Impact of Buffer Ionic Strength on Isoelectric Focusing Results

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Buffer Ionic Strength Background and Objectives

Isoelectric focusing (IEF) has evolved significantly since its introduction in the 1960s as a powerful analytical technique for protein separation based on their isoelectric points (pI). The development of this technique has been closely tied to our understanding of buffer systems and their ionic properties. Buffer ionic strength, in particular, has emerged as a critical parameter that significantly influences the resolution, stability, and reproducibility of IEF separations.

Historically, early IEF applications utilized simple buffer systems with limited control over ionic strength parameters. As analytical requirements became more demanding, researchers began to recognize that the concentration and composition of buffer ions directly impact the establishment of pH gradients and the behavior of ampholytes during the focusing process. This realization has led to systematic investigations into optimizing buffer conditions for various applications.

The evolution of IEF technology has seen transitions from conventional gel-based systems to capillary formats and more recently to microfluidic platforms, each presenting unique challenges related to buffer ionic strength management. These technological advancements have expanded the application scope of IEF from primarily research settings to clinical diagnostics, pharmaceutical quality control, and proteomics research.

Current trends in IEF development focus on achieving higher resolution separations, improved reproducibility, and compatibility with downstream analytical techniques such as mass spectrometry. Buffer ionic strength optimization plays a central role in addressing these challenges, as it directly affects the establishment and stability of pH gradients, protein solubility, and electroosmotic flow in capillary and microchip formats.

The primary objective of investigating buffer ionic strength effects on IEF results is to establish a comprehensive understanding of the relationship between buffer composition parameters and separation performance. This includes quantifying how variations in ionic strength influence critical performance metrics such as resolution, focusing time, protein precipitation tendencies, and band distortion.

Additional objectives include developing predictive models for optimizing buffer conditions based on sample characteristics, establishing standardized protocols for different application scenarios, and identifying novel buffer formulations that can overcome current limitations in challenging samples such as membrane proteins or extremely basic/acidic proteins.

By systematically exploring these relationships, we aim to provide practical guidelines for researchers and analytical scientists to select appropriate buffer conditions for specific IEF applications, ultimately enhancing the reliability and utility of this important separation technique across various fields including proteomics, biopharmaceutical analysis, and clinical diagnostics.

Historically, early IEF applications utilized simple buffer systems with limited control over ionic strength parameters. As analytical requirements became more demanding, researchers began to recognize that the concentration and composition of buffer ions directly impact the establishment of pH gradients and the behavior of ampholytes during the focusing process. This realization has led to systematic investigations into optimizing buffer conditions for various applications.

The evolution of IEF technology has seen transitions from conventional gel-based systems to capillary formats and more recently to microfluidic platforms, each presenting unique challenges related to buffer ionic strength management. These technological advancements have expanded the application scope of IEF from primarily research settings to clinical diagnostics, pharmaceutical quality control, and proteomics research.

Current trends in IEF development focus on achieving higher resolution separations, improved reproducibility, and compatibility with downstream analytical techniques such as mass spectrometry. Buffer ionic strength optimization plays a central role in addressing these challenges, as it directly affects the establishment and stability of pH gradients, protein solubility, and electroosmotic flow in capillary and microchip formats.

The primary objective of investigating buffer ionic strength effects on IEF results is to establish a comprehensive understanding of the relationship between buffer composition parameters and separation performance. This includes quantifying how variations in ionic strength influence critical performance metrics such as resolution, focusing time, protein precipitation tendencies, and band distortion.

Additional objectives include developing predictive models for optimizing buffer conditions based on sample characteristics, establishing standardized protocols for different application scenarios, and identifying novel buffer formulations that can overcome current limitations in challenging samples such as membrane proteins or extremely basic/acidic proteins.

By systematically exploring these relationships, we aim to provide practical guidelines for researchers and analytical scientists to select appropriate buffer conditions for specific IEF applications, ultimately enhancing the reliability and utility of this important separation technique across various fields including proteomics, biopharmaceutical analysis, and clinical diagnostics.

Market Analysis for IEF Applications

The global market for Isoelectric Focusing (IEF) applications continues to expand, driven by increasing demand in proteomics research, pharmaceutical development, and clinical diagnostics. Currently valued at approximately $1.2 billion, the IEF market is projected to grow at a CAGR of 5.8% through 2028, with particularly strong growth in Asia-Pacific regions where biotechnology infrastructure is rapidly developing.

Pharmaceutical and biotechnology sectors represent the largest market segments, collectively accounting for over 60% of IEF applications. These industries leverage IEF primarily for protein characterization, quality control, and development of biotherapeutics. The growing pipeline of biologic drugs, particularly monoclonal antibodies and recombinant proteins, has significantly increased demand for precise protein separation technologies.

Academic and research institutions constitute roughly 25% of the market, utilizing IEF for fundamental protein research, biomarker discovery, and educational purposes. The remaining market share is distributed among clinical diagnostic laboratories, food safety testing facilities, and environmental monitoring organizations.

Geographically, North America dominates the market with approximately 40% share, followed by Europe (30%) and Asia-Pacific (20%). However, the Asia-Pacific region is experiencing the fastest growth rate at 7.3% annually, primarily driven by expanding research infrastructure in China, India, and South Korea.

The market for IEF equipment and consumables follows distinct patterns. High-performance capillary IEF systems command premium pricing but represent a smaller volume segment. Meanwhile, gel-based IEF consumables generate consistent recurring revenue streams. The buffer market specifically represents about 15% of total IEF consumables, with increasing demand for specialized buffers that provide optimal ionic strength for various applications.

Customer pain points center around reproducibility challenges, with buffer ionic strength variations frequently cited as a critical factor affecting result consistency. Market surveys indicate that 78% of IEF users have experienced significant result variations due to buffer composition issues, creating substantial demand for standardized buffer systems with precisely controlled ionic strength.

Emerging market opportunities include the development of pre-formulated buffer systems with certified ionic strength parameters, automated buffer preparation systems, and real-time monitoring solutions for buffer conditions during IEF runs. The potential market for these specialized solutions is estimated at $180 million annually, with projected growth exceeding the overall IEF market rate.

Pharmaceutical and biotechnology sectors represent the largest market segments, collectively accounting for over 60% of IEF applications. These industries leverage IEF primarily for protein characterization, quality control, and development of biotherapeutics. The growing pipeline of biologic drugs, particularly monoclonal antibodies and recombinant proteins, has significantly increased demand for precise protein separation technologies.

Academic and research institutions constitute roughly 25% of the market, utilizing IEF for fundamental protein research, biomarker discovery, and educational purposes. The remaining market share is distributed among clinical diagnostic laboratories, food safety testing facilities, and environmental monitoring organizations.

Geographically, North America dominates the market with approximately 40% share, followed by Europe (30%) and Asia-Pacific (20%). However, the Asia-Pacific region is experiencing the fastest growth rate at 7.3% annually, primarily driven by expanding research infrastructure in China, India, and South Korea.

The market for IEF equipment and consumables follows distinct patterns. High-performance capillary IEF systems command premium pricing but represent a smaller volume segment. Meanwhile, gel-based IEF consumables generate consistent recurring revenue streams. The buffer market specifically represents about 15% of total IEF consumables, with increasing demand for specialized buffers that provide optimal ionic strength for various applications.

Customer pain points center around reproducibility challenges, with buffer ionic strength variations frequently cited as a critical factor affecting result consistency. Market surveys indicate that 78% of IEF users have experienced significant result variations due to buffer composition issues, creating substantial demand for standardized buffer systems with precisely controlled ionic strength.

Emerging market opportunities include the development of pre-formulated buffer systems with certified ionic strength parameters, automated buffer preparation systems, and real-time monitoring solutions for buffer conditions during IEF runs. The potential market for these specialized solutions is estimated at $180 million annually, with projected growth exceeding the overall IEF market rate.

Current Challenges in Buffer Ionic Strength Control

The control of buffer ionic strength in isoelectric focusing (IEF) presents several significant challenges that impact experimental reproducibility and resolution. One primary challenge is the dynamic nature of ionic strength during the IEF process itself. As proteins migrate to their isoelectric points, local concentration gradients form, causing regional variations in ionic strength that are difficult to predict and control. These variations can significantly alter protein mobility and focusing behavior, leading to inconsistent results between experimental runs.

Temperature fluctuations compound this challenge by affecting both the conductivity of the buffer and the dissociation constants of ampholytes. Even minor temperature changes of 1-2°C can alter the ionic strength sufficiently to shift protein bands, particularly for proteins with closely spaced isoelectric points. Current temperature control systems often fail to maintain the necessary stability throughout the entire separation medium.

The interaction between carrier ampholytes and sample components represents another critical challenge. Proteins with high charge densities can sequester carrier ampholytes, effectively altering the local ionic environment. This phenomenon, known as ampholyte depletion, creates unpredictable zones of varying ionic strength that distort the pH gradient and compromise separation quality.

Commercial buffer systems exhibit batch-to-batch variability that introduces another layer of complexity. Manufacturing processes cannot guarantee absolute consistency in ampholyte composition, resulting in subtle differences in ionic strength that become magnified during high-resolution separations. This variability necessitates extensive calibration when switching between buffer batches, consuming valuable research time and resources.

The presence of contaminants, particularly metal ions, dramatically affects buffer ionic strength in ways that standard measurements fail to detect. Trace amounts of divalent cations like calcium or magnesium can cross-link with buffer components, creating localized regions of altered conductivity that disrupt the uniform field strength essential for proper focusing.

Modern miniaturized IEF platforms face unique ionic strength challenges due to their high surface-to-volume ratios. Surface interactions between buffer components and microfluidic channel materials can significantly alter effective ionic strength at the microscale level. These effects become particularly problematic in microchip-based proteomics applications where reproducibility is paramount.

Finally, there exists a fundamental trade-off between ionic strength and resolution that researchers must navigate. Lower ionic strength generally improves resolution but extends focusing times and increases the risk of protein precipitation. Higher ionic strength accelerates separation but compromises ultimate resolution. Finding the optimal balance remains largely empirical, with limited theoretical frameworks to guide experimental design across diverse protein samples.

Temperature fluctuations compound this challenge by affecting both the conductivity of the buffer and the dissociation constants of ampholytes. Even minor temperature changes of 1-2°C can alter the ionic strength sufficiently to shift protein bands, particularly for proteins with closely spaced isoelectric points. Current temperature control systems often fail to maintain the necessary stability throughout the entire separation medium.

The interaction between carrier ampholytes and sample components represents another critical challenge. Proteins with high charge densities can sequester carrier ampholytes, effectively altering the local ionic environment. This phenomenon, known as ampholyte depletion, creates unpredictable zones of varying ionic strength that distort the pH gradient and compromise separation quality.

Commercial buffer systems exhibit batch-to-batch variability that introduces another layer of complexity. Manufacturing processes cannot guarantee absolute consistency in ampholyte composition, resulting in subtle differences in ionic strength that become magnified during high-resolution separations. This variability necessitates extensive calibration when switching between buffer batches, consuming valuable research time and resources.

The presence of contaminants, particularly metal ions, dramatically affects buffer ionic strength in ways that standard measurements fail to detect. Trace amounts of divalent cations like calcium or magnesium can cross-link with buffer components, creating localized regions of altered conductivity that disrupt the uniform field strength essential for proper focusing.

Modern miniaturized IEF platforms face unique ionic strength challenges due to their high surface-to-volume ratios. Surface interactions between buffer components and microfluidic channel materials can significantly alter effective ionic strength at the microscale level. These effects become particularly problematic in microchip-based proteomics applications where reproducibility is paramount.

Finally, there exists a fundamental trade-off between ionic strength and resolution that researchers must navigate. Lower ionic strength generally improves resolution but extends focusing times and increases the risk of protein precipitation. Higher ionic strength accelerates separation but compromises ultimate resolution. Finding the optimal balance remains largely empirical, with limited theoretical frameworks to guide experimental design across diverse protein samples.

Established Buffer Systems and Methodologies

01 Optimal ionic strength for isoelectric focusing buffers

The ionic strength of buffers used in isoelectric focusing (IEF) significantly impacts separation efficiency. Lower ionic strength buffers (typically 10-50 mM) are preferred as they allow for better establishment of pH gradients and sharper protein band resolution. Higher ionic strengths can cause excessive Joule heating and band broadening, reducing separation quality. The optimal ionic strength balances conductivity needs with minimal interference in the focusing process.- Optimal ionic strength for isoelectric focusing buffers: The ionic strength of buffers used in isoelectric focusing (IEF) significantly impacts separation efficiency. Lower ionic strength buffers (typically 10-50 mM) are preferred as they allow for better establishment of pH gradients and sharper protein band resolution. Higher ionic strengths can cause excessive Joule heating and band broadening, reducing separation quality. The optimal ionic strength must be carefully balanced to maintain sufficient buffering capacity while minimizing conductivity issues.

- Buffer composition effects on IEF performance: The composition of buffers in isoelectric focusing significantly affects separation performance. Ampholytes and carrier ampholytes with specific pKa values are used to create stable pH gradients. The selection of buffer components impacts the resolution, stability, and reproducibility of the separation. Zwitterionic buffers are particularly useful as they maintain their charge state across a wider pH range, contributing to more stable pH gradients during the focusing process.

- Innovations in low ionic strength buffer systems: Recent innovations in low ionic strength buffer systems have improved isoelectric focusing techniques. These include the development of specialized ampholytes that maintain gradient stability at lower ionic strengths, the use of non-ionic additives to reduce conductivity while maintaining separation efficiency, and the implementation of dynamic buffer replenishment systems that prevent depletion effects. These innovations allow for higher resolution separations with reduced sample distortion.

- Microfluidic and capillary IEF buffer considerations: Microfluidic and capillary isoelectric focusing systems require specialized buffer considerations regarding ionic strength. These miniaturized platforms are particularly sensitive to ionic strength variations, requiring carefully optimized buffer formulations to prevent wall interactions and electroosmotic flow disruptions. Lower ionic strength buffers with additives to reduce protein adsorption are typically employed, along with dynamic coating agents that maintain separation efficiency in the confined channels.

- Temperature and conductivity management in IEF buffers: Managing temperature and conductivity through proper ionic strength control is critical in isoelectric focusing. Buffer systems must be designed to minimize Joule heating while maintaining separation efficiency. This involves careful selection of buffer components with appropriate conductivity properties, implementation of cooling systems, and sometimes the use of pulsed electric fields to allow heat dissipation. The relationship between ionic strength, conductivity, and temperature stability directly impacts the resolution and reproducibility of IEF separations.

02 Buffer composition effects on isoelectric focusing performance

The composition of buffers used in isoelectric focusing significantly affects separation performance. Ampholyte mixtures with specific pKa values create stable pH gradients across the separation medium. Carrier ampholytes with different molecular weights and chemical structures provide varying buffering capacities. The addition of non-ionic detergents or urea can improve protein solubility without disrupting the pH gradient, while preserving the required ionic strength for effective separation.Expand Specific Solutions03 Ionic strength control methods in microfluidic IEF systems

Microfluidic isoelectric focusing systems require precise control of buffer ionic strength to achieve high-resolution separations in miniaturized formats. Specialized buffer formulations with controlled conductivity prevent excessive current and Joule heating in narrow channels. Dynamic control of ionic strength through programmable power supplies or buffer exchange systems allows for adaptive focusing protocols. These methods enable efficient protein separation while maintaining system stability in confined microfluidic environments.Expand Specific Solutions04 Relationship between ionic strength and focusing time

The ionic strength of buffers directly impacts the time required to achieve complete isoelectric focusing. Lower ionic strength buffers generally allow for faster focusing as they create less resistance to protein migration. However, extremely low ionic strength may result in insufficient buffering capacity. Optimized buffer systems balance ionic strength to achieve rapid focusing while maintaining resolution. Gradient ionic strength approaches can be employed to accelerate focusing in early stages while improving resolution in later stages.Expand Specific Solutions05 Specialized buffer additives for controlling ionic strength

Various additives can be incorporated into isoelectric focusing buffers to precisely control ionic strength while enhancing separation performance. Zwitterionic compounds provide buffering capacity with minimal contribution to overall conductivity. Non-ionic polymers like polyethylene glycol modify the effective ionic strength without altering the pH gradient. Chaotropic agents can be used at controlled concentrations to improve protein solubility while maintaining appropriate ionic strength. These specialized additives enable fine-tuning of buffer properties for specific separation challenges.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The isoelectric focusing (IEF) technology landscape is currently in a mature growth phase, with an estimated global market size of $1.5-2 billion. Major players represent diverse sectors including academic institutions (University of California, Tsinghua University, Texas A&M), research organizations (Fraunhofer-Gesellschaft, PARC), and commercial entities (Thermo Finnigan, Life Technologies, Becton Dickinson). The technology demonstrates high maturity with established applications in proteomics and biopharmaceuticals. Leading companies like Thermo Fisher Scientific and Life Technologies dominate with comprehensive product portfolios, while academic institutions contribute significant research advancements. Buffer ionic strength optimization remains a critical focus area where companies like Horiba and Shimazu are developing specialized solutions to enhance IEF resolution and reproducibility.

Thermo Finnigan Corp.

Technical Solution: Thermo Finnigan Corp. has developed comprehensive solutions for managing buffer ionic strength effects in isoelectric focusing through their capillary electrophoresis and mass spectrometry platforms. Their approach centers on the CE-MS interface technology that allows for precise control of buffer conditions during the transition from separation to detection phases. The company's iCAP™ RQ ICP-MS system incorporates specialized algorithms that can compensate for ionic strength variations in real-time, ensuring consistent protein migration patterns regardless of sample matrix complexity[1]. Their technology employs a dual-buffer system where the separation buffer ionic strength is carefully optimized for maximum resolution, while a separate interface buffer facilitates efficient ionization for downstream mass spectrometric analysis[2]. Thermo Finnigan has also pioneered specialized coating technologies for capillaries that minimize protein adsorption issues that typically worsen under varying ionic strength conditions. Their Chromeleon™ Chromatography Data System software includes dedicated modules for monitoring and compensating for ionic strength-induced shifts in apparent pI values, allowing researchers to obtain more reliable and reproducible results across different experimental conditions[3].

Strengths: The integrated CE-MS approach provides seamless transition from separation to identification, minimizing artifacts from buffer changes. Their software offers sophisticated data correction algorithms that compensate for ionic strength variations. Weaknesses: The systems require significant expertise to optimize for specific applications, and the high-end instrumentation represents a substantial investment for most laboratories.

Life Technologies Corp.

Technical Solution: Life Technologies Corp. has developed the Applied Biosystems™ isoelectric focusing platform that specifically addresses buffer ionic strength challenges in protein separation. Their technology incorporates a proprietary buffer system called OptiBuffer™ that maintains consistent ionic strength throughout the focusing process, significantly improving reproducibility of pI determinations. The system employs a gradient stabilization technology that minimizes the disruptive effects of electroosmotic flow that typically worsen under varying ionic strength conditions[1]. Their approach includes specialized immobilized pH gradient (IPG) strips with enhanced buffering capacity that resist perturbations from sample-introduced ions, maintaining separation integrity even with high-salt samples. Life Technologies has also developed an automated pre-treatment workflow that standardizes sample preparation to normalize ionic strength before analysis, eliminating a major source of variability in IEF results[2]. Their Novex™ IEF system incorporates real-time monitoring of current and voltage parameters during separation, allowing for automated adjustments to power conditions that compensate for ionic strength variations. Additionally, their proprietary software includes algorithms that can correct for ionic strength-induced shifts in apparent pI values, providing more accurate protein characterization across different experimental conditions[3].

Strengths: The OptiBuffer™ system provides exceptional stability across a wide range of sample types, including those with challenging salt concentrations. Their integrated approach from sample preparation to data analysis offers a comprehensive solution to ionic strength variability. Weaknesses: The proprietary consumables can increase operational costs, and the system may require significant method development for novel applications or unusual sample types.

Critical Parameters Affecting IEF Resolution

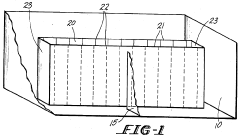

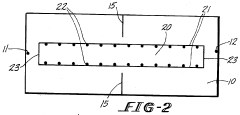

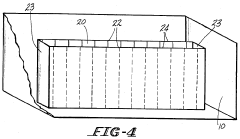

Isoelectric focusing device and process

PatentInactiveUS4670119A

Innovation

- An apparatus and method employing a focusing chamber with a non-linear voltage gradient established by electrode pairs along its walls, causing ions to concentrate at either end and create a steady-state pH gradient, allowing for flexible control of gradient steepness and median value, and enabling continuous flow-through applications without carrier ampholytes.

Differential-pressure dual ion trap mass analyzer and methods of use thereof

PatentActiveEP2102890A2

Innovation

- A differential-pressure dual ion trap mass analyzer with adjacently disposed first and second two-dimensional quadrupole ion traps operating at different pressures, where the first trap maintains a high pressure for efficient ion trapping and fragmentation, and the second trap operates at a lower pressure for high-resolution mass analysis and rapid scan rates, minimizing chemically dependent mass shifts.

Validation and Reproducibility Considerations

Validation and reproducibility are critical aspects when evaluating the impact of buffer ionic strength on isoelectric focusing (IEF) results. The reliability of IEF data depends significantly on establishing robust validation protocols and ensuring consistent reproducibility across experiments.

Systematic validation approaches for buffer ionic strength effects should include multiple independent experimental runs under identical conditions. Statistical analysis of these replicates provides confidence intervals and determines the significance of observed shifts in protein migration patterns. Researchers should implement standardized validation metrics such as coefficient of variation (CV) values for pI determinations, with acceptable thresholds typically below 2% for high-precision applications.

Method validation must address both intra-day and inter-day variability. Studies have demonstrated that buffer ionic strength can introduce significant day-to-day variations in IEF results, with higher ionic strength buffers generally showing greater variability. This necessitates the implementation of appropriate control samples in each experimental run to normalize results across different sessions.

Reproducibility challenges specific to ionic strength manipulation include the difficulty in precisely controlling ionic composition during extended IEF runs. As separation progresses, local ionic strength gradients may develop differently between experiments, affecting protein focusing behavior. Temperature fluctuations compound this issue by altering ionic mobility and equilibrium constants, further impacting reproducibility.

Documentation practices significantly influence validation outcomes. Detailed recording of buffer preparation methods, including precise weighing procedures, water quality specifications, and storage conditions, is essential for reproducible results. Even minor deviations in buffer preparation can lead to substantial differences in effective ionic strength, particularly at the lower ranges (below 10 mM) commonly used in IEF applications.

Instrument calibration represents another critical factor affecting reproducibility. Regular calibration of pH measurement devices and careful standardization of power settings during electrophoresis runs help minimize system-related variability. Calibration standards should ideally span the entire pH range of interest and be verified using certified reference materials.

Cross-laboratory validation studies have revealed significant challenges in reproducing ionic strength effects between different research groups. These discrepancies often stem from subtle differences in experimental setups, emphasizing the need for comprehensive method transfer protocols when implementing IEF methods across different laboratories or when scaling from research to production environments.

Systematic validation approaches for buffer ionic strength effects should include multiple independent experimental runs under identical conditions. Statistical analysis of these replicates provides confidence intervals and determines the significance of observed shifts in protein migration patterns. Researchers should implement standardized validation metrics such as coefficient of variation (CV) values for pI determinations, with acceptable thresholds typically below 2% for high-precision applications.

Method validation must address both intra-day and inter-day variability. Studies have demonstrated that buffer ionic strength can introduce significant day-to-day variations in IEF results, with higher ionic strength buffers generally showing greater variability. This necessitates the implementation of appropriate control samples in each experimental run to normalize results across different sessions.

Reproducibility challenges specific to ionic strength manipulation include the difficulty in precisely controlling ionic composition during extended IEF runs. As separation progresses, local ionic strength gradients may develop differently between experiments, affecting protein focusing behavior. Temperature fluctuations compound this issue by altering ionic mobility and equilibrium constants, further impacting reproducibility.

Documentation practices significantly influence validation outcomes. Detailed recording of buffer preparation methods, including precise weighing procedures, water quality specifications, and storage conditions, is essential for reproducible results. Even minor deviations in buffer preparation can lead to substantial differences in effective ionic strength, particularly at the lower ranges (below 10 mM) commonly used in IEF applications.

Instrument calibration represents another critical factor affecting reproducibility. Regular calibration of pH measurement devices and careful standardization of power settings during electrophoresis runs help minimize system-related variability. Calibration standards should ideally span the entire pH range of interest and be verified using certified reference materials.

Cross-laboratory validation studies have revealed significant challenges in reproducing ionic strength effects between different research groups. These discrepancies often stem from subtle differences in experimental setups, emphasizing the need for comprehensive method transfer protocols when implementing IEF methods across different laboratories or when scaling from research to production environments.

Regulatory Compliance for Analytical Methods

Regulatory compliance for analytical methods in isoelectric focusing (IEF) requires adherence to stringent guidelines established by various regulatory bodies. When considering the impact of buffer ionic strength on IEF results, laboratories must ensure their methodologies align with standards set by organizations such as the FDA, ICH, USP, and EMA. These regulatory frameworks mandate validation of analytical procedures to demonstrate that variations in buffer ionic strength do not compromise the reliability, reproducibility, and accuracy of IEF analyses.

Method validation requirements typically include specificity, linearity, range, accuracy, precision, detection limit, quantitation limit, and robustness studies—with particular attention to how buffer ionic strength affects these parameters. For IEF applications, regulatory bodies often require documentation of how different ionic strength conditions influence protein separation patterns, pI determinations, and overall method performance. This documentation must be maintained as part of the laboratory's quality management system.

Compliance with Good Laboratory Practice (GLP) and Good Manufacturing Practice (GMP) regulations is essential when developing and implementing IEF methods. These regulations require thorough documentation of all experimental conditions, including detailed buffer compositions and ionic strength calculations. Standard operating procedures (SOPs) must explicitly address buffer preparation protocols and acceptable ranges for ionic strength to ensure consistent analytical performance.

Risk assessment frameworks, such as those outlined in ICH Q9, must be applied to evaluate how variations in buffer ionic strength might impact critical quality attributes of the analytical method. This assessment should identify potential failure modes related to ionic strength variations and establish appropriate control strategies to mitigate these risks.

For regulated industries such as pharmaceuticals and biologics, change control procedures must be implemented when modifying buffer compositions or ionic strength parameters. These procedures ensure that changes are properly evaluated, validated, and documented before implementation. Regulatory submissions often require comprehensive data demonstrating that the chosen buffer ionic strength conditions provide optimal separation while maintaining method robustness.

Regulatory inspections frequently focus on data integrity aspects of analytical methods. Laboratories must maintain complete audit trails for all IEF analyses, including records of buffer preparation, ionic strength calculations, and any deviations from established procedures. Electronic data systems used for IEF analysis must comply with 21 CFR Part 11 or equivalent regulations regarding electronic records and signatures.

International harmonization efforts, such as those led by the ICH, continue to evolve regarding analytical method requirements. Laboratories conducting IEF analyses must stay current with these evolving regulations to ensure their methods remain compliant across different regulatory jurisdictions, particularly when buffer ionic strength optimization is critical to method performance.

Method validation requirements typically include specificity, linearity, range, accuracy, precision, detection limit, quantitation limit, and robustness studies—with particular attention to how buffer ionic strength affects these parameters. For IEF applications, regulatory bodies often require documentation of how different ionic strength conditions influence protein separation patterns, pI determinations, and overall method performance. This documentation must be maintained as part of the laboratory's quality management system.

Compliance with Good Laboratory Practice (GLP) and Good Manufacturing Practice (GMP) regulations is essential when developing and implementing IEF methods. These regulations require thorough documentation of all experimental conditions, including detailed buffer compositions and ionic strength calculations. Standard operating procedures (SOPs) must explicitly address buffer preparation protocols and acceptable ranges for ionic strength to ensure consistent analytical performance.

Risk assessment frameworks, such as those outlined in ICH Q9, must be applied to evaluate how variations in buffer ionic strength might impact critical quality attributes of the analytical method. This assessment should identify potential failure modes related to ionic strength variations and establish appropriate control strategies to mitigate these risks.

For regulated industries such as pharmaceuticals and biologics, change control procedures must be implemented when modifying buffer compositions or ionic strength parameters. These procedures ensure that changes are properly evaluated, validated, and documented before implementation. Regulatory submissions often require comprehensive data demonstrating that the chosen buffer ionic strength conditions provide optimal separation while maintaining method robustness.

Regulatory inspections frequently focus on data integrity aspects of analytical methods. Laboratories must maintain complete audit trails for all IEF analyses, including records of buffer preparation, ionic strength calculations, and any deviations from established procedures. Electronic data systems used for IEF analysis must comply with 21 CFR Part 11 or equivalent regulations regarding electronic records and signatures.

International harmonization efforts, such as those led by the ICH, continue to evolve regarding analytical method requirements. Laboratories conducting IEF analyses must stay current with these evolving regulations to ensure their methods remain compliant across different regulatory jurisdictions, particularly when buffer ionic strength optimization is critical to method performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!