How Vacuum Pumps Aid Advanced Membrane Technology Development

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vacuum Pump Tech Evolution

Vacuum pump technology has undergone significant evolution since its inception, playing a crucial role in the development of advanced membrane technologies. The journey began with simple mechanical pumps in the early 20th century, which provided basic vacuum capabilities for industrial processes. These pumps, while effective for their time, had limitations in achieving high vacuum levels and maintaining consistent performance.

The mid-20th century saw the introduction of oil-sealed rotary vane pumps, which marked a significant improvement in vacuum technology. These pumps offered better vacuum levels and more reliable operation, making them suitable for a wider range of applications, including early membrane separation processes. However, the potential for oil contamination remained a concern in sensitive applications.

The 1960s and 1970s brought about the development of turbomolecular pumps, which revolutionized high-vacuum applications. These pumps utilized high-speed rotors to impart momentum to gas molecules, achieving much higher vacuum levels than their predecessors. This advancement was particularly beneficial for membrane technology research, allowing for more precise control of gas environments during membrane fabrication and testing.

In the 1980s and 1990s, dry pumps emerged as a solution to the oil contamination issues associated with traditional vacuum pumps. These oil-free pumps, such as scroll pumps and diaphragm pumps, provided clean vacuum environments crucial for the production of high-purity membranes used in advanced separation processes. The elimination of oil contamination risk opened up new possibilities in membrane technology, particularly in the semiconductor and pharmaceutical industries.

The turn of the millennium saw the integration of smart technologies into vacuum pump systems. Computerized control systems and sensors allowed for real-time monitoring and adjustment of pump performance, enhancing the precision and reliability of vacuum environments. This development was particularly beneficial for membrane technology, as it enabled more accurate control of pressure differentials across membranes during both research and production processes.

Recent years have witnessed the advent of energy-efficient and environmentally friendly vacuum pump technologies. Variable speed drives and advanced materials have led to pumps that consume less energy while maintaining high performance. Additionally, the development of hybrid pump systems, combining different pump technologies, has allowed for optimized vacuum solutions tailored to specific membrane technology applications.

The ongoing evolution of vacuum pump technology continues to push the boundaries of what is possible in membrane science. Current research focuses on further improving energy efficiency, reducing pump size, and enhancing vacuum quality. These advancements are expected to enable the development of even more sophisticated membrane technologies, potentially revolutionizing fields such as water purification, gas separation, and biomedical applications.

The mid-20th century saw the introduction of oil-sealed rotary vane pumps, which marked a significant improvement in vacuum technology. These pumps offered better vacuum levels and more reliable operation, making them suitable for a wider range of applications, including early membrane separation processes. However, the potential for oil contamination remained a concern in sensitive applications.

The 1960s and 1970s brought about the development of turbomolecular pumps, which revolutionized high-vacuum applications. These pumps utilized high-speed rotors to impart momentum to gas molecules, achieving much higher vacuum levels than their predecessors. This advancement was particularly beneficial for membrane technology research, allowing for more precise control of gas environments during membrane fabrication and testing.

In the 1980s and 1990s, dry pumps emerged as a solution to the oil contamination issues associated with traditional vacuum pumps. These oil-free pumps, such as scroll pumps and diaphragm pumps, provided clean vacuum environments crucial for the production of high-purity membranes used in advanced separation processes. The elimination of oil contamination risk opened up new possibilities in membrane technology, particularly in the semiconductor and pharmaceutical industries.

The turn of the millennium saw the integration of smart technologies into vacuum pump systems. Computerized control systems and sensors allowed for real-time monitoring and adjustment of pump performance, enhancing the precision and reliability of vacuum environments. This development was particularly beneficial for membrane technology, as it enabled more accurate control of pressure differentials across membranes during both research and production processes.

Recent years have witnessed the advent of energy-efficient and environmentally friendly vacuum pump technologies. Variable speed drives and advanced materials have led to pumps that consume less energy while maintaining high performance. Additionally, the development of hybrid pump systems, combining different pump technologies, has allowed for optimized vacuum solutions tailored to specific membrane technology applications.

The ongoing evolution of vacuum pump technology continues to push the boundaries of what is possible in membrane science. Current research focuses on further improving energy efficiency, reducing pump size, and enhancing vacuum quality. These advancements are expected to enable the development of even more sophisticated membrane technologies, potentially revolutionizing fields such as water purification, gas separation, and biomedical applications.

Membrane Market Demand

The membrane technology market has experienced significant growth in recent years, driven by increasing demand across various industries. The global membrane market is projected to reach substantial value by 2025, with a compound annual growth rate (CAGR) exceeding 7% during the forecast period. This growth is primarily attributed to the rising need for water and wastewater treatment solutions, as well as applications in food and beverage processing, pharmaceuticals, and industrial separations.

In the water treatment sector, membrane technology plays a crucial role in addressing global water scarcity issues. The demand for clean water in both developed and developing countries has led to increased adoption of membrane-based filtration systems. Reverse osmosis (RO) membranes, in particular, have gained prominence in desalination plants and municipal water treatment facilities. The growing emphasis on water reuse and recycling in industrial processes has further boosted the demand for membrane technologies.

The food and beverage industry has emerged as another significant driver for membrane market growth. Membrane filtration processes are widely used for concentration, purification, and separation of various food products. The dairy industry, for instance, relies heavily on membrane technology for milk processing, whey concentration, and cheese production. Additionally, the beverage sector utilizes membranes for clarification and sterilization of juices, wines, and other drinks.

In the pharmaceutical and biotechnology sectors, membrane technology has become indispensable for drug purification, protein separation, and sterile filtration processes. The increasing focus on biopharmaceuticals and personalized medicine has further accelerated the demand for advanced membrane solutions in these industries. Membrane-based processes offer advantages such as high selectivity, reduced energy consumption, and improved product quality, making them attractive for pharmaceutical manufacturers.

The industrial gas separation market has also witnessed growing adoption of membrane technology. Applications in hydrogen recovery, carbon dioxide capture, and nitrogen generation have gained traction due to their energy efficiency and lower operational costs compared to traditional separation methods. As industries strive to reduce their carbon footprint and improve process efficiency, the demand for membrane-based gas separation systems is expected to rise.

Geographically, Asia-Pacific region is anticipated to be the fastest-growing market for membrane technology, driven by rapid industrialization, urbanization, and increasing environmental regulations. North America and Europe continue to be significant markets, with a focus on upgrading existing infrastructure and adopting advanced membrane solutions for various applications.

The market demand for membrane technology is further propelled by ongoing research and development efforts to enhance membrane performance, durability, and cost-effectiveness. Innovations in materials science, such as the development of novel polymers and nanocomposites, are expected to expand the application scope of membrane technology and drive market growth in the coming years.

In the water treatment sector, membrane technology plays a crucial role in addressing global water scarcity issues. The demand for clean water in both developed and developing countries has led to increased adoption of membrane-based filtration systems. Reverse osmosis (RO) membranes, in particular, have gained prominence in desalination plants and municipal water treatment facilities. The growing emphasis on water reuse and recycling in industrial processes has further boosted the demand for membrane technologies.

The food and beverage industry has emerged as another significant driver for membrane market growth. Membrane filtration processes are widely used for concentration, purification, and separation of various food products. The dairy industry, for instance, relies heavily on membrane technology for milk processing, whey concentration, and cheese production. Additionally, the beverage sector utilizes membranes for clarification and sterilization of juices, wines, and other drinks.

In the pharmaceutical and biotechnology sectors, membrane technology has become indispensable for drug purification, protein separation, and sterile filtration processes. The increasing focus on biopharmaceuticals and personalized medicine has further accelerated the demand for advanced membrane solutions in these industries. Membrane-based processes offer advantages such as high selectivity, reduced energy consumption, and improved product quality, making them attractive for pharmaceutical manufacturers.

The industrial gas separation market has also witnessed growing adoption of membrane technology. Applications in hydrogen recovery, carbon dioxide capture, and nitrogen generation have gained traction due to their energy efficiency and lower operational costs compared to traditional separation methods. As industries strive to reduce their carbon footprint and improve process efficiency, the demand for membrane-based gas separation systems is expected to rise.

Geographically, Asia-Pacific region is anticipated to be the fastest-growing market for membrane technology, driven by rapid industrialization, urbanization, and increasing environmental regulations. North America and Europe continue to be significant markets, with a focus on upgrading existing infrastructure and adopting advanced membrane solutions for various applications.

The market demand for membrane technology is further propelled by ongoing research and development efforts to enhance membrane performance, durability, and cost-effectiveness. Innovations in materials science, such as the development of novel polymers and nanocomposites, are expected to expand the application scope of membrane technology and drive market growth in the coming years.

Vacuum Pump Challenges

Vacuum pumps play a crucial role in the development of advanced membrane technology, but they also face several challenges that can impact their performance and efficiency. One of the primary challenges is maintaining consistent vacuum levels across large membrane surfaces. As membrane technology advances, the size and complexity of membrane systems increase, requiring vacuum pumps to operate over larger areas while maintaining uniform pressure distribution.

Another significant challenge is the prevention of contamination. Membrane processes often involve sensitive materials and delicate structures that can be easily compromised by impurities. Vacuum pumps must be designed and operated in a way that minimizes the risk of introducing contaminants into the system, which can be particularly challenging in industrial settings where environmental factors are less controlled.

The energy efficiency of vacuum pumps is an ongoing concern in membrane technology development. As the scale of membrane operations grows, so does the energy demand for maintaining the required vacuum levels. Improving the energy efficiency of vacuum pumps without compromising their performance is a key challenge that researchers and engineers are actively addressing.

Durability and reliability of vacuum pumps under continuous operation is another critical issue. Membrane technology applications often require long periods of uninterrupted vacuum, putting significant stress on pump components. Developing pumps that can withstand extended use while maintaining consistent performance is essential for the advancement of membrane technology.

The need for precise control and automation presents additional challenges. Advanced membrane processes often require dynamic vacuum adjustments based on real-time process parameters. Integrating vacuum pumps with sophisticated control systems and ensuring their responsiveness to rapid changes in operating conditions is a complex task that demands ongoing innovation.

Furthermore, the compatibility of vacuum pumps with different membrane materials and configurations poses a challenge. As new membrane materials are developed, vacuum pump designs must evolve to accommodate their specific requirements, such as chemical resistance or temperature sensitivity.

Lastly, the scalability of vacuum pump technology is a significant hurdle in the progression of membrane technology. As membrane applications expand from laboratory scale to industrial production, vacuum pumps must be scaled up accordingly while maintaining their efficiency and effectiveness. This scaling process often reveals new challenges that were not apparent at smaller scales, requiring continuous refinement and innovation in vacuum pump design and operation.

Another significant challenge is the prevention of contamination. Membrane processes often involve sensitive materials and delicate structures that can be easily compromised by impurities. Vacuum pumps must be designed and operated in a way that minimizes the risk of introducing contaminants into the system, which can be particularly challenging in industrial settings where environmental factors are less controlled.

The energy efficiency of vacuum pumps is an ongoing concern in membrane technology development. As the scale of membrane operations grows, so does the energy demand for maintaining the required vacuum levels. Improving the energy efficiency of vacuum pumps without compromising their performance is a key challenge that researchers and engineers are actively addressing.

Durability and reliability of vacuum pumps under continuous operation is another critical issue. Membrane technology applications often require long periods of uninterrupted vacuum, putting significant stress on pump components. Developing pumps that can withstand extended use while maintaining consistent performance is essential for the advancement of membrane technology.

The need for precise control and automation presents additional challenges. Advanced membrane processes often require dynamic vacuum adjustments based on real-time process parameters. Integrating vacuum pumps with sophisticated control systems and ensuring their responsiveness to rapid changes in operating conditions is a complex task that demands ongoing innovation.

Furthermore, the compatibility of vacuum pumps with different membrane materials and configurations poses a challenge. As new membrane materials are developed, vacuum pump designs must evolve to accommodate their specific requirements, such as chemical resistance or temperature sensitivity.

Lastly, the scalability of vacuum pump technology is a significant hurdle in the progression of membrane technology. As membrane applications expand from laboratory scale to industrial production, vacuum pumps must be scaled up accordingly while maintaining their efficiency and effectiveness. This scaling process often reveals new challenges that were not apparent at smaller scales, requiring continuous refinement and innovation in vacuum pump design and operation.

Current Vacuum Solutions

01 Improved vacuum pump designs

Various innovations in vacuum pump designs aim to enhance efficiency and performance. These improvements include novel rotor configurations, advanced sealing mechanisms, and optimized fluid flow paths. Such designs can lead to increased pumping speeds, better vacuum levels, and improved energy efficiency.- Improved vacuum pump designs: Various innovations in vacuum pump designs aim to enhance efficiency and performance. These improvements include novel rotor configurations, advanced sealing mechanisms, and optimized flow paths. Such designs can lead to increased pumping speed, better vacuum levels, and reduced power consumption.

- Control systems for vacuum pumps: Advanced control systems are developed to optimize vacuum pump operation. These systems may include intelligent algorithms, sensor integration, and adaptive control strategies. They can adjust pump parameters in real-time, monitor performance, and ensure optimal operation under varying conditions.

- Energy-efficient vacuum pump technologies: Focus on developing energy-efficient vacuum pump technologies to reduce power consumption and operational costs. This includes the use of variable speed drives, energy recovery systems, and innovative motor designs. These technologies aim to maintain high performance while minimizing energy usage.

- Vacuum pump maintenance and diagnostics: Advancements in maintenance techniques and diagnostic tools for vacuum pumps. This includes the development of predictive maintenance systems, remote monitoring capabilities, and easy-to-service designs. These innovations aim to reduce downtime, extend pump life, and improve overall reliability.

- Application-specific vacuum pump solutions: Tailored vacuum pump designs for specific applications such as semiconductor manufacturing, food processing, or medical equipment. These specialized pumps incorporate features like contamination control, chemical resistance, or ultra-high vacuum capabilities to meet the unique requirements of different industries.

02 Control systems for vacuum pumps

Advanced control systems are developed to optimize vacuum pump operation. These systems may include intelligent algorithms, sensors, and feedback mechanisms to adjust pump parameters in real-time. Such controls can enhance pump performance, reduce energy consumption, and extend equipment lifespan.Expand Specific Solutions03 Vacuum pump cooling solutions

Innovative cooling solutions are implemented to manage heat generation in vacuum pumps. These may include advanced heat exchanger designs, novel cooling fluid circulation systems, or the use of thermally conductive materials. Effective cooling can improve pump efficiency and reliability, especially in high-demand applications.Expand Specific Solutions04 Vacuum pump noise reduction

Techniques are developed to minimize noise and vibration in vacuum pump operation. These may include acoustic enclosures, vibration dampening systems, or redesigned components to reduce mechanical noise. Noise reduction can improve the working environment and extend the pump's operational life.Expand Specific Solutions05 Vacuum pump maintenance and diagnostics

Advanced maintenance and diagnostic tools are created to support vacuum pump operation. These may include predictive maintenance algorithms, remote monitoring systems, or integrated sensors for real-time performance analysis. Such tools can help prevent unexpected downtime, optimize maintenance schedules, and extend equipment lifespan.Expand Specific Solutions

Key Industry Players

The development of advanced membrane technology aided by vacuum pumps is in a growth phase, with increasing market size and technological advancements. The global market for this technology is expanding due to its applications in various industries, including water treatment, pharmaceuticals, and energy. Key players like Edwards Ltd., Shimadzu Corp., and Pfeiffer Vacuum GmbH are driving innovation in vacuum pump technology, enhancing membrane performance and efficiency. The technology's maturity is progressing, with companies like Applied Materials, Inc. and Tokyo Electron Ltd. contributing to its advancement through their semiconductor expertise. As the industry evolves, collaboration between vacuum pump manufacturers and membrane technology developers is likely to accelerate progress and market expansion.

Edwards Ltd.

Technical Solution: Edwards has developed a range of vacuum pumps tailored for membrane technology applications. Their dry scroll pumps, such as the nXDS series, provide oil-free vacuum essential for clean processing environments in membrane fabrication[9]. These pumps offer stable vacuum performance and low maintenance requirements, crucial for long-term membrane development processes. Edwards' turbomolecular pumps, combined with their backing pump systems, enable the creation of ultra-high vacuum environments necessary for advanced membrane characterization techniques. Their vacuum systems often include intelligent controls for precise pressure management, critical for maintaining consistent conditions during membrane formation and testing[10].

Strengths: Oil-free operation for clean processing, robust design for long-term reliability, and integrated control systems for precise vacuum management. Weaknesses: May have lower pumping speeds compared to some competitors, and initial cost can be high for comprehensive vacuum systems.

Shimadzu Corp.

Technical Solution: Shimadzu Corporation has developed specialized vacuum systems for membrane characterization and testing. Their mass spectrometers, operating under high vacuum, enable precise analysis of gas permeation through membranes, crucial for evaluating membrane selectivity and performance[7]. Shimadzu's thermal desorption systems, integrated with vacuum technology, allow for detailed analysis of membrane surface properties and adsorption characteristics. Their advanced vacuum-based analytical instruments, such as X-ray photoelectron spectroscopy (XPS) systems, provide in-depth analysis of membrane surface chemistry and composition at the molecular level[8]. These tools are essential for understanding and optimizing membrane properties during the development process.

Strengths: High-precision analytical capabilities, versatility in membrane characterization techniques, and integration of multiple analysis methods. Weaknesses: High equipment costs and need for specialized training to operate and interpret results effectively.

Innovative Pump Designs

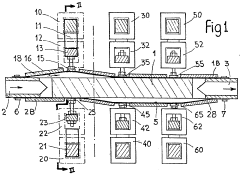

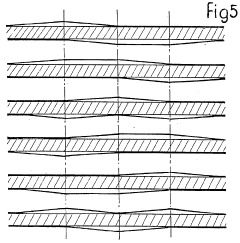

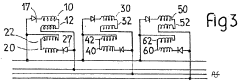

Pump and method for pumping a fluid

PatentInactiveEP0015180A1

Innovation

- A flexible impermeable membrane pump with electromechanical devices powered by polyphase alternating current, creating chambers to transfer fluid from the inlet to the discharge orifice without dead volume, using a rigid body with suction and discharge orifices and membrane maneuvering devices to displace fluid efficiently.

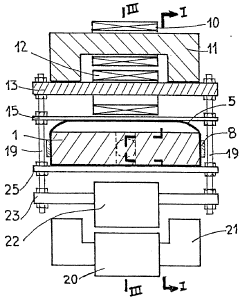

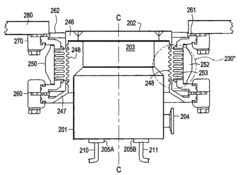

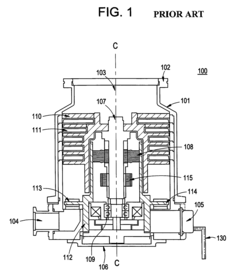

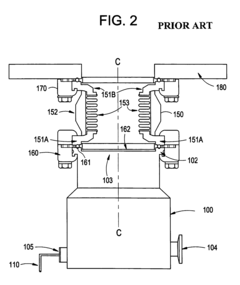

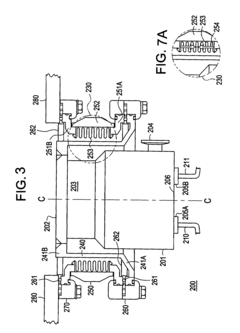

Vibration damper with nested turbo molecular pump

PatentInactiveUS7300261B2

Innovation

- A nested vibration damping arrangement is implemented, where a flexible bellow damper surrounds a major portion of the turbo pump, providing effective damping with a direct connection to the vacuum chamber inlet port, reducing the size and cost of the pump while maintaining high throughput and low vibration.

Environmental Impact

The development of advanced membrane technology, aided by vacuum pumps, has significant environmental implications. This synergy between membrane systems and vacuum technology contributes to more sustainable industrial processes and environmental protection efforts.

Vacuum-assisted membrane technology enhances the efficiency of various separation processes, leading to reduced energy consumption and minimized waste generation. In water treatment applications, these advanced systems enable more effective removal of contaminants, producing higher quality effluent while consuming less energy compared to conventional treatment methods. This not only conserves water resources but also reduces the environmental impact of wastewater discharge.

In industrial gas separation, vacuum-enhanced membrane systems offer a more environmentally friendly alternative to traditional cryogenic or chemical absorption processes. By operating at lower pressures and temperatures, these systems reduce the carbon footprint associated with gas purification and recovery. This is particularly beneficial in applications such as carbon capture and storage, where efficient CO2 separation is crucial for mitigating greenhouse gas emissions.

The use of vacuum pumps in membrane technology also facilitates the development of more compact and efficient systems. This results in smaller equipment footprints, reduced material usage, and lower transportation-related emissions. Additionally, the improved performance of these systems often translates to longer operational lifespans, further reducing the environmental impact associated with equipment manufacturing and disposal.

In the field of desalination, vacuum-assisted membrane distillation shows promise for reducing the energy intensity of freshwater production. By operating at lower temperatures and pressures, these systems can potentially utilize low-grade waste heat or renewable energy sources, making the desalination process more sustainable and reducing reliance on fossil fuels.

Furthermore, the integration of vacuum technology in membrane-based processes enables the recovery and reuse of valuable resources from waste streams. This circular economy approach minimizes the depletion of natural resources and reduces the environmental burden of waste disposal. For instance, in the food and beverage industry, vacuum-enhanced membrane systems can recover and concentrate valuable compounds from process streams, reducing both waste and the need for raw materials.

However, it is important to note that the environmental benefits of vacuum-assisted membrane technology must be balanced against the potential impacts of vacuum pump operation. Ongoing research and development efforts are focused on improving the energy efficiency of vacuum pumps and exploring the use of environmentally friendly working fluids to further enhance the overall sustainability of these systems.

Vacuum-assisted membrane technology enhances the efficiency of various separation processes, leading to reduced energy consumption and minimized waste generation. In water treatment applications, these advanced systems enable more effective removal of contaminants, producing higher quality effluent while consuming less energy compared to conventional treatment methods. This not only conserves water resources but also reduces the environmental impact of wastewater discharge.

In industrial gas separation, vacuum-enhanced membrane systems offer a more environmentally friendly alternative to traditional cryogenic or chemical absorption processes. By operating at lower pressures and temperatures, these systems reduce the carbon footprint associated with gas purification and recovery. This is particularly beneficial in applications such as carbon capture and storage, where efficient CO2 separation is crucial for mitigating greenhouse gas emissions.

The use of vacuum pumps in membrane technology also facilitates the development of more compact and efficient systems. This results in smaller equipment footprints, reduced material usage, and lower transportation-related emissions. Additionally, the improved performance of these systems often translates to longer operational lifespans, further reducing the environmental impact associated with equipment manufacturing and disposal.

In the field of desalination, vacuum-assisted membrane distillation shows promise for reducing the energy intensity of freshwater production. By operating at lower temperatures and pressures, these systems can potentially utilize low-grade waste heat or renewable energy sources, making the desalination process more sustainable and reducing reliance on fossil fuels.

Furthermore, the integration of vacuum technology in membrane-based processes enables the recovery and reuse of valuable resources from waste streams. This circular economy approach minimizes the depletion of natural resources and reduces the environmental burden of waste disposal. For instance, in the food and beverage industry, vacuum-enhanced membrane systems can recover and concentrate valuable compounds from process streams, reducing both waste and the need for raw materials.

However, it is important to note that the environmental benefits of vacuum-assisted membrane technology must be balanced against the potential impacts of vacuum pump operation. Ongoing research and development efforts are focused on improving the energy efficiency of vacuum pumps and exploring the use of environmentally friendly working fluids to further enhance the overall sustainability of these systems.

Regulatory Compliance

Regulatory compliance plays a crucial role in the development and implementation of advanced membrane technology utilizing vacuum pumps. As this technology continues to evolve and find applications in various industries, adherence to regulatory standards becomes increasingly important to ensure safety, quality, and environmental protection.

In the context of membrane technology and vacuum pump systems, regulatory compliance encompasses a wide range of standards and guidelines set by national and international regulatory bodies. These regulations often cover aspects such as material compatibility, process safety, emissions control, and product quality assurance.

One of the primary regulatory considerations for vacuum pump-assisted membrane technology is the prevention of contamination. Regulatory bodies such as the FDA (Food and Drug Administration) in the United States and the EMA (European Medicines Agency) in Europe have established strict guidelines for the use of membrane filtration systems in pharmaceutical and biotechnology applications. These regulations often require validation of the membrane filtration process, including integrity testing and documentation of operating parameters.

Environmental regulations also play a significant role in the development of advanced membrane technology. Many countries have implemented stringent emissions standards, particularly for industrial processes. Vacuum pump systems used in membrane technology must comply with these regulations, often requiring the implementation of additional filtration or scrubbing systems to capture and treat exhaust gases.

In the water treatment sector, regulatory compliance is particularly critical. Membrane technology used for water purification and desalination must meet strict water quality standards set by organizations such as the WHO (World Health Organization) and EPA (Environmental Protection Agency). These standards often dictate the required removal efficiency of contaminants and the acceptable levels of residual substances in treated water.

Occupational health and safety regulations also impact the design and operation of vacuum pump systems in membrane technology applications. Regulatory bodies such as OSHA (Occupational Safety and Health Administration) in the United States mandate safety measures to protect workers from potential hazards associated with vacuum systems, including noise exposure and mechanical risks.

As membrane technology continues to advance, regulatory frameworks are evolving to keep pace with new developments. This dynamic regulatory landscape requires ongoing vigilance and adaptation from manufacturers and end-users of vacuum pump-assisted membrane systems. Compliance with these regulations not only ensures legal operation but also contributes to the overall safety, efficiency, and reliability of advanced membrane technology applications.

In the context of membrane technology and vacuum pump systems, regulatory compliance encompasses a wide range of standards and guidelines set by national and international regulatory bodies. These regulations often cover aspects such as material compatibility, process safety, emissions control, and product quality assurance.

One of the primary regulatory considerations for vacuum pump-assisted membrane technology is the prevention of contamination. Regulatory bodies such as the FDA (Food and Drug Administration) in the United States and the EMA (European Medicines Agency) in Europe have established strict guidelines for the use of membrane filtration systems in pharmaceutical and biotechnology applications. These regulations often require validation of the membrane filtration process, including integrity testing and documentation of operating parameters.

Environmental regulations also play a significant role in the development of advanced membrane technology. Many countries have implemented stringent emissions standards, particularly for industrial processes. Vacuum pump systems used in membrane technology must comply with these regulations, often requiring the implementation of additional filtration or scrubbing systems to capture and treat exhaust gases.

In the water treatment sector, regulatory compliance is particularly critical. Membrane technology used for water purification and desalination must meet strict water quality standards set by organizations such as the WHO (World Health Organization) and EPA (Environmental Protection Agency). These standards often dictate the required removal efficiency of contaminants and the acceptable levels of residual substances in treated water.

Occupational health and safety regulations also impact the design and operation of vacuum pump systems in membrane technology applications. Regulatory bodies such as OSHA (Occupational Safety and Health Administration) in the United States mandate safety measures to protect workers from potential hazards associated with vacuum systems, including noise exposure and mechanical risks.

As membrane technology continues to advance, regulatory frameworks are evolving to keep pace with new developments. This dynamic regulatory landscape requires ongoing vigilance and adaptation from manufacturers and end-users of vacuum pump-assisted membrane systems. Compliance with these regulations not only ensures legal operation but also contributes to the overall safety, efficiency, and reliability of advanced membrane technology applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!