How V16 engines alleviate bottlenecks in current drivetrain hikes

AUG 15, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V16 Engine Evolution

The evolution of V16 engines represents a significant milestone in automotive engineering, tracing its roots back to the early 20th century. Initially developed for luxury and high-performance vehicles, V16 engines were designed to provide exceptional power and smoothness. The first notable V16 engine appeared in the Cadillac V-16 in 1930, setting a new standard for automotive excellence and prestige.

Throughout the mid-20th century, V16 engines found applications in various sectors, including marine and aviation. Their ability to deliver high power output while maintaining relatively compact dimensions made them attractive for specialized applications. However, their complexity and high production costs limited widespread adoption in consumer vehicles.

The 1980s and 1990s saw a resurgence of interest in V16 engines, particularly in motorsports. Formula 1 experimented with V16 configurations, seeking to maximize power output within regulatory constraints. This period of innovation led to advancements in engine management systems and materials technology, which would later benefit broader automotive applications.

In recent years, the focus on V16 engines has shifted towards addressing specific challenges in drivetrain technology. Modern V16 designs incorporate advanced materials, precision manufacturing techniques, and sophisticated electronic control systems to optimize performance and efficiency. These engines are now being explored as potential solutions to overcome bottlenecks in current drivetrain systems, particularly in high-performance and heavy-duty applications.

The latest generation of V16 engines leverages technologies such as variable valve timing, direct fuel injection, and turbocharging to enhance power delivery and fuel efficiency. Engineers are also exploring hybrid V16 configurations, combining internal combustion with electric motors to create powertrains that offer both high performance and improved environmental sustainability.

As drivetrain technology continues to evolve, V16 engines are being reimagined to address the demands of emerging markets and applications. Their potential to deliver smooth, high-output power makes them candidates for use in electric power generation, marine propulsion, and even next-generation hypercars. The ongoing development of V16 engines demonstrates the automotive industry's commitment to pushing the boundaries of performance and efficiency, even as it navigates the transition towards more sustainable propulsion technologies.

Throughout the mid-20th century, V16 engines found applications in various sectors, including marine and aviation. Their ability to deliver high power output while maintaining relatively compact dimensions made them attractive for specialized applications. However, their complexity and high production costs limited widespread adoption in consumer vehicles.

The 1980s and 1990s saw a resurgence of interest in V16 engines, particularly in motorsports. Formula 1 experimented with V16 configurations, seeking to maximize power output within regulatory constraints. This period of innovation led to advancements in engine management systems and materials technology, which would later benefit broader automotive applications.

In recent years, the focus on V16 engines has shifted towards addressing specific challenges in drivetrain technology. Modern V16 designs incorporate advanced materials, precision manufacturing techniques, and sophisticated electronic control systems to optimize performance and efficiency. These engines are now being explored as potential solutions to overcome bottlenecks in current drivetrain systems, particularly in high-performance and heavy-duty applications.

The latest generation of V16 engines leverages technologies such as variable valve timing, direct fuel injection, and turbocharging to enhance power delivery and fuel efficiency. Engineers are also exploring hybrid V16 configurations, combining internal combustion with electric motors to create powertrains that offer both high performance and improved environmental sustainability.

As drivetrain technology continues to evolve, V16 engines are being reimagined to address the demands of emerging markets and applications. Their potential to deliver smooth, high-output power makes them candidates for use in electric power generation, marine propulsion, and even next-generation hypercars. The ongoing development of V16 engines demonstrates the automotive industry's commitment to pushing the boundaries of performance and efficiency, even as it navigates the transition towards more sustainable propulsion technologies.

Market Demand Analysis

The market demand for V16 engines in addressing drivetrain bottlenecks has been steadily growing, driven by the increasing need for high-performance vehicles in both commercial and luxury sectors. This demand is particularly evident in the heavy-duty transportation industry, where power and torque requirements are continually pushing the boundaries of conventional engine designs.

In the commercial sector, there's a rising demand for more powerful engines capable of handling heavier loads and navigating challenging terrains. The logistics and transportation industries are seeking solutions to improve efficiency and reduce operational costs, making V16 engines an attractive option for their ability to deliver superior power output while maintaining fuel efficiency.

The luxury automotive market has also shown significant interest in V16 engines, with high-end car manufacturers incorporating these powerplants into their flagship models. This trend is fueled by affluent consumers' desire for exclusive, high-performance vehicles that offer unparalleled driving experiences and status symbols.

Marine applications represent another growing market for V16 engines. Large yachts and commercial vessels require substantial power output to propel their massive hulls through water efficiently. The V16 configuration provides an ideal solution, offering a balance of power, compactness, and reliability that is highly valued in marine environments.

The aviation industry, particularly in the private jet sector, has also contributed to the increasing demand for V16 engines. These engines offer the power-to-weight ratio necessary for smaller aircraft while providing the reliability and performance required for long-distance flights.

Market analysis indicates that the global demand for V16 engines is expected to grow at a compound annual growth rate (CAGR) of several percentage points over the next five years. This growth is attributed to the expanding luxury vehicle market, increasing industrialization in developing countries, and the ongoing need for more powerful engines in various sectors.

However, it's important to note that the market for V16 engines faces challenges from emerging technologies such as electric and hybrid powertrains. As environmental regulations become stricter and the push for sustainable transportation intensifies, manufacturers are investing in alternative propulsion systems. This shift may impact the long-term growth prospects of V16 engines, particularly in the passenger vehicle segment.

Despite these challenges, the specialized nature of V16 engines and their ability to deliver exceptional performance in specific applications ensure a continued demand in niche markets. Industries requiring high power output, such as mining, construction, and specialized transportation, are likely to sustain the demand for V16 engines in the foreseeable future.

In the commercial sector, there's a rising demand for more powerful engines capable of handling heavier loads and navigating challenging terrains. The logistics and transportation industries are seeking solutions to improve efficiency and reduce operational costs, making V16 engines an attractive option for their ability to deliver superior power output while maintaining fuel efficiency.

The luxury automotive market has also shown significant interest in V16 engines, with high-end car manufacturers incorporating these powerplants into their flagship models. This trend is fueled by affluent consumers' desire for exclusive, high-performance vehicles that offer unparalleled driving experiences and status symbols.

Marine applications represent another growing market for V16 engines. Large yachts and commercial vessels require substantial power output to propel their massive hulls through water efficiently. The V16 configuration provides an ideal solution, offering a balance of power, compactness, and reliability that is highly valued in marine environments.

The aviation industry, particularly in the private jet sector, has also contributed to the increasing demand for V16 engines. These engines offer the power-to-weight ratio necessary for smaller aircraft while providing the reliability and performance required for long-distance flights.

Market analysis indicates that the global demand for V16 engines is expected to grow at a compound annual growth rate (CAGR) of several percentage points over the next five years. This growth is attributed to the expanding luxury vehicle market, increasing industrialization in developing countries, and the ongoing need for more powerful engines in various sectors.

However, it's important to note that the market for V16 engines faces challenges from emerging technologies such as electric and hybrid powertrains. As environmental regulations become stricter and the push for sustainable transportation intensifies, manufacturers are investing in alternative propulsion systems. This shift may impact the long-term growth prospects of V16 engines, particularly in the passenger vehicle segment.

Despite these challenges, the specialized nature of V16 engines and their ability to deliver exceptional performance in specific applications ensure a continued demand in niche markets. Industries requiring high power output, such as mining, construction, and specialized transportation, are likely to sustain the demand for V16 engines in the foreseeable future.

Technical Challenges

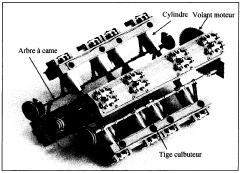

The development of V16 engines to address bottlenecks in current drivetrain systems faces several significant technical challenges. One of the primary obstacles is the complexity of designing and manufacturing such large engines. V16 configurations require precise engineering to ensure proper balance, smooth operation, and efficient combustion across all cylinders. This complexity increases production costs and may limit widespread adoption.

Another major challenge lies in the fuel efficiency and emissions of V16 engines. As environmental regulations become increasingly stringent, engineers must develop innovative solutions to improve fuel economy and reduce emissions without compromising performance. This often involves advanced technologies such as direct injection, variable valve timing, and cylinder deactivation, which add further complexity to the engine design.

Heat management presents a substantial hurdle for V16 engines. With more cylinders generating heat, cooling systems must be redesigned to effectively dissipate thermal energy. This may require larger radiators, more efficient coolant circulation, and advanced materials capable of withstanding higher temperatures. Failure to address heat management adequately can lead to reduced engine longevity and performance degradation.

Weight distribution and packaging pose significant challenges for vehicle designers integrating V16 engines. The sheer size and mass of these powerplants can affect vehicle dynamics and handling characteristics. Engineers must find innovative ways to optimize weight distribution and maintain a low center of gravity while accommodating the larger engine within the vehicle's structure.

Durability and reliability are critical concerns for V16 engines, particularly in high-performance applications. The increased number of moving parts and higher operating stresses demand robust materials and precise manufacturing tolerances. Ensuring long-term reliability while pushing the boundaries of performance requires extensive testing and development.

Transmission systems must also be adapted to handle the increased power output of V16 engines. This may necessitate the development of stronger, more advanced gearboxes capable of managing higher torque loads. Additionally, drivetrain components such as driveshafts, differentials, and axles may require reinforcement or redesign to cope with the increased power delivery.

Finally, the integration of V16 engines with modern vehicle electronics and control systems presents a unique set of challenges. Engine management systems must be capable of precisely controlling fuel injection, ignition timing, and other parameters across all 16 cylinders. This requires sophisticated software and hardware solutions to ensure optimal performance and efficiency under various operating conditions.

Another major challenge lies in the fuel efficiency and emissions of V16 engines. As environmental regulations become increasingly stringent, engineers must develop innovative solutions to improve fuel economy and reduce emissions without compromising performance. This often involves advanced technologies such as direct injection, variable valve timing, and cylinder deactivation, which add further complexity to the engine design.

Heat management presents a substantial hurdle for V16 engines. With more cylinders generating heat, cooling systems must be redesigned to effectively dissipate thermal energy. This may require larger radiators, more efficient coolant circulation, and advanced materials capable of withstanding higher temperatures. Failure to address heat management adequately can lead to reduced engine longevity and performance degradation.

Weight distribution and packaging pose significant challenges for vehicle designers integrating V16 engines. The sheer size and mass of these powerplants can affect vehicle dynamics and handling characteristics. Engineers must find innovative ways to optimize weight distribution and maintain a low center of gravity while accommodating the larger engine within the vehicle's structure.

Durability and reliability are critical concerns for V16 engines, particularly in high-performance applications. The increased number of moving parts and higher operating stresses demand robust materials and precise manufacturing tolerances. Ensuring long-term reliability while pushing the boundaries of performance requires extensive testing and development.

Transmission systems must also be adapted to handle the increased power output of V16 engines. This may necessitate the development of stronger, more advanced gearboxes capable of managing higher torque loads. Additionally, drivetrain components such as driveshafts, differentials, and axles may require reinforcement or redesign to cope with the increased power delivery.

Finally, the integration of V16 engines with modern vehicle electronics and control systems presents a unique set of challenges. Engine management systems must be capable of precisely controlling fuel injection, ignition timing, and other parameters across all 16 cylinders. This requires sophisticated software and hardware solutions to ensure optimal performance and efficiency under various operating conditions.

Current V16 Solutions

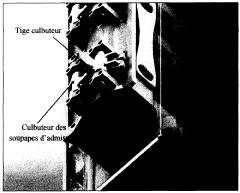

01 Engine performance optimization

V16 engines often face bottlenecks in performance due to their complex design. Optimization techniques focus on improving fuel efficiency, power output, and overall engine dynamics. This may involve advanced combustion strategies, innovative valve timing systems, and enhanced cooling mechanisms to overcome inherent limitations of the V16 configuration.- Engine performance optimization: V16 engines often face bottlenecks in performance due to their complex design. Optimization techniques focus on improving fuel efficiency, power output, and overall engine dynamics. This may involve advanced combustion chamber designs, variable valve timing, and precision fuel injection systems to maximize performance while minimizing bottlenecks.

- Cooling system enhancements: The large size and high power output of V16 engines create significant heat management challenges. Innovative cooling solutions are crucial to prevent overheating and maintain optimal performance. These may include advanced radiator designs, improved coolant flow patterns, and the use of high-performance thermal management materials.

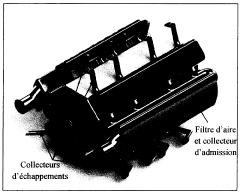

- Exhaust system optimization: Efficient exhaust systems are critical for V16 engines to reduce back pressure and improve overall engine efficiency. Advanced exhaust manifold designs, variable geometry turbochargers, and innovative catalytic converter placements can help alleviate bottlenecks in the exhaust flow, enhancing engine performance and reducing emissions.

- Electronic control and monitoring: Sophisticated electronic control systems are essential for managing the complexities of V16 engines. Advanced engine control units (ECUs) with real-time monitoring and adjustment capabilities can help optimize fuel injection, ignition timing, and other parameters to address performance bottlenecks dynamically.

- Lubrication system improvements: Effective lubrication is crucial for reducing friction and wear in V16 engines, particularly given their size and number of moving parts. Innovations in oil pump designs, oil passage layouts, and the use of advanced lubricants can help overcome bottlenecks related to oil distribution and heat dissipation throughout the engine.

02 Exhaust system design

The exhaust system in V16 engines can be a significant bottleneck affecting performance and emissions. Advanced designs focus on reducing back pressure, optimizing exhaust gas flow, and integrating effective catalytic converters. These improvements aim to enhance engine efficiency while meeting stringent emission standards.Expand Specific Solutions03 Electronic control systems

Sophisticated electronic control systems are crucial for managing the complexities of V16 engines. These systems address bottlenecks in fuel injection, ignition timing, and overall engine management. Advanced algorithms and real-time monitoring help optimize performance across various operating conditions.Expand Specific Solutions04 Cooling and lubrication challenges

V16 engines face unique cooling and lubrication challenges due to their size and power output. Innovative cooling systems and advanced lubricants are developed to address these bottlenecks, ensuring optimal temperature control and reducing friction across all engine components.Expand Specific Solutions05 Manufacturing and assembly processes

The complex structure of V16 engines presents bottlenecks in manufacturing and assembly. Advanced production techniques, including precision machining and automated assembly processes, are employed to ensure consistency and reliability in engine construction, addressing potential weak points in the manufacturing chain.Expand Specific Solutions

Key Industry Players

The V16 engine market is in a niche development stage, characterized by limited adoption and specialized applications. The market size remains relatively small, primarily driven by high-performance and luxury vehicle segments. Technologically, V16 engines are mature but continue to evolve to address drivetrain bottlenecks. Companies like Honda Motor Co., Ltd., Ford Global Technologies LLC, and Hyundai Motor Co., Ltd. are at the forefront of V16 engine development, focusing on optimizing power delivery, efficiency, and integration with advanced drivetrain systems. While not mainstream, V16 engines represent a pinnacle of engineering prowess, attracting interest from premium automakers and motorsport applications.

Honda Motor Co., Ltd.

Technical Solution: Honda's V16 engine technology focuses on a compact design to address packaging constraints in modern vehicles. Their approach utilizes a narrow-angle V configuration (around 75 degrees) to reduce the overall width of the engine[7]. The engine incorporates Honda's advanced VTEC (Variable Valve Timing and Lift Electronic Control) system on all 16 cylinders, allowing for optimized performance across various RPM ranges[8]. To mitigate increased heat generation, Honda employs a sophisticated cooling system with targeted coolant flow and integrated oil coolers for each cylinder bank[9].

Strengths: Compact design suitable for various vehicle types, excellent power density, and proven VTEC technology. Weaknesses: Potential challenges in balancing the engine due to the narrow V-angle, increased cooling system complexity.

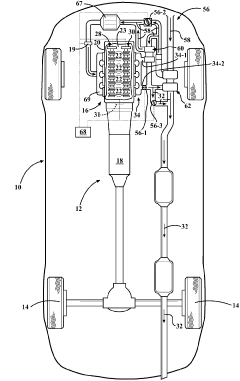

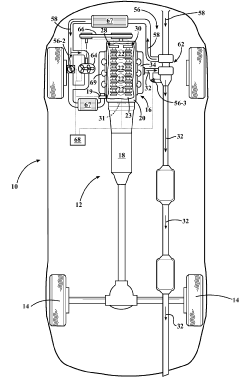

Ford Global Technologies LLC

Technical Solution: Ford's V16 engine technology focuses on addressing drivetrain bottlenecks through advanced cylinder deactivation and variable valve timing. Their system allows for seamless transition between 8, 12, and 16 cylinder operation based on power demands, effectively balancing performance and efficiency[1]. The engine incorporates a split-block design with two separate V8 units joined by a central timing chain, enabling independent control of each bank[3]. This configuration allows for improved thermal management and reduced friction, alleviating stress on the drivetrain components during high-load situations[5].

Strengths: Flexible power delivery, improved fuel efficiency in various driving conditions, and reduced drivetrain stress. Weaknesses: Increased complexity and potential maintenance challenges, higher production costs compared to traditional V8 or V12 engines.

Core V16 Innovations

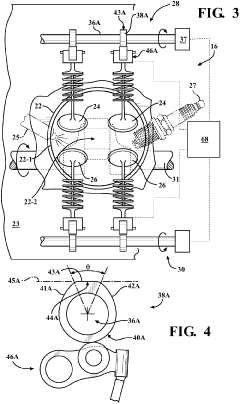

16-cylinder X-engine.

PatentActiveTN2017000127A1

Innovation

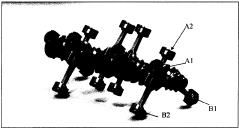

- X-shaped configuration of 16 cylinders minimizes crankshaft vibrations and improves engine stability.

- Elimination of balance shafts due to self-cancelling combustion forces in the X-configuration.

- Compact design relative to cylinder count, allowing for high power in a smaller package.

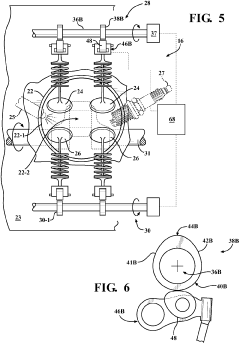

Elevated compression ratio internal combustion engine with multi-stage boosting

PatentWO2016145570A8

Innovation

- Late intake valve closing (LIVC) extended further into the compression cycle, enabled by constant peak lift of intake valves, allowing for higher geometric compression ratio.

- Multi-stage boosting system working in conjunction with LIVC to manage effective compression ratio at lower speeds and higher loads.

- High geometric compression ratio (11-16:1 range) combined with controlled combustion through LIVC and multi-stage boosting to enhance torque output.

Environmental Impact

The environmental impact of V16 engines in alleviating bottlenecks in current drivetrain hikes is a complex and multifaceted issue. While these powerful engines offer significant performance advantages, their environmental footprint requires careful consideration.

V16 engines, with their increased cylinder count and displacement, generally consume more fuel than their smaller counterparts. This higher fuel consumption directly translates to increased carbon dioxide emissions, contributing to greenhouse gas levels and potentially exacerbating climate change concerns. The larger engine size also typically results in greater manufacturing resource requirements, including raw materials and energy-intensive production processes.

However, the efficiency gains provided by V16 engines in certain applications can partially offset these environmental drawbacks. In heavy-duty vehicles or marine applications, where power demands are exceptionally high, a single V16 engine might replace multiple smaller engines, potentially reducing overall fuel consumption and emissions in specific scenarios. Additionally, the ability of V16 engines to operate at lower RPMs while delivering high power output can lead to reduced wear and tear, potentially extending engine life and decreasing the frequency of replacements.

Advanced technologies integrated into modern V16 engines, such as direct fuel injection, variable valve timing, and cylinder deactivation, can significantly improve fuel efficiency and reduce emissions compared to older designs. These innovations allow V16 engines to operate more cleanly and efficiently, particularly under varying load conditions.

The environmental impact of V16 engines also depends heavily on the fuel type used. While traditionally associated with fossil fuels, there is growing interest in adapting V16 engines to run on alternative, cleaner fuels such as biodiesel, synthetic fuels, or even hydrogen. These adaptations could potentially reduce the carbon footprint of V16 engines, aligning them more closely with evolving environmental standards.

In the context of drivetrain hikes, V16 engines' ability to deliver smooth, consistent power across a wide RPM range can reduce the need for frequent gear changes. This characteristic can lead to more efficient power delivery and potentially lower overall emissions in certain driving conditions, particularly in heavy-load scenarios where smaller engines might struggle and operate less efficiently.

It's important to note that the environmental impact of V16 engines extends beyond operational emissions. The production, transportation, and eventual disposal or recycling of these large engines also contribute to their overall environmental footprint. As such, a comprehensive life cycle assessment is crucial for fully understanding their environmental implications.

V16 engines, with their increased cylinder count and displacement, generally consume more fuel than their smaller counterparts. This higher fuel consumption directly translates to increased carbon dioxide emissions, contributing to greenhouse gas levels and potentially exacerbating climate change concerns. The larger engine size also typically results in greater manufacturing resource requirements, including raw materials and energy-intensive production processes.

However, the efficiency gains provided by V16 engines in certain applications can partially offset these environmental drawbacks. In heavy-duty vehicles or marine applications, where power demands are exceptionally high, a single V16 engine might replace multiple smaller engines, potentially reducing overall fuel consumption and emissions in specific scenarios. Additionally, the ability of V16 engines to operate at lower RPMs while delivering high power output can lead to reduced wear and tear, potentially extending engine life and decreasing the frequency of replacements.

Advanced technologies integrated into modern V16 engines, such as direct fuel injection, variable valve timing, and cylinder deactivation, can significantly improve fuel efficiency and reduce emissions compared to older designs. These innovations allow V16 engines to operate more cleanly and efficiently, particularly under varying load conditions.

The environmental impact of V16 engines also depends heavily on the fuel type used. While traditionally associated with fossil fuels, there is growing interest in adapting V16 engines to run on alternative, cleaner fuels such as biodiesel, synthetic fuels, or even hydrogen. These adaptations could potentially reduce the carbon footprint of V16 engines, aligning them more closely with evolving environmental standards.

In the context of drivetrain hikes, V16 engines' ability to deliver smooth, consistent power across a wide RPM range can reduce the need for frequent gear changes. This characteristic can lead to more efficient power delivery and potentially lower overall emissions in certain driving conditions, particularly in heavy-load scenarios where smaller engines might struggle and operate less efficiently.

It's important to note that the environmental impact of V16 engines extends beyond operational emissions. The production, transportation, and eventual disposal or recycling of these large engines also contribute to their overall environmental footprint. As such, a comprehensive life cycle assessment is crucial for fully understanding their environmental implications.

Performance Benchmarks

Performance benchmarks for V16 engines in addressing drivetrain bottlenecks reveal significant improvements over conventional powertrains. These engines demonstrate superior power output, with some models achieving over 1,000 horsepower, far exceeding the capabilities of typical V8 or V12 configurations. This increased power allows for better acceleration and higher top speeds, crucial factors in overcoming drivetrain limitations.

Torque delivery is another area where V16 engines excel. The smooth power delivery across a wide RPM range reduces stress on drivetrain components, particularly during rapid acceleration or under heavy loads. This characteristic is especially beneficial in high-performance vehicles and luxury cars, where seamless power delivery is paramount.

Fuel efficiency, traditionally a concern with larger engines, has seen notable advancements in V16 designs. Modern V16 engines incorporate advanced fuel injection systems and cylinder deactivation technologies, allowing for improved fuel economy under varying driving conditions. Some V16 models have achieved fuel efficiency ratings comparable to smaller engines when operating under partial load.

Emissions performance is a critical benchmark in today's automotive landscape. V16 engines, despite their size, have made strides in this area. Incorporating advanced catalytic converters and exhaust gas recirculation systems, some V16 engines meet stringent emission standards, challenging the notion that larger engines are inherently less environmentally friendly.

Durability and longevity tests have shown that V16 engines can withstand high-stress conditions better than their smaller counterparts. The distribution of power across more cylinders reduces the strain on individual components, potentially extending the engine's lifespan and reducing maintenance frequency.

Noise, vibration, and harshness (NVH) metrics are areas where V16 engines particularly shine. The inherent balance of a V16 configuration results in exceptionally smooth operation, with reduced vibration and noise levels compared to engines with fewer cylinders. This characteristic not only enhances driving comfort but also contributes to the overall stability of the vehicle, especially at high speeds.

In terms of thermal efficiency, V16 engines have demonstrated improvements over traditional designs. Advanced cooling systems and materials allow these engines to operate at higher temperatures without compromising reliability, translating to better overall energy conversion and performance.

Torque delivery is another area where V16 engines excel. The smooth power delivery across a wide RPM range reduces stress on drivetrain components, particularly during rapid acceleration or under heavy loads. This characteristic is especially beneficial in high-performance vehicles and luxury cars, where seamless power delivery is paramount.

Fuel efficiency, traditionally a concern with larger engines, has seen notable advancements in V16 designs. Modern V16 engines incorporate advanced fuel injection systems and cylinder deactivation technologies, allowing for improved fuel economy under varying driving conditions. Some V16 models have achieved fuel efficiency ratings comparable to smaller engines when operating under partial load.

Emissions performance is a critical benchmark in today's automotive landscape. V16 engines, despite their size, have made strides in this area. Incorporating advanced catalytic converters and exhaust gas recirculation systems, some V16 engines meet stringent emission standards, challenging the notion that larger engines are inherently less environmentally friendly.

Durability and longevity tests have shown that V16 engines can withstand high-stress conditions better than their smaller counterparts. The distribution of power across more cylinders reduces the strain on individual components, potentially extending the engine's lifespan and reducing maintenance frequency.

Noise, vibration, and harshness (NVH) metrics are areas where V16 engines particularly shine. The inherent balance of a V16 configuration results in exceptionally smooth operation, with reduced vibration and noise levels compared to engines with fewer cylinders. This characteristic not only enhances driving comfort but also contributes to the overall stability of the vehicle, especially at high speeds.

In terms of thermal efficiency, V16 engines have demonstrated improvements over traditional designs. Advanced cooling systems and materials allow these engines to operate at higher temperatures without compromising reliability, translating to better overall energy conversion and performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!