nuclear medicine facilities, and industrial radiography. Tungsten shields may be designed as wearable protective gear, structural components, or portable screens to minimize radiation exposure to personnel and sensitive equipment.

- Nanostructured tungsten for enhanced radiation shielding: Nanostructured tungsten materials are explored for improved radiation shielding effectiveness. These materials may have unique properties due to their nanoscale structure, potentially offering better shielding performance compared to bulk tungsten. Nanostructured tungsten can be incorporated into coatings, films, or bulk materials for various shielding applications.

- Tungsten alloys with rare earth elements for radiation protection: Tungsten alloys incorporating rare earth elements are developed to enhance radiation shielding properties. These alloys may offer improved absorption of specific types of radiation or provide better mechanical properties compared to pure tungsten. The combination of tungsten with rare earth elements can result in materials tailored for specific shielding requirements.

- Manufacturing techniques for tungsten radiation shields: Advanced manufacturing techniques are employed to produce tungsten-based radiation shielding components. These may include powder metallurgy, additive manufacturing, or novel forming processes that allow for the creation of complex geometries or gradient structures. Such techniques aim to optimize the shielding effectiveness, reduce material waste, and enable the production of customized shielding solutions.

02 Tungsten alloys for improved radiation shielding performance

Specialized tungsten alloys are engineered to enhance radiation shielding capabilities. These alloys may include elements like nickel, iron, or copper to improve mechanical properties and fabrication processes while maintaining excellent shielding characteristics. The alloys can be optimized for specific radiation environments, offering superior protection compared to pure tungsten.Expand Specific Solutions03 Nanostructured tungsten materials for radiation shielding

Nanostructured tungsten materials are developed to enhance radiation shielding effectiveness. These materials leverage the unique properties of nanoscale tungsten particles or structures to improve shielding performance, potentially reducing the overall weight and thickness of shielding components. The nanostructured approach can lead to more efficient and compact radiation protection solutions.Expand Specific Solutions04 Tungsten-based coatings and films for radiation protection

Thin films and coatings containing tungsten are developed for radiation shielding applications. These coatings can be applied to various substrates, providing a flexible and adaptable approach to radiation protection. The films may incorporate multiple layers or gradients to optimize shielding across different radiation types and energy levels.Expand Specific Solutions05 Tungsten-infused polymers and composites for flexible shielding

Polymers and composite materials infused with tungsten particles or compounds are developed for flexible radiation shielding applications. These materials combine the high atomic number of tungsten with the versatility and formability of polymers, allowing for the creation of adaptable shielding solutions. The resulting materials can be molded or shaped into various forms to protect complex geometries or create wearable radiation protection.Expand Specific Solutions

Key Players in Tungsten Industry

The radiation shielding market utilizing tungsten is in a growth phase, driven by increasing applications in healthcare, nuclear energy, and aerospace sectors. The global market size for radiation shielding is projected to expand significantly in the coming years. Technologically, tungsten-based shielding is relatively mature, with ongoing innovations focused on enhancing efficiency and reducing weight. Companies like Sumitomo Electric Industries Ltd., Nuclear Power Institute of China, and Agilent Technologies, Inc. are at the forefront of developing advanced tungsten shielding solutions. Emerging players such as Xiamen Honglu Tungsten Molybdenum Industry Co., Ltd. and Space Micro, Inc. are also contributing to market competitiveness through specialized applications and novel manufacturing techniques.

Nuclear Power Institute of China

China General Nuclear Power Corp.

Innovations in Tungsten Composites

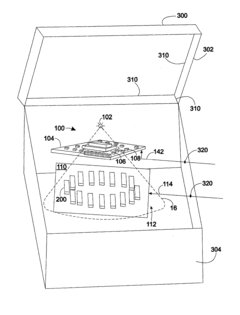

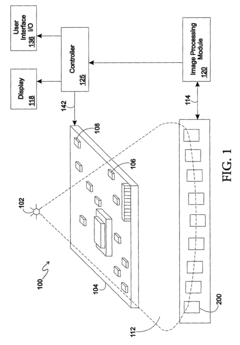

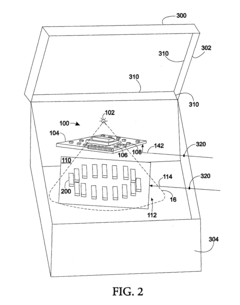

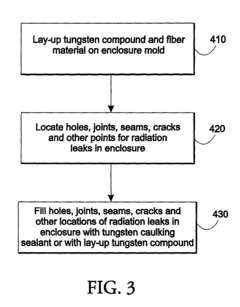

- A radiation shielding enclosure using a tungsten composite material with a lay-up process or pressure spray method, incorporating condensed tungsten powder in an epoxy or polyester substrate with fiberglass for structural reinforcement, and a tungsten caulking compound for sealing leaks, offering a lightweight, environmentally friendly, and cost-effective alternative.

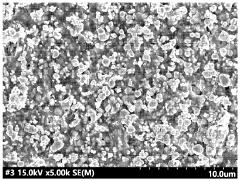

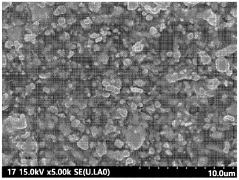

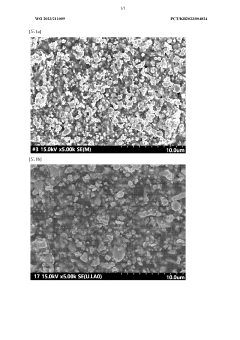

- A radiation shielding film composed of tungsten powder with an average particle size of 80 to 200 nm dispersed in a polymer base, processed through repeated stirring and heat molding to create an ultra-thin, high-density film with enhanced tensile strength and flexibility.

Safety Regulations for Radiation Shielding

The utilization of tungsten for radiation shielding must adhere to strict safety regulations to ensure the protection of workers, the public, and the environment. These regulations are typically established by national and international regulatory bodies, such as the Nuclear Regulatory Commission (NRC) in the United States and the International Atomic Energy Agency (IAEA) globally.

Regulatory frameworks often require comprehensive risk assessments and safety analyses before the implementation of tungsten-based radiation shielding. These assessments must consider factors such as the type and intensity of radiation, exposure scenarios, and potential failure modes of the shielding system. The results of these analyses inform the design, installation, and maintenance procedures for tungsten shielding solutions.

Material specifications for tungsten used in radiation shielding are subject to rigorous standards. These standards typically define the required purity, density, and structural integrity of the tungsten components. Manufacturers must provide certification that their tungsten products meet these specifications, and regular quality control checks are mandated to ensure ongoing compliance.

Occupational exposure limits are a critical aspect of safety regulations for radiation shielding. Workers involved in the installation, maintenance, or operation of tungsten shielding must be protected from excessive radiation exposure. Regulations often specify maximum permissible doses, monitoring requirements, and the use of personal protective equipment when working with or around tungsten shielding materials.

Installation and maintenance procedures for tungsten radiation shielding are typically subject to regulatory oversight. These procedures must be documented, validated, and performed by qualified personnel. Regular inspections and integrity tests may be required to ensure the continued effectiveness of the shielding over time.

Emergency response plans are another crucial component of safety regulations. Facilities utilizing tungsten for radiation shielding must have protocols in place for addressing potential failures or breaches in the shielding system. These plans should include evacuation procedures, containment strategies, and notification systems for relevant authorities.

Disposal and decommissioning of tungsten shielding materials are also regulated to prevent environmental contamination and unauthorized reuse. Proper disposal methods must be employed, and documentation of the disposal process is typically required for regulatory compliance.

Training and certification requirements for personnel working with tungsten radiation shielding are often mandated by safety regulations. This ensures that individuals involved in the design, installation, operation, and maintenance of shielding systems have the necessary knowledge and skills to perform their duties safely and effectively.

Environmental Impact of Tungsten Mining

The environmental impact of tungsten mining is a significant concern in the utilization of tungsten for radiation shielding. Tungsten extraction processes can have substantial effects on ecosystems, water resources, and local communities. Open-pit mining, the most common method for tungsten extraction, leads to large-scale land disturbance and habitat destruction. This often results in the loss of biodiversity and disruption of local ecosystems.

Water pollution is another major issue associated with tungsten mining. The extraction process can release heavy metals and other contaminants into nearby water sources, potentially affecting both surface and groundwater quality. Acid mine drainage, a common problem in metal mining, can occur when sulfide minerals are exposed to air and water, leading to the formation of sulfuric acid. This acidic runoff can severely impact aquatic life and render water sources unusable for human consumption or agricultural purposes.

Air quality is also affected by tungsten mining operations. Dust generated during extraction and processing activities can contain harmful particulates, potentially causing respiratory issues for workers and nearby communities. Furthermore, the energy-intensive nature of tungsten mining and processing contributes to increased greenhouse gas emissions, exacerbating climate change concerns.

The disposal of mining waste presents another environmental challenge. Tailings, the materials left over after the extraction process, can contain toxic substances and heavy metals. Improper management of these waste materials can lead to soil contamination and long-term environmental degradation.

Efforts to mitigate the environmental impact of tungsten mining have led to the development of more sustainable practices. These include improved water management techniques, such as water recycling and treatment systems, to reduce pollution and conserve water resources. Reclamation and rehabilitation of mined areas are increasingly prioritized to restore ecosystems and minimize long-term environmental damage.

Advanced mining technologies and practices are being implemented to reduce the overall environmental footprint of tungsten extraction. These include more efficient ore processing methods that minimize waste generation and energy consumption. Additionally, stricter environmental regulations and monitoring systems are being put in place in many regions to ensure compliance with environmental standards and to protect local ecosystems and communities.