How Vacuum Pumps Facilitate Advanced Solar Thermal Technology

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Solar Thermal Tech Evolution

Solar thermal technology has undergone significant evolution since its inception, with vacuum pumps playing an increasingly crucial role in advancing its capabilities. The journey of solar thermal technology began in the late 19th century with simple solar water heaters. However, it wasn't until the mid-20th century that more sophisticated systems emerged, incorporating vacuum technology to enhance efficiency.

In the 1970s and 1980s, the oil crisis sparked renewed interest in solar thermal technology. This period saw the development of evacuated tube collectors, which utilized vacuum insulation to minimize heat loss and improve energy capture. Vacuum pumps were essential in creating and maintaining the low-pressure environment within these tubes, marking a significant leap in solar thermal efficiency.

The 1990s and early 2000s witnessed the integration of vacuum pumps into more advanced solar thermal systems. Concentrated Solar Power (CSP) plants began employing vacuum technology in their heat transfer systems, allowing for higher operating temperatures and improved overall system performance. Vacuum pumps played a critical role in maintaining the integrity of these systems, removing air and other gases that could compromise efficiency.

As the technology progressed into the 2010s, vacuum pumps became integral to cutting-edge solar thermal applications. In solar thermochemical fuel production, vacuum pumps are used to control reaction conditions and separate products. Similarly, in advanced solar desalination systems, vacuum pumps help create low-pressure environments that lower the boiling point of water, enhancing the efficiency of the desalination process.

The most recent developments in solar thermal technology have seen vacuum pumps facilitating even more innovative applications. In solar thermal energy storage systems, vacuum insulation techniques, enabled by high-performance vacuum pumps, have dramatically reduced heat losses in thermal storage tanks. This advancement has significantly improved the ability to store and utilize solar thermal energy during non-sunlight hours.

Looking towards the future, the role of vacuum pumps in solar thermal technology is set to expand further. Emerging concepts such as solar thermochemical hydrogen production and advanced solar cooling systems rely heavily on precise vacuum control. As these technologies mature, the demands on vacuum pump performance and reliability will continue to increase, driving further innovation in both solar thermal and vacuum technologies.

In the 1970s and 1980s, the oil crisis sparked renewed interest in solar thermal technology. This period saw the development of evacuated tube collectors, which utilized vacuum insulation to minimize heat loss and improve energy capture. Vacuum pumps were essential in creating and maintaining the low-pressure environment within these tubes, marking a significant leap in solar thermal efficiency.

The 1990s and early 2000s witnessed the integration of vacuum pumps into more advanced solar thermal systems. Concentrated Solar Power (CSP) plants began employing vacuum technology in their heat transfer systems, allowing for higher operating temperatures and improved overall system performance. Vacuum pumps played a critical role in maintaining the integrity of these systems, removing air and other gases that could compromise efficiency.

As the technology progressed into the 2010s, vacuum pumps became integral to cutting-edge solar thermal applications. In solar thermochemical fuel production, vacuum pumps are used to control reaction conditions and separate products. Similarly, in advanced solar desalination systems, vacuum pumps help create low-pressure environments that lower the boiling point of water, enhancing the efficiency of the desalination process.

The most recent developments in solar thermal technology have seen vacuum pumps facilitating even more innovative applications. In solar thermal energy storage systems, vacuum insulation techniques, enabled by high-performance vacuum pumps, have dramatically reduced heat losses in thermal storage tanks. This advancement has significantly improved the ability to store and utilize solar thermal energy during non-sunlight hours.

Looking towards the future, the role of vacuum pumps in solar thermal technology is set to expand further. Emerging concepts such as solar thermochemical hydrogen production and advanced solar cooling systems rely heavily on precise vacuum control. As these technologies mature, the demands on vacuum pump performance and reliability will continue to increase, driving further innovation in both solar thermal and vacuum technologies.

Market Demand Analysis

The market demand for advanced solar thermal technology facilitated by vacuum pumps has been experiencing significant growth in recent years. This surge is primarily driven by the increasing global focus on renewable energy sources and the push for more efficient and sustainable power generation methods. Solar thermal technology, particularly when enhanced by vacuum pumps, offers a promising solution to meet these demands.

The solar thermal market is projected to expand substantially over the coming decade, with a compound annual growth rate (CAGR) expected to exceed 10% through 2030. This growth is fueled by several factors, including government initiatives to reduce carbon emissions, rising energy costs, and the need for reliable and clean energy sources in both developed and developing countries.

Vacuum pumps play a crucial role in enhancing the efficiency and performance of solar thermal systems. They are essential in maintaining the vacuum within evacuated tube collectors, which are a key component of many advanced solar thermal installations. The vacuum environment significantly reduces heat loss, allowing for higher operating temperatures and improved overall system efficiency. This increased efficiency translates to greater energy output and improved cost-effectiveness, making solar thermal technology more attractive to both residential and commercial consumers.

The industrial sector represents a particularly promising market for advanced solar thermal technology. Industries with high thermal energy requirements, such as food processing, textiles, and chemical manufacturing, are increasingly looking to solar thermal solutions to reduce their reliance on fossil fuels and lower operational costs. The ability of vacuum pump-enhanced solar thermal systems to provide high-temperature process heat makes them especially valuable in these applications.

Geographically, the market demand is strongest in regions with high solar irradiance and supportive renewable energy policies. Countries in the Middle East, North Africa, and Southern Europe are at the forefront of adopting large-scale solar thermal projects. However, there is also growing interest in regions with less optimal solar conditions, as advancements in technology, including the use of vacuum pumps, are expanding the viability of solar thermal systems in diverse climates.

The residential sector is another key driver of market demand, particularly in areas with high electricity costs or unreliable grid power. Homeowners are increasingly recognizing the long-term cost savings and energy independence offered by solar thermal systems for water heating and space heating applications. The integration of vacuum pump technology in these systems is enhancing their appeal by improving performance and reducing the physical footprint required for installation.

As the technology continues to advance and costs decrease, the market for vacuum pump-facilitated solar thermal systems is expected to expand into new applications and regions. This growth is likely to be further accelerated by ongoing research and development efforts aimed at improving system efficiency, reducing maintenance requirements, and integrating solar thermal technology with other renewable energy sources and energy storage solutions.

The solar thermal market is projected to expand substantially over the coming decade, with a compound annual growth rate (CAGR) expected to exceed 10% through 2030. This growth is fueled by several factors, including government initiatives to reduce carbon emissions, rising energy costs, and the need for reliable and clean energy sources in both developed and developing countries.

Vacuum pumps play a crucial role in enhancing the efficiency and performance of solar thermal systems. They are essential in maintaining the vacuum within evacuated tube collectors, which are a key component of many advanced solar thermal installations. The vacuum environment significantly reduces heat loss, allowing for higher operating temperatures and improved overall system efficiency. This increased efficiency translates to greater energy output and improved cost-effectiveness, making solar thermal technology more attractive to both residential and commercial consumers.

The industrial sector represents a particularly promising market for advanced solar thermal technology. Industries with high thermal energy requirements, such as food processing, textiles, and chemical manufacturing, are increasingly looking to solar thermal solutions to reduce their reliance on fossil fuels and lower operational costs. The ability of vacuum pump-enhanced solar thermal systems to provide high-temperature process heat makes them especially valuable in these applications.

Geographically, the market demand is strongest in regions with high solar irradiance and supportive renewable energy policies. Countries in the Middle East, North Africa, and Southern Europe are at the forefront of adopting large-scale solar thermal projects. However, there is also growing interest in regions with less optimal solar conditions, as advancements in technology, including the use of vacuum pumps, are expanding the viability of solar thermal systems in diverse climates.

The residential sector is another key driver of market demand, particularly in areas with high electricity costs or unreliable grid power. Homeowners are increasingly recognizing the long-term cost savings and energy independence offered by solar thermal systems for water heating and space heating applications. The integration of vacuum pump technology in these systems is enhancing their appeal by improving performance and reducing the physical footprint required for installation.

As the technology continues to advance and costs decrease, the market for vacuum pump-facilitated solar thermal systems is expected to expand into new applications and regions. This growth is likely to be further accelerated by ongoing research and development efforts aimed at improving system efficiency, reducing maintenance requirements, and integrating solar thermal technology with other renewable energy sources and energy storage solutions.

Vacuum Pump Challenges

Vacuum pumps play a crucial role in advanced solar thermal technology, but they also face several significant challenges. One of the primary issues is maintaining consistent performance under extreme temperature conditions. Solar thermal systems often operate at high temperatures, which can cause thermal stress on vacuum pump components, leading to reduced efficiency and potential failure.

Another challenge is the need for high vacuum levels in solar thermal applications. Achieving and maintaining these levels requires sophisticated pump designs and materials that can withstand the harsh operating environment. The presence of contaminants, such as outgassing from system components or ingress of atmospheric gases, can compromise vacuum integrity and reduce overall system efficiency.

Durability and reliability are also major concerns for vacuum pumps in solar thermal technology. The pumps must operate continuously for extended periods, often in remote locations with limited maintenance access. This necessitates robust construction and advanced monitoring systems to predict and prevent failures.

Energy efficiency is another critical challenge. While vacuum pumps are essential for the operation of solar thermal systems, they also consume energy. Balancing the energy consumption of the pumps with the overall energy output of the solar thermal system is crucial for maximizing net energy production. This has led to ongoing research into more efficient pump designs and control strategies.

The size and weight of vacuum pumps can also pose challenges, particularly in large-scale solar thermal installations. Compact, lightweight designs that maintain high performance are in demand to reduce installation costs and space requirements. However, achieving this without compromising on vacuum quality or reliability is a significant engineering challenge.

Corrosion resistance is another important factor, as solar thermal systems may involve the use of heat transfer fluids or generate corrosive byproducts. Vacuum pumps must be constructed from materials that can withstand these corrosive environments while maintaining their performance characteristics over time.

Lastly, the cost of high-performance vacuum pumps suitable for advanced solar thermal applications remains a challenge. The specialized nature of these pumps, combined with the need for advanced materials and precision engineering, contributes to their high cost. This can impact the overall economic viability of solar thermal projects, particularly in regions where cost competitiveness with other energy sources is crucial.

Another challenge is the need for high vacuum levels in solar thermal applications. Achieving and maintaining these levels requires sophisticated pump designs and materials that can withstand the harsh operating environment. The presence of contaminants, such as outgassing from system components or ingress of atmospheric gases, can compromise vacuum integrity and reduce overall system efficiency.

Durability and reliability are also major concerns for vacuum pumps in solar thermal technology. The pumps must operate continuously for extended periods, often in remote locations with limited maintenance access. This necessitates robust construction and advanced monitoring systems to predict and prevent failures.

Energy efficiency is another critical challenge. While vacuum pumps are essential for the operation of solar thermal systems, they also consume energy. Balancing the energy consumption of the pumps with the overall energy output of the solar thermal system is crucial for maximizing net energy production. This has led to ongoing research into more efficient pump designs and control strategies.

The size and weight of vacuum pumps can also pose challenges, particularly in large-scale solar thermal installations. Compact, lightweight designs that maintain high performance are in demand to reduce installation costs and space requirements. However, achieving this without compromising on vacuum quality or reliability is a significant engineering challenge.

Corrosion resistance is another important factor, as solar thermal systems may involve the use of heat transfer fluids or generate corrosive byproducts. Vacuum pumps must be constructed from materials that can withstand these corrosive environments while maintaining their performance characteristics over time.

Lastly, the cost of high-performance vacuum pumps suitable for advanced solar thermal applications remains a challenge. The specialized nature of these pumps, combined with the need for advanced materials and precision engineering, contributes to their high cost. This can impact the overall economic viability of solar thermal projects, particularly in regions where cost competitiveness with other energy sources is crucial.

Current Vacuum Solutions

01 Improved vacuum pump design

Advancements in vacuum pump design focus on enhancing efficiency and performance. These improvements may include optimized rotor configurations, advanced sealing mechanisms, and innovative materials to reduce friction and wear. Such design enhancements contribute to increased pumping speed, better ultimate vacuum, and improved reliability in various applications.- Improved vacuum pump designs: Advanced vacuum pump designs focus on enhancing efficiency and performance. These improvements may include optimized rotor configurations, innovative sealing mechanisms, and advanced materials to reduce friction and wear. Such designs aim to increase pumping speed, improve ultimate vacuum levels, and extend the operational life of the pumps.

- Control systems for vacuum pumps: Sophisticated control systems are developed to optimize vacuum pump operation. These systems may incorporate sensors, microprocessors, and adaptive algorithms to monitor and adjust pump parameters in real-time. Features can include automatic pressure regulation, energy-efficient operation modes, and predictive maintenance capabilities.

- Integration of vacuum pumps in industrial processes: Vacuum pumps are increasingly integrated into various industrial processes to enhance efficiency and product quality. This integration involves designing pump systems that seamlessly connect with production lines, cleanrooms, or other manufacturing equipment. Specialized interfaces and control protocols are developed to ensure optimal performance within specific industrial applications.

- Energy-efficient vacuum pump technologies: Development of energy-efficient vacuum pump technologies is a key focus area. This includes the use of variable speed drives, heat recovery systems, and intelligent power management. These technologies aim to reduce energy consumption, lower operating costs, and minimize environmental impact while maintaining high performance levels.

- Vacuum pump maintenance and diagnostics: Advanced maintenance and diagnostic tools are being developed to facilitate vacuum pump upkeep. These may include IoT-enabled monitoring systems, augmented reality-assisted maintenance procedures, and AI-driven predictive maintenance algorithms. Such tools aim to reduce downtime, extend pump lifespan, and optimize maintenance schedules.

02 Control systems for vacuum pumps

Sophisticated control systems are developed to optimize vacuum pump operation. These systems may incorporate sensors, microprocessors, and adaptive algorithms to monitor and adjust pump parameters in real-time. Features can include automatic pressure regulation, energy-saving modes, and predictive maintenance capabilities, enhancing overall system efficiency and reliability.Expand Specific Solutions03 Integration of vacuum pumps in industrial processes

Vacuum pumps are increasingly integrated into complex industrial processes for improved efficiency. This integration involves optimizing pump placement, sizing, and operation to meet specific process requirements. Advanced integration strategies may include cascading systems, heat recovery, and synchronization with other process equipment to maximize overall system performance.Expand Specific Solutions04 Energy-efficient vacuum pump technologies

Development of energy-efficient vacuum pump technologies aims to reduce power consumption and environmental impact. These technologies may include variable speed drives, high-efficiency motors, and innovative compression techniques. Additionally, the use of smart control algorithms and energy recovery systems contributes to overall energy savings in vacuum pump operations.Expand Specific Solutions05 Vacuum pump maintenance and diagnostics

Advanced maintenance and diagnostic tools are developed to enhance vacuum pump reliability and longevity. These may include condition monitoring systems, remote diagnostics, and predictive maintenance algorithms. Such tools help identify potential issues before they lead to failures, optimize maintenance schedules, and reduce downtime in critical applications.Expand Specific Solutions

Key Industry Players

The vacuum pump technology for advanced solar thermal systems is in a growth phase, with increasing market size driven by the rising demand for renewable energy solutions. The technology's maturity is progressing, with companies like Edwards Japan Ltd. and Pfeiffer Vacuum GmbH leading in vacuum pump development. Emerging players such as TVP Solar SA and Vögelin GmbH are focusing on solar thermal applications, while established firms like PetroChina Co., Ltd. are exploring integration possibilities. The competitive landscape is diverse, with a mix of specialized vacuum technology providers and solar energy companies collaborating to advance the field.

Pfeiffer Vacuum GmbH

Technical Solution: Pfeiffer Vacuum GmbH has developed advanced vacuum pumps specifically designed for solar thermal technology applications. Their pumps utilize a combination of turbomolecular and backing pump technologies to achieve high vacuum levels necessary for efficient solar thermal processes[1]. The company's HiPace turbopumps, coupled with multi-stage roots pumps, provide a robust vacuum solution for solar thermal applications, enabling the creation of highly insulated environments for heat transfer and energy conversion[2]. These pumps are engineered to maintain stable vacuum conditions even in high-temperature environments, which is crucial for concentrated solar power (CSP) systems[3]. Pfeiffer's vacuum technology also incorporates smart monitoring and control systems, allowing for real-time adjustments and optimized performance in varying solar conditions[4].

Strengths: High vacuum efficiency, temperature resistance, and smart control systems. Weaknesses: Potentially higher initial costs and complexity compared to simpler vacuum solutions.

TVP Solar SA

Technical Solution: TVP Solar SA specializes in high-vacuum flat solar thermal panels that leverage advanced vacuum pump technology. Their panels use a proprietary vacuum-sealed design to minimize heat losses, significantly improving energy efficiency in solar thermal applications[1]. The company employs ultra-high vacuum levels (10^-5 mbar) maintained by specialized getter pumps integrated into each panel[2]. This vacuum environment virtually eliminates convection and conduction losses, allowing for high-temperature operations (up to 200°C) even in cold climates[3]. TVP's panels incorporate a unique evacuation and sealing process that ensures long-term vacuum stability without the need for continuous pumping, reducing operational costs and complexity[4].

Strengths: Exceptional thermal insulation, high operating temperatures, and low maintenance requirements. Weaknesses: Higher production costs and potential for vacuum failure over extended periods.

Core Vacuum Innovations

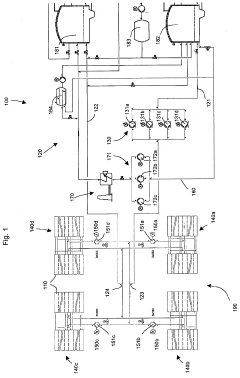

Heat pump solar installation

PatentWO2007147186A2

Innovation

- A heat pump solar system with a variable temperature lift using a medium with a low boiling point, where two machines with interconnected shafts or housed in a common housing operate with flow-controlled mechanisms to adjust compression and expansion, allowing for efficient energy transfer and mechanical energy conversion, reducing electrical energy consumption by utilizing solar and environmental heat.

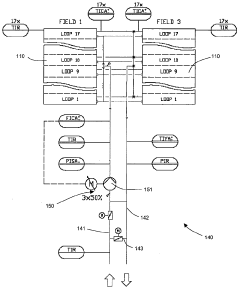

Solar installation with an improved heat carrier fluid circuit

PatentWO2009109220A1

Innovation

- The solar system employs hydraulic decoupling of the central circuit section and branch circuit sections, using a central pumping station with lower delivery pressure and branch pump stations to increase pressure as needed, allowing for decentralized pressure management and precise temperature control, enabling the use of less expensive heat transfer fluids and reducing wear and maintenance.

Environmental Impact

The integration of vacuum pumps in advanced solar thermal technology has significant environmental implications, both positive and negative. On the positive side, this combination contributes to the expansion of renewable energy sources, potentially reducing reliance on fossil fuels and mitigating greenhouse gas emissions. Solar thermal systems enhanced by vacuum pumps can achieve higher efficiency in energy conversion, maximizing the utilization of solar resources and minimizing waste.

However, the environmental impact of manufacturing and disposing of vacuum pumps must be considered. The production process involves the use of various materials, including metals and plastics, which may have associated extraction and processing impacts. Additionally, the energy consumed during the manufacturing phase should be factored into the overall environmental assessment of the technology.

Vacuum pumps in solar thermal systems often require regular maintenance and replacement of components, which can generate waste. Proper disposal and recycling protocols are essential to minimize the environmental footprint of these systems throughout their lifecycle. The use of lubricants and coolants in vacuum pumps also presents potential environmental risks if not managed correctly, as leaks or improper disposal could lead to soil or water contamination.

On the other hand, the improved efficiency of solar thermal systems facilitated by vacuum pumps can lead to a reduction in land use requirements for solar installations. This efficiency gain may help preserve natural habitats and minimize the visual impact of large-scale solar projects on landscapes. Furthermore, the enhanced performance of these systems could accelerate the adoption of solar thermal technology, indirectly contributing to a decrease in air pollution and water consumption associated with conventional power generation methods.

The noise pollution generated by vacuum pumps in solar thermal installations is another environmental consideration. While generally not as significant as other industrial noise sources, it may still impact local ecosystems and nearby communities. Implementing noise reduction measures and strategic placement of pump systems can help mitigate this issue.

Lastly, the potential for vacuum pump technology to enable more efficient thermal energy storage in solar systems could have far-reaching environmental benefits. Improved storage capabilities could address the intermittency challenges of solar power, reducing the need for backup fossil fuel generation and further decreasing overall emissions from the energy sector.

In conclusion, while vacuum pumps in advanced solar thermal technology offer substantial environmental benefits through increased renewable energy efficiency, careful consideration must be given to their production, operation, and end-of-life management to ensure a net positive environmental impact.

However, the environmental impact of manufacturing and disposing of vacuum pumps must be considered. The production process involves the use of various materials, including metals and plastics, which may have associated extraction and processing impacts. Additionally, the energy consumed during the manufacturing phase should be factored into the overall environmental assessment of the technology.

Vacuum pumps in solar thermal systems often require regular maintenance and replacement of components, which can generate waste. Proper disposal and recycling protocols are essential to minimize the environmental footprint of these systems throughout their lifecycle. The use of lubricants and coolants in vacuum pumps also presents potential environmental risks if not managed correctly, as leaks or improper disposal could lead to soil or water contamination.

On the other hand, the improved efficiency of solar thermal systems facilitated by vacuum pumps can lead to a reduction in land use requirements for solar installations. This efficiency gain may help preserve natural habitats and minimize the visual impact of large-scale solar projects on landscapes. Furthermore, the enhanced performance of these systems could accelerate the adoption of solar thermal technology, indirectly contributing to a decrease in air pollution and water consumption associated with conventional power generation methods.

The noise pollution generated by vacuum pumps in solar thermal installations is another environmental consideration. While generally not as significant as other industrial noise sources, it may still impact local ecosystems and nearby communities. Implementing noise reduction measures and strategic placement of pump systems can help mitigate this issue.

Lastly, the potential for vacuum pump technology to enable more efficient thermal energy storage in solar systems could have far-reaching environmental benefits. Improved storage capabilities could address the intermittency challenges of solar power, reducing the need for backup fossil fuel generation and further decreasing overall emissions from the energy sector.

In conclusion, while vacuum pumps in advanced solar thermal technology offer substantial environmental benefits through increased renewable energy efficiency, careful consideration must be given to their production, operation, and end-of-life management to ensure a net positive environmental impact.

Cost-Benefit Analysis

The integration of vacuum pumps in advanced solar thermal technology presents a complex cost-benefit scenario that requires careful analysis. On the cost side, the initial investment for high-quality vacuum pumps can be substantial, often representing a significant portion of the overall system expenses. These pumps, designed to maintain the necessary vacuum environment in solar thermal collectors, demand precision engineering and durable materials, contributing to their higher price point. Additionally, the installation process may require specialized expertise, further adding to the upfront costs.

Operational expenses must also be considered, including energy consumption for pump operation and regular maintenance to ensure optimal performance. While modern vacuum pumps are designed for efficiency, they still contribute to the overall energy footprint of the solar thermal system. Periodic servicing, replacement of wear parts, and potential downtime for repairs factor into the long-term cost calculations.

However, the benefits of incorporating vacuum pumps in advanced solar thermal technology are considerable and often outweigh the costs over the system's lifespan. The primary advantage is the significant increase in thermal efficiency. By creating and maintaining a vacuum within the solar collectors, heat loss through convection and conduction is drastically reduced. This results in higher operating temperatures and improved energy capture, especially in regions with variable climate conditions.

The enhanced efficiency translates directly into economic benefits. Systems equipped with vacuum technology can generate more usable heat from the same solar input, effectively lowering the cost per unit of energy produced. This improved performance can lead to faster return on investment and increased long-term savings on energy costs for end-users.

Furthermore, the use of vacuum pumps extends the operational range of solar thermal systems. They enable effective heat collection even in lower ambient temperatures or during periods of reduced sunlight, expanding the geographical areas and seasons in which solar thermal technology is viable. This broader applicability can open new markets and increase the overall adoption of solar thermal solutions.

From an environmental perspective, the increased efficiency and extended operational range contribute to a reduction in fossil fuel dependence and associated carbon emissions. While the production and operation of vacuum pumps have their own environmental footprint, the net effect is generally positive when considering the lifecycle emissions of the entire solar thermal system.

In conclusion, while the integration of vacuum pumps in advanced solar thermal technology does incur additional costs, the long-term benefits in terms of improved efficiency, expanded applicability, and environmental impact present a compelling value proposition. As technology advances and economies of scale come into play, it is likely that the cost-benefit ratio will continue to improve, further solidifying the role of vacuum pumps in the future of solar thermal energy.

Operational expenses must also be considered, including energy consumption for pump operation and regular maintenance to ensure optimal performance. While modern vacuum pumps are designed for efficiency, they still contribute to the overall energy footprint of the solar thermal system. Periodic servicing, replacement of wear parts, and potential downtime for repairs factor into the long-term cost calculations.

However, the benefits of incorporating vacuum pumps in advanced solar thermal technology are considerable and often outweigh the costs over the system's lifespan. The primary advantage is the significant increase in thermal efficiency. By creating and maintaining a vacuum within the solar collectors, heat loss through convection and conduction is drastically reduced. This results in higher operating temperatures and improved energy capture, especially in regions with variable climate conditions.

The enhanced efficiency translates directly into economic benefits. Systems equipped with vacuum technology can generate more usable heat from the same solar input, effectively lowering the cost per unit of energy produced. This improved performance can lead to faster return on investment and increased long-term savings on energy costs for end-users.

Furthermore, the use of vacuum pumps extends the operational range of solar thermal systems. They enable effective heat collection even in lower ambient temperatures or during periods of reduced sunlight, expanding the geographical areas and seasons in which solar thermal technology is viable. This broader applicability can open new markets and increase the overall adoption of solar thermal solutions.

From an environmental perspective, the increased efficiency and extended operational range contribute to a reduction in fossil fuel dependence and associated carbon emissions. While the production and operation of vacuum pumps have their own environmental footprint, the net effect is generally positive when considering the lifecycle emissions of the entire solar thermal system.

In conclusion, while the integration of vacuum pumps in advanced solar thermal technology does incur additional costs, the long-term benefits in terms of improved efficiency, expanded applicability, and environmental impact present a compelling value proposition. As technology advances and economies of scale come into play, it is likely that the cost-benefit ratio will continue to improve, further solidifying the role of vacuum pumps in the future of solar thermal energy.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!