How Vacuum Pumps Influence Ultra-High-Vacuum Sputtering Processes

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vacuum Pump Technology Evolution and Objectives

Vacuum pump technology has undergone significant evolution since its inception in the early 20th century. The development of vacuum pumps has been closely tied to advancements in various scientific and industrial fields, particularly in the realm of thin film deposition and ultra-high-vacuum sputtering processes. The journey began with simple mechanical pumps and has progressed to sophisticated systems capable of achieving extremely low pressures.

In the 1950s and 1960s, the introduction of turbomolecular pumps marked a significant milestone in vacuum technology. These pumps, utilizing high-speed rotors, enabled the achievement of much lower pressures than their predecessors. This advancement was crucial for the emerging semiconductor industry and the development of more precise sputtering techniques.

The 1970s and 1980s saw the rise of cryogenic pumps, which use extremely low temperatures to condense gases and create high vacuums. This technology proved particularly valuable in ultra-high-vacuum applications, including advanced sputtering processes used in the production of complex electronic components and optical coatings.

The late 20th and early 21st centuries witnessed the refinement of existing technologies and the introduction of new pump designs. Dry pumps, which eliminate the need for oil and reduce contamination risks, became increasingly popular in sensitive applications such as semiconductor manufacturing. Combination pumps, integrating multiple vacuum-generating mechanisms, emerged to provide more efficient and versatile solutions for complex vacuum systems.

The primary objective of vacuum pump technology in the context of ultra-high-vacuum sputtering processes has been to achieve and maintain extremely low pressures with high reliability and minimal contamination. This goal has driven continuous improvements in pump design, materials, and control systems. Modern vacuum pumps aim to provide faster pump-down times, higher throughput, and enhanced process stability, all of which are critical factors in the efficiency and quality of sputtering processes.

Looking forward, the objectives for vacuum pump technology in sputtering applications include further reductions in base pressures, improved energy efficiency, and enhanced integration with smart manufacturing systems. There is also a growing focus on developing pumps that can handle increasingly complex gas mixtures and maintain stable performance under varying process conditions. These advancements are essential to support the evolving demands of nanotechnology, advanced materials science, and next-generation electronic devices.

In the 1950s and 1960s, the introduction of turbomolecular pumps marked a significant milestone in vacuum technology. These pumps, utilizing high-speed rotors, enabled the achievement of much lower pressures than their predecessors. This advancement was crucial for the emerging semiconductor industry and the development of more precise sputtering techniques.

The 1970s and 1980s saw the rise of cryogenic pumps, which use extremely low temperatures to condense gases and create high vacuums. This technology proved particularly valuable in ultra-high-vacuum applications, including advanced sputtering processes used in the production of complex electronic components and optical coatings.

The late 20th and early 21st centuries witnessed the refinement of existing technologies and the introduction of new pump designs. Dry pumps, which eliminate the need for oil and reduce contamination risks, became increasingly popular in sensitive applications such as semiconductor manufacturing. Combination pumps, integrating multiple vacuum-generating mechanisms, emerged to provide more efficient and versatile solutions for complex vacuum systems.

The primary objective of vacuum pump technology in the context of ultra-high-vacuum sputtering processes has been to achieve and maintain extremely low pressures with high reliability and minimal contamination. This goal has driven continuous improvements in pump design, materials, and control systems. Modern vacuum pumps aim to provide faster pump-down times, higher throughput, and enhanced process stability, all of which are critical factors in the efficiency and quality of sputtering processes.

Looking forward, the objectives for vacuum pump technology in sputtering applications include further reductions in base pressures, improved energy efficiency, and enhanced integration with smart manufacturing systems. There is also a growing focus on developing pumps that can handle increasingly complex gas mixtures and maintain stable performance under varying process conditions. These advancements are essential to support the evolving demands of nanotechnology, advanced materials science, and next-generation electronic devices.

Market Demand for UHV Sputtering Systems

The market demand for ultra-high-vacuum (UHV) sputtering systems has been experiencing significant growth in recent years, driven by advancements in various high-tech industries. These systems are crucial for the production of thin films and coatings with exceptional purity and precision, making them indispensable in sectors such as semiconductor manufacturing, optics, and advanced materials research.

In the semiconductor industry, the push for smaller, more powerful, and energy-efficient devices has led to increased demand for UHV sputtering systems. These systems enable the deposition of ultra-thin layers of materials with atomic-level precision, which is essential for the production of advanced microchips and integrated circuits. As the industry continues to pursue Moore's Law and beyond, the need for more sophisticated UHV sputtering equipment is expected to grow.

The optics and photonics sector also contributes significantly to the market demand for UHV sputtering systems. High-performance optical coatings for lenses, mirrors, and other optical components require the precision and purity offered by these systems. Applications in areas such as laser technology, telecommunications, and aerospace rely heavily on the capabilities of UHV sputtering for producing specialized optical coatings.

Advanced materials research and development represent another key driver of market demand. UHV sputtering systems are essential tools for creating novel materials with unique properties, such as superconductors, magnetic materials, and advanced composites. As industries seek to innovate and develop new products, the demand for these systems in research laboratories and industrial R&D facilities continues to rise.

The renewable energy sector, particularly in the production of solar cells and energy-efficient coatings, has also contributed to the growing market for UHV sputtering systems. These systems play a crucial role in depositing thin-film photovoltaic materials and creating specialized coatings that enhance the efficiency of solar panels and other energy-related devices.

Geographically, the market demand for UHV sputtering systems is strongest in regions with a high concentration of technology-driven industries. East Asia, particularly countries like Japan, South Korea, and Taiwan, shows robust demand due to their strong semiconductor and electronics manufacturing sectors. North America and Europe also represent significant markets, driven by research institutions, aerospace industries, and advanced manufacturing facilities.

As industries continue to push the boundaries of technology and material science, the market for UHV sputtering systems is expected to expand further. The ongoing trend towards miniaturization, increased functionality, and improved efficiency across various sectors will likely sustain and potentially accelerate the demand for these sophisticated systems in the foreseeable future.

In the semiconductor industry, the push for smaller, more powerful, and energy-efficient devices has led to increased demand for UHV sputtering systems. These systems enable the deposition of ultra-thin layers of materials with atomic-level precision, which is essential for the production of advanced microchips and integrated circuits. As the industry continues to pursue Moore's Law and beyond, the need for more sophisticated UHV sputtering equipment is expected to grow.

The optics and photonics sector also contributes significantly to the market demand for UHV sputtering systems. High-performance optical coatings for lenses, mirrors, and other optical components require the precision and purity offered by these systems. Applications in areas such as laser technology, telecommunications, and aerospace rely heavily on the capabilities of UHV sputtering for producing specialized optical coatings.

Advanced materials research and development represent another key driver of market demand. UHV sputtering systems are essential tools for creating novel materials with unique properties, such as superconductors, magnetic materials, and advanced composites. As industries seek to innovate and develop new products, the demand for these systems in research laboratories and industrial R&D facilities continues to rise.

The renewable energy sector, particularly in the production of solar cells and energy-efficient coatings, has also contributed to the growing market for UHV sputtering systems. These systems play a crucial role in depositing thin-film photovoltaic materials and creating specialized coatings that enhance the efficiency of solar panels and other energy-related devices.

Geographically, the market demand for UHV sputtering systems is strongest in regions with a high concentration of technology-driven industries. East Asia, particularly countries like Japan, South Korea, and Taiwan, shows robust demand due to their strong semiconductor and electronics manufacturing sectors. North America and Europe also represent significant markets, driven by research institutions, aerospace industries, and advanced manufacturing facilities.

As industries continue to push the boundaries of technology and material science, the market for UHV sputtering systems is expected to expand further. The ongoing trend towards miniaturization, increased functionality, and improved efficiency across various sectors will likely sustain and potentially accelerate the demand for these sophisticated systems in the foreseeable future.

Current Challenges in UHV Pump Technology

Ultra-high-vacuum (UHV) pump technology faces several significant challenges in the context of sputtering processes. One of the primary issues is achieving and maintaining the extremely low pressures required for UHV conditions, typically below 10^-9 mbar. This demands pumps with exceptional performance characteristics and reliability.

The contamination control in UHV systems presents another major challenge. Even minute amounts of impurities can significantly affect the sputtering process and the quality of deposited films. Pumps must not only remove gases but also prevent backstreaming of pump fluids or other contaminants into the vacuum chamber.

Heat management is a critical concern in UHV pump technology. The heat generated during operation can lead to outgassing, which compromises vacuum quality. Developing efficient cooling systems and materials with low outgassing properties is essential for maintaining stable UHV conditions during extended sputtering processes.

Pump speed and capacity pose additional challenges, particularly for large-scale industrial applications. UHV pumps must be capable of rapidly evacuating substantial volumes while maintaining extremely low pressures. This necessitates the development of high-capacity pumps that can operate efficiently at very low pressures without compromising vacuum quality.

The energy efficiency of UHV pumps is another area of concern. The power consumption of these pumps can be substantial, especially in continuous operation scenarios common in industrial sputtering processes. Improving the energy efficiency of UHV pumps without sacrificing performance is a significant technological challenge.

Durability and maintenance requirements of UHV pumps present ongoing challenges. The harsh operating conditions and the need for prolonged, uninterrupted operation in sputtering processes demand pumps with exceptional longevity and minimal maintenance needs. Developing materials and designs that can withstand these conditions while maintaining performance is a complex engineering task.

Finally, the integration of UHV pumps with advanced process control and monitoring systems represents a growing challenge. As sputtering processes become more sophisticated, there is an increasing need for pumps that can be seamlessly integrated into automated systems, providing real-time data and adjusting performance parameters dynamically.

The contamination control in UHV systems presents another major challenge. Even minute amounts of impurities can significantly affect the sputtering process and the quality of deposited films. Pumps must not only remove gases but also prevent backstreaming of pump fluids or other contaminants into the vacuum chamber.

Heat management is a critical concern in UHV pump technology. The heat generated during operation can lead to outgassing, which compromises vacuum quality. Developing efficient cooling systems and materials with low outgassing properties is essential for maintaining stable UHV conditions during extended sputtering processes.

Pump speed and capacity pose additional challenges, particularly for large-scale industrial applications. UHV pumps must be capable of rapidly evacuating substantial volumes while maintaining extremely low pressures. This necessitates the development of high-capacity pumps that can operate efficiently at very low pressures without compromising vacuum quality.

The energy efficiency of UHV pumps is another area of concern. The power consumption of these pumps can be substantial, especially in continuous operation scenarios common in industrial sputtering processes. Improving the energy efficiency of UHV pumps without sacrificing performance is a significant technological challenge.

Durability and maintenance requirements of UHV pumps present ongoing challenges. The harsh operating conditions and the need for prolonged, uninterrupted operation in sputtering processes demand pumps with exceptional longevity and minimal maintenance needs. Developing materials and designs that can withstand these conditions while maintaining performance is a complex engineering task.

Finally, the integration of UHV pumps with advanced process control and monitoring systems represents a growing challenge. As sputtering processes become more sophisticated, there is an increasing need for pumps that can be seamlessly integrated into automated systems, providing real-time data and adjusting performance parameters dynamically.

Existing UHV Pump Solutions for Sputtering

01 Ultra-high vacuum pump designs

Various designs for ultra-high vacuum pumps have been developed to achieve extremely low pressures. These designs may include improvements in sealing mechanisms, rotor configurations, and pump chamber geometries to enhance vacuum performance and efficiency.- Ultra-high vacuum pump designs: Various designs for ultra-high vacuum pumps have been developed to achieve extremely low pressures. These designs may include improvements in sealing mechanisms, rotor configurations, and materials to enhance vacuum performance and reliability in ultra-high vacuum applications.

- Turbomolecular pumps for ultra-high vacuum: Turbomolecular pumps are widely used for achieving ultra-high vacuum conditions. These pumps utilize high-speed rotating blades to impart momentum to gas molecules, effectively removing them from the vacuum chamber. Advancements in turbomolecular pump technology focus on improving pumping speed, compression ratios, and overall efficiency.

- Cryogenic pumping techniques: Cryogenic pumping methods are employed in ultra-high vacuum systems to trap and remove residual gases. These techniques involve cooling surfaces to extremely low temperatures, causing gas molecules to condense or adsorb onto the cold surfaces. Innovations in cryogenic pump design aim to enhance pumping capacity and reduce regeneration time.

- Combination pumping systems: Ultra-high vacuum systems often utilize a combination of different pump types to achieve and maintain extremely low pressures. These systems may integrate roughing pumps, turbomolecular pumps, and ion pumps in a staged configuration to effectively remove gases across a wide pressure range. Innovations focus on optimizing the integration and control of multiple pump types.

- Vacuum sealing and contamination control: Effective sealing and contamination control are crucial for maintaining ultra-high vacuum conditions. Advancements in this area include improved seal designs, materials with low outgassing properties, and techniques for reducing particle generation within the vacuum system. These innovations contribute to achieving and sustaining lower ultimate pressures in ultra-high vacuum applications.

02 Turbomolecular pumps for ultra-high vacuum

Turbomolecular pumps are widely used for achieving ultra-high vacuum conditions. These pumps utilize high-speed rotating blades to impart momentum to gas molecules, effectively removing them from the vacuum chamber. Advancements in turbomolecular pump technology focus on improving blade design, rotor speed, and overall pump efficiency.Expand Specific Solutions03 Cryogenic pumping techniques

Cryogenic pumping methods are employed in ultra-high vacuum systems to trap and remove residual gases. These techniques involve cooling surfaces to extremely low temperatures, causing gas molecules to condense or adsorb onto the cold surfaces. Innovations in cryogenic pump design aim to enhance pumping speed and capacity.Expand Specific Solutions04 Combination pumping systems

Ultra-high vacuum systems often utilize a combination of different pump types to achieve and maintain extremely low pressures. These systems may integrate roughing pumps, turbomolecular pumps, and ion pumps in a staged configuration to effectively remove gases across a wide pressure range.Expand Specific Solutions05 Vacuum sealing and contamination control

Achieving and maintaining ultra-high vacuum conditions requires advanced sealing technologies and contamination control measures. Innovations in this area include improved gasket materials, leak detection methods, and strategies to minimize outgassing from vacuum chamber components.Expand Specific Solutions

Key Players in UHV Pump Manufacturing

The ultra-high-vacuum sputtering process market is in a mature growth stage, with a global market size estimated to be in the billions of dollars. The technology has reached a high level of maturity, with ongoing innovations focused on improving efficiency and precision. Key players like Edwards Vacuum LLC, Applied Materials, Inc., and ULVAC, Inc. are driving advancements in vacuum pump technology, which is crucial for enhancing sputtering processes. These companies, along with others such as Tokyo Electron Ltd. and Pfeiffer Vacuum GmbH, are competing to develop more efficient, reliable, and cost-effective vacuum solutions. The market is characterized by intense competition and continuous R&D efforts to meet the demanding requirements of semiconductor and display manufacturing industries.

Edwards Vacuum LLC

Technical Solution: Edwards Vacuum LLC has developed advanced vacuum pump technologies specifically tailored for ultra-high-vacuum sputtering processes. Their iXL series dry pumps utilize a unique screw mechanism that provides high pumping speeds and ultimate pressures down to 10^-3 mbar[1]. These pumps incorporate intelligent control systems that optimize performance based on process conditions, resulting in improved film uniformity and reduced particle contamination. Edwards has also introduced their nEXT turbomolecular pumps, which feature a hybrid bearing design combining ceramic ball bearings and magnetic levitation, allowing for higher rotational speeds and improved pumping efficiency in the molecular flow regime[2]. This technology enables the achievement of ultra-high vacuum levels (10^-10 mbar) required for precise thin film deposition in advanced semiconductor manufacturing.

Strengths: High pumping speeds, intelligent control systems, and hybrid bearing design for improved efficiency. Weaknesses: Higher initial cost compared to conventional pumps, and potential complexity in maintenance due to advanced features.

Applied Materials, Inc.

Technical Solution: Applied Materials has developed the Endura® platform, which integrates advanced vacuum pump technology with their PVD (Physical Vapor Deposition) systems for ultra-high-vacuum sputtering processes. The platform utilizes a combination of cryogenic pumps and turbomolecular pumps to achieve base pressures as low as 10^-9 Torr[3]. Their proprietary vacuum management system incorporates real-time pressure monitoring and adaptive pumping algorithms to maintain optimal vacuum conditions throughout the sputtering process. Applied Materials has also introduced the iSprint™ technology, which combines high-conductance vacuum pathways with advanced pump designs to reduce pump-down times by up to 50%[4]. This innovation significantly improves throughput in high-volume manufacturing environments while maintaining the ultra-high vacuum levels required for precise thin film deposition.

Strengths: Integrated platform approach, advanced vacuum management system, and improved throughput. Weaknesses: High system complexity may require specialized training for operation and maintenance.

Core Innovations in UHV Pump Design

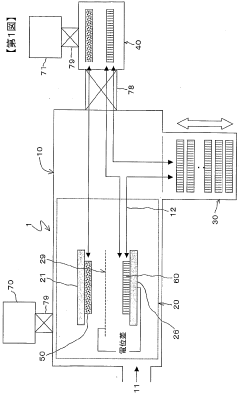

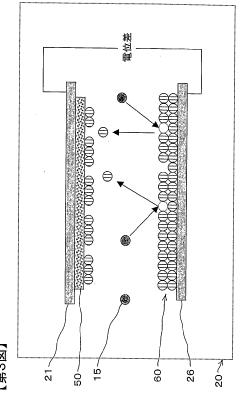

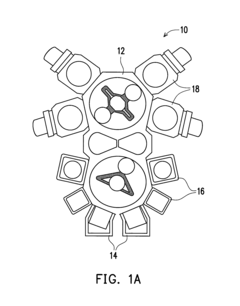

Ultra-high vacuum sputtering system for forming multilayer thin film continuously and ultra-high vacuum sputtering method for forming multilayer thin film continuously

PatentWO2005116288A1

Innovation

- An ultra-high vacuum sputtering apparatus with a target exchange function that allows continuous target replacement on a single electrode, integrated target storage, and a vacuum pump system enabling substrate and target transfer without breaking the vacuum, along with substrate heating up to 1200°C to achieve high-purity films.

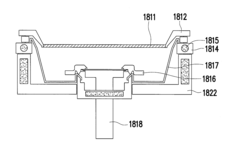

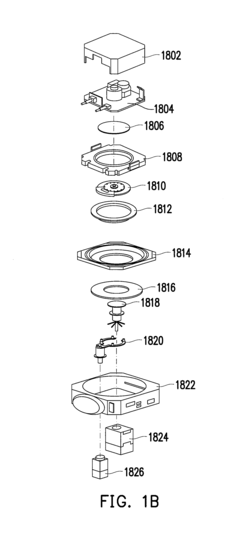

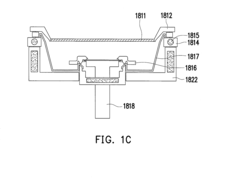

Adapter of sputtering chamber

PatentInactiveUS20140027275A1

Innovation

- An adapter with embedded cooling channels is integrated into the sputtering chamber, circulating a fluid such as de-ionized water to enhance cooling efficiency and maintain stable process temperatures.

Vacuum Pump Performance Metrics

Vacuum pump performance metrics are crucial in evaluating the efficiency and effectiveness of ultra-high-vacuum sputtering processes. These metrics provide quantitative measures of a pump's ability to create and maintain the required vacuum levels for optimal sputtering conditions. The primary performance indicators include pumping speed, ultimate pressure, and gas throughput.

Pumping speed, typically measured in liters per second (L/s), represents the volume of gas a pump can remove from a chamber in a given time. This metric is particularly important in sputtering processes, as it determines how quickly the desired vacuum level can be achieved and maintained. Higher pumping speeds generally lead to faster process times and improved overall efficiency.

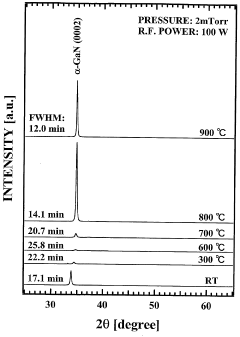

Ultimate pressure, expressed in units such as Torr or Pascal, indicates the lowest pressure a pump can achieve in a closed system. For ultra-high-vacuum sputtering, pumps capable of reaching pressures in the range of 10^-9 to 10^-11 Torr are often required. The ability to achieve and sustain such low pressures is critical for ensuring the purity of the sputtered films and minimizing contamination.

Gas throughput, measured in units like mbar·L/s or Pa·m³/s, represents the pump's capacity to handle gas loads. This metric is particularly relevant in sputtering processes where process gases are continuously introduced. A pump with high gas throughput can maintain stable vacuum levels even under significant gas influx, ensuring consistent sputtering conditions throughout the deposition process.

Another important performance metric is the pump's compression ratio, which quantifies its ability to create a pressure differential between its inlet and outlet. A high compression ratio is essential for achieving and maintaining ultra-high vacuum levels, especially in the presence of process gases.

The power consumption and efficiency of vacuum pumps are also significant considerations. These metrics not only affect operational costs but can also impact the overall thermal management of the sputtering system. More efficient pumps generate less heat, potentially reducing the need for additional cooling systems and improving process stability.

Reliability and maintenance requirements are critical long-term performance metrics. Pumps with longer mean time between failures (MTBF) and lower maintenance needs can significantly reduce downtime and operational costs in industrial sputtering applications.

Understanding and optimizing these performance metrics is essential for designing and operating efficient ultra-high-vacuum sputtering systems. The selection of appropriate vacuum pumps based on these metrics can significantly influence the quality, consistency, and cost-effectiveness of the sputtering process.

Pumping speed, typically measured in liters per second (L/s), represents the volume of gas a pump can remove from a chamber in a given time. This metric is particularly important in sputtering processes, as it determines how quickly the desired vacuum level can be achieved and maintained. Higher pumping speeds generally lead to faster process times and improved overall efficiency.

Ultimate pressure, expressed in units such as Torr or Pascal, indicates the lowest pressure a pump can achieve in a closed system. For ultra-high-vacuum sputtering, pumps capable of reaching pressures in the range of 10^-9 to 10^-11 Torr are often required. The ability to achieve and sustain such low pressures is critical for ensuring the purity of the sputtered films and minimizing contamination.

Gas throughput, measured in units like mbar·L/s or Pa·m³/s, represents the pump's capacity to handle gas loads. This metric is particularly relevant in sputtering processes where process gases are continuously introduced. A pump with high gas throughput can maintain stable vacuum levels even under significant gas influx, ensuring consistent sputtering conditions throughout the deposition process.

Another important performance metric is the pump's compression ratio, which quantifies its ability to create a pressure differential between its inlet and outlet. A high compression ratio is essential for achieving and maintaining ultra-high vacuum levels, especially in the presence of process gases.

The power consumption and efficiency of vacuum pumps are also significant considerations. These metrics not only affect operational costs but can also impact the overall thermal management of the sputtering system. More efficient pumps generate less heat, potentially reducing the need for additional cooling systems and improving process stability.

Reliability and maintenance requirements are critical long-term performance metrics. Pumps with longer mean time between failures (MTBF) and lower maintenance needs can significantly reduce downtime and operational costs in industrial sputtering applications.

Understanding and optimizing these performance metrics is essential for designing and operating efficient ultra-high-vacuum sputtering systems. The selection of appropriate vacuum pumps based on these metrics can significantly influence the quality, consistency, and cost-effectiveness of the sputtering process.

Environmental Impact of UHV Processes

Ultra-high-vacuum (UHV) sputtering processes, while essential for advanced materials science and semiconductor manufacturing, have significant environmental implications that warrant careful consideration. The environmental impact of UHV processes primarily stems from energy consumption, resource utilization, and potential emissions.

Energy consumption is a major concern in UHV sputtering processes. The creation and maintenance of ultra-high vacuum conditions require substantial power input, primarily for vacuum pumps and cooling systems. This high energy demand contributes to increased carbon emissions if the power source is not renewable, exacerbating climate change concerns.

Resource utilization in UHV processes also poses environmental challenges. The production of ultra-pure materials used in these processes often involves energy-intensive mining and refining operations. Additionally, the specialized equipment required for UHV sputtering, such as vacuum chambers and pumps, relies on rare earth elements and other scarce resources, potentially contributing to resource depletion.

Emissions from UHV sputtering processes, though minimal due to the contained nature of the system, can still have environmental impacts. Trace amounts of process gases, including inert gases like argon, may be released. While these gases are not directly harmful, their production and transportation contribute to the overall carbon footprint of the process.

Waste management is another critical environmental aspect of UHV processes. The disposal of used targets, substrates, and other consumables requires careful handling to prevent contamination. Some materials used in UHV sputtering, particularly in semiconductor manufacturing, may be hazardous and require specialized disposal methods to prevent environmental pollution.

Water usage in cooling systems for UHV equipment can also have environmental implications, especially in water-stressed regions. The need for ultra-pure water in some UHV applications further compounds this issue, as the purification process itself is resource-intensive.

On a positive note, the precision and efficiency of UHV sputtering processes can lead to reduced material waste and improved product quality, potentially offsetting some environmental impacts through increased product longevity and performance. Furthermore, advancements in UHV technology are continually improving energy efficiency and reducing resource requirements.

To mitigate the environmental impact of UHV processes, several strategies can be employed. These include investing in more energy-efficient vacuum pumps and cooling systems, exploring renewable energy sources for power-intensive operations, implementing closed-loop recycling systems for process gases and cooling water, and developing more environmentally friendly alternatives to hazardous materials used in the process.

Energy consumption is a major concern in UHV sputtering processes. The creation and maintenance of ultra-high vacuum conditions require substantial power input, primarily for vacuum pumps and cooling systems. This high energy demand contributes to increased carbon emissions if the power source is not renewable, exacerbating climate change concerns.

Resource utilization in UHV processes also poses environmental challenges. The production of ultra-pure materials used in these processes often involves energy-intensive mining and refining operations. Additionally, the specialized equipment required for UHV sputtering, such as vacuum chambers and pumps, relies on rare earth elements and other scarce resources, potentially contributing to resource depletion.

Emissions from UHV sputtering processes, though minimal due to the contained nature of the system, can still have environmental impacts. Trace amounts of process gases, including inert gases like argon, may be released. While these gases are not directly harmful, their production and transportation contribute to the overall carbon footprint of the process.

Waste management is another critical environmental aspect of UHV processes. The disposal of used targets, substrates, and other consumables requires careful handling to prevent contamination. Some materials used in UHV sputtering, particularly in semiconductor manufacturing, may be hazardous and require specialized disposal methods to prevent environmental pollution.

Water usage in cooling systems for UHV equipment can also have environmental implications, especially in water-stressed regions. The need for ultra-pure water in some UHV applications further compounds this issue, as the purification process itself is resource-intensive.

On a positive note, the precision and efficiency of UHV sputtering processes can lead to reduced material waste and improved product quality, potentially offsetting some environmental impacts through increased product longevity and performance. Furthermore, advancements in UHV technology are continually improving energy efficiency and reducing resource requirements.

To mitigate the environmental impact of UHV processes, several strategies can be employed. These include investing in more energy-efficient vacuum pumps and cooling systems, exploring renewable energy sources for power-intensive operations, implementing closed-loop recycling systems for process gases and cooling water, and developing more environmentally friendly alternatives to hazardous materials used in the process.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!