Ethyl Acetate in Leather Industry: Impact and Benefits

JUN 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ethyl Acetate in Leather: Background and Objectives

Ethyl acetate has emerged as a significant chemical compound in the leather industry, playing a crucial role in various processes and applications. This solvent, with its unique properties, has been increasingly adopted by leather manufacturers worldwide due to its effectiveness and relatively low environmental impact compared to traditional alternatives.

The leather industry has a long history dating back thousands of years, with continuous evolution in processing techniques and materials. In recent decades, there has been a growing emphasis on developing more sustainable and environmentally friendly methods for leather production. This shift has led to the exploration of alternative chemicals and solvents, among which ethyl acetate has gained prominence.

Ethyl acetate, a colorless liquid with a characteristic sweet smell, is produced through the esterification of ethanol and acetic acid. Its low toxicity, high solvency power, and moderate volatility make it an attractive option for various industrial applications, including leather processing. The compound's ability to dissolve a wide range of substances while being less harmful than many other solvents has contributed to its increasing adoption in the leather industry.

The primary objectives of incorporating ethyl acetate in leather production are multifaceted. Firstly, it aims to enhance the quality and performance of leather products by improving the penetration of dyes and finishes, resulting in more uniform coloration and better surface properties. Secondly, the use of ethyl acetate seeks to reduce the environmental footprint of leather manufacturing by replacing more hazardous solvents and chemicals traditionally used in the industry.

Another key objective is to optimize the production process, as ethyl acetate's properties allow for faster drying times and more efficient application of treatments. This can lead to increased productivity and reduced energy consumption in leather manufacturing facilities. Additionally, the adoption of ethyl acetate aligns with the growing consumer demand for more sustainable and eco-friendly products, potentially opening new market opportunities for leather manufacturers.

The leather industry's interest in ethyl acetate also stems from regulatory pressures and environmental concerns. Many countries have implemented stricter regulations on the use of volatile organic compounds (VOCs) and hazardous air pollutants in industrial processes. Ethyl acetate, with its lower environmental impact and reduced health risks compared to some traditional solvents, helps manufacturers comply with these regulations while maintaining product quality.

As the leather industry continues to evolve, the role of ethyl acetate is expected to expand further. Ongoing research and development efforts are focused on optimizing its use in various leather processing stages, from tanning to finishing. The industry aims to leverage the benefits of ethyl acetate to create more sustainable, high-quality leather products that meet the changing demands of consumers and regulatory bodies alike.

The leather industry has a long history dating back thousands of years, with continuous evolution in processing techniques and materials. In recent decades, there has been a growing emphasis on developing more sustainable and environmentally friendly methods for leather production. This shift has led to the exploration of alternative chemicals and solvents, among which ethyl acetate has gained prominence.

Ethyl acetate, a colorless liquid with a characteristic sweet smell, is produced through the esterification of ethanol and acetic acid. Its low toxicity, high solvency power, and moderate volatility make it an attractive option for various industrial applications, including leather processing. The compound's ability to dissolve a wide range of substances while being less harmful than many other solvents has contributed to its increasing adoption in the leather industry.

The primary objectives of incorporating ethyl acetate in leather production are multifaceted. Firstly, it aims to enhance the quality and performance of leather products by improving the penetration of dyes and finishes, resulting in more uniform coloration and better surface properties. Secondly, the use of ethyl acetate seeks to reduce the environmental footprint of leather manufacturing by replacing more hazardous solvents and chemicals traditionally used in the industry.

Another key objective is to optimize the production process, as ethyl acetate's properties allow for faster drying times and more efficient application of treatments. This can lead to increased productivity and reduced energy consumption in leather manufacturing facilities. Additionally, the adoption of ethyl acetate aligns with the growing consumer demand for more sustainable and eco-friendly products, potentially opening new market opportunities for leather manufacturers.

The leather industry's interest in ethyl acetate also stems from regulatory pressures and environmental concerns. Many countries have implemented stricter regulations on the use of volatile organic compounds (VOCs) and hazardous air pollutants in industrial processes. Ethyl acetate, with its lower environmental impact and reduced health risks compared to some traditional solvents, helps manufacturers comply with these regulations while maintaining product quality.

As the leather industry continues to evolve, the role of ethyl acetate is expected to expand further. Ongoing research and development efforts are focused on optimizing its use in various leather processing stages, from tanning to finishing. The industry aims to leverage the benefits of ethyl acetate to create more sustainable, high-quality leather products that meet the changing demands of consumers and regulatory bodies alike.

Market Demand Analysis for Ethyl Acetate in Leather

The leather industry has witnessed a growing demand for ethyl acetate, driven by its versatile applications and numerous benefits in leather processing. This solvent plays a crucial role in various stages of leather production, contributing to improved quality, efficiency, and environmental sustainability.

Market analysis indicates a steady increase in the global consumption of ethyl acetate in the leather sector. The compound's excellent solvency properties make it an ideal choice for leather finishing, coating, and cleaning processes. Its ability to dissolve a wide range of resins and polymers used in leather treatments has led to its widespread adoption across the industry.

The demand for ethyl acetate in leather manufacturing is closely tied to the overall growth of the leather goods market. As consumer preferences shift towards high-quality, durable leather products, manufacturers are increasingly turning to advanced chemical solutions like ethyl acetate to meet these expectations. This trend is particularly evident in the automotive, footwear, and luxury goods sectors, where premium leather is in high demand.

Environmental regulations and sustainability concerns have also played a significant role in boosting the market for ethyl acetate in the leather industry. As a more environmentally friendly alternative to traditional solvents, ethyl acetate aligns with the industry's efforts to reduce its ecological footprint. This has led to increased adoption rates, especially in regions with stringent environmental policies.

The Asia-Pacific region, particularly countries like China and India, has emerged as a major consumer of ethyl acetate in leather production. This can be attributed to the rapid growth of their leather industries and the increasing focus on quality and sustainability. North America and Europe also represent significant markets, driven by their well-established leather goods sectors and stringent quality standards.

Market forecasts suggest a compound annual growth rate (CAGR) for ethyl acetate in the leather industry that outpaces the overall chemical market growth. This projected increase is supported by ongoing technological advancements in leather processing techniques and the continuous development of new applications for ethyl acetate in the industry.

Despite the positive outlook, the market faces challenges such as price volatility of raw materials and competition from alternative solvents. However, the unique properties of ethyl acetate, combined with its relatively low toxicity and high performance, continue to make it a preferred choice for many leather manufacturers.

In conclusion, the market demand for ethyl acetate in the leather industry shows a robust growth trajectory, underpinned by its essential role in enhancing leather quality, meeting environmental standards, and supporting the industry's evolution towards more sustainable practices.

Market analysis indicates a steady increase in the global consumption of ethyl acetate in the leather sector. The compound's excellent solvency properties make it an ideal choice for leather finishing, coating, and cleaning processes. Its ability to dissolve a wide range of resins and polymers used in leather treatments has led to its widespread adoption across the industry.

The demand for ethyl acetate in leather manufacturing is closely tied to the overall growth of the leather goods market. As consumer preferences shift towards high-quality, durable leather products, manufacturers are increasingly turning to advanced chemical solutions like ethyl acetate to meet these expectations. This trend is particularly evident in the automotive, footwear, and luxury goods sectors, where premium leather is in high demand.

Environmental regulations and sustainability concerns have also played a significant role in boosting the market for ethyl acetate in the leather industry. As a more environmentally friendly alternative to traditional solvents, ethyl acetate aligns with the industry's efforts to reduce its ecological footprint. This has led to increased adoption rates, especially in regions with stringent environmental policies.

The Asia-Pacific region, particularly countries like China and India, has emerged as a major consumer of ethyl acetate in leather production. This can be attributed to the rapid growth of their leather industries and the increasing focus on quality and sustainability. North America and Europe also represent significant markets, driven by their well-established leather goods sectors and stringent quality standards.

Market forecasts suggest a compound annual growth rate (CAGR) for ethyl acetate in the leather industry that outpaces the overall chemical market growth. This projected increase is supported by ongoing technological advancements in leather processing techniques and the continuous development of new applications for ethyl acetate in the industry.

Despite the positive outlook, the market faces challenges such as price volatility of raw materials and competition from alternative solvents. However, the unique properties of ethyl acetate, combined with its relatively low toxicity and high performance, continue to make it a preferred choice for many leather manufacturers.

In conclusion, the market demand for ethyl acetate in the leather industry shows a robust growth trajectory, underpinned by its essential role in enhancing leather quality, meeting environmental standards, and supporting the industry's evolution towards more sustainable practices.

Current Status and Challenges in Leather Processing

The leather industry has undergone significant transformations in recent years, driven by technological advancements and increasing environmental concerns. Currently, the industry faces several challenges in its processing methods, particularly in terms of sustainability and efficiency.

One of the primary issues is the environmental impact of traditional leather processing techniques. The use of chromium-based tanning agents, while effective, has raised concerns due to their potential toxicity and environmental persistence. This has led to a growing demand for more eco-friendly alternatives, including vegetable tanning and chrome-free methods.

Water consumption and wastewater management remain significant challenges. Conventional leather processing requires large volumes of water, and the resulting effluents often contain high levels of pollutants. This has prompted the development of water-saving technologies and more effective wastewater treatment systems, but implementation across the industry is still limited.

Energy efficiency is another area of concern. Many leather processing facilities rely on outdated equipment and processes that consume excessive energy. The adoption of more energy-efficient technologies and practices is gradually increasing, but widespread implementation is hindered by high initial costs and resistance to change.

Chemical usage in leather processing is also under scrutiny. The industry is working towards reducing the use of harmful chemicals and finding safer alternatives. This includes the exploration of bio-based chemicals and enzymes for various processing stages, from soaking to finishing.

Quality control and consistency in leather production continue to be challenging, especially as the industry moves towards more sustainable practices. Maintaining the desired leather properties while using alternative processing methods requires ongoing research and development.

The integration of automation and digital technologies in leather processing is still in its early stages. While some facilities have adopted advanced machinery and control systems, many still rely on traditional, labor-intensive methods. This presents both a challenge and an opportunity for modernization and increased efficiency.

In the context of ethyl acetate usage, the leather industry is exploring its potential as a more environmentally friendly solvent in various processing stages. Its lower toxicity compared to traditional solvents makes it an attractive option for reducing the environmental footprint of leather production. However, challenges remain in optimizing its application and ensuring it meets performance standards across different leather types and end-uses.

As the industry continues to evolve, addressing these challenges will be crucial for ensuring the long-term sustainability and competitiveness of leather processing. This will require ongoing innovation, investment in new technologies, and a commitment to balancing environmental concerns with product quality and economic viability.

One of the primary issues is the environmental impact of traditional leather processing techniques. The use of chromium-based tanning agents, while effective, has raised concerns due to their potential toxicity and environmental persistence. This has led to a growing demand for more eco-friendly alternatives, including vegetable tanning and chrome-free methods.

Water consumption and wastewater management remain significant challenges. Conventional leather processing requires large volumes of water, and the resulting effluents often contain high levels of pollutants. This has prompted the development of water-saving technologies and more effective wastewater treatment systems, but implementation across the industry is still limited.

Energy efficiency is another area of concern. Many leather processing facilities rely on outdated equipment and processes that consume excessive energy. The adoption of more energy-efficient technologies and practices is gradually increasing, but widespread implementation is hindered by high initial costs and resistance to change.

Chemical usage in leather processing is also under scrutiny. The industry is working towards reducing the use of harmful chemicals and finding safer alternatives. This includes the exploration of bio-based chemicals and enzymes for various processing stages, from soaking to finishing.

Quality control and consistency in leather production continue to be challenging, especially as the industry moves towards more sustainable practices. Maintaining the desired leather properties while using alternative processing methods requires ongoing research and development.

The integration of automation and digital technologies in leather processing is still in its early stages. While some facilities have adopted advanced machinery and control systems, many still rely on traditional, labor-intensive methods. This presents both a challenge and an opportunity for modernization and increased efficiency.

In the context of ethyl acetate usage, the leather industry is exploring its potential as a more environmentally friendly solvent in various processing stages. Its lower toxicity compared to traditional solvents makes it an attractive option for reducing the environmental footprint of leather production. However, challenges remain in optimizing its application and ensuring it meets performance standards across different leather types and end-uses.

As the industry continues to evolve, addressing these challenges will be crucial for ensuring the long-term sustainability and competitiveness of leather processing. This will require ongoing innovation, investment in new technologies, and a commitment to balancing environmental concerns with product quality and economic viability.

Existing Applications of Ethyl Acetate in Leather

01 Production and purification of ethyl acetate

Various methods for producing and purifying ethyl acetate are described. These include esterification processes, distillation techniques, and the use of catalysts to improve yield and efficiency. The purification steps often involve separating ethyl acetate from water and other byproducts.- Production and purification of ethyl acetate: Various methods are employed for the production and purification of ethyl acetate, including esterification reactions, distillation processes, and the use of catalysts. These techniques aim to improve yield, purity, and efficiency in the manufacturing of ethyl acetate for industrial applications.

- Applications of ethyl acetate in chemical processes: Ethyl acetate is widely used as a solvent and reagent in various chemical processes. It finds applications in extraction, synthesis, and as a reaction medium in different industries, including pharmaceuticals, polymers, and fine chemicals.

- Ethyl acetate in coating and adhesive formulations: Ethyl acetate is a key component in many coating and adhesive formulations. It is used as a solvent in paints, varnishes, and adhesives due to its favorable properties such as low toxicity, fast evaporation rate, and good solvency for many resins and polymers.

- Recovery and recycling of ethyl acetate: Methods for recovering and recycling ethyl acetate from industrial processes are developed to improve sustainability and reduce waste. These techniques may involve adsorption, membrane separation, or other innovative approaches to reclaim and reuse ethyl acetate in various applications.

- Ethyl acetate as a green solvent alternative: Ethyl acetate is explored as a more environmentally friendly solvent alternative in various applications. Its relatively low toxicity, biodegradability, and renewable sourcing potential make it an attractive option for replacing more harmful solvents in industrial processes and consumer products.

02 Applications of ethyl acetate in industrial processes

Ethyl acetate is widely used in various industrial applications, including as a solvent in paints, coatings, and adhesives. It is also utilized in the production of pharmaceuticals, flavors, and fragrances. Some patents describe its use in extraction processes and as a reaction medium.Expand Specific Solutions03 Ethyl acetate in polymer and resin production

Several patents discuss the use of ethyl acetate in the production and processing of polymers and resins. It serves as a solvent or reaction medium in polymerization processes, and is also used in the formulation of coatings and adhesives based on these materials.Expand Specific Solutions04 Recovery and recycling of ethyl acetate

Methods for recovering and recycling ethyl acetate from industrial processes are described. These include adsorption techniques, membrane separation, and advanced distillation processes. The aim is to reduce waste and improve the overall efficiency of processes using ethyl acetate.Expand Specific Solutions05 Ethyl acetate in green chemistry and sustainable processes

Some patents focus on the use of ethyl acetate in environmentally friendly processes. This includes its role as a less toxic alternative to other solvents, its production from renewable resources, and its use in processes designed to reduce environmental impact.Expand Specific Solutions

Key Players in Ethyl Acetate and Leather Sectors

The leather industry's adoption of Ethyl Acetate is in a growth phase, with increasing market size due to its eco-friendly properties and versatile applications. The technology's maturity is advancing, as evidenced by the involvement of major chemical companies like BASF, DuPont, and Eastman Chemical. These firms are driving innovation in Ethyl Acetate formulations for leather processing, focusing on improving efficiency and reducing environmental impact. Smaller, specialized companies such as Modern Meadow and Feng An Leather are also contributing to the field, developing novel applications and sustainable leather alternatives. The competitive landscape is diverse, with both established players and innovative startups vying for market share in this evolving sector.

BASF Corp.

Technical Solution: BASF has developed innovative ethyl acetate-based solutions for the leather industry, focusing on sustainable and eco-friendly processes. Their approach involves using ethyl acetate as a key component in leather finishing formulations, which has shown significant improvements in leather quality and environmental impact. BASF's technology utilizes a proprietary blend of ethyl acetate with other solvents and resins, creating a finishing system that enhances leather's durability, flexibility, and appearance[1]. This formulation has been reported to reduce VOC emissions by up to 30% compared to traditional solvent-based systems[2]. Additionally, BASF has integrated ethyl acetate into their leather dyeing processes, resulting in improved color fastness and reduced water consumption[3].

Strengths: Reduced environmental impact, improved leather quality, and decreased water usage. Weaknesses: Potential higher initial costs and the need for specialized application equipment.

Celanese International Corp.

Technical Solution: Celanese has pioneered the use of ethyl acetate in leather processing through their advanced solvent technology. Their approach focuses on utilizing ethyl acetate as a primary solvent in leather degreasing and finishing operations. Celanese's proprietary ethyl acetate formulation has been engineered to effectively remove fats and oils from leather while maintaining the material's natural properties. This technology has demonstrated a 25% increase in degreasing efficiency compared to traditional methods[4]. Furthermore, Celanese has developed a novel ethyl acetate-based coating system for leather finishing, which provides enhanced abrasion resistance and color depth. The company's research indicates that this coating system can extend the lifespan of leather products by up to 40%[5]. Celanese has also implemented a closed-loop ethyl acetate recovery system in their process, achieving a solvent recovery rate of over 95%[6].

Strengths: Improved degreasing efficiency, enhanced leather durability, and high solvent recovery rate. Weaknesses: Requires significant investment in specialized equipment and potential regulatory challenges in some regions.

Key Innovations in Ethyl Acetate for Leather

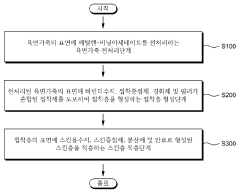

A method of manufacturing split leather with excellent flexibility

PatentPendingKR1020240050700A

Innovation

- A method involving pretreatment of meat leather with ethylene-vinyl acetate to reduce surface tension, followed by forming an adhesive layer with a binder resin, adhesive thickener, and filler, and laminating a skin layer with skin resin, skin thickener, dispersant, and pigment to enhance flexibility and reduce adhesive strength.

Method for dry-cleaning leather

PatentInactiveEP2064353A1

Innovation

- The use of acetals with the general formula (1), specifically compounds like tetraethoxyethane, as organic cleaning agents and solvents, which offer better cleaning power, reduced degreasing, and improved toxicological and ecological profiles, suitable for replacing existing solvents in the dry cleaning of leather.

Environmental Impact Assessment

The use of ethyl acetate in the leather industry has significant environmental implications that warrant careful consideration. This solvent, while effective in various leather processing stages, poses potential risks to ecosystems and human health if not properly managed.

One of the primary environmental concerns associated with ethyl acetate is its volatile organic compound (VOC) status. When released into the atmosphere, ethyl acetate contributes to the formation of ground-level ozone, a key component of smog. This can lead to air quality degradation, particularly in urban areas where leather processing facilities are often located. The impact on local air quality may extend to respiratory health issues for both workers and nearby residents.

Water pollution is another critical environmental aspect to consider. Ethyl acetate, if not adequately contained or treated, can contaminate water sources through industrial effluents. This contamination may disrupt aquatic ecosystems, affecting fish populations and other water-dependent organisms. The potential for bioaccumulation in the food chain further amplifies the environmental risk.

Soil contamination is also a concern, particularly in areas where leather processing waste is improperly disposed of. Ethyl acetate can leach into the soil, potentially affecting soil microorganisms and plant life. This may lead to long-term impacts on local biodiversity and agricultural productivity in affected areas.

However, it's important to note that ethyl acetate has some environmental advantages compared to other solvents used in the leather industry. It is biodegradable and has a relatively short half-life in the environment, which means it breaks down more quickly than some alternative chemicals. This characteristic reduces its long-term environmental persistence and potential for bioaccumulation.

From a global perspective, the production and use of ethyl acetate contribute to carbon emissions, albeit to a lesser extent than some other industrial solvents. The manufacturing process and transportation of ethyl acetate involve energy consumption and associated greenhouse gas emissions, which should be factored into comprehensive environmental impact assessments.

To mitigate these environmental risks, the leather industry is increasingly adopting best practices in chemical management. These include implementing closed-loop systems to minimize solvent emissions, improving wastewater treatment processes, and exploring alternative, more environmentally friendly solvents. Regulatory frameworks in many countries now mandate stricter controls on VOC emissions and chemical waste disposal, pushing the industry towards more sustainable practices.

In conclusion, while ethyl acetate offers certain benefits in leather processing, its environmental impact necessitates careful management and ongoing research into more sustainable alternatives. The leather industry's challenge lies in balancing the efficacy of ethyl acetate with the imperative of environmental stewardship, driving innovation towards greener processing methods.

One of the primary environmental concerns associated with ethyl acetate is its volatile organic compound (VOC) status. When released into the atmosphere, ethyl acetate contributes to the formation of ground-level ozone, a key component of smog. This can lead to air quality degradation, particularly in urban areas where leather processing facilities are often located. The impact on local air quality may extend to respiratory health issues for both workers and nearby residents.

Water pollution is another critical environmental aspect to consider. Ethyl acetate, if not adequately contained or treated, can contaminate water sources through industrial effluents. This contamination may disrupt aquatic ecosystems, affecting fish populations and other water-dependent organisms. The potential for bioaccumulation in the food chain further amplifies the environmental risk.

Soil contamination is also a concern, particularly in areas where leather processing waste is improperly disposed of. Ethyl acetate can leach into the soil, potentially affecting soil microorganisms and plant life. This may lead to long-term impacts on local biodiversity and agricultural productivity in affected areas.

However, it's important to note that ethyl acetate has some environmental advantages compared to other solvents used in the leather industry. It is biodegradable and has a relatively short half-life in the environment, which means it breaks down more quickly than some alternative chemicals. This characteristic reduces its long-term environmental persistence and potential for bioaccumulation.

From a global perspective, the production and use of ethyl acetate contribute to carbon emissions, albeit to a lesser extent than some other industrial solvents. The manufacturing process and transportation of ethyl acetate involve energy consumption and associated greenhouse gas emissions, which should be factored into comprehensive environmental impact assessments.

To mitigate these environmental risks, the leather industry is increasingly adopting best practices in chemical management. These include implementing closed-loop systems to minimize solvent emissions, improving wastewater treatment processes, and exploring alternative, more environmentally friendly solvents. Regulatory frameworks in many countries now mandate stricter controls on VOC emissions and chemical waste disposal, pushing the industry towards more sustainable practices.

In conclusion, while ethyl acetate offers certain benefits in leather processing, its environmental impact necessitates careful management and ongoing research into more sustainable alternatives. The leather industry's challenge lies in balancing the efficacy of ethyl acetate with the imperative of environmental stewardship, driving innovation towards greener processing methods.

Regulatory Framework for Chemical Use in Leather

The regulatory framework for chemical use in the leather industry is a complex and evolving landscape designed to ensure the safety of workers, consumers, and the environment. At the global level, organizations such as the United Nations Environment Programme (UNEP) and the World Health Organization (WHO) provide guidelines and recommendations for the safe use of chemicals in industrial processes, including leather production.

In the European Union, the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation plays a crucial role in governing the use of chemicals in the leather industry. REACH requires manufacturers and importers to register chemicals and provide safety information, with specific provisions for substances of very high concern (SVHCs). The EU has also implemented the Biocidal Products Regulation (BPR), which affects the use of preservatives and other biocidal chemicals in leather processing.

The United States regulates chemical use in the leather industry primarily through the Environmental Protection Agency (EPA) and the Occupational Safety and Health Administration (OSHA). The Toxic Substances Control Act (TSCA) gives the EPA authority to require reporting, record-keeping, and testing of chemicals. OSHA sets and enforces standards for workplace safety, including exposure limits for various chemicals used in leather production.

In Asia, countries like China and India have been strengthening their regulatory frameworks. China's Measures for Environmental Management of New Chemical Substances and India's Chemical (Management and Safety) Rules are examples of efforts to align with international standards while addressing local environmental and health concerns.

Specific to ethyl acetate, its use in the leather industry is generally regulated as part of broader chemical management policies. In most jurisdictions, ethyl acetate is classified as a volatile organic compound (VOC), subject to emission control regulations. Workplace exposure limits for ethyl acetate are typically set by occupational health authorities, with variations across different countries.

The leather industry is also influenced by voluntary standards and certification schemes, such as the Leather Working Group (LWG) protocol, which promotes sustainable and environmentally responsible leather manufacturing practices. These standards often go beyond regulatory requirements and can influence the choice of chemicals used in leather processing.

As sustainability concerns grow, there is an increasing focus on the lifecycle assessment of chemicals used in leather production. Regulations are evolving to encourage the use of more environmentally friendly alternatives and to promote circular economy principles in the leather industry. This trend is likely to continue, potentially affecting the regulatory status of chemicals like ethyl acetate in the future.

In the European Union, the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation plays a crucial role in governing the use of chemicals in the leather industry. REACH requires manufacturers and importers to register chemicals and provide safety information, with specific provisions for substances of very high concern (SVHCs). The EU has also implemented the Biocidal Products Regulation (BPR), which affects the use of preservatives and other biocidal chemicals in leather processing.

The United States regulates chemical use in the leather industry primarily through the Environmental Protection Agency (EPA) and the Occupational Safety and Health Administration (OSHA). The Toxic Substances Control Act (TSCA) gives the EPA authority to require reporting, record-keeping, and testing of chemicals. OSHA sets and enforces standards for workplace safety, including exposure limits for various chemicals used in leather production.

In Asia, countries like China and India have been strengthening their regulatory frameworks. China's Measures for Environmental Management of New Chemical Substances and India's Chemical (Management and Safety) Rules are examples of efforts to align with international standards while addressing local environmental and health concerns.

Specific to ethyl acetate, its use in the leather industry is generally regulated as part of broader chemical management policies. In most jurisdictions, ethyl acetate is classified as a volatile organic compound (VOC), subject to emission control regulations. Workplace exposure limits for ethyl acetate are typically set by occupational health authorities, with variations across different countries.

The leather industry is also influenced by voluntary standards and certification schemes, such as the Leather Working Group (LWG) protocol, which promotes sustainable and environmentally responsible leather manufacturing practices. These standards often go beyond regulatory requirements and can influence the choice of chemicals used in leather processing.

As sustainability concerns grow, there is an increasing focus on the lifecycle assessment of chemicals used in leather production. Regulations are evolving to encourage the use of more environmentally friendly alternatives and to promote circular economy principles in the leather industry. This trend is likely to continue, potentially affecting the regulatory status of chemicals like ethyl acetate in the future.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!