HPLC vs UPLC: Resolution and Throughput Compared

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Chromatography Evolution and Objectives

Chromatography has undergone significant evolution since its inception in the early 20th century. The journey from simple paper chromatography to sophisticated high-performance liquid chromatography (HPLC) represents one of the most impactful technological progressions in analytical chemistry. HPLC emerged in the 1970s as a revolutionary technique, offering unprecedented separation capabilities and analytical precision compared to traditional column chromatography methods.

The development trajectory continued with the introduction of Ultra-Performance Liquid Chromatography (UPLC) in the early 2000s, marking another pivotal advancement. UPLC systems operate at significantly higher pressures than conventional HPLC, utilizing sub-2μm particle columns that dramatically enhance separation efficiency and speed. This evolution reflects the persistent industry demand for improved resolution, increased throughput, and reduced analysis time.

The technological progression in chromatography has been driven by several key factors: the need for more sensitive detection of complex mixtures, requirements for faster analytical processes in high-volume testing environments, and the economic imperative to reduce solvent consumption and operational costs. These drivers continue to shape the development of chromatographic technologies today.

Current objectives in the field focus on optimizing the balance between resolution and throughput. Resolution—the ability to distinguish between closely related compounds—remains a fundamental parameter in chromatographic analysis. Meanwhile, throughput—the number of samples that can be processed in a given timeframe—has become increasingly critical in commercial and research applications where time efficiency translates directly to economic value.

The comparison between HPLC and UPLC represents a classic example of technology evolution addressing these dual objectives. While HPLC offers robust performance with moderate pressure requirements (typically up to 6,000 psi), UPLC pushes operational boundaries with pressures exceeding 15,000 psi, enabling faster analyses without sacrificing separation quality.

Looking forward, the field aims to further enhance both parameters simultaneously, rather than trading one for the other. Emerging trends include the development of novel stationary phases, advanced particle technologies, and innovative system designs that minimize dead volume and optimize flow dynamics. Additionally, integration with cutting-edge detection technologies and automation systems represents a significant focus area for future development.

The ultimate goal remains consistent: to develop chromatographic methods that deliver superior resolution in shorter timeframes, thereby increasing laboratory productivity while maintaining or improving analytical precision and reliability.

The development trajectory continued with the introduction of Ultra-Performance Liquid Chromatography (UPLC) in the early 2000s, marking another pivotal advancement. UPLC systems operate at significantly higher pressures than conventional HPLC, utilizing sub-2μm particle columns that dramatically enhance separation efficiency and speed. This evolution reflects the persistent industry demand for improved resolution, increased throughput, and reduced analysis time.

The technological progression in chromatography has been driven by several key factors: the need for more sensitive detection of complex mixtures, requirements for faster analytical processes in high-volume testing environments, and the economic imperative to reduce solvent consumption and operational costs. These drivers continue to shape the development of chromatographic technologies today.

Current objectives in the field focus on optimizing the balance between resolution and throughput. Resolution—the ability to distinguish between closely related compounds—remains a fundamental parameter in chromatographic analysis. Meanwhile, throughput—the number of samples that can be processed in a given timeframe—has become increasingly critical in commercial and research applications where time efficiency translates directly to economic value.

The comparison between HPLC and UPLC represents a classic example of technology evolution addressing these dual objectives. While HPLC offers robust performance with moderate pressure requirements (typically up to 6,000 psi), UPLC pushes operational boundaries with pressures exceeding 15,000 psi, enabling faster analyses without sacrificing separation quality.

Looking forward, the field aims to further enhance both parameters simultaneously, rather than trading one for the other. Emerging trends include the development of novel stationary phases, advanced particle technologies, and innovative system designs that minimize dead volume and optimize flow dynamics. Additionally, integration with cutting-edge detection technologies and automation systems represents a significant focus area for future development.

The ultimate goal remains consistent: to develop chromatographic methods that deliver superior resolution in shorter timeframes, thereby increasing laboratory productivity while maintaining or improving analytical precision and reliability.

Market Demand Analysis for High-Performance Liquid Chromatography

The global market for High-Performance Liquid Chromatography (HPLC) continues to experience robust growth, driven by increasing applications across pharmaceutical, biotechnology, food safety, environmental monitoring, and clinical diagnostics sectors. Current market valuations place the HPLC market at approximately 4.5 billion USD, with projections indicating growth to reach 6.4 billion USD by 2027, representing a compound annual growth rate of 5.2%.

The pharmaceutical and biotechnology sectors remain the largest consumers of HPLC technology, accounting for nearly 60% of market demand. This dominance stems from stringent regulatory requirements for drug development and quality control processes, where precise analytical methods are non-negotiable. The rising complexity of biopharmaceuticals has further intensified the need for advanced chromatography solutions.

Recent market surveys reveal a significant shift in customer preferences toward Ultra-Performance Liquid Chromatography (UPLC) systems, which offer superior resolution and substantially higher throughput compared to traditional HPLC. This transition is particularly evident in high-volume testing environments where efficiency and productivity are paramount concerns.

The food and beverage industry represents the fastest-growing segment for HPLC/UPLC adoption, with increasing regulatory scrutiny on food safety and authenticity driving demand. Similarly, environmental monitoring agencies are expanding their analytical capabilities, contributing to market growth in regions with strengthening environmental protection policies.

Geographically, North America and Europe currently dominate market consumption, collectively accounting for approximately 65% of global HPLC/UPLC instrument sales. However, Asia-Pacific markets, particularly China and India, are demonstrating the highest growth rates, fueled by expanding pharmaceutical manufacturing, contract research organizations, and increasing government investments in analytical infrastructure.

Customer demand patterns indicate growing interest in integrated systems that offer enhanced automation, reduced analysis time, and lower solvent consumption. The market is increasingly valuing total cost of ownership over initial acquisition costs, with particular attention to operational efficiency and environmental sustainability.

The academic and research segment presents unique market characteristics, often prioritizing versatility and adaptability over pure throughput metrics. This segment frequently serves as an innovation incubator, where novel applications and methodologies are developed before wider industrial adoption.

Market forecasts suggest that the transition from HPLC to UPLC will accelerate, with UPLC systems expected to capture over 40% of new system sales by 2025. This transition is being facilitated by decreasing price differentials between high-end HPLC and entry-level UPLC systems, making the superior performance of UPLC increasingly accessible to mid-sized laboratories.

The pharmaceutical and biotechnology sectors remain the largest consumers of HPLC technology, accounting for nearly 60% of market demand. This dominance stems from stringent regulatory requirements for drug development and quality control processes, where precise analytical methods are non-negotiable. The rising complexity of biopharmaceuticals has further intensified the need for advanced chromatography solutions.

Recent market surveys reveal a significant shift in customer preferences toward Ultra-Performance Liquid Chromatography (UPLC) systems, which offer superior resolution and substantially higher throughput compared to traditional HPLC. This transition is particularly evident in high-volume testing environments where efficiency and productivity are paramount concerns.

The food and beverage industry represents the fastest-growing segment for HPLC/UPLC adoption, with increasing regulatory scrutiny on food safety and authenticity driving demand. Similarly, environmental monitoring agencies are expanding their analytical capabilities, contributing to market growth in regions with strengthening environmental protection policies.

Geographically, North America and Europe currently dominate market consumption, collectively accounting for approximately 65% of global HPLC/UPLC instrument sales. However, Asia-Pacific markets, particularly China and India, are demonstrating the highest growth rates, fueled by expanding pharmaceutical manufacturing, contract research organizations, and increasing government investments in analytical infrastructure.

Customer demand patterns indicate growing interest in integrated systems that offer enhanced automation, reduced analysis time, and lower solvent consumption. The market is increasingly valuing total cost of ownership over initial acquisition costs, with particular attention to operational efficiency and environmental sustainability.

The academic and research segment presents unique market characteristics, often prioritizing versatility and adaptability over pure throughput metrics. This segment frequently serves as an innovation incubator, where novel applications and methodologies are developed before wider industrial adoption.

Market forecasts suggest that the transition from HPLC to UPLC will accelerate, with UPLC systems expected to capture over 40% of new system sales by 2025. This transition is being facilitated by decreasing price differentials between high-end HPLC and entry-level UPLC systems, making the superior performance of UPLC increasingly accessible to mid-sized laboratories.

HPLC vs UPLC: Current Technical Status and Challenges

High-Performance Liquid Chromatography (HPLC) and Ultra-Performance Liquid Chromatography (UPLC) represent two generations of separation technology that have significantly impacted analytical chemistry. Currently, HPLC remains the most widely deployed chromatographic technique globally, with an estimated 75% market share in liquid chromatography applications across pharmaceutical, environmental, and food safety sectors.

UPLC technology, introduced commercially in 2004 by Waters Corporation, has been gaining substantial market traction, growing at approximately 15% annually compared to HPLC's 5%. This growth differential highlights the gradual technological transition occurring in analytical laboratories worldwide. The primary technical distinction lies in UPLC's ability to operate at significantly higher pressures (up to 15,000 psi) compared to conventional HPLC systems (typically limited to 6,000 psi).

Resolution capabilities present a marked difference between these technologies. Current UPLC systems routinely achieve separation efficiencies 2-3 times greater than traditional HPLC, with typical plate counts exceeding 300,000 plates/meter versus HPLC's 100,000 plates/meter. This translates to superior peak capacity and the ability to resolve complex mixtures that would be challenging or impossible with conventional HPLC methods.

Throughput comparison reveals UPLC's distinct advantage, with analysis times typically reduced by 50-80% while maintaining or improving separation quality. This efficiency gain stems from UPLC's compatibility with sub-2μm particle columns, whereas HPLC systems generally operate optimally with 3-5μm particles due to pressure limitations.

Despite UPLC's technical superiority, several challenges impede its universal adoption. The higher acquisition cost (approximately 30-50% premium over comparable HPLC systems) represents a significant barrier, particularly for smaller laboratories and educational institutions. Additionally, the transition from established HPLC methods to UPLC protocols requires substantial method development and validation efforts, creating regulatory hurdles in highly regulated industries.

Instrument durability presents another challenge, as UPLC systems operating at elevated pressures may experience accelerated wear on critical components like pumps, seals, and valves. This potentially increases maintenance requirements and operational costs compared to more robust HPLC platforms.

Geographically, UPLC adoption shows significant regional variation, with North America and Europe leading implementation (estimated 40% and 35% market penetration respectively), while developing regions maintain stronger reliance on traditional HPLC technology due to cost constraints and established infrastructure. This creates a technological divide that influences global analytical standardization efforts.

UPLC technology, introduced commercially in 2004 by Waters Corporation, has been gaining substantial market traction, growing at approximately 15% annually compared to HPLC's 5%. This growth differential highlights the gradual technological transition occurring in analytical laboratories worldwide. The primary technical distinction lies in UPLC's ability to operate at significantly higher pressures (up to 15,000 psi) compared to conventional HPLC systems (typically limited to 6,000 psi).

Resolution capabilities present a marked difference between these technologies. Current UPLC systems routinely achieve separation efficiencies 2-3 times greater than traditional HPLC, with typical plate counts exceeding 300,000 plates/meter versus HPLC's 100,000 plates/meter. This translates to superior peak capacity and the ability to resolve complex mixtures that would be challenging or impossible with conventional HPLC methods.

Throughput comparison reveals UPLC's distinct advantage, with analysis times typically reduced by 50-80% while maintaining or improving separation quality. This efficiency gain stems from UPLC's compatibility with sub-2μm particle columns, whereas HPLC systems generally operate optimally with 3-5μm particles due to pressure limitations.

Despite UPLC's technical superiority, several challenges impede its universal adoption. The higher acquisition cost (approximately 30-50% premium over comparable HPLC systems) represents a significant barrier, particularly for smaller laboratories and educational institutions. Additionally, the transition from established HPLC methods to UPLC protocols requires substantial method development and validation efforts, creating regulatory hurdles in highly regulated industries.

Instrument durability presents another challenge, as UPLC systems operating at elevated pressures may experience accelerated wear on critical components like pumps, seals, and valves. This potentially increases maintenance requirements and operational costs compared to more robust HPLC platforms.

Geographically, UPLC adoption shows significant regional variation, with North America and Europe leading implementation (estimated 40% and 35% market penetration respectively), while developing regions maintain stronger reliance on traditional HPLC technology due to cost constraints and established infrastructure. This creates a technological divide that influences global analytical standardization efforts.

Comparative Analysis of HPLC and UPLC Methodologies

01 Column technology advancements for improved resolution

Advanced column technologies in HPLC and UPLC systems significantly enhance chromatographic resolution. These include sub-2μm particle columns, core-shell particles, and monolithic columns that provide better separation efficiency. The reduced particle size and improved packing materials allow for sharper peaks, better separation of complex mixtures, and higher plate counts, ultimately leading to superior resolution in analytical applications.- Column technology advancements for improved resolution: Advanced column technologies in HPLC and UPLC systems significantly enhance chromatographic resolution. These include sub-2μm particle columns, core-shell particles, and monolithic columns that provide better separation efficiency. The reduced particle size and improved particle morphology allow for sharper peaks, better resolution of complex mixtures, and the ability to separate closely related compounds that would co-elute on traditional columns.

- High-pressure system design for increased throughput: Modern UPLC systems operate at significantly higher pressures than conventional HPLC, allowing for faster flow rates and shorter analysis times without sacrificing resolution. These systems incorporate reinforced pumps, specialized seals, and pressure-resistant components that can withstand pressures up to 15,000 psi or higher. The high-pressure capability enables the use of shorter columns with smaller particles, dramatically reducing analysis time and increasing laboratory throughput.

- Advanced detection technologies for sensitivity and resolution: Integration of sophisticated detection technologies enhances both resolution and throughput in chromatography systems. These include high-speed detectors with improved sampling rates, multiple wavelength detection capabilities, and mass spectrometry interfaces. Advanced detector designs reduce peak broadening by minimizing dead volume and optimizing flow cell geometry, while faster data acquisition rates ensure accurate representation of narrow chromatographic peaks generated by UPLC systems.

- Automated method development and optimization systems: Intelligent software platforms and automated method development tools significantly improve chromatographic resolution and throughput. These systems can automatically screen multiple column and mobile phase combinations, optimize gradient profiles, and adjust critical parameters like temperature and pH. Machine learning algorithms predict separation outcomes and suggest optimal conditions, reducing method development time from weeks to days while achieving superior resolution for complex samples.

- Temperature control and thermal management innovations: Precise temperature control systems enhance chromatographic resolution and reproducibility in both HPLC and UPLC. Advanced thermal management includes pre-column heating of mobile phases, precise column compartment temperature regulation, and post-column cooling for temperature-sensitive detectors. These innovations allow for the use of elevated temperatures to reduce mobile phase viscosity, improving mass transfer kinetics and enabling faster separations without compromising resolution.

02 High-pressure system design for increased throughput

Modern UPLC systems employ high-pressure pumps and reinforced components capable of operating at pressures exceeding 15,000 psi. This high-pressure capability allows for faster flow rates and the use of smaller particle columns, significantly reducing analysis time while maintaining separation quality. The robust engineering of these systems enables rapid sample processing and higher sample throughput compared to conventional HPLC methods.Expand Specific Solutions03 Advanced detection technologies for sensitivity and resolution

Integration of sophisticated detection technologies enhances both resolution and throughput in chromatography systems. These include high-speed diode array detectors, mass spectrometers with improved scan rates, and multi-wavelength UV detectors. The advanced detection systems provide better signal-to-noise ratios, faster data acquisition rates, and the ability to detect co-eluting compounds, contributing to improved analytical performance and faster method development.Expand Specific Solutions04 Software and automation solutions for efficiency

Intelligent chromatography software and automation solutions optimize both resolution and throughput in HPLC and UPLC systems. These include automated method development tools, peak integration algorithms, and system control software that can adjust parameters in real-time. Advanced data processing capabilities, automated sample preparation, and intelligent sequence management reduce analysis time and improve laboratory efficiency while maintaining high-quality analytical results.Expand Specific Solutions05 Temperature and gradient optimization techniques

Precise control of column temperature and mobile phase gradients significantly impacts chromatographic performance. Advanced thermal management systems allow for stable temperature control and even temperature gradients along the column. Similarly, sophisticated gradient formation technologies enable precise solvent mixing and gradient delivery. These optimizations improve peak shape, enhance resolution of closely eluting compounds, and increase method reproducibility while allowing for faster analyses.Expand Specific Solutions

Key Manufacturers and Research Institutions in LC Industry

The HPLC vs UPLC technology landscape is currently in a mature growth phase, with the global chromatography market exceeding $10 billion and growing steadily. Waters Technology Corp. leads the UPLC innovation, having pioneered the technology, while established players like Agilent Technologies and Phenomenex dominate the broader chromatography space. The competitive landscape features pharmaceutical companies (Merck, Bayer) leveraging these technologies for drug development, alongside specialized equipment manufacturers (IDEX Health & Science, Excelitas). Academic institutions (University of Washington, Leiden University) contribute significant research advancing separation science. The technology has reached commercial maturity with standardized implementations, though continuous innovations in column technology and detection methods are driving incremental performance improvements.

Waters Technology Corp.

Technical Solution: Waters Technology Corp. pioneered UPLC (Ultra Performance Liquid Chromatography) technology with their ACQUITY UPLC systems, which operate at pressures up to 15,000 psi compared to conventional HPLC's 6,000 psi limit. Their patented sub-2-micron particle technology enables significantly improved chromatographic resolution and sensitivity. Waters' UPLC systems feature specialized pumps capable of delivering precise solvent flow at ultra-high pressures, coupled with advanced detector technologies that can handle the narrower peaks produced by UPLC separations. Their systems incorporate sophisticated temperature control mechanisms to maintain column stability under high-pressure conditions, which is critical for reproducibility. Waters has also developed specialized UPLC columns with hybrid particle technology that combines the mechanical strength needed for high-pressure operation with the chemical selectivity required for complex separations[1][2].

Strengths: Industry-leading resolution capabilities with up to 3x better separation efficiency than HPLC; significantly reduced analysis times (up to 10x faster); improved sensitivity allowing detection of trace compounds. Weaknesses: Higher initial investment costs; requires more specialized training for operators; higher operating pressures demand more rigorous system maintenance schedules.

Phenomenex, Inc.

Technical Solution: Phenomenex has developed specialized column technologies that bridge the gap between HPLC and UPLC applications. Their core-shell particle technology (Kinetex columns) provides performance comparable to sub-2-micron fully porous particles but at significantly lower backpressures. This approach allows users to achieve UPLC-like efficiency improvements on existing HPLC systems without requiring entirely new instrumentation. Phenomenex's bioZen series specifically addresses biomolecule analysis challenges in both HPLC and UPLC modes, featuring specialized surface chemistries that reduce non-specific binding of proteins and peptides. Their SecurityGuard ULTRA column protection system is specifically designed to extend column lifetime under high-pressure UPLC conditions. Phenomenex also offers method translation tools that help scientists convert between HPLC and UPLC methods while maintaining separation selectivity, addressing one of the key challenges in transitioning between these technologies[5][6].

Strengths: Core-shell technology provides an excellent compromise between performance and pressure requirements; wide range of selectivities available for different application needs; strong focus on method transferability between platforms. Weaknesses: Not a complete instrument solution provider (columns only); some complex separations may still require true UPLC conditions; requires careful selection of column chemistry to achieve optimal results.

Critical Innovations in Column Technology and Particle Size Reduction

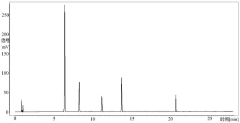

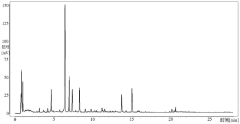

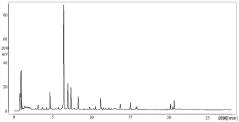

Method for determining contents of multiple components in Xintong oral liquid

PatentPendingCN115616095A

Innovation

- Simultaneous determination of puerarin, daidzin, 2,3,5,4'-tetrahydroxystilbene-2-O-β-D-glucoside, naringin and epimedium in Xintong oral liquid using UPLC method The content of glycosides can be measured simultaneously through gradient elution procedures, simplifying operations and improving detection efficiency.

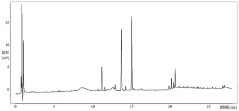

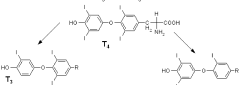

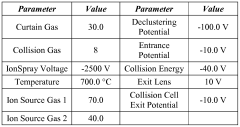

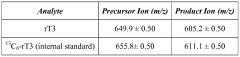

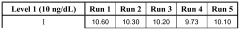

Methods for detecting reverse triiodothyronine by mass spectrometry

PatentWO2013085818A1

Innovation

- The method involves ionizing rT3 from body fluid samples using mass spectrometry, potentially after protein precipitation and liquid chromatography, without prior solid phase extraction, to detect and quantify rT3 using tandem mass spectrometry, with the option of using internal standards and specific ionization modes like electrospray ionization.

Cost-Benefit Analysis of HPLC to UPLC Transition

Transitioning from HPLC to UPLC represents a significant investment decision for laboratories that requires thorough financial analysis. The initial capital expenditure for UPLC systems typically ranges from $75,000 to $150,000, substantially higher than traditional HPLC systems which generally cost between $30,000 and $60,000. This price differential creates an immediate barrier to adoption, particularly for smaller laboratories or academic institutions with limited budgets.

However, the long-term operational economics strongly favor UPLC technology. Analysis of running costs reveals that UPLC systems consume approximately 60-80% less mobile phase than conventional HPLC methods. For laboratories processing high sample volumes, this translates to savings of $5,000-$15,000 annually on solvents alone, depending on analysis frequency and solvent types used.

Maintenance costs present a more complex picture. UPLC systems operate at higher pressures (up to 15,000 psi compared to HPLC's 6,000 psi), potentially leading to more frequent replacement of components such as pumps, seals, and columns. UPLC columns, while more expensive per unit ($500-800 vs. $200-400 for HPLC columns), typically demonstrate longer lifespans when properly maintained, partially offsetting the higher acquisition cost.

The most compelling economic advantage of UPLC emerges in throughput calculations. With analysis times reduced by 50-90%, laboratories can process significantly more samples per instrument. Case studies from pharmaceutical quality control laboratories indicate throughput increases of 200-300%, effectively reducing the cost per sample by 50-70% when factoring in labor, overhead, and operational expenses.

Return on investment (ROI) modeling suggests that high-volume laboratories typically recoup UPLC investment costs within 12-24 months through combined savings in labor, solvents, and increased capacity. Medium-volume laboratories may see ROI periods of 24-36 months, while low-volume operations might require 3-5 years to realize full financial benefits.

Productivity gains extend beyond direct financial metrics. The faster turnaround times enabled by UPLC technology allow laboratories to meet tighter deadlines, improve service levels, and potentially capture additional business opportunities. In regulated environments such as pharmaceutical manufacturing, faster analytical results can accelerate batch release processes, reducing inventory holding costs and improving cash flow.

Organizations should also consider the transition costs beyond equipment purchase, including method validation, staff training, and potential workflow disruptions during implementation. These factors typically add 15-25% to the total transition cost but are essential for successful technology adoption and realizing the projected benefits.

However, the long-term operational economics strongly favor UPLC technology. Analysis of running costs reveals that UPLC systems consume approximately 60-80% less mobile phase than conventional HPLC methods. For laboratories processing high sample volumes, this translates to savings of $5,000-$15,000 annually on solvents alone, depending on analysis frequency and solvent types used.

Maintenance costs present a more complex picture. UPLC systems operate at higher pressures (up to 15,000 psi compared to HPLC's 6,000 psi), potentially leading to more frequent replacement of components such as pumps, seals, and columns. UPLC columns, while more expensive per unit ($500-800 vs. $200-400 for HPLC columns), typically demonstrate longer lifespans when properly maintained, partially offsetting the higher acquisition cost.

The most compelling economic advantage of UPLC emerges in throughput calculations. With analysis times reduced by 50-90%, laboratories can process significantly more samples per instrument. Case studies from pharmaceutical quality control laboratories indicate throughput increases of 200-300%, effectively reducing the cost per sample by 50-70% when factoring in labor, overhead, and operational expenses.

Return on investment (ROI) modeling suggests that high-volume laboratories typically recoup UPLC investment costs within 12-24 months through combined savings in labor, solvents, and increased capacity. Medium-volume laboratories may see ROI periods of 24-36 months, while low-volume operations might require 3-5 years to realize full financial benefits.

Productivity gains extend beyond direct financial metrics. The faster turnaround times enabled by UPLC technology allow laboratories to meet tighter deadlines, improve service levels, and potentially capture additional business opportunities. In regulated environments such as pharmaceutical manufacturing, faster analytical results can accelerate batch release processes, reducing inventory holding costs and improving cash flow.

Organizations should also consider the transition costs beyond equipment purchase, including method validation, staff training, and potential workflow disruptions during implementation. These factors typically add 15-25% to the total transition cost but are essential for successful technology adoption and realizing the projected benefits.

Environmental Impact and Green Chemistry Considerations

The environmental impact of analytical techniques has become increasingly important in laboratory settings as sustainability concerns grow. When comparing HPLC (High-Performance Liquid Chromatography) and UPLC (Ultra-Performance Liquid Chromatography) systems, several key environmental factors must be considered within the framework of green chemistry principles.

UPLC demonstrates significant environmental advantages through substantially reduced solvent consumption. Typical UPLC methods require 60-80% less mobile phase than traditional HPLC methods, directly translating to decreased chemical waste generation and reduced exposure of laboratory personnel to potentially harmful solvents. This reduction aligns with multiple green chemistry principles, particularly waste prevention and safer solvent selection.

Energy consumption represents another critical environmental consideration. UPLC systems generally operate at higher pressures but complete analyses in significantly shorter timeframes. Studies indicate that UPLC can reduce energy consumption by 30-45% compared to conventional HPLC methods when normalized per sample analysis, primarily due to shorter run times and more efficient temperature control systems.

The carbon footprint differential between these technologies extends beyond direct laboratory operations. HPLC methods typically require larger volumes of solvents, many derived from petroleum sources, contributing to upstream environmental impacts through manufacturing and transportation. UPLC's reduced solvent requirements consequently diminish these associated indirect environmental impacts.

Waste management considerations favor UPLC systems, which generate substantially less liquid waste requiring specialized disposal. A typical analytical laboratory running 50 samples daily might produce 15-20 liters less waste monthly by transitioning from HPLC to UPLC methodologies, reducing both disposal costs and environmental burden.

Instrument lifecycle assessment reveals that while UPLC systems may require more resources during manufacturing due to more sophisticated components, their higher efficiency and throughput often result in fewer instruments needed for equivalent workloads. This potentially offsets the initial manufacturing impact through reduced overall resource consumption across laboratory operations.

Recent innovations in both technologies have focused on environmental optimization. Green HPLC and UPLC approaches include the development of aqueous mobile phases, biodegradable solvents, and solvent recycling systems. UPLC systems, however, demonstrate greater compatibility with these green chemistry adaptations due to their inherent efficiency and smaller solvent requirements.

When laboratories transition from HPLC to UPLC, they often report 65-75% reductions in their environmental impact metrics, demonstrating that technological advancement in chromatography aligns with sustainability goals without compromising analytical performance.

UPLC demonstrates significant environmental advantages through substantially reduced solvent consumption. Typical UPLC methods require 60-80% less mobile phase than traditional HPLC methods, directly translating to decreased chemical waste generation and reduced exposure of laboratory personnel to potentially harmful solvents. This reduction aligns with multiple green chemistry principles, particularly waste prevention and safer solvent selection.

Energy consumption represents another critical environmental consideration. UPLC systems generally operate at higher pressures but complete analyses in significantly shorter timeframes. Studies indicate that UPLC can reduce energy consumption by 30-45% compared to conventional HPLC methods when normalized per sample analysis, primarily due to shorter run times and more efficient temperature control systems.

The carbon footprint differential between these technologies extends beyond direct laboratory operations. HPLC methods typically require larger volumes of solvents, many derived from petroleum sources, contributing to upstream environmental impacts through manufacturing and transportation. UPLC's reduced solvent requirements consequently diminish these associated indirect environmental impacts.

Waste management considerations favor UPLC systems, which generate substantially less liquid waste requiring specialized disposal. A typical analytical laboratory running 50 samples daily might produce 15-20 liters less waste monthly by transitioning from HPLC to UPLC methodologies, reducing both disposal costs and environmental burden.

Instrument lifecycle assessment reveals that while UPLC systems may require more resources during manufacturing due to more sophisticated components, their higher efficiency and throughput often result in fewer instruments needed for equivalent workloads. This potentially offsets the initial manufacturing impact through reduced overall resource consumption across laboratory operations.

Recent innovations in both technologies have focused on environmental optimization. Green HPLC and UPLC approaches include the development of aqueous mobile phases, biodegradable solvents, and solvent recycling systems. UPLC systems, however, demonstrate greater compatibility with these green chemistry adaptations due to their inherent efficiency and smaller solvent requirements.

When laboratories transition from HPLC to UPLC, they often report 65-75% reductions in their environmental impact metrics, demonstrating that technological advancement in chromatography aligns with sustainability goals without compromising analytical performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!