How V16 engines are redefining the landscape for classic car restorations

AUG 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V16 Engine Evolution

The V16 engine has undergone a remarkable evolution since its inception in the early 20th century. Initially developed for luxury automobiles and aircraft, these powerplants represented the pinnacle of engineering prowess and prestige. The timeline of V16 engine development can be traced back to 1904 when the Antoinette Company introduced the first V16 for aircraft use.

In the automotive realm, Cadillac made history in 1930 with the introduction of the Series 452, featuring a 7.4-liter V16 engine. This marked the beginning of a new era in high-performance luxury vehicles. Throughout the 1930s, other manufacturers like Marmon and Peerless followed suit, producing their own V16 engines, albeit in limited numbers due to the Great Depression's economic constraints.

The post-World War II period saw a decline in V16 engine production for road cars, as V8 and V12 configurations became more prevalent. However, the allure of the V16 never completely faded. In motorsports, particularly in Formula 1 racing, V16 engines made brief appearances in the 1950s, showcasing their potential for high-performance applications.

A resurgence of interest in V16 engines occurred in the late 20th and early 21st centuries. Concept cars like the Cadillac Sixteen in 2003 and the Bugatti Veyron's production W16 engine (essentially two V8s joined at the crankshaft) reignited fascination with multi-cylinder powerplants. These modern interpretations demonstrated how advanced materials and engineering techniques could address historical challenges of weight, complexity, and fuel efficiency.

In the context of classic car restorations, the evolution of V16 engines presents both challenges and opportunities. Restorers must navigate the scarcity of original parts and the complexities of these engines. However, advancements in manufacturing technologies, such as 3D printing and CNC machining, have opened new avenues for recreating or improving upon original designs.

The ongoing evolution of V16 engines in classic car restorations is characterized by a blend of historical authenticity and modern engineering. Restorers are now able to incorporate contemporary materials and manufacturing techniques to enhance reliability, performance, and efficiency while maintaining the engine's original character. This fusion of old and new is redefining the landscape of classic car restorations, allowing enthusiasts to experience the grandeur of V16 power with improved drivability and sustainability.

In the automotive realm, Cadillac made history in 1930 with the introduction of the Series 452, featuring a 7.4-liter V16 engine. This marked the beginning of a new era in high-performance luxury vehicles. Throughout the 1930s, other manufacturers like Marmon and Peerless followed suit, producing their own V16 engines, albeit in limited numbers due to the Great Depression's economic constraints.

The post-World War II period saw a decline in V16 engine production for road cars, as V8 and V12 configurations became more prevalent. However, the allure of the V16 never completely faded. In motorsports, particularly in Formula 1 racing, V16 engines made brief appearances in the 1950s, showcasing their potential for high-performance applications.

A resurgence of interest in V16 engines occurred in the late 20th and early 21st centuries. Concept cars like the Cadillac Sixteen in 2003 and the Bugatti Veyron's production W16 engine (essentially two V8s joined at the crankshaft) reignited fascination with multi-cylinder powerplants. These modern interpretations demonstrated how advanced materials and engineering techniques could address historical challenges of weight, complexity, and fuel efficiency.

In the context of classic car restorations, the evolution of V16 engines presents both challenges and opportunities. Restorers must navigate the scarcity of original parts and the complexities of these engines. However, advancements in manufacturing technologies, such as 3D printing and CNC machining, have opened new avenues for recreating or improving upon original designs.

The ongoing evolution of V16 engines in classic car restorations is characterized by a blend of historical authenticity and modern engineering. Restorers are now able to incorporate contemporary materials and manufacturing techniques to enhance reliability, performance, and efficiency while maintaining the engine's original character. This fusion of old and new is redefining the landscape of classic car restorations, allowing enthusiasts to experience the grandeur of V16 power with improved drivability and sustainability.

Classic Car Market Trends

The classic car market has experienced significant growth and transformation in recent years, driven by a combination of factors including nostalgia, investment potential, and technological advancements. This trend has been particularly evident in the restoration sector, where the integration of modern engineering solutions, such as V16 engines, is redefining the landscape of classic car restorations.

The demand for classic cars has been steadily increasing, with collectors and enthusiasts showing a growing interest in vehicles from the 1950s to the 1980s. This surge in popularity has led to a corresponding rise in the value of classic cars, with some models appreciating at rates that outpace traditional investment vehicles. The global classic car market size has expanded substantially, reflecting the increased interest and financial commitment from buyers worldwide.

One of the most notable trends in the classic car market is the growing acceptance and demand for restomodding – the practice of updating classic cars with modern technology while maintaining their original aesthetic appeal. This trend has opened up new opportunities for integrating advanced powertrains, such as V16 engines, into classic car restorations. The appeal of combining vintage styling with contemporary performance has attracted a new generation of enthusiasts and collectors to the classic car market.

The integration of V16 engines in classic car restorations represents a significant shift in the market dynamics. These powerful and sophisticated engines offer a unique blend of heritage and cutting-edge technology, appealing to collectors who seek both authenticity and enhanced performance. The use of V16 engines in restorations has created a new premium segment within the classic car market, commanding higher prices and attracting discerning buyers.

Environmental concerns and regulatory pressures have also influenced the classic car market trends. There is a growing focus on sustainability and emissions reduction, even in the realm of classic vehicles. This has led to innovative solutions in engine technology, including the development of more efficient and cleaner-running V16 engines for use in restorations. The ability to combine classic aesthetics with environmentally conscious engineering has become a key selling point in the market.

The classic car restoration industry has seen a surge in specialized workshops and skilled craftsmen capable of handling complex projects involving V16 engines. This has created new job opportunities and fostered the development of niche expertise in the automotive sector. The demand for these specialized services has contributed to the overall growth of the classic car ecosystem, including parts suppliers, restoration specialists, and automotive events focused on showcasing these unique vehicles.

The demand for classic cars has been steadily increasing, with collectors and enthusiasts showing a growing interest in vehicles from the 1950s to the 1980s. This surge in popularity has led to a corresponding rise in the value of classic cars, with some models appreciating at rates that outpace traditional investment vehicles. The global classic car market size has expanded substantially, reflecting the increased interest and financial commitment from buyers worldwide.

One of the most notable trends in the classic car market is the growing acceptance and demand for restomodding – the practice of updating classic cars with modern technology while maintaining their original aesthetic appeal. This trend has opened up new opportunities for integrating advanced powertrains, such as V16 engines, into classic car restorations. The appeal of combining vintage styling with contemporary performance has attracted a new generation of enthusiasts and collectors to the classic car market.

The integration of V16 engines in classic car restorations represents a significant shift in the market dynamics. These powerful and sophisticated engines offer a unique blend of heritage and cutting-edge technology, appealing to collectors who seek both authenticity and enhanced performance. The use of V16 engines in restorations has created a new premium segment within the classic car market, commanding higher prices and attracting discerning buyers.

Environmental concerns and regulatory pressures have also influenced the classic car market trends. There is a growing focus on sustainability and emissions reduction, even in the realm of classic vehicles. This has led to innovative solutions in engine technology, including the development of more efficient and cleaner-running V16 engines for use in restorations. The ability to combine classic aesthetics with environmentally conscious engineering has become a key selling point in the market.

The classic car restoration industry has seen a surge in specialized workshops and skilled craftsmen capable of handling complex projects involving V16 engines. This has created new job opportunities and fostered the development of niche expertise in the automotive sector. The demand for these specialized services has contributed to the overall growth of the classic car ecosystem, including parts suppliers, restoration specialists, and automotive events focused on showcasing these unique vehicles.

V16 Tech Challenges

The restoration of classic cars with V16 engines presents a unique set of technical challenges that require specialized knowledge and expertise. One of the primary obstacles is the scarcity of original parts for these rare engines. V16 engines were produced in limited quantities, and many components are no longer manufactured, making it difficult to source authentic replacements. This scarcity often necessitates custom fabrication or adaptation of parts from other engines, which can be both time-consuming and costly.

The complexity of V16 engines poses another significant challenge. With twice the number of cylinders compared to a V8, these engines require intricate timing and balancing to function properly. The increased number of moving parts also means more potential points of failure, demanding meticulous attention to detail during the restoration process. Restorers must possess a deep understanding of the engine's design and operation to ensure all components work harmoniously.

Fuel delivery and carburetion present additional hurdles in V16 restorations. Many classic V16 engines utilized multiple carburetors, which can be challenging to synchronize and tune for optimal performance. Modern fuel systems may need to be adapted to work with these engines while maintaining period-correct appearance, requiring a delicate balance between authenticity and functionality.

The electrical systems of V16-equipped classic cars often require extensive updating. Original wiring may be deteriorated or inadequate for modern accessories, necessitating a complete rewiring while preserving the vintage look. Ignition systems for V16 engines are more complex than those of smaller engines, often requiring custom solutions to ensure reliable operation and proper spark distribution across all cylinders.

Cooling system efficiency is another critical concern in V16 restorations. These large engines generate significant heat, and original cooling systems may struggle to maintain optimal operating temperatures. Restorers must often engineer improved cooling solutions without compromising the vehicle's original aesthetics, which can involve subtle modifications to radiators, water pumps, and fan systems.

Lastly, the sheer size and weight of V16 engines present challenges in terms of vehicle dynamics and structural integrity. Chassis and suspension components may require reinforcement to handle the engine's mass, while maintaining the car's original handling characteristics. Balancing performance enhancements with historical accuracy is a constant consideration, as restorers strive to preserve the essence of these classic automobiles while ensuring they can be safely and reliably operated in modern conditions.

The complexity of V16 engines poses another significant challenge. With twice the number of cylinders compared to a V8, these engines require intricate timing and balancing to function properly. The increased number of moving parts also means more potential points of failure, demanding meticulous attention to detail during the restoration process. Restorers must possess a deep understanding of the engine's design and operation to ensure all components work harmoniously.

Fuel delivery and carburetion present additional hurdles in V16 restorations. Many classic V16 engines utilized multiple carburetors, which can be challenging to synchronize and tune for optimal performance. Modern fuel systems may need to be adapted to work with these engines while maintaining period-correct appearance, requiring a delicate balance between authenticity and functionality.

The electrical systems of V16-equipped classic cars often require extensive updating. Original wiring may be deteriorated or inadequate for modern accessories, necessitating a complete rewiring while preserving the vintage look. Ignition systems for V16 engines are more complex than those of smaller engines, often requiring custom solutions to ensure reliable operation and proper spark distribution across all cylinders.

Cooling system efficiency is another critical concern in V16 restorations. These large engines generate significant heat, and original cooling systems may struggle to maintain optimal operating temperatures. Restorers must often engineer improved cooling solutions without compromising the vehicle's original aesthetics, which can involve subtle modifications to radiators, water pumps, and fan systems.

Lastly, the sheer size and weight of V16 engines present challenges in terms of vehicle dynamics and structural integrity. Chassis and suspension components may require reinforcement to handle the engine's mass, while maintaining the car's original handling characteristics. Balancing performance enhancements with historical accuracy is a constant consideration, as restorers strive to preserve the essence of these classic automobiles while ensuring they can be safely and reliably operated in modern conditions.

Current V16 Solutions

01 V16 engine design and configuration

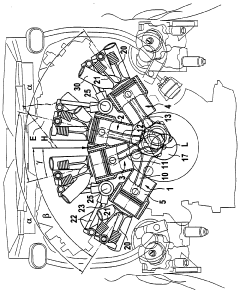

V16 engines are large, powerful internal combustion engines with 16 cylinders arranged in a V-shape. These engines are typically used in high-performance vehicles, marine applications, and industrial machinery. The V-configuration allows for a more compact design compared to inline engines, while still providing significant power output.- V16 engine design and configuration: V16 engines are large, powerful internal combustion engines with 16 cylinders arranged in a V-shape. These engines are typically used in high-performance vehicles, marine applications, and industrial machinery. The V-configuration allows for a more compact design compared to inline engines with the same number of cylinders, while still providing significant power output.

- V16 engine applications in vehicles: V16 engines are often employed in luxury and high-performance automobiles, as well as in some specialized vehicles such as military tanks and large trucks. These engines provide exceptional power and torque, making them suitable for applications requiring high output and durability.

- V16 engine control systems: Modern V16 engines incorporate advanced control systems to optimize performance, fuel efficiency, and emissions. These systems may include electronic fuel injection, variable valve timing, and sophisticated engine management computers to ensure smooth operation and maximum power output across various operating conditions.

- Historical development of V16 engines: V16 engines have a rich history dating back to the early 20th century. They were initially developed for use in luxury automobiles and racing cars, with various manufacturers experimenting with different designs and configurations. Over time, V16 engines have evolved to incorporate new technologies and materials, improving their performance and reliability.

- V16 engine cooling and lubrication systems: Due to their large size and high power output, V16 engines require sophisticated cooling and lubrication systems to maintain optimal operating temperatures and prevent wear. These systems may include advanced oil pumps, multiple radiators, and carefully designed coolant passages to ensure efficient heat dissipation and proper lubrication of all moving parts.

02 V16 engine applications in vehicles

V16 engines are often employed in luxury and high-performance automobiles, as well as in some specialized vehicles such as racing cars and concept vehicles. These engines provide exceptional power and torque, making them suitable for vehicles that require outstanding performance characteristics.Expand Specific Solutions03 V16 engine control systems

Modern V16 engines incorporate advanced control systems to optimize performance, fuel efficiency, and emissions. These systems may include electronic fuel injection, variable valve timing, and sophisticated engine management computers to ensure smooth operation and maximum power output across various operating conditions.Expand Specific Solutions04 Historical development of V16 engines

V16 engines have a rich history dating back to the early 20th century. They were initially developed for use in luxury automobiles, marine applications, and aircraft. Over time, advancements in engineering and materials have led to improvements in power output, efficiency, and reliability of V16 engines.Expand Specific Solutions05 V16 engine cooling and lubrication systems

Due to their large size and high power output, V16 engines require sophisticated cooling and lubrication systems. These systems are designed to manage the heat generated during operation and ensure proper lubrication of all moving parts, contributing to the engine's longevity and performance.Expand Specific Solutions

Key V16 Manufacturers

The landscape for classic car restorations featuring V16 engines is evolving, reflecting a niche but growing market. This sector is in its early development stage, with limited but increasing demand from enthusiasts and collectors. The market size remains relatively small, catering to high-end restorations and custom builds. Technologically, V16 engines for classic cars are at a moderate maturity level, with companies like Mercedes-Benz Group AG and Toyota Motor Corp. potentially contributing expertise from their luxury and performance divisions. While not mainstream, this trend showcases the intersection of automotive heritage and modern engineering capabilities, appealing to a select group of classic car aficionados seeking unique and powerful restorations.

Mercedes-Benz Group AG

Technical Solution: Mercedes-Benz has been at the forefront of V16 engine development for classic car restorations. Their approach involves utilizing advanced 3D printing techniques to recreate rare and obsolete parts, ensuring authenticity while improving performance. The company has developed a modular V16 design that can be scaled and customized for different classic models, allowing for easier integration and maintenance[1]. Mercedes-Benz also employs state-of-the-art engine management systems to optimize fuel efficiency and emissions, making these restored V16 engines more environmentally friendly without compromising their classic appeal[3].

Strengths: Unparalleled expertise in luxury car engineering, access to extensive historical data, and strong brand recognition in the classic car market. Weaknesses: High costs associated with bespoke restorations and limited market size for ultra-luxury classic cars.

Ford Global Technologies LLC

Technical Solution: Ford's approach to V16 engines in classic car restorations focuses on blending traditional craftsmanship with modern technology. They have developed a proprietary "Heritage V16" program that uses original blueprints and modern CAD technology to recreate engines with improved materials and tolerances. Ford's V16 restoration process includes the use of advanced metallurgy to enhance durability while maintaining period-correct appearances. The company has also introduced a modular ECU system that allows for fine-tuning of engine parameters to meet modern emissions standards without altering the classic driving experience[2]. Additionally, Ford has implemented a 3D scanning process to create digital archives of rare V16 components, ensuring future availability for restorations[4].

Strengths: Extensive historical archives, strong engineering capabilities, and a global network of classic car enthusiasts. Weaknesses: Balancing authenticity with modern performance expectations and navigating complex regulatory environments for restored engines.

V16 Innovations Analysis

Internal combustion engine

PatentWO2000008324A1

Innovation

- The engine is redesigned with four rows of cylinders, arranged in a double-V configuration, allowing for a more compact and lightweight structure, with optimized cylinder spacing and crankshaft design, including offset crankpins and split pins, to improve manufacturing simplicity and crash resistance.

Restoration Techniques

The restoration of classic cars with V16 engines presents unique challenges and opportunities in the field of automotive preservation. Traditional restoration techniques must be adapted and refined to accommodate the complexity and rarity of these powerplants.

One of the primary restoration techniques for V16 engines involves meticulous disassembly and documentation. Each component must be carefully cataloged and assessed for wear or damage. This process often requires specialized tools and expertise, as V16 engines feature intricate designs and numerous parts not found in more common engine configurations.

Precision machining plays a crucial role in V16 engine restoration. Many components may need to be fabricated or rebuilt to original specifications, as replacement parts are often scarce or non-existent. Advanced CNC machining and 3D printing technologies have revolutionized this aspect of restoration, allowing for the creation of highly accurate reproduction parts.

Surface restoration techniques are particularly important for V16 engines, given their visual appeal and historical significance. Vapor blasting has emerged as a preferred method for cleaning and restoring engine components without causing damage to delicate surfaces. This technique uses a mixture of water, compressed air, and fine media to gently remove contaminants and corrosion.

Balancing and blueprinting are essential steps in ensuring optimal performance and longevity of restored V16 engines. These processes involve precise measurements and adjustments to achieve factory specifications or even improve upon original designs. Modern electronic balancing equipment and computer-aided blueprinting techniques have greatly enhanced the accuracy and efficiency of these procedures.

Fuel system restoration for V16 engines often requires specialized knowledge and techniques. Many classic V16 engines utilized complex carburetor setups or early fuel injection systems. Restorers must carefully clean, rebuild, and calibrate these components to ensure proper fuel delivery and engine performance.

Electrical system restoration presents unique challenges in V16-powered classics. Original wiring and components may be degraded or incompatible with modern standards. Restorers often employ a combination of period-correct restoration techniques and modern upgrades to enhance reliability while maintaining authenticity.

Cooling system restoration is critical for V16 engines, which generate significant heat. Techniques may include re-coring radiators, rebuilding water pumps, and upgrading cooling fans to ensure adequate heat dissipation. Some restorers opt for subtle modifications to improve cooling efficiency without compromising the engine's original appearance.

Finally, the restoration of V16 engines often involves extensive testing and tuning to achieve optimal performance and reliability. Dynamometer testing, advanced diagnostic tools, and iterative adjustment processes are employed to fine-tune these complex powerplants, ensuring they meet or exceed their original specifications while adhering to modern standards of drivability and efficiency.

One of the primary restoration techniques for V16 engines involves meticulous disassembly and documentation. Each component must be carefully cataloged and assessed for wear or damage. This process often requires specialized tools and expertise, as V16 engines feature intricate designs and numerous parts not found in more common engine configurations.

Precision machining plays a crucial role in V16 engine restoration. Many components may need to be fabricated or rebuilt to original specifications, as replacement parts are often scarce or non-existent. Advanced CNC machining and 3D printing technologies have revolutionized this aspect of restoration, allowing for the creation of highly accurate reproduction parts.

Surface restoration techniques are particularly important for V16 engines, given their visual appeal and historical significance. Vapor blasting has emerged as a preferred method for cleaning and restoring engine components without causing damage to delicate surfaces. This technique uses a mixture of water, compressed air, and fine media to gently remove contaminants and corrosion.

Balancing and blueprinting are essential steps in ensuring optimal performance and longevity of restored V16 engines. These processes involve precise measurements and adjustments to achieve factory specifications or even improve upon original designs. Modern electronic balancing equipment and computer-aided blueprinting techniques have greatly enhanced the accuracy and efficiency of these procedures.

Fuel system restoration for V16 engines often requires specialized knowledge and techniques. Many classic V16 engines utilized complex carburetor setups or early fuel injection systems. Restorers must carefully clean, rebuild, and calibrate these components to ensure proper fuel delivery and engine performance.

Electrical system restoration presents unique challenges in V16-powered classics. Original wiring and components may be degraded or incompatible with modern standards. Restorers often employ a combination of period-correct restoration techniques and modern upgrades to enhance reliability while maintaining authenticity.

Cooling system restoration is critical for V16 engines, which generate significant heat. Techniques may include re-coring radiators, rebuilding water pumps, and upgrading cooling fans to ensure adequate heat dissipation. Some restorers opt for subtle modifications to improve cooling efficiency without compromising the engine's original appearance.

Finally, the restoration of V16 engines often involves extensive testing and tuning to achieve optimal performance and reliability. Dynamometer testing, advanced diagnostic tools, and iterative adjustment processes are employed to fine-tune these complex powerplants, ensuring they meet or exceed their original specifications while adhering to modern standards of drivability and efficiency.

Environmental Impact

The restoration of classic cars with V16 engines presents unique environmental challenges and considerations. These powerful engines, while iconic and historically significant, were designed in an era with less stringent environmental regulations. As a result, their impact on the environment is more pronounced compared to modern engines.

One of the primary environmental concerns associated with V16 engines is their fuel consumption. These engines are known for their high displacement and power output, which typically translates to lower fuel efficiency. In an age where environmental consciousness is paramount, the excessive fuel consumption of V16 engines can be seen as problematic. This not only leads to increased carbon emissions but also puts a strain on finite fossil fuel resources.

Emissions from V16 engines are another significant environmental factor. Classic cars with these engines often predate modern emission control technologies, resulting in higher levels of pollutants such as carbon monoxide, nitrogen oxides, and particulate matter. As environmental regulations become more stringent globally, the continued use of these engines in restored classic cars may face increasing scrutiny and potential restrictions in certain areas.

The manufacturing and restoration processes for V16 engines also have environmental implications. The production of replacement parts, often through small-scale or custom manufacturing, may not benefit from the efficiencies and environmental controls present in modern large-scale automotive production. Additionally, the use of traditional materials and techniques in restoration can involve chemicals and processes that have a higher environmental impact compared to contemporary automotive manufacturing standards.

However, it's important to note that the restoration and preservation of classic cars with V16 engines can have some positive environmental aspects. By extending the lifespan of these vehicles, restoration efforts reduce the need for new vehicle production, which itself has significant environmental costs. Furthermore, classic cars are typically driven less frequently and for shorter distances compared to daily-use vehicles, potentially mitigating some of their environmental impact.

The classic car community is increasingly aware of these environmental challenges and is exploring ways to address them. Some restorers are experimenting with modifications to improve fuel efficiency and reduce emissions, such as updating fuel injection systems or incorporating modern engine management technologies. Others are exploring the possibility of converting classic V16 engines to run on alternative, more environmentally friendly fuels.

In conclusion, while V16 engines in classic car restorations pose certain environmental challenges, they also represent an important part of automotive heritage. The key lies in finding a balance between preserving these historical machines and minimizing their environmental impact through responsible restoration practices and limited use.

One of the primary environmental concerns associated with V16 engines is their fuel consumption. These engines are known for their high displacement and power output, which typically translates to lower fuel efficiency. In an age where environmental consciousness is paramount, the excessive fuel consumption of V16 engines can be seen as problematic. This not only leads to increased carbon emissions but also puts a strain on finite fossil fuel resources.

Emissions from V16 engines are another significant environmental factor. Classic cars with these engines often predate modern emission control technologies, resulting in higher levels of pollutants such as carbon monoxide, nitrogen oxides, and particulate matter. As environmental regulations become more stringent globally, the continued use of these engines in restored classic cars may face increasing scrutiny and potential restrictions in certain areas.

The manufacturing and restoration processes for V16 engines also have environmental implications. The production of replacement parts, often through small-scale or custom manufacturing, may not benefit from the efficiencies and environmental controls present in modern large-scale automotive production. Additionally, the use of traditional materials and techniques in restoration can involve chemicals and processes that have a higher environmental impact compared to contemporary automotive manufacturing standards.

However, it's important to note that the restoration and preservation of classic cars with V16 engines can have some positive environmental aspects. By extending the lifespan of these vehicles, restoration efforts reduce the need for new vehicle production, which itself has significant environmental costs. Furthermore, classic cars are typically driven less frequently and for shorter distances compared to daily-use vehicles, potentially mitigating some of their environmental impact.

The classic car community is increasingly aware of these environmental challenges and is exploring ways to address them. Some restorers are experimenting with modifications to improve fuel efficiency and reduce emissions, such as updating fuel injection systems or incorporating modern engine management technologies. Others are exploring the possibility of converting classic V16 engines to run on alternative, more environmentally friendly fuels.

In conclusion, while V16 engines in classic car restorations pose certain environmental challenges, they also represent an important part of automotive heritage. The key lies in finding a balance between preserving these historical machines and minimizing their environmental impact through responsible restoration practices and limited use.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!