How Vacuum Pumps Influence Sustainable Cement Production Techniques

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vacuum Pump Evolution in Cement Industry

The evolution of vacuum pumps in the cement industry has been a crucial factor in enhancing the efficiency and sustainability of cement production techniques. Over the past decades, vacuum technology has undergone significant advancements, revolutionizing various stages of the cement manufacturing process.

In the early stages of cement production, vacuum pumps were primarily used for simple dewatering applications. However, as the industry recognized the potential of vacuum technology, its application expanded to more complex processes. The 1970s saw the introduction of vacuum filters in raw material preparation, which significantly improved the efficiency of slurry dewatering.

The 1980s marked a turning point with the development of more robust and energy-efficient vacuum pumps. These innovations allowed for the implementation of vacuum technology in clinker cooling systems, leading to improved product quality and reduced energy consumption. This period also witnessed the integration of vacuum systems in pneumatic conveying, enhancing material handling capabilities within cement plants.

The 1990s brought about a focus on environmental sustainability, driving the development of vacuum pumps with lower emissions and noise levels. This era saw the widespread adoption of vacuum degassing systems in cement grinding, resulting in improved cement fineness and strength. Additionally, vacuum technology began to play a crucial role in waste heat recovery systems, contributing to the overall energy efficiency of cement plants.

The turn of the millennium ushered in a new era of digital control and automation in vacuum pump systems. Smart vacuum pumps with advanced monitoring and control capabilities were introduced, allowing for real-time optimization of vacuum processes. This period also saw the development of multi-stage vacuum systems, capable of handling a wider range of applications within cement production.

In recent years, the focus has shifted towards developing vacuum pumps that align with the principles of Industry 4.0. IoT-enabled vacuum systems have emerged, offering predictive maintenance capabilities and seamless integration with plant-wide control systems. Furthermore, there has been a growing emphasis on developing vacuum pumps that can operate efficiently with alternative fuels and raw materials, supporting the cement industry's transition towards more sustainable practices.

The latest advancements in vacuum pump technology for the cement industry include the development of high-efficiency, oil-free vacuum pumps that minimize contamination risks and reduce maintenance requirements. Additionally, there is ongoing research into the application of vacuum technology in carbon capture and storage systems, positioning vacuum pumps as a key component in the cement industry's efforts to reduce its carbon footprint.

In the early stages of cement production, vacuum pumps were primarily used for simple dewatering applications. However, as the industry recognized the potential of vacuum technology, its application expanded to more complex processes. The 1970s saw the introduction of vacuum filters in raw material preparation, which significantly improved the efficiency of slurry dewatering.

The 1980s marked a turning point with the development of more robust and energy-efficient vacuum pumps. These innovations allowed for the implementation of vacuum technology in clinker cooling systems, leading to improved product quality and reduced energy consumption. This period also witnessed the integration of vacuum systems in pneumatic conveying, enhancing material handling capabilities within cement plants.

The 1990s brought about a focus on environmental sustainability, driving the development of vacuum pumps with lower emissions and noise levels. This era saw the widespread adoption of vacuum degassing systems in cement grinding, resulting in improved cement fineness and strength. Additionally, vacuum technology began to play a crucial role in waste heat recovery systems, contributing to the overall energy efficiency of cement plants.

The turn of the millennium ushered in a new era of digital control and automation in vacuum pump systems. Smart vacuum pumps with advanced monitoring and control capabilities were introduced, allowing for real-time optimization of vacuum processes. This period also saw the development of multi-stage vacuum systems, capable of handling a wider range of applications within cement production.

In recent years, the focus has shifted towards developing vacuum pumps that align with the principles of Industry 4.0. IoT-enabled vacuum systems have emerged, offering predictive maintenance capabilities and seamless integration with plant-wide control systems. Furthermore, there has been a growing emphasis on developing vacuum pumps that can operate efficiently with alternative fuels and raw materials, supporting the cement industry's transition towards more sustainable practices.

The latest advancements in vacuum pump technology for the cement industry include the development of high-efficiency, oil-free vacuum pumps that minimize contamination risks and reduce maintenance requirements. Additionally, there is ongoing research into the application of vacuum technology in carbon capture and storage systems, positioning vacuum pumps as a key component in the cement industry's efforts to reduce its carbon footprint.

Sustainable Cement Market Analysis

The sustainable cement market has been experiencing significant growth in recent years, driven by increasing environmental concerns and stringent regulations aimed at reducing carbon emissions in the construction industry. This market segment is characterized by the production of cement using alternative raw materials, energy-efficient processes, and innovative technologies that minimize the environmental impact of traditional cement manufacturing.

Global demand for sustainable cement is on the rise, with major markets including Europe, North America, and Asia-Pacific leading the adoption of eco-friendly construction materials. The market is expected to continue its upward trajectory, fueled by government initiatives promoting green building practices and the growing awareness among consumers and businesses about the importance of sustainable construction.

Key drivers of the sustainable cement market include the push for carbon neutrality in the construction sector, the implementation of circular economy principles, and the increasing focus on lifecycle assessment of building materials. Additionally, the rising costs associated with carbon emissions and the potential for carbon pricing mechanisms in various regions are incentivizing cement manufacturers to invest in sustainable production techniques.

The market is witnessing a shift towards the use of supplementary cementitious materials (SCMs) such as fly ash, slag, and silica fume, which not only reduce the carbon footprint of cement but also improve its performance characteristics. Furthermore, the adoption of alternative fuels and raw materials in cement production is gaining traction, with waste-derived fuels and industrial by-products increasingly being utilized to reduce reliance on fossil fuels and virgin raw materials.

Technological advancements play a crucial role in shaping the sustainable cement market. Innovations in clinker substitution, carbon capture and utilization (CCU) technologies, and energy-efficient grinding processes are contributing to the development of low-carbon cement products. The integration of digital technologies and automation in cement production is also enhancing process efficiency and reducing energy consumption.

Market challenges include the higher initial costs associated with sustainable cement production, the need for significant infrastructure investments, and the varying availability of alternative raw materials across different regions. However, these challenges are gradually being addressed through collaborative efforts between industry stakeholders, research institutions, and policymakers.

The competitive landscape of the sustainable cement market is characterized by a mix of established cement manufacturers adapting their processes and new entrants specializing in innovative, low-carbon cement solutions. Strategic partnerships and collaborations are becoming increasingly common as companies seek to leverage complementary expertise and resources to accelerate the development and commercialization of sustainable cement technologies.

Global demand for sustainable cement is on the rise, with major markets including Europe, North America, and Asia-Pacific leading the adoption of eco-friendly construction materials. The market is expected to continue its upward trajectory, fueled by government initiatives promoting green building practices and the growing awareness among consumers and businesses about the importance of sustainable construction.

Key drivers of the sustainable cement market include the push for carbon neutrality in the construction sector, the implementation of circular economy principles, and the increasing focus on lifecycle assessment of building materials. Additionally, the rising costs associated with carbon emissions and the potential for carbon pricing mechanisms in various regions are incentivizing cement manufacturers to invest in sustainable production techniques.

The market is witnessing a shift towards the use of supplementary cementitious materials (SCMs) such as fly ash, slag, and silica fume, which not only reduce the carbon footprint of cement but also improve its performance characteristics. Furthermore, the adoption of alternative fuels and raw materials in cement production is gaining traction, with waste-derived fuels and industrial by-products increasingly being utilized to reduce reliance on fossil fuels and virgin raw materials.

Technological advancements play a crucial role in shaping the sustainable cement market. Innovations in clinker substitution, carbon capture and utilization (CCU) technologies, and energy-efficient grinding processes are contributing to the development of low-carbon cement products. The integration of digital technologies and automation in cement production is also enhancing process efficiency and reducing energy consumption.

Market challenges include the higher initial costs associated with sustainable cement production, the need for significant infrastructure investments, and the varying availability of alternative raw materials across different regions. However, these challenges are gradually being addressed through collaborative efforts between industry stakeholders, research institutions, and policymakers.

The competitive landscape of the sustainable cement market is characterized by a mix of established cement manufacturers adapting their processes and new entrants specializing in innovative, low-carbon cement solutions. Strategic partnerships and collaborations are becoming increasingly common as companies seek to leverage complementary expertise and resources to accelerate the development and commercialization of sustainable cement technologies.

Vacuum Technology Challenges in Cement Production

Vacuum technology plays a crucial role in sustainable cement production, yet it faces several significant challenges. One of the primary issues is the harsh operating environment within cement manufacturing facilities. The presence of fine cement particles, dust, and abrasive materials can severely impact the performance and longevity of vacuum pumps. These particles can infiltrate the pump mechanisms, causing accelerated wear and tear, reduced efficiency, and increased maintenance requirements.

Another major challenge is the high energy consumption associated with vacuum systems in cement production. Traditional vacuum pumps often operate continuously, consuming substantial amounts of electricity. This not only increases production costs but also contradicts sustainability goals by contributing to higher carbon emissions. The industry is thus faced with the task of developing more energy-efficient vacuum solutions that can maintain the required performance levels while reducing power consumption.

The variability in cement production processes also presents a significant challenge for vacuum technology. Different stages of cement manufacturing require varying levels of vacuum, from moderate suction for material handling to high vacuum for deaeration processes. Designing versatile vacuum systems that can adapt to these changing requirements without compromising efficiency or reliability is a complex engineering challenge.

Maintenance and reliability issues further compound the challenges faced by vacuum technology in cement production. The continuous operation in harsh conditions leads to frequent breakdowns and the need for regular maintenance. This not only increases operational costs but also results in production downtime, affecting overall plant efficiency. Developing robust, low-maintenance vacuum solutions that can withstand the rigors of cement production environments is a key focus area for technology developers.

The integration of vacuum systems with other cement production processes also presents challenges. Ensuring seamless operation and communication between vacuum pumps and other equipment, such as filters, conveying systems, and process control systems, is essential for optimizing production efficiency. This requires advanced control systems and automation technologies that can manage complex interactions between different components of the cement manufacturing process.

Lastly, the industry faces the challenge of balancing the need for high-performance vacuum technology with environmental considerations. As sustainability becomes increasingly important, there is growing pressure to develop vacuum solutions that not only improve energy efficiency but also minimize environmental impact through reduced emissions, noise pollution, and waste generation. This necessitates innovative approaches to vacuum pump design, materials selection, and operational strategies.

Another major challenge is the high energy consumption associated with vacuum systems in cement production. Traditional vacuum pumps often operate continuously, consuming substantial amounts of electricity. This not only increases production costs but also contradicts sustainability goals by contributing to higher carbon emissions. The industry is thus faced with the task of developing more energy-efficient vacuum solutions that can maintain the required performance levels while reducing power consumption.

The variability in cement production processes also presents a significant challenge for vacuum technology. Different stages of cement manufacturing require varying levels of vacuum, from moderate suction for material handling to high vacuum for deaeration processes. Designing versatile vacuum systems that can adapt to these changing requirements without compromising efficiency or reliability is a complex engineering challenge.

Maintenance and reliability issues further compound the challenges faced by vacuum technology in cement production. The continuous operation in harsh conditions leads to frequent breakdowns and the need for regular maintenance. This not only increases operational costs but also results in production downtime, affecting overall plant efficiency. Developing robust, low-maintenance vacuum solutions that can withstand the rigors of cement production environments is a key focus area for technology developers.

The integration of vacuum systems with other cement production processes also presents challenges. Ensuring seamless operation and communication between vacuum pumps and other equipment, such as filters, conveying systems, and process control systems, is essential for optimizing production efficiency. This requires advanced control systems and automation technologies that can manage complex interactions between different components of the cement manufacturing process.

Lastly, the industry faces the challenge of balancing the need for high-performance vacuum technology with environmental considerations. As sustainability becomes increasingly important, there is growing pressure to develop vacuum solutions that not only improve energy efficiency but also minimize environmental impact through reduced emissions, noise pollution, and waste generation. This necessitates innovative approaches to vacuum pump design, materials selection, and operational strategies.

Current Vacuum-Based Cement Production Methods

01 Energy-efficient vacuum pump designs

Developing vacuum pumps with improved energy efficiency is a key focus for sustainability. This includes optimizing pump mechanisms, using advanced materials, and implementing smart control systems to reduce power consumption while maintaining performance.- Energy-efficient vacuum pump designs: Developing vacuum pumps with improved energy efficiency is a key focus for sustainability. This includes optimizing pump mechanisms, reducing power consumption, and implementing advanced control systems to minimize energy waste during operation.

- Eco-friendly materials and manufacturing processes: Incorporating sustainable materials and environmentally friendly manufacturing processes in vacuum pump production. This involves using recycled or biodegradable materials, reducing waste, and implementing cleaner production techniques to minimize the environmental impact of pump manufacturing.

- Smart monitoring and predictive maintenance: Implementing advanced monitoring systems and predictive maintenance techniques to extend the lifespan of vacuum pumps. This includes using sensors, data analytics, and AI-driven algorithms to optimize performance, reduce downtime, and prevent premature equipment failure.

- Sustainable cooling and lubrication systems: Developing environmentally friendly cooling and lubrication systems for vacuum pumps. This involves using biodegradable lubricants, implementing closed-loop cooling systems, and reducing the use of harmful chemicals to minimize environmental impact and improve overall sustainability.

- Integration with renewable energy sources: Designing vacuum pump systems that can be powered by renewable energy sources such as solar or wind power. This includes developing pumps with variable speed drives and energy storage capabilities to optimize performance when using intermittent renewable energy sources.

02 Eco-friendly materials and manufacturing processes

Incorporating sustainable materials and environmentally friendly manufacturing processes in vacuum pump production. This involves using recycled or biodegradable materials, reducing waste, and implementing cleaner production techniques to minimize environmental impact.Expand Specific Solutions03 Vacuum pump lifecycle management and recycling

Implementing strategies for extending the lifespan of vacuum pumps and improving their recyclability. This includes designing for easy maintenance, refurbishment, and end-of-life disassembly, as well as establishing recycling programs for used pumps and components.Expand Specific Solutions04 Integration of renewable energy sources

Developing vacuum pump systems that can be powered by renewable energy sources such as solar or wind power. This includes designing pumps with variable power input capabilities and creating hybrid systems that can switch between conventional and renewable energy sources.Expand Specific Solutions05 Smart monitoring and predictive maintenance

Implementing advanced sensors and AI-driven monitoring systems for vacuum pumps to optimize performance, predict maintenance needs, and prevent failures. This approach enhances energy efficiency, extends equipment lifespan, and reduces waste from premature replacements.Expand Specific Solutions

Key Vacuum Pump Manufacturers and Cement Producers

The vacuum pump industry for sustainable cement production is in a growth phase, driven by increasing environmental regulations and the need for energy-efficient solutions. The market size is expanding as cement manufacturers worldwide adopt advanced vacuum technologies to reduce emissions and improve production efficiency. Technologically, the field is moderately mature, with established players like Edwards Ltd. and Pfeiffer Vacuum GmbH offering sophisticated solutions. However, there's ongoing innovation, particularly in energy efficiency and process optimization. Emerging companies like Furno Materials, Inc. are introducing novel approaches to decarbonize cement production, indicating potential for further technological advancements and market disruption in this sector.

Edwards Ltd.

Technical Solution: Edwards Ltd. has developed advanced vacuum pump technologies specifically tailored for sustainable cement production. Their GXS dry screw vacuum pumps are designed to operate in harsh cement manufacturing environments, providing reliable performance with reduced energy consumption[1]. These pumps utilize a variable speed drive to optimize energy efficiency, adapting to process demands and reducing overall power usage by up to 50% compared to traditional liquid ring pumps[2]. Edwards has also implemented intelligent control systems that monitor pump performance in real-time, allowing for predictive maintenance and minimizing unexpected downtime in cement production lines[3]. Their vacuum solutions contribute to more sustainable cement manufacturing by reducing water consumption, as they eliminate the need for sealing water used in conventional pumps[4].

Strengths: Energy-efficient operation, reduced water consumption, and intelligent monitoring systems. Weaknesses: Higher initial investment cost compared to traditional pumps, and potential complexity in maintenance for advanced features.

Oerlikon Leybold Vacuum

Technical Solution: Oerlikon Leybold Vacuum has developed the SOGEVAC NEO D, a dry compressing vacuum pump specifically designed for the cement industry. This pump operates without oil or water, significantly reducing environmental impact and maintenance requirements[1]. The SOGEVAC NEO D incorporates advanced rotor technology that enhances pumping speed and ultimate pressure, crucial for efficient clinker cooling in cement production[2]. Leybold's pumps are equipped with variable frequency drives, allowing for precise control of vacuum levels and energy consumption optimization[3]. Their vacuum systems also feature integrated heat recovery mechanisms, which capture waste heat from the pumps and redirect it back into the cement production process, improving overall energy efficiency[4].

Strengths: Oil-free and water-free operation, advanced rotor technology, and integrated heat recovery. Weaknesses: Potentially higher upfront costs and specialized maintenance requirements.

Innovative Vacuum Technologies for Cement Industry

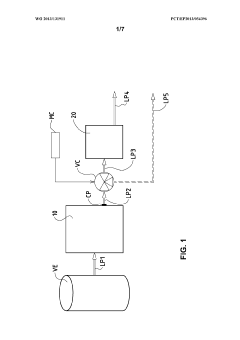

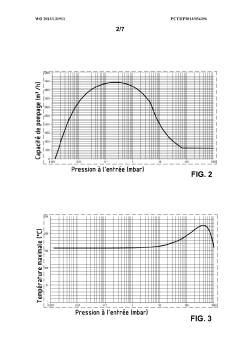

Improved pumping unit and method for controlling such a pumping unit

PatentWO2013131911A1

Innovation

- A pumping installation comprising a first and second volumetric machine, along with a control module and control valve, allows for precise control of gas flow between the inlet and outlet, enabling adaptation of the system's performance and heat management without complex cooling systems by switching between single and dual pump operation based on pressure or temperature thresholds.

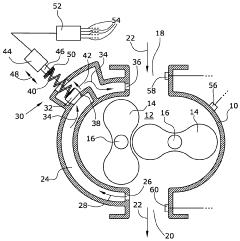

Vacuum pump, and method for operating a vacuum pump

PatentWO2009074408A2

Innovation

- A controllable valve device in the flow channel, connected to a control device that adjusts based on pump parameters like time, temperature, and pressure, allowing for increased differential pressures without overheating, utilizing an electric servomotor to vary the spring force and control the valve position.

Environmental Impact Assessment

The environmental impact assessment of vacuum pumps in sustainable cement production techniques reveals both positive and negative effects on the ecosystem. On the positive side, the implementation of vacuum technology significantly reduces energy consumption in the cement manufacturing process. Traditional cement production methods are energy-intensive, contributing to high carbon emissions. Vacuum pumps, by enhancing the efficiency of various stages such as material handling and clinker cooling, lead to a substantial decrease in overall energy requirements.

Furthermore, the use of vacuum pumps enables better control over particulate emissions. By creating negative pressure in certain production areas, these pumps help contain and capture dust particles that would otherwise be released into the atmosphere. This results in improved air quality around cement plants, reducing the environmental burden on local communities and ecosystems.

Water conservation is another notable benefit. Vacuum systems in cement production often facilitate the recycling and reuse of process water, minimizing freshwater consumption and reducing wastewater discharge. This is particularly crucial in regions facing water scarcity, where cement production can strain local water resources.

However, the environmental assessment also highlights some concerns. The production and disposal of vacuum pumps themselves have environmental implications. The manufacturing process of these pumps involves resource extraction and energy consumption, while their eventual disposal at the end of their lifecycle can contribute to electronic waste if not properly managed.

Noise pollution is another consideration. While vacuum pumps generally operate more quietly than some traditional cement production equipment, they still contribute to the overall noise levels in industrial settings. This can have impacts on local wildlife and nearby human populations, necessitating proper acoustic management strategies.

The use of lubricants and coolants in vacuum pumps also presents potential environmental risks. These substances, if not properly handled or disposed of, can lead to soil and water contamination. Implementing strict maintenance protocols and using environmentally friendly lubricants can mitigate these risks.

In conclusion, while vacuum pumps offer significant environmental benefits in sustainable cement production, particularly in terms of energy efficiency and emissions reduction, their implementation must be accompanied by careful management of their lifecycle impacts to ensure a truly sustainable approach to cement manufacturing.

Furthermore, the use of vacuum pumps enables better control over particulate emissions. By creating negative pressure in certain production areas, these pumps help contain and capture dust particles that would otherwise be released into the atmosphere. This results in improved air quality around cement plants, reducing the environmental burden on local communities and ecosystems.

Water conservation is another notable benefit. Vacuum systems in cement production often facilitate the recycling and reuse of process water, minimizing freshwater consumption and reducing wastewater discharge. This is particularly crucial in regions facing water scarcity, where cement production can strain local water resources.

However, the environmental assessment also highlights some concerns. The production and disposal of vacuum pumps themselves have environmental implications. The manufacturing process of these pumps involves resource extraction and energy consumption, while their eventual disposal at the end of their lifecycle can contribute to electronic waste if not properly managed.

Noise pollution is another consideration. While vacuum pumps generally operate more quietly than some traditional cement production equipment, they still contribute to the overall noise levels in industrial settings. This can have impacts on local wildlife and nearby human populations, necessitating proper acoustic management strategies.

The use of lubricants and coolants in vacuum pumps also presents potential environmental risks. These substances, if not properly handled or disposed of, can lead to soil and water contamination. Implementing strict maintenance protocols and using environmentally friendly lubricants can mitigate these risks.

In conclusion, while vacuum pumps offer significant environmental benefits in sustainable cement production, particularly in terms of energy efficiency and emissions reduction, their implementation must be accompanied by careful management of their lifecycle impacts to ensure a truly sustainable approach to cement manufacturing.

Energy Efficiency Optimization Strategies

Energy efficiency optimization strategies play a crucial role in sustainable cement production techniques, particularly when considering the influence of vacuum pumps. These strategies focus on reducing energy consumption while maintaining or improving production efficiency, ultimately contributing to a more environmentally friendly cement manufacturing process.

One key approach to energy efficiency optimization is the implementation of advanced control systems for vacuum pumps. These systems utilize real-time monitoring and data analysis to adjust pump operation based on production demands. By optimizing the vacuum levels and pump speeds, manufacturers can significantly reduce energy waste and improve overall system performance.

Another important strategy involves the integration of variable frequency drives (VFDs) in vacuum pump systems. VFDs allow for precise control of pump motor speeds, enabling operators to match pump output with actual process requirements. This flexibility results in substantial energy savings, especially during periods of reduced production or when operating at partial capacity.

Heat recovery systems represent another vital component of energy efficiency optimization in cement production. Vacuum pumps generate considerable heat during operation, which can be captured and repurposed for various processes within the plant. This recovered heat can be used for preheating raw materials, drying processes, or even converted into electricity, further reducing the overall energy footprint of the cement production facility.

The implementation of high-efficiency vacuum pump technologies is also a key strategy for optimizing energy use. Modern vacuum pumps designed specifically for cement production applications offer improved performance and reduced energy consumption compared to older models. These pumps often incorporate advanced materials and design features that minimize friction losses and optimize airflow, resulting in higher efficiency and lower operating costs.

Regular maintenance and performance monitoring of vacuum pump systems are essential for sustaining energy efficiency gains. Predictive maintenance techniques, such as vibration analysis and oil analysis, can help identify potential issues before they lead to equipment failure or reduced efficiency. By addressing problems proactively, manufacturers can ensure that their vacuum pump systems continue to operate at peak efficiency, minimizing energy waste and production downtime.

Lastly, the adoption of energy management systems (EMS) provides a comprehensive approach to optimizing energy efficiency across the entire cement production process. These systems integrate data from various equipment and processes, including vacuum pumps, to provide a holistic view of energy consumption. By analyzing this data, plant operators can identify areas for improvement, set energy reduction targets, and implement targeted strategies to achieve sustainable energy efficiency gains.

One key approach to energy efficiency optimization is the implementation of advanced control systems for vacuum pumps. These systems utilize real-time monitoring and data analysis to adjust pump operation based on production demands. By optimizing the vacuum levels and pump speeds, manufacturers can significantly reduce energy waste and improve overall system performance.

Another important strategy involves the integration of variable frequency drives (VFDs) in vacuum pump systems. VFDs allow for precise control of pump motor speeds, enabling operators to match pump output with actual process requirements. This flexibility results in substantial energy savings, especially during periods of reduced production or when operating at partial capacity.

Heat recovery systems represent another vital component of energy efficiency optimization in cement production. Vacuum pumps generate considerable heat during operation, which can be captured and repurposed for various processes within the plant. This recovered heat can be used for preheating raw materials, drying processes, or even converted into electricity, further reducing the overall energy footprint of the cement production facility.

The implementation of high-efficiency vacuum pump technologies is also a key strategy for optimizing energy use. Modern vacuum pumps designed specifically for cement production applications offer improved performance and reduced energy consumption compared to older models. These pumps often incorporate advanced materials and design features that minimize friction losses and optimize airflow, resulting in higher efficiency and lower operating costs.

Regular maintenance and performance monitoring of vacuum pump systems are essential for sustaining energy efficiency gains. Predictive maintenance techniques, such as vibration analysis and oil analysis, can help identify potential issues before they lead to equipment failure or reduced efficiency. By addressing problems proactively, manufacturers can ensure that their vacuum pump systems continue to operate at peak efficiency, minimizing energy waste and production downtime.

Lastly, the adoption of energy management systems (EMS) provides a comprehensive approach to optimizing energy efficiency across the entire cement production process. These systems integrate data from various equipment and processes, including vacuum pumps, to provide a holistic view of energy consumption. By analyzing this data, plant operators can identify areas for improvement, set energy reduction targets, and implement targeted strategies to achieve sustainable energy efficiency gains.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!