How Vacuum Pumps Influence High-Efficiency Catalyst Recovery

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vacuum Pump Tech Evolution

Vacuum pump technology has undergone significant evolution since its inception, playing a crucial role in various industrial processes, including catalyst recovery. The journey of vacuum pump development can be traced back to the 17th century with the invention of the first mechanical vacuum pump by Otto von Guericke. However, it wasn't until the 20th century that vacuum pumps began to see widespread industrial applications.

In the early 1900s, the introduction of rotary vane pumps marked a significant milestone in vacuum technology. These pumps offered improved efficiency and reliability compared to their predecessors, making them suitable for a wide range of industrial applications. The mid-20th century saw the development of diffusion pumps, which could achieve much higher vacuum levels, opening up new possibilities in scientific research and industrial processes.

The 1960s and 1970s witnessed the emergence of turbomolecular pumps, revolutionizing high-vacuum applications. These pumps utilized high-speed rotors to impart momentum to gas molecules, effectively creating a vacuum. Their ability to achieve ultra-high vacuum levels made them invaluable in semiconductor manufacturing and particle accelerators.

The late 20th century brought about significant advancements in dry vacuum pump technology. Unlike oil-sealed pumps, dry pumps eliminated the risk of oil contamination, making them ideal for clean processes such as those in the pharmaceutical and food industries. This innovation also proved beneficial for catalyst recovery processes, where purity is paramount.

In recent years, the focus has shifted towards energy efficiency and environmental sustainability. Modern vacuum pumps incorporate advanced materials, precision engineering, and intelligent control systems to optimize performance while minimizing energy consumption. Variable speed drives and smart monitoring systems have become common features, allowing for adaptive operation based on process requirements.

The advent of Industry 4.0 has further transformed vacuum pump technology. Integration with IoT (Internet of Things) platforms enables real-time monitoring, predictive maintenance, and remote operation of vacuum systems. This connectivity has significantly improved the reliability and efficiency of vacuum-dependent processes, including catalyst recovery.

Looking towards the future, emerging technologies such as quantum vacuum pumps and plasma-assisted vacuum generation show promise for achieving even higher vacuum levels with greater efficiency. These innovations could potentially revolutionize catalyst recovery processes by enabling more precise control over reaction conditions and separation techniques.

Throughout this evolution, the impact of vacuum pump technology on catalyst recovery has been profound. Improved vacuum capabilities have enhanced the efficiency of separation processes, reduced contamination risks, and enabled the recovery of increasingly valuable and sensitive catalysts. As vacuum pump technology continues to advance, it is expected to play an even more critical role in developing sustainable and economically viable catalyst recovery methods.

In the early 1900s, the introduction of rotary vane pumps marked a significant milestone in vacuum technology. These pumps offered improved efficiency and reliability compared to their predecessors, making them suitable for a wide range of industrial applications. The mid-20th century saw the development of diffusion pumps, which could achieve much higher vacuum levels, opening up new possibilities in scientific research and industrial processes.

The 1960s and 1970s witnessed the emergence of turbomolecular pumps, revolutionizing high-vacuum applications. These pumps utilized high-speed rotors to impart momentum to gas molecules, effectively creating a vacuum. Their ability to achieve ultra-high vacuum levels made them invaluable in semiconductor manufacturing and particle accelerators.

The late 20th century brought about significant advancements in dry vacuum pump technology. Unlike oil-sealed pumps, dry pumps eliminated the risk of oil contamination, making them ideal for clean processes such as those in the pharmaceutical and food industries. This innovation also proved beneficial for catalyst recovery processes, where purity is paramount.

In recent years, the focus has shifted towards energy efficiency and environmental sustainability. Modern vacuum pumps incorporate advanced materials, precision engineering, and intelligent control systems to optimize performance while minimizing energy consumption. Variable speed drives and smart monitoring systems have become common features, allowing for adaptive operation based on process requirements.

The advent of Industry 4.0 has further transformed vacuum pump technology. Integration with IoT (Internet of Things) platforms enables real-time monitoring, predictive maintenance, and remote operation of vacuum systems. This connectivity has significantly improved the reliability and efficiency of vacuum-dependent processes, including catalyst recovery.

Looking towards the future, emerging technologies such as quantum vacuum pumps and plasma-assisted vacuum generation show promise for achieving even higher vacuum levels with greater efficiency. These innovations could potentially revolutionize catalyst recovery processes by enabling more precise control over reaction conditions and separation techniques.

Throughout this evolution, the impact of vacuum pump technology on catalyst recovery has been profound. Improved vacuum capabilities have enhanced the efficiency of separation processes, reduced contamination risks, and enabled the recovery of increasingly valuable and sensitive catalysts. As vacuum pump technology continues to advance, it is expected to play an even more critical role in developing sustainable and economically viable catalyst recovery methods.

Catalyst Recovery Market

The catalyst recovery market has experienced significant growth in recent years, driven by increasing environmental regulations and the rising demand for sustainable industrial processes. This market encompasses a wide range of industries, including petrochemicals, pharmaceuticals, and fine chemicals, where catalysts play a crucial role in enhancing reaction efficiency and product yield.

The global catalyst recovery market is expected to continue its upward trajectory, with a compound annual growth rate (CAGR) projected to remain strong over the next five years. This growth is primarily attributed to the expanding industrial sectors in emerging economies and the growing emphasis on circular economy principles in developed nations.

One of the key factors influencing market dynamics is the increasing focus on resource conservation and waste reduction. As catalysts often contain precious metals or rare earth elements, their recovery and recycling have become economically viable and environmentally necessary. This trend has led to the development of more efficient recovery technologies, including advanced vacuum pump systems that enhance the separation and purification processes.

The market is characterized by a diverse range of recovery methods, each tailored to specific catalyst types and industrial applications. Hydrometallurgical and pyrometallurgical processes remain dominant, but newer technologies such as supercritical fluid extraction and electrochemical recovery are gaining traction. Vacuum-based separation techniques have emerged as a particularly promising area, offering improved efficiency and reduced environmental impact.

Geographically, North America and Europe currently lead the catalyst recovery market, owing to their stringent environmental regulations and well-established industrial infrastructure. However, the Asia-Pacific region is expected to witness the fastest growth, driven by rapid industrialization in countries like China and India, coupled with increasing awareness of sustainable practices.

The market landscape is highly competitive, with a mix of large multinational corporations and specialized service providers. Key players are investing heavily in research and development to improve recovery rates and reduce processing costs. Collaborations between catalyst manufacturers, end-users, and recovery specialists are becoming more common, fostering innovation and creating integrated solutions.

As the industry evolves, several trends are shaping its future. There is a growing emphasis on developing recovery processes that are not only efficient but also environmentally friendly and energy-efficient. This has led to increased interest in green chemistry approaches and the use of renewable energy sources in recovery operations. Additionally, the integration of digital technologies, such as artificial intelligence and machine learning, is expected to optimize recovery processes and improve overall efficiency.

The global catalyst recovery market is expected to continue its upward trajectory, with a compound annual growth rate (CAGR) projected to remain strong over the next five years. This growth is primarily attributed to the expanding industrial sectors in emerging economies and the growing emphasis on circular economy principles in developed nations.

One of the key factors influencing market dynamics is the increasing focus on resource conservation and waste reduction. As catalysts often contain precious metals or rare earth elements, their recovery and recycling have become economically viable and environmentally necessary. This trend has led to the development of more efficient recovery technologies, including advanced vacuum pump systems that enhance the separation and purification processes.

The market is characterized by a diverse range of recovery methods, each tailored to specific catalyst types and industrial applications. Hydrometallurgical and pyrometallurgical processes remain dominant, but newer technologies such as supercritical fluid extraction and electrochemical recovery are gaining traction. Vacuum-based separation techniques have emerged as a particularly promising area, offering improved efficiency and reduced environmental impact.

Geographically, North America and Europe currently lead the catalyst recovery market, owing to their stringent environmental regulations and well-established industrial infrastructure. However, the Asia-Pacific region is expected to witness the fastest growth, driven by rapid industrialization in countries like China and India, coupled with increasing awareness of sustainable practices.

The market landscape is highly competitive, with a mix of large multinational corporations and specialized service providers. Key players are investing heavily in research and development to improve recovery rates and reduce processing costs. Collaborations between catalyst manufacturers, end-users, and recovery specialists are becoming more common, fostering innovation and creating integrated solutions.

As the industry evolves, several trends are shaping its future. There is a growing emphasis on developing recovery processes that are not only efficient but also environmentally friendly and energy-efficient. This has led to increased interest in green chemistry approaches and the use of renewable energy sources in recovery operations. Additionally, the integration of digital technologies, such as artificial intelligence and machine learning, is expected to optimize recovery processes and improve overall efficiency.

Vacuum Pump Challenges

Vacuum pumps play a crucial role in high-efficiency catalyst recovery processes, but they also face several significant challenges. One of the primary issues is the handling of corrosive and abrasive materials. Catalysts often contain reactive compounds that can damage pump components, leading to reduced performance and increased maintenance requirements. This necessitates the use of specialized materials and coatings to protect pump internals, which can substantially increase costs.

Another challenge is maintaining consistent vacuum levels across different operating conditions. Fluctuations in temperature, pressure, and gas composition can affect pump efficiency and stability. This is particularly problematic in catalyst recovery systems where precise control over process parameters is essential for optimal performance. Pump manufacturers must develop advanced control systems and adaptive technologies to ensure stable operation under varying conditions.

The need for high vacuum levels in catalyst recovery processes also presents a significant challenge. Achieving and maintaining deep vacuum conditions requires sophisticated pump designs and often multiple stages of pumping. This complexity increases both capital and operating costs, as well as the potential for system failures. Additionally, the energy consumption of high-performance vacuum pumps can be substantial, impacting the overall efficiency and sustainability of the recovery process.

Contamination control is another critical challenge for vacuum pumps in catalyst recovery applications. Fine catalyst particles can enter the pump system, causing wear and potentially contaminating the recovered product. This necessitates the implementation of effective filtration and separation systems, which can add complexity and pressure drop to the overall process.

Scaling vacuum pump technology for industrial-scale catalyst recovery operations presents its own set of challenges. Large-scale systems require pumps with high throughput capacities while maintaining efficiency and reliability. Balancing these factors often involves trade-offs in design and performance, requiring careful optimization for specific applications.

Maintenance and downtime management are ongoing challenges in vacuum pump operation for catalyst recovery. The harsh operating conditions and potential for contamination mean that pumps may require frequent servicing or replacement of components. Minimizing downtime while ensuring proper maintenance is crucial for maintaining process efficiency and avoiding costly production interruptions.

Lastly, the integration of vacuum pumps with other process equipment in catalyst recovery systems can be complex. Ensuring compatibility with upstream and downstream processes, as well as with control and monitoring systems, requires careful design and engineering. This integration challenge is further complicated by the need for flexibility to accommodate different catalyst types and recovery processes.

Another challenge is maintaining consistent vacuum levels across different operating conditions. Fluctuations in temperature, pressure, and gas composition can affect pump efficiency and stability. This is particularly problematic in catalyst recovery systems where precise control over process parameters is essential for optimal performance. Pump manufacturers must develop advanced control systems and adaptive technologies to ensure stable operation under varying conditions.

The need for high vacuum levels in catalyst recovery processes also presents a significant challenge. Achieving and maintaining deep vacuum conditions requires sophisticated pump designs and often multiple stages of pumping. This complexity increases both capital and operating costs, as well as the potential for system failures. Additionally, the energy consumption of high-performance vacuum pumps can be substantial, impacting the overall efficiency and sustainability of the recovery process.

Contamination control is another critical challenge for vacuum pumps in catalyst recovery applications. Fine catalyst particles can enter the pump system, causing wear and potentially contaminating the recovered product. This necessitates the implementation of effective filtration and separation systems, which can add complexity and pressure drop to the overall process.

Scaling vacuum pump technology for industrial-scale catalyst recovery operations presents its own set of challenges. Large-scale systems require pumps with high throughput capacities while maintaining efficiency and reliability. Balancing these factors often involves trade-offs in design and performance, requiring careful optimization for specific applications.

Maintenance and downtime management are ongoing challenges in vacuum pump operation for catalyst recovery. The harsh operating conditions and potential for contamination mean that pumps may require frequent servicing or replacement of components. Minimizing downtime while ensuring proper maintenance is crucial for maintaining process efficiency and avoiding costly production interruptions.

Lastly, the integration of vacuum pumps with other process equipment in catalyst recovery systems can be complex. Ensuring compatibility with upstream and downstream processes, as well as with control and monitoring systems, requires careful design and engineering. This integration challenge is further complicated by the need for flexibility to accommodate different catalyst types and recovery processes.

Current Vacuum Solutions

01 Improved rotor design for vacuum pumps

Enhancing the rotor design in vacuum pumps can significantly improve efficiency. This includes optimizing the shape, material, and configuration of the rotor to reduce friction, minimize energy loss, and increase pumping capacity. Advanced rotor designs can lead to better performance and higher vacuum levels.- Improved rotor design for vacuum pumps: Enhancing the rotor design in vacuum pumps can significantly improve efficiency. This includes optimizing the shape, material, and configuration of the rotor to reduce friction, minimize energy loss, and increase pumping speed. Advanced rotor designs can also help in maintaining consistent performance across different pressure ranges.

- Multi-stage vacuum pump systems: Implementing multi-stage vacuum pump systems can enhance overall efficiency. By combining different types of pumps in series or parallel configurations, these systems can achieve higher vacuum levels and improved pumping speeds. Each stage is optimized for a specific pressure range, allowing for better performance across the entire vacuum range.

- Advanced sealing technologies: Incorporating advanced sealing technologies in vacuum pumps can significantly reduce leakage and improve efficiency. This includes the use of innovative materials and designs for gaskets, O-rings, and other sealing components. Improved seals help maintain vacuum integrity, reduce power consumption, and extend the operational life of the pump.

- Energy-efficient motor and drive systems: Utilizing energy-efficient motors and drive systems can greatly enhance the overall efficiency of vacuum pumps. This includes the use of variable speed drives, high-efficiency electric motors, and advanced control systems that optimize power consumption based on the required vacuum level and pumping speed.

- Innovative cooling and lubrication methods: Implementing innovative cooling and lubrication methods can improve the efficiency and longevity of vacuum pumps. This includes advanced heat dissipation techniques, the use of specialized lubricants, and optimized lubrication systems that reduce friction and wear while maintaining optimal operating temperatures.

02 Multi-stage vacuum pump systems

Implementing multi-stage vacuum pump systems can enhance overall efficiency. By combining different types of pumps or multiple pumping stages, these systems can achieve higher vacuum levels and improved pumping speeds. This approach allows for better performance across a wider range of pressure conditions.Expand Specific Solutions03 Advanced sealing technologies

Incorporating advanced sealing technologies in vacuum pumps can significantly reduce leakage and improve efficiency. This includes the use of innovative materials and designs for gaskets, O-rings, and other sealing components. Better seals lead to improved vacuum maintenance and reduced power consumption.Expand Specific Solutions04 Energy-efficient motor and drive systems

Utilizing energy-efficient motors and drive systems can greatly enhance the overall efficiency of vacuum pumps. This includes the use of variable speed drives, high-efficiency electric motors, and advanced control systems that optimize power consumption based on the required vacuum level and pumping speed.Expand Specific Solutions05 Innovative cooling and lubrication methods

Implementing innovative cooling and lubrication methods can improve the efficiency and longevity of vacuum pumps. This includes advanced heat dissipation techniques, optimized lubricant formulations, and novel lubrication systems that reduce friction and wear while maintaining optimal operating temperatures.Expand Specific Solutions

Key Vacuum Pump Makers

The vacuum pump industry for high-efficiency catalyst recovery is in a mature stage, with a global market size estimated to be in the billions of dollars. The technology has reached a high level of sophistication, with companies like LEYBOLD AG and Pfeiffer Vacuum GmbH leading in innovation. Major players such as Air Products & Chemicals, Inc. and China Petroleum & Chemical Corp. are integrating these technologies into their large-scale operations. The competitive landscape is characterized by a mix of specialized vacuum pump manufacturers and diversified industrial conglomerates, with increasing focus on energy efficiency and process optimization. Emerging trends include the development of smart, IoT-enabled pumps and the application of advanced materials to enhance performance and durability.

LEYBOLD AG

Technical Solution: LEYBOLD AG has developed advanced vacuum pump technologies specifically designed for high-efficiency catalyst recovery processes. Their SCREWLINE series of dry screw vacuum pumps offers robust performance in harsh chemical environments, with corrosion-resistant materials and specialized coatings[1]. These pumps can achieve deep vacuum levels down to 0.01 mbar, crucial for efficient catalyst separation and recovery[2]. LEYBOLD's pumps incorporate innovative sealing systems and temperature management to handle condensable vapors and fine catalyst particles without contamination or degradation[3]. The company has also implemented smart control systems that optimize pump performance based on process conditions, leading to energy savings of up to 50% compared to conventional systems[4].

Strengths: Specialized designs for chemical resistance, high vacuum capability, and energy efficiency. Weaknesses: May have higher initial costs compared to general-purpose vacuum pumps.

Air Products & Chemicals, Inc.

Technical Solution: Air Products & Chemicals has developed a comprehensive approach to catalyst recovery using advanced vacuum technology. Their system integrates custom-designed vacuum pumps with proprietary separation and purification processes. The company's vacuum pumps are engineered to handle high-temperature, corrosive environments typical in catalyst recovery operations[5]. They employ multi-stage vacuum systems that can achieve pressures as low as 10^-6 torr, enabling efficient separation of valuable catalysts from process streams[6]. Air Products has also pioneered the use of cryogenic vacuum pumps in certain catalyst recovery applications, allowing for the capture of ultra-fine catalyst particles that might be lost in conventional systems[7]. Their integrated approach includes real-time monitoring and adaptive control algorithms to optimize recovery rates and energy consumption.

Strengths: Integrated systems approach, expertise in handling challenging process conditions, and high recovery rates. Weaknesses: Solutions may be complex and require significant process integration.

Vacuum Pump Innovations

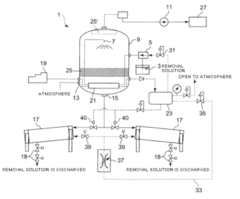

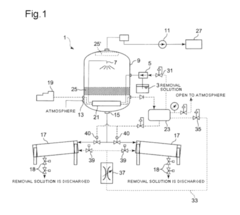

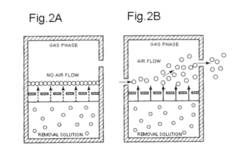

Vacuum-evaporation-based VOC recovery device and method therefor

PatentInactiveUS20120193301A1

Innovation

- A VOC removal solution regeneration and recovery apparatus that uses a vacuum vessel, a compressor to generate compressed air for thermal and pressure energy, and a heat exchanger to efficiently evaporate VOC without a heater or gas-permeable membrane, utilizing an air-driven pump and evaporation enhancing gas to increase surface area and efficiency.

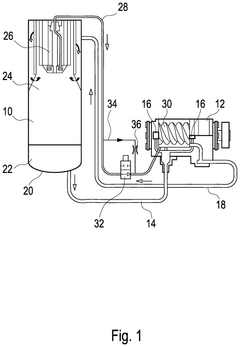

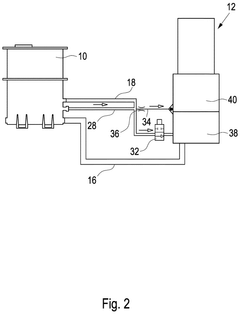

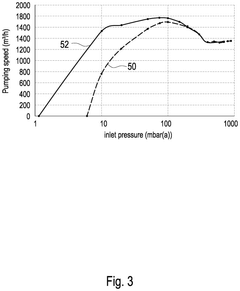

Vacuum pump lubricant recovery system returning lubricant from the air filter based on pressure measurements in the vacuum pump

PatentActiveUS12104597B2

Innovation

- A lubricant recovery system with an air filter inside the reservoir, a valve in the scavenge line controlled by a pressure gauge, and a bypass line to maintain low-pressure at the air filter, ensuring continuous lubricant filtration and scavenging, even under conditions of reduced lubricant carryover, thereby preventing air from entering the vacuum pump.

Environmental Regulations

Environmental regulations play a crucial role in shaping the landscape of catalyst recovery processes, particularly those involving vacuum pumps. These regulations are designed to minimize the environmental impact of industrial operations and promote sustainable practices in the chemical and manufacturing sectors.

In recent years, there has been a significant increase in the stringency of environmental regulations worldwide, with a focus on reducing emissions, improving energy efficiency, and minimizing waste generation. This regulatory landscape has had a profound impact on the development and implementation of catalyst recovery technologies, including those utilizing vacuum pumps.

One of the primary areas of concern for environmental regulators is the emission of volatile organic compounds (VOCs) and particulate matter during catalyst recovery processes. Vacuum pumps, when used in these applications, can potentially contribute to these emissions if not properly controlled. As a result, many jurisdictions have implemented strict emission limits and monitoring requirements for industrial facilities engaged in catalyst recovery.

To comply with these regulations, companies are increasingly adopting advanced vacuum pump technologies that offer improved sealing and filtration capabilities. These innovations help to minimize fugitive emissions and ensure that the recovered catalyst materials are effectively contained within the system. Additionally, some regulatory frameworks now require the use of best available techniques (BAT) for catalyst recovery, which often include state-of-the-art vacuum pump systems.

Energy efficiency is another key focus of environmental regulations affecting catalyst recovery processes. Many countries have implemented energy efficiency standards and incentives to encourage the adoption of more efficient technologies. In the context of vacuum pumps, this has led to the development of energy-efficient pump designs that consume less power while maintaining high performance in catalyst recovery applications.

Water conservation and wastewater management are also important aspects of environmental regulations impacting catalyst recovery. Vacuum pumps that utilize water for sealing or cooling purposes must adhere to strict water usage and discharge limits. This has prompted the development of dry vacuum pump technologies that eliminate the need for water in the recovery process, thereby reducing water consumption and the associated environmental impact.

The regulatory landscape also emphasizes the importance of proper handling and disposal of recovered catalysts and associated waste materials. Vacuum pump systems used in catalyst recovery must be designed to facilitate the safe collection and containment of these materials, ensuring compliance with hazardous waste regulations and minimizing the risk of environmental contamination.

As environmental regulations continue to evolve, it is likely that the requirements for catalyst recovery processes will become even more stringent. This ongoing regulatory pressure is expected to drive further innovations in vacuum pump technology, leading to more efficient, environmentally friendly, and sustainable catalyst recovery solutions in the future.

In recent years, there has been a significant increase in the stringency of environmental regulations worldwide, with a focus on reducing emissions, improving energy efficiency, and minimizing waste generation. This regulatory landscape has had a profound impact on the development and implementation of catalyst recovery technologies, including those utilizing vacuum pumps.

One of the primary areas of concern for environmental regulators is the emission of volatile organic compounds (VOCs) and particulate matter during catalyst recovery processes. Vacuum pumps, when used in these applications, can potentially contribute to these emissions if not properly controlled. As a result, many jurisdictions have implemented strict emission limits and monitoring requirements for industrial facilities engaged in catalyst recovery.

To comply with these regulations, companies are increasingly adopting advanced vacuum pump technologies that offer improved sealing and filtration capabilities. These innovations help to minimize fugitive emissions and ensure that the recovered catalyst materials are effectively contained within the system. Additionally, some regulatory frameworks now require the use of best available techniques (BAT) for catalyst recovery, which often include state-of-the-art vacuum pump systems.

Energy efficiency is another key focus of environmental regulations affecting catalyst recovery processes. Many countries have implemented energy efficiency standards and incentives to encourage the adoption of more efficient technologies. In the context of vacuum pumps, this has led to the development of energy-efficient pump designs that consume less power while maintaining high performance in catalyst recovery applications.

Water conservation and wastewater management are also important aspects of environmental regulations impacting catalyst recovery. Vacuum pumps that utilize water for sealing or cooling purposes must adhere to strict water usage and discharge limits. This has prompted the development of dry vacuum pump technologies that eliminate the need for water in the recovery process, thereby reducing water consumption and the associated environmental impact.

The regulatory landscape also emphasizes the importance of proper handling and disposal of recovered catalysts and associated waste materials. Vacuum pump systems used in catalyst recovery must be designed to facilitate the safe collection and containment of these materials, ensuring compliance with hazardous waste regulations and minimizing the risk of environmental contamination.

As environmental regulations continue to evolve, it is likely that the requirements for catalyst recovery processes will become even more stringent. This ongoing regulatory pressure is expected to drive further innovations in vacuum pump technology, leading to more efficient, environmentally friendly, and sustainable catalyst recovery solutions in the future.

Economic Impact Analysis

The economic impact of vacuum pumps on high-efficiency catalyst recovery is significant and multifaceted. The implementation of advanced vacuum pump technologies in catalyst recovery processes has led to substantial cost savings and increased operational efficiency across various industries, particularly in petrochemical, chemical, and pharmaceutical sectors.

Vacuum pumps play a crucial role in enhancing the recovery rate of catalysts, which are often expensive and critical components in many industrial processes. By improving the efficiency of catalyst recovery, companies can significantly reduce their raw material costs and minimize waste. This cost reduction directly translates to improved profit margins and increased competitiveness in the market.

The use of high-performance vacuum pumps in catalyst recovery systems has also resulted in reduced energy consumption. Modern vacuum pumps are designed to operate more efficiently, requiring less power to achieve the same or better performance levels compared to older models. This energy efficiency not only reduces operational costs but also aligns with global sustainability goals, potentially leading to carbon credits or other environmental incentives for companies.

Furthermore, the enhanced catalyst recovery efficiency enabled by advanced vacuum pump technologies has led to increased production capacity. With more efficient recovery processes, downtime for catalyst replacement or regeneration is reduced, allowing for longer production runs and higher overall output. This increased productivity can significantly boost a company's revenue potential and market share.

The economic benefits extend beyond individual companies to the broader industry ecosystem. The demand for high-efficiency vacuum pumps has stimulated innovation and competition among equipment manufacturers, leading to continuous improvements in pump technology. This technological advancement has created new job opportunities in research, development, and manufacturing sectors related to vacuum pump production and catalyst recovery systems.

Additionally, the improved catalyst recovery processes have contributed to the development of a more circular economy within industries that heavily rely on catalysts. By maximizing the reuse and recycling of catalysts, companies can reduce their dependence on raw material imports and minimize the environmental impact of their operations. This shift towards a more sustainable business model can lead to long-term economic benefits, including reduced exposure to supply chain disruptions and potential regulatory advantages.

In conclusion, the influence of vacuum pumps on high-efficiency catalyst recovery has far-reaching economic implications. From direct cost savings and increased productivity to broader industry innovation and sustainability benefits, the economic impact is substantial and continues to shape the competitive landscape of catalyst-dependent industries.

Vacuum pumps play a crucial role in enhancing the recovery rate of catalysts, which are often expensive and critical components in many industrial processes. By improving the efficiency of catalyst recovery, companies can significantly reduce their raw material costs and minimize waste. This cost reduction directly translates to improved profit margins and increased competitiveness in the market.

The use of high-performance vacuum pumps in catalyst recovery systems has also resulted in reduced energy consumption. Modern vacuum pumps are designed to operate more efficiently, requiring less power to achieve the same or better performance levels compared to older models. This energy efficiency not only reduces operational costs but also aligns with global sustainability goals, potentially leading to carbon credits or other environmental incentives for companies.

Furthermore, the enhanced catalyst recovery efficiency enabled by advanced vacuum pump technologies has led to increased production capacity. With more efficient recovery processes, downtime for catalyst replacement or regeneration is reduced, allowing for longer production runs and higher overall output. This increased productivity can significantly boost a company's revenue potential and market share.

The economic benefits extend beyond individual companies to the broader industry ecosystem. The demand for high-efficiency vacuum pumps has stimulated innovation and competition among equipment manufacturers, leading to continuous improvements in pump technology. This technological advancement has created new job opportunities in research, development, and manufacturing sectors related to vacuum pump production and catalyst recovery systems.

Additionally, the improved catalyst recovery processes have contributed to the development of a more circular economy within industries that heavily rely on catalysts. By maximizing the reuse and recycling of catalysts, companies can reduce their dependence on raw material imports and minimize the environmental impact of their operations. This shift towards a more sustainable business model can lead to long-term economic benefits, including reduced exposure to supply chain disruptions and potential regulatory advantages.

In conclusion, the influence of vacuum pumps on high-efficiency catalyst recovery has far-reaching economic implications. From direct cost savings and increased productivity to broader industry innovation and sustainability benefits, the economic impact is substantial and continues to shape the competitive landscape of catalyst-dependent industries.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!