How Vacuum Pumps Enhance Desalination Technology Efficiency

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vacuum Pump Desalination Background and Objectives

Desalination technology has emerged as a critical solution to address global water scarcity, with vacuum pumps playing a pivotal role in enhancing its efficiency. The evolution of desalination techniques can be traced back to ancient times, but modern vacuum-assisted desalination represents a significant leap forward in terms of energy efficiency and water production capacity.

The primary objective of integrating vacuum pumps into desalination systems is to reduce the energy requirements and increase the overall efficiency of the process. By creating a low-pressure environment, vacuum pumps lower the boiling point of water, allowing for evaporation at lower temperatures. This fundamental principle has led to the development of various vacuum-enhanced desalination methods, including Multi-Effect Distillation (MED) and Vacuum Vapor Compression (VVC).

As global water demand continues to rise, driven by population growth, urbanization, and industrial expansion, the need for more efficient desalination technologies becomes increasingly urgent. The United Nations estimates that by 2025, two-thirds of the world's population may face water-stressed conditions. In this context, vacuum pump desalination technology aims to address several key challenges: reducing energy consumption, minimizing environmental impact, and increasing freshwater output.

The technological progression in this field has been marked by continuous improvements in vacuum pump design, materials science, and system integration. Early vacuum-assisted desalination plants faced issues with corrosion, scaling, and high maintenance costs. However, recent advancements in corrosion-resistant materials, improved pump designs, and sophisticated control systems have significantly enhanced the reliability and efficiency of these systems.

One of the most promising developments in vacuum pump desalination is the integration of renewable energy sources. Solar-powered vacuum pumps, for instance, offer a sustainable solution for remote coastal areas and islands where traditional energy infrastructure is limited. This synergy between renewable energy and vacuum-enhanced desalination aligns with global efforts to reduce carbon emissions and promote sustainable water production.

Looking ahead, the objectives for further advancement in vacuum pump desalination technology are multifaceted. Researchers and engineers are focusing on developing more energy-efficient vacuum pumps, improving heat recovery systems, and optimizing the overall plant design to reduce capital and operational costs. Additionally, there is a growing emphasis on developing hybrid systems that combine vacuum-assisted processes with other desalination technologies, such as reverse osmosis, to maximize efficiency and output.

In conclusion, the background and objectives of vacuum pump desalination technology reflect a dynamic and evolving field. As water scarcity becomes an increasingly pressing global issue, the continued development and refinement of this technology will play a crucial role in ensuring sustainable water supplies for future generations.

The primary objective of integrating vacuum pumps into desalination systems is to reduce the energy requirements and increase the overall efficiency of the process. By creating a low-pressure environment, vacuum pumps lower the boiling point of water, allowing for evaporation at lower temperatures. This fundamental principle has led to the development of various vacuum-enhanced desalination methods, including Multi-Effect Distillation (MED) and Vacuum Vapor Compression (VVC).

As global water demand continues to rise, driven by population growth, urbanization, and industrial expansion, the need for more efficient desalination technologies becomes increasingly urgent. The United Nations estimates that by 2025, two-thirds of the world's population may face water-stressed conditions. In this context, vacuum pump desalination technology aims to address several key challenges: reducing energy consumption, minimizing environmental impact, and increasing freshwater output.

The technological progression in this field has been marked by continuous improvements in vacuum pump design, materials science, and system integration. Early vacuum-assisted desalination plants faced issues with corrosion, scaling, and high maintenance costs. However, recent advancements in corrosion-resistant materials, improved pump designs, and sophisticated control systems have significantly enhanced the reliability and efficiency of these systems.

One of the most promising developments in vacuum pump desalination is the integration of renewable energy sources. Solar-powered vacuum pumps, for instance, offer a sustainable solution for remote coastal areas and islands where traditional energy infrastructure is limited. This synergy between renewable energy and vacuum-enhanced desalination aligns with global efforts to reduce carbon emissions and promote sustainable water production.

Looking ahead, the objectives for further advancement in vacuum pump desalination technology are multifaceted. Researchers and engineers are focusing on developing more energy-efficient vacuum pumps, improving heat recovery systems, and optimizing the overall plant design to reduce capital and operational costs. Additionally, there is a growing emphasis on developing hybrid systems that combine vacuum-assisted processes with other desalination technologies, such as reverse osmosis, to maximize efficiency and output.

In conclusion, the background and objectives of vacuum pump desalination technology reflect a dynamic and evolving field. As water scarcity becomes an increasingly pressing global issue, the continued development and refinement of this technology will play a crucial role in ensuring sustainable water supplies for future generations.

Global Water Scarcity and Desalination Market Analysis

The global water crisis has emerged as one of the most pressing challenges of the 21st century, with water scarcity affecting billions of people worldwide. As freshwater resources become increasingly strained due to population growth, urbanization, and climate change, the demand for alternative water sources has surged. This has led to a significant expansion of the desalination market, which offers a viable solution to address water shortages by converting seawater into potable water.

The desalination market has experienced robust growth in recent years, driven by the urgent need for sustainable water supplies in water-stressed regions. According to recent market analyses, the global desalination market was valued at approximately $17 billion in 2020 and is projected to reach $32 billion by 2027, growing at a compound annual growth rate (CAGR) of around 9% during the forecast period.

The Middle East and North Africa (MENA) region continues to dominate the desalination market, accounting for over 50% of global installed capacity. Countries such as Saudi Arabia, the United Arab Emirates, and Israel have made substantial investments in large-scale desalination plants to meet their growing water demands. However, other regions, including Asia-Pacific, North America, and Europe, are also witnessing increased adoption of desalination technologies as they grapple with water scarcity issues.

Reverse osmosis (RO) has emerged as the leading desalination technology, capturing over 60% of the market share due to its cost-effectiveness and energy efficiency compared to thermal desalination methods. The RO market is expected to maintain its dominance in the coming years, driven by ongoing technological advancements and improvements in membrane materials.

The desalination industry faces several challenges, including high energy consumption, environmental concerns related to brine disposal, and the need for more sustainable and cost-effective technologies. These challenges have spurred innovation in the sector, with a focus on developing energy-efficient processes, renewable energy integration, and advanced brine management solutions.

The market landscape is characterized by a mix of established players and new entrants, with key companies including Veolia, Suez, Doosan Heavy Industries, and IDE Technologies. These companies are investing heavily in research and development to improve desalination technologies and expand their market presence.

As water scarcity continues to intensify globally, the desalination market is poised for sustained growth. The integration of advanced technologies, such as vacuum pumps, promises to enhance the efficiency and cost-effectiveness of desalination processes, further driving market expansion and addressing the critical need for reliable water supplies in water-stressed regions worldwide.

The desalination market has experienced robust growth in recent years, driven by the urgent need for sustainable water supplies in water-stressed regions. According to recent market analyses, the global desalination market was valued at approximately $17 billion in 2020 and is projected to reach $32 billion by 2027, growing at a compound annual growth rate (CAGR) of around 9% during the forecast period.

The Middle East and North Africa (MENA) region continues to dominate the desalination market, accounting for over 50% of global installed capacity. Countries such as Saudi Arabia, the United Arab Emirates, and Israel have made substantial investments in large-scale desalination plants to meet their growing water demands. However, other regions, including Asia-Pacific, North America, and Europe, are also witnessing increased adoption of desalination technologies as they grapple with water scarcity issues.

Reverse osmosis (RO) has emerged as the leading desalination technology, capturing over 60% of the market share due to its cost-effectiveness and energy efficiency compared to thermal desalination methods. The RO market is expected to maintain its dominance in the coming years, driven by ongoing technological advancements and improvements in membrane materials.

The desalination industry faces several challenges, including high energy consumption, environmental concerns related to brine disposal, and the need for more sustainable and cost-effective technologies. These challenges have spurred innovation in the sector, with a focus on developing energy-efficient processes, renewable energy integration, and advanced brine management solutions.

The market landscape is characterized by a mix of established players and new entrants, with key companies including Veolia, Suez, Doosan Heavy Industries, and IDE Technologies. These companies are investing heavily in research and development to improve desalination technologies and expand their market presence.

As water scarcity continues to intensify globally, the desalination market is poised for sustained growth. The integration of advanced technologies, such as vacuum pumps, promises to enhance the efficiency and cost-effectiveness of desalination processes, further driving market expansion and addressing the critical need for reliable water supplies in water-stressed regions worldwide.

Current Vacuum Pump Technology in Desalination

Vacuum pumps play a crucial role in enhancing the efficiency of desalination technology. In current desalination processes, particularly in thermal-based systems like Multi-Stage Flash (MSF) and Multi-Effect Distillation (MED), vacuum pumps are essential for maintaining optimal operating conditions.

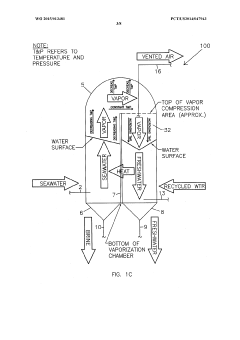

The primary function of vacuum pumps in desalination is to create and maintain a low-pressure environment within the evaporation chambers. This reduced pressure lowers the boiling point of water, allowing for more efficient evaporation at lower temperatures. As a result, less energy is required to produce freshwater, significantly improving the overall efficiency of the desalination process.

Modern vacuum pump technology in desalination typically employs two main types: liquid ring pumps and dry screw pumps. Liquid ring pumps are widely used due to their reliability and ability to handle large volumes of vapor. They operate by using a rotating impeller within a cylindrical casing partially filled with liquid, creating a series of compression chambers.

Dry screw pumps, on the other hand, offer advantages in terms of energy efficiency and reduced maintenance requirements. These pumps use two intermeshing screws to compress and remove gases from the system without the need for sealing or lubricating fluids. This design makes them particularly suitable for applications where contamination must be minimized.

Recent advancements in vacuum pump technology have focused on improving energy efficiency and reducing environmental impact. Variable speed drives have been incorporated into pump designs, allowing for better control of vacuum levels and energy consumption. Additionally, the development of corrosion-resistant materials has extended the lifespan of pumps operating in the harsh, saline environment of desalination plants.

Another significant innovation is the integration of heat recovery systems with vacuum pumps. These systems capture and utilize the heat generated during the compression process, further enhancing the overall energy efficiency of the desalination plant. Some advanced designs even incorporate multiple stages of compression to optimize performance across a wide range of operating conditions.

The size and capacity of vacuum pumps used in desalination have also evolved to meet the demands of increasingly large-scale operations. Modern pumps can handle flow rates of several thousand cubic meters per hour, enabling the processing of vast quantities of seawater in industrial-scale desalination plants.

In conclusion, current vacuum pump technology in desalination represents a critical component in the quest for more efficient and sustainable water production. As global water scarcity continues to be a pressing issue, ongoing research and development in this field aim to further improve pump performance, reduce energy consumption, and ultimately make desalination a more viable solution for addressing water needs worldwide.

The primary function of vacuum pumps in desalination is to create and maintain a low-pressure environment within the evaporation chambers. This reduced pressure lowers the boiling point of water, allowing for more efficient evaporation at lower temperatures. As a result, less energy is required to produce freshwater, significantly improving the overall efficiency of the desalination process.

Modern vacuum pump technology in desalination typically employs two main types: liquid ring pumps and dry screw pumps. Liquid ring pumps are widely used due to their reliability and ability to handle large volumes of vapor. They operate by using a rotating impeller within a cylindrical casing partially filled with liquid, creating a series of compression chambers.

Dry screw pumps, on the other hand, offer advantages in terms of energy efficiency and reduced maintenance requirements. These pumps use two intermeshing screws to compress and remove gases from the system without the need for sealing or lubricating fluids. This design makes them particularly suitable for applications where contamination must be minimized.

Recent advancements in vacuum pump technology have focused on improving energy efficiency and reducing environmental impact. Variable speed drives have been incorporated into pump designs, allowing for better control of vacuum levels and energy consumption. Additionally, the development of corrosion-resistant materials has extended the lifespan of pumps operating in the harsh, saline environment of desalination plants.

Another significant innovation is the integration of heat recovery systems with vacuum pumps. These systems capture and utilize the heat generated during the compression process, further enhancing the overall energy efficiency of the desalination plant. Some advanced designs even incorporate multiple stages of compression to optimize performance across a wide range of operating conditions.

The size and capacity of vacuum pumps used in desalination have also evolved to meet the demands of increasingly large-scale operations. Modern pumps can handle flow rates of several thousand cubic meters per hour, enabling the processing of vast quantities of seawater in industrial-scale desalination plants.

In conclusion, current vacuum pump technology in desalination represents a critical component in the quest for more efficient and sustainable water production. As global water scarcity continues to be a pressing issue, ongoing research and development in this field aim to further improve pump performance, reduce energy consumption, and ultimately make desalination a more viable solution for addressing water needs worldwide.

Vacuum Pump Integration in Desalination Systems

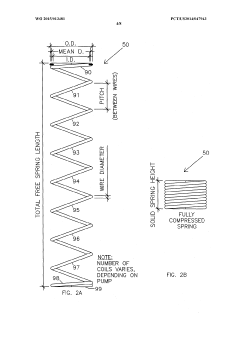

01 Improved rotor design for vacuum pumps

Enhancing the rotor design in vacuum pumps can significantly improve efficiency. This includes optimizing the shape, material, and configuration of the rotor to reduce friction, minimize energy loss, and increase pumping capacity. Advanced rotor designs can lead to better sealing, reduced wear, and improved overall performance of the vacuum pump.- Improved rotor design for vacuum pumps: Enhancing the rotor design in vacuum pumps can significantly improve efficiency. This includes optimizing the shape, material, and configuration of the rotor to reduce friction, minimize energy loss, and increase pumping speed. Advanced rotor designs can also help in maintaining consistent performance across different pressure ranges.

- Innovative sealing mechanisms: Developing new sealing mechanisms or improving existing ones can greatly enhance vacuum pump efficiency. This involves creating better seals between moving parts to prevent leakage, reduce contamination, and maintain optimal vacuum levels. Advanced sealing technologies can also contribute to extended pump life and reduced maintenance requirements.

- Energy-efficient motor and drive systems: Incorporating energy-efficient motors and drive systems can significantly improve the overall efficiency of vacuum pumps. This includes using variable speed drives, high-efficiency electric motors, and intelligent control systems that adjust pump operation based on demand. Such improvements can lead to reduced power consumption and improved performance across various operating conditions.

- Advanced cooling and lubrication techniques: Implementing advanced cooling and lubrication techniques can enhance vacuum pump efficiency by reducing friction, heat generation, and wear. This may involve innovative oil circulation systems, the use of specialized lubricants, or the development of oil-free pump designs. Effective cooling and lubrication can lead to improved pump longevity and consistent performance.

- Optimized pump chamber geometry: Refining the geometry of the pump chamber can lead to improved vacuum pump efficiency. This includes optimizing the shape and size of the chamber, as well as the positioning of inlet and outlet ports. Advanced computational fluid dynamics simulations can be used to design pump chambers that minimize turbulence, reduce dead space, and enhance overall pumping performance.

02 Enhanced sealing mechanisms

Implementing advanced sealing mechanisms in vacuum pumps can greatly increase their efficiency. This involves developing innovative sealing technologies that minimize leakage, reduce friction, and maintain a high vacuum level. Improved seals can lead to better pump performance, lower power consumption, and increased reliability in various applications.Expand Specific Solutions03 Optimized pump chamber geometry

Refining the geometry of the pump chamber can enhance the efficiency of vacuum pumps. This includes optimizing the shape, size, and configuration of the chamber to improve gas flow, reduce turbulence, and maximize pumping speed. Careful design of the pump chamber can lead to better compression ratios and overall improved pump performance.Expand Specific Solutions04 Advanced control systems and automation

Incorporating advanced control systems and automation technologies can significantly improve vacuum pump efficiency. This includes implementing intelligent monitoring, adaptive control algorithms, and predictive maintenance systems. Such advancements can optimize pump operation, reduce energy consumption, and extend the lifespan of the equipment.Expand Specific Solutions05 Novel materials and coatings

Utilizing innovative materials and coatings can enhance the efficiency of vacuum pumps. This involves developing and applying advanced materials with improved wear resistance, thermal properties, and reduced friction. Novel coatings can also be used to protect pump components, extend their lifespan, and maintain optimal performance over time.Expand Specific Solutions

Key Players in Vacuum Pump Desalination Industry

The desalination technology market is in a growth phase, driven by increasing water scarcity and technological advancements. The global market size is projected to reach $26 billion by 2025, with a CAGR of 7.8%. Vacuum pump technology is becoming increasingly mature, enhancing desalination efficiency. Key players like ULVAC, Inc., Pfeiffer Vacuum GmbH, and Edwards Japan Ltd. are leading innovation in this field. Universities such as King's College London and Oregon State University are contributing to research and development. The industry is seeing collaboration between academic institutions and companies like BYD Co., Ltd. and RTX Corp., further accelerating technological progress in desalination efficiency.

Ide Water Technologies Ltd

Technical Solution: Ide Water Technologies has developed an innovative vacuum-assisted desalination technology called Mechanical Vapor Compression (MVC). This system utilizes a vacuum pump to lower the boiling point of seawater, reducing energy requirements for evaporation. The vapor is then compressed, raising its temperature and pressure, allowing it to serve as a heat source for further evaporation. This closed-loop process significantly enhances energy efficiency, with reported thermal energy consumption as low as 7-12 kWh/m³ of fresh water produced [1][3]. The company's MVC units are modular and scalable, capable of producing from 500 to 5,000 m³ of water per day, making them suitable for various applications from small communities to industrial use [2].

Strengths: High energy efficiency, low operating costs, and scalability. Weaknesses: Higher initial capital investment compared to conventional desalination methods, and potential maintenance challenges due to the complexity of the vacuum system.

ULVAC, Inc.

Technical Solution: ULVAC has developed advanced vacuum pump technologies specifically tailored for desalination processes. Their multi-stage dry vacuum pumps are designed to create and maintain low-pressure environments in desalination systems, particularly in Multi-Effect Distillation (MED) and Vacuum Vapor Compression (VVC) processes. These pumps can achieve vacuum levels as low as 0.1 mbar, significantly lowering the boiling point of seawater and reducing energy consumption [4]. ULVAC's pumps incorporate corrosion-resistant materials and specialized coatings to withstand the harsh, saline environment typical in desalination plants. The company has also implemented smart monitoring systems in their pumps, allowing for predictive maintenance and optimized performance, which can lead to energy savings of up to 30% compared to conventional vacuum systems in desalination plants [5].

Strengths: High vacuum efficiency, corrosion resistance, and smart monitoring capabilities. Weaknesses: Potentially higher initial costs and the need for specialized maintenance.

Innovative Vacuum Pump Designs for Desalination

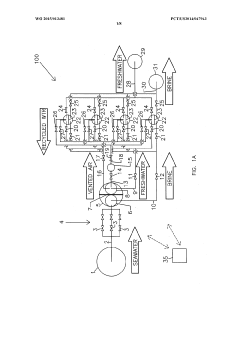

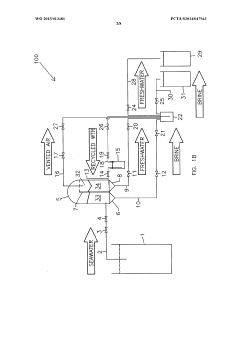

Desalination using atmospheric pressure as renewable energy

PatentWO2015013481A1

Innovation

- The system exploits the phase change cycle associated with cavitation on the suction side of a pump, using atmospheric pressure and a heat exchanger to efficiently desalinate seawater, with renewable energy providing at least 99% of the total energy required, significantly reducing electrical energy input.

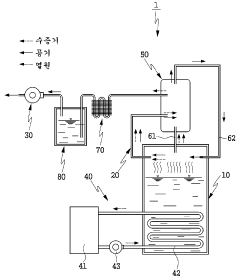

Desalination apparatus using vacuum and membrane method

PatentPendingKR1020230033067A

Innovation

- A desalination device integrating a vacuum and membrane method, comprising a seawater storage unit, heating unit, vacuum pump, separation unit, cooling unit, and storage tank, which separates and condenses water vapor to enhance efficiency by combining evaporation and membrane processes.

Energy Efficiency Improvements in Desalination

Energy efficiency improvements in desalination have become a critical focus in the quest for sustainable water production. As global water scarcity intensifies, the need for more efficient desalination processes has never been more pressing. Recent advancements in vacuum pump technology have played a pivotal role in enhancing the overall efficiency of desalination systems.

Vacuum pumps contribute significantly to energy savings in various desalination methods, particularly in thermal-based processes such as Multi-Effect Distillation (MED) and Multi-Stage Flash (MSF) distillation. By creating and maintaining low-pressure environments, these pumps facilitate the evaporation of water at lower temperatures, thus reducing the thermal energy requirements of the system.

In Reverse Osmosis (RO) systems, which dominate the desalination market, vacuum pumps are utilized in energy recovery devices (ERDs) to recapture pressure energy from the concentrated brine stream. This recovered energy is then used to pressurize the incoming feedwater, substantially reducing the overall energy consumption of the RO process.

The integration of advanced vacuum pump designs, such as liquid ring vacuum pumps and dry screw vacuum pumps, has further improved the energy efficiency of desalination plants. These pumps offer higher reliability, lower maintenance requirements, and better performance under varying operating conditions compared to traditional pump designs.

Moreover, the application of variable frequency drives (VFDs) to vacuum pumps allows for precise control of pump speed and capacity. This adaptability enables desalination plants to optimize their energy usage based on fluctuating water demand and feed water conditions, resulting in significant energy savings over time.

Recent innovations in vacuum pump materials and coatings have also contributed to efficiency gains. Corrosion-resistant materials and specialized coatings extend the lifespan of pump components, reducing the frequency of replacements and maintenance downtime. This not only improves the overall operational efficiency but also reduces the long-term energy costs associated with pump replacements and system shutdowns.

The synergy between vacuum pump technology and other energy-saving measures in desalination plants has led to remarkable improvements in overall plant efficiency. For instance, the combination of high-efficiency vacuum pumps with advanced membrane materials in RO systems has pushed the energy consumption of some plants below 3 kWh/m³ of produced water, a significant reduction from the average consumption of 4-5 kWh/m³ just a decade ago.

As research and development in vacuum pump technology continue, further enhancements in desalination energy efficiency are anticipated. Emerging technologies such as smart pump systems with predictive maintenance capabilities and the integration of renewable energy sources for pump operation hold promise for even greater energy savings in the future of desalination.

Vacuum pumps contribute significantly to energy savings in various desalination methods, particularly in thermal-based processes such as Multi-Effect Distillation (MED) and Multi-Stage Flash (MSF) distillation. By creating and maintaining low-pressure environments, these pumps facilitate the evaporation of water at lower temperatures, thus reducing the thermal energy requirements of the system.

In Reverse Osmosis (RO) systems, which dominate the desalination market, vacuum pumps are utilized in energy recovery devices (ERDs) to recapture pressure energy from the concentrated brine stream. This recovered energy is then used to pressurize the incoming feedwater, substantially reducing the overall energy consumption of the RO process.

The integration of advanced vacuum pump designs, such as liquid ring vacuum pumps and dry screw vacuum pumps, has further improved the energy efficiency of desalination plants. These pumps offer higher reliability, lower maintenance requirements, and better performance under varying operating conditions compared to traditional pump designs.

Moreover, the application of variable frequency drives (VFDs) to vacuum pumps allows for precise control of pump speed and capacity. This adaptability enables desalination plants to optimize their energy usage based on fluctuating water demand and feed water conditions, resulting in significant energy savings over time.

Recent innovations in vacuum pump materials and coatings have also contributed to efficiency gains. Corrosion-resistant materials and specialized coatings extend the lifespan of pump components, reducing the frequency of replacements and maintenance downtime. This not only improves the overall operational efficiency but also reduces the long-term energy costs associated with pump replacements and system shutdowns.

The synergy between vacuum pump technology and other energy-saving measures in desalination plants has led to remarkable improvements in overall plant efficiency. For instance, the combination of high-efficiency vacuum pumps with advanced membrane materials in RO systems has pushed the energy consumption of some plants below 3 kWh/m³ of produced water, a significant reduction from the average consumption of 4-5 kWh/m³ just a decade ago.

As research and development in vacuum pump technology continue, further enhancements in desalination energy efficiency are anticipated. Emerging technologies such as smart pump systems with predictive maintenance capabilities and the integration of renewable energy sources for pump operation hold promise for even greater energy savings in the future of desalination.

Environmental Impact of Vacuum Pump Desalination

The environmental impact of vacuum pump desalination technology is a critical consideration in the broader context of sustainable water management. This innovative approach to desalination offers significant advantages in terms of energy efficiency and water production, but it also presents unique environmental challenges that must be carefully addressed.

One of the primary environmental benefits of vacuum pump desalination is its reduced energy consumption compared to traditional desalination methods. By operating at lower pressures, vacuum pump systems require less energy to separate salt from water, resulting in a smaller carbon footprint. This reduction in energy demand translates to lower greenhouse gas emissions, aligning with global efforts to combat climate change and reduce dependence on fossil fuels.

However, the environmental impact of vacuum pump desalination extends beyond energy considerations. The concentrated brine produced as a byproduct of the desalination process poses a significant challenge. When discharged into marine environments, this hypersaline solution can disrupt local ecosystems, affecting marine life and altering the chemical composition of coastal waters. To mitigate these effects, advanced brine management strategies must be implemented, such as dilution techniques or the development of beneficial uses for the brine.

The construction and operation of vacuum pump desalination facilities also have potential impacts on local environments. Land use changes, habitat disruption, and noise pollution are concerns that need to be addressed through careful site selection and design. Additionally, the materials used in the construction of these facilities, including specialized membranes and pumps, have their own environmental footprint in terms of production and eventual disposal.

On the positive side, vacuum pump desalination technology can contribute to the preservation of freshwater resources by providing an alternative water source. This is particularly crucial in water-scarce regions where overexploitation of groundwater and surface water sources has led to environmental degradation. By reducing pressure on these natural water sources, vacuum pump desalination can indirectly support ecosystem restoration and biodiversity conservation.

The technology also offers opportunities for integration with renewable energy sources, such as solar or wind power. This synergy can further reduce the environmental impact of desalination by minimizing reliance on grid electricity and fostering the development of sustainable water-energy nexus solutions.

In conclusion, while vacuum pump desalination presents promising environmental benefits, particularly in terms of energy efficiency and freshwater resource preservation, it also introduces new challenges that require innovative solutions. The overall environmental impact of this technology will depend on careful implementation, ongoing research into brine management, and the development of holistic approaches that consider the entire lifecycle of desalination facilities.

One of the primary environmental benefits of vacuum pump desalination is its reduced energy consumption compared to traditional desalination methods. By operating at lower pressures, vacuum pump systems require less energy to separate salt from water, resulting in a smaller carbon footprint. This reduction in energy demand translates to lower greenhouse gas emissions, aligning with global efforts to combat climate change and reduce dependence on fossil fuels.

However, the environmental impact of vacuum pump desalination extends beyond energy considerations. The concentrated brine produced as a byproduct of the desalination process poses a significant challenge. When discharged into marine environments, this hypersaline solution can disrupt local ecosystems, affecting marine life and altering the chemical composition of coastal waters. To mitigate these effects, advanced brine management strategies must be implemented, such as dilution techniques or the development of beneficial uses for the brine.

The construction and operation of vacuum pump desalination facilities also have potential impacts on local environments. Land use changes, habitat disruption, and noise pollution are concerns that need to be addressed through careful site selection and design. Additionally, the materials used in the construction of these facilities, including specialized membranes and pumps, have their own environmental footprint in terms of production and eventual disposal.

On the positive side, vacuum pump desalination technology can contribute to the preservation of freshwater resources by providing an alternative water source. This is particularly crucial in water-scarce regions where overexploitation of groundwater and surface water sources has led to environmental degradation. By reducing pressure on these natural water sources, vacuum pump desalination can indirectly support ecosystem restoration and biodiversity conservation.

The technology also offers opportunities for integration with renewable energy sources, such as solar or wind power. This synergy can further reduce the environmental impact of desalination by minimizing reliance on grid electricity and fostering the development of sustainable water-energy nexus solutions.

In conclusion, while vacuum pump desalination presents promising environmental benefits, particularly in terms of energy efficiency and freshwater resource preservation, it also introduces new challenges that require innovative solutions. The overall environmental impact of this technology will depend on careful implementation, ongoing research into brine management, and the development of holistic approaches that consider the entire lifecycle of desalination facilities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!