Implementing Ethyl Acetate in Novel Green Processes

JUN 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ethyl Acetate Background and Objectives

Ethyl acetate, a versatile organic compound, has been a staple in various industries for decades. Its journey from a simple solvent to a key player in green chemistry exemplifies the evolution of sustainable practices in chemical processes. The historical development of ethyl acetate production has seen significant shifts, moving from traditional petrochemical-based methods to more environmentally friendly approaches.

Initially, ethyl acetate was primarily produced through the esterification of ethanol and acetic acid, a process that, while effective, often relied on non-renewable resources. As environmental concerns grew, the industry began exploring alternative production methods. This led to the development of bio-based ethyl acetate, derived from renewable resources such as corn and sugarcane, marking a pivotal turn towards sustainability.

The current technological landscape for ethyl acetate production is characterized by a blend of conventional and innovative approaches. While traditional methods still dominate, there is a growing emphasis on green processes that minimize environmental impact. These novel approaches aim to reduce energy consumption, utilize renewable feedstocks, and minimize waste generation.

The objectives of implementing ethyl acetate in novel green processes are multifaceted. Primarily, there is a drive to enhance the sustainability of ethyl acetate production and utilization across various applications. This includes developing more efficient synthesis routes, exploring new catalytic systems that operate under milder conditions, and integrating ethyl acetate into circular economy models.

Another key objective is to expand the application scope of ethyl acetate in green chemistry. This involves identifying new areas where ethyl acetate can replace more harmful solvents, thereby reducing the overall environmental footprint of chemical processes. Additionally, there is a focus on improving the recovery and recycling of ethyl acetate in industrial processes, further enhancing its green credentials.

The technological goals also extend to optimizing the properties of ethyl acetate for specific applications. This includes enhancing its stability, purity, and performance in various chemical reactions and formulations. By tailoring the characteristics of ethyl acetate, researchers aim to broaden its utility in emerging fields such as advanced materials and biotechnology.

As the chemical industry continues to evolve towards more sustainable practices, the implementation of ethyl acetate in novel green processes stands at the forefront of this transformation. The ongoing research and development in this area not only promise to revolutionize the production and use of this important compound but also to set new standards for environmental responsibility in chemical manufacturing.

Initially, ethyl acetate was primarily produced through the esterification of ethanol and acetic acid, a process that, while effective, often relied on non-renewable resources. As environmental concerns grew, the industry began exploring alternative production methods. This led to the development of bio-based ethyl acetate, derived from renewable resources such as corn and sugarcane, marking a pivotal turn towards sustainability.

The current technological landscape for ethyl acetate production is characterized by a blend of conventional and innovative approaches. While traditional methods still dominate, there is a growing emphasis on green processes that minimize environmental impact. These novel approaches aim to reduce energy consumption, utilize renewable feedstocks, and minimize waste generation.

The objectives of implementing ethyl acetate in novel green processes are multifaceted. Primarily, there is a drive to enhance the sustainability of ethyl acetate production and utilization across various applications. This includes developing more efficient synthesis routes, exploring new catalytic systems that operate under milder conditions, and integrating ethyl acetate into circular economy models.

Another key objective is to expand the application scope of ethyl acetate in green chemistry. This involves identifying new areas where ethyl acetate can replace more harmful solvents, thereby reducing the overall environmental footprint of chemical processes. Additionally, there is a focus on improving the recovery and recycling of ethyl acetate in industrial processes, further enhancing its green credentials.

The technological goals also extend to optimizing the properties of ethyl acetate for specific applications. This includes enhancing its stability, purity, and performance in various chemical reactions and formulations. By tailoring the characteristics of ethyl acetate, researchers aim to broaden its utility in emerging fields such as advanced materials and biotechnology.

As the chemical industry continues to evolve towards more sustainable practices, the implementation of ethyl acetate in novel green processes stands at the forefront of this transformation. The ongoing research and development in this area not only promise to revolutionize the production and use of this important compound but also to set new standards for environmental responsibility in chemical manufacturing.

Green Process Market Analysis

The global market for green processes has been experiencing significant growth in recent years, driven by increasing environmental concerns and stringent regulations. The implementation of ethyl acetate in novel green processes represents a promising opportunity within this expanding market. Ethyl acetate, a versatile organic compound, has gained attention due to its potential as a more environmentally friendly solvent and reagent in various industrial applications.

The demand for green processes utilizing ethyl acetate is primarily fueled by industries such as pharmaceuticals, paints and coatings, adhesives, and food processing. These sectors are actively seeking sustainable alternatives to traditional chemical processes, aiming to reduce their environmental footprint and comply with evolving regulatory standards. The pharmaceutical industry, in particular, has shown a strong interest in adopting green chemistry principles, with ethyl acetate playing a crucial role in the development of cleaner synthesis routes for active pharmaceutical ingredients.

Market analysis indicates that the Asia-Pacific region is emerging as a key growth area for green processes involving ethyl acetate. This trend is attributed to the rapid industrialization in countries like China and India, coupled with increasing awareness of environmental issues. North America and Europe continue to be significant markets, driven by stringent environmental regulations and a well-established chemical industry focused on sustainability.

The market for green processes using ethyl acetate is characterized by a growing emphasis on circular economy principles. Companies are exploring innovative ways to recycle and reuse ethyl acetate in closed-loop systems, further enhancing the environmental benefits and economic viability of these processes. This approach aligns with the broader industry trend towards waste reduction and resource efficiency.

Technological advancements in process intensification and continuous flow chemistry are expected to further boost the adoption of ethyl acetate in green processes. These innovations promise improved efficiency, reduced energy consumption, and enhanced product quality, making ethyl acetate-based processes more attractive to industries seeking sustainable solutions.

The market analysis also reveals a growing interest in bio-based ethyl acetate, derived from renewable resources such as biomass. This development is in line with the broader shift towards bio-based chemicals and is expected to open up new opportunities in the green process market. The potential for carbon footprint reduction and the appeal of renewable sourcing are driving factors behind this trend.

Overall, the market for implementing ethyl acetate in novel green processes shows promising growth potential. As industries continue to prioritize sustainability and environmental responsibility, the demand for innovative, eco-friendly solutions is expected to drive further expansion and technological advancements in this sector.

The demand for green processes utilizing ethyl acetate is primarily fueled by industries such as pharmaceuticals, paints and coatings, adhesives, and food processing. These sectors are actively seeking sustainable alternatives to traditional chemical processes, aiming to reduce their environmental footprint and comply with evolving regulatory standards. The pharmaceutical industry, in particular, has shown a strong interest in adopting green chemistry principles, with ethyl acetate playing a crucial role in the development of cleaner synthesis routes for active pharmaceutical ingredients.

Market analysis indicates that the Asia-Pacific region is emerging as a key growth area for green processes involving ethyl acetate. This trend is attributed to the rapid industrialization in countries like China and India, coupled with increasing awareness of environmental issues. North America and Europe continue to be significant markets, driven by stringent environmental regulations and a well-established chemical industry focused on sustainability.

The market for green processes using ethyl acetate is characterized by a growing emphasis on circular economy principles. Companies are exploring innovative ways to recycle and reuse ethyl acetate in closed-loop systems, further enhancing the environmental benefits and economic viability of these processes. This approach aligns with the broader industry trend towards waste reduction and resource efficiency.

Technological advancements in process intensification and continuous flow chemistry are expected to further boost the adoption of ethyl acetate in green processes. These innovations promise improved efficiency, reduced energy consumption, and enhanced product quality, making ethyl acetate-based processes more attractive to industries seeking sustainable solutions.

The market analysis also reveals a growing interest in bio-based ethyl acetate, derived from renewable resources such as biomass. This development is in line with the broader shift towards bio-based chemicals and is expected to open up new opportunities in the green process market. The potential for carbon footprint reduction and the appeal of renewable sourcing are driving factors behind this trend.

Overall, the market for implementing ethyl acetate in novel green processes shows promising growth potential. As industries continue to prioritize sustainability and environmental responsibility, the demand for innovative, eco-friendly solutions is expected to drive further expansion and technological advancements in this sector.

Current Challenges in Ethyl Acetate Synthesis

The synthesis of ethyl acetate, a widely used solvent and chemical intermediate, faces several challenges in the context of implementing novel green processes. One of the primary issues is the reliance on traditional petrochemical-based feedstocks, which are not sustainable in the long term. The current industrial production methods often involve energy-intensive processes and generate significant amounts of waste, contradicting the principles of green chemistry.

The use of sulfuric acid as a catalyst in the esterification process presents environmental and safety concerns. This strong mineral acid is corrosive and requires special handling and disposal procedures. Additionally, the need for excess ethanol in the reaction to drive equilibrium towards the product side leads to increased energy consumption during separation and purification stages.

Another challenge lies in the separation of the ethyl acetate product from the reaction mixture. The formation of azeotropes with water and ethanol complicates the distillation process, necessitating additional separation techniques that increase energy consumption and process complexity. This aspect of the production process contributes significantly to the overall environmental footprint of ethyl acetate synthesis.

The development of more efficient catalysts remains a critical challenge. While some progress has been made with heterogeneous catalysts, there is still a need for catalysts that can operate at lower temperatures, provide higher selectivity, and maintain long-term stability under industrial conditions. The ideal catalyst would also be easily recoverable and reusable, minimizing waste generation and reducing production costs.

Water management in the reaction system poses another significant challenge. Water is a byproduct of the esterification reaction and its presence can shift the equilibrium, limiting conversion rates. Effective water removal strategies are crucial for improving yields, but current methods often involve energy-intensive processes or the use of additional chemicals, which can compromise the green aspects of the synthesis.

The integration of continuous flow processes for ethyl acetate production presents both opportunities and challenges. While continuous processes can offer improved efficiency and reduced waste, they require careful design and control to maintain optimal reaction conditions and prevent issues such as catalyst deactivation or product quality fluctuations.

Lastly, the economic viability of green ethyl acetate synthesis processes remains a significant hurdle. Many novel approaches, while environmentally promising, struggle to compete with traditional methods in terms of cost-effectiveness at industrial scales. Balancing the environmental benefits with economic feasibility is crucial for the widespread adoption of greener ethyl acetate production technologies.

The use of sulfuric acid as a catalyst in the esterification process presents environmental and safety concerns. This strong mineral acid is corrosive and requires special handling and disposal procedures. Additionally, the need for excess ethanol in the reaction to drive equilibrium towards the product side leads to increased energy consumption during separation and purification stages.

Another challenge lies in the separation of the ethyl acetate product from the reaction mixture. The formation of azeotropes with water and ethanol complicates the distillation process, necessitating additional separation techniques that increase energy consumption and process complexity. This aspect of the production process contributes significantly to the overall environmental footprint of ethyl acetate synthesis.

The development of more efficient catalysts remains a critical challenge. While some progress has been made with heterogeneous catalysts, there is still a need for catalysts that can operate at lower temperatures, provide higher selectivity, and maintain long-term stability under industrial conditions. The ideal catalyst would also be easily recoverable and reusable, minimizing waste generation and reducing production costs.

Water management in the reaction system poses another significant challenge. Water is a byproduct of the esterification reaction and its presence can shift the equilibrium, limiting conversion rates. Effective water removal strategies are crucial for improving yields, but current methods often involve energy-intensive processes or the use of additional chemicals, which can compromise the green aspects of the synthesis.

The integration of continuous flow processes for ethyl acetate production presents both opportunities and challenges. While continuous processes can offer improved efficiency and reduced waste, they require careful design and control to maintain optimal reaction conditions and prevent issues such as catalyst deactivation or product quality fluctuations.

Lastly, the economic viability of green ethyl acetate synthesis processes remains a significant hurdle. Many novel approaches, while environmentally promising, struggle to compete with traditional methods in terms of cost-effectiveness at industrial scales. Balancing the environmental benefits with economic feasibility is crucial for the widespread adoption of greener ethyl acetate production technologies.

Existing Green Processes for Ethyl Acetate

01 Production and purification of ethyl acetate

Various methods for producing and purifying ethyl acetate are described, including esterification processes, distillation techniques, and separation methods. These processes aim to improve the yield and purity of ethyl acetate for industrial applications.- Production and purification of ethyl acetate: Various methods and processes for producing and purifying ethyl acetate are described. These include distillation techniques, reactive distillation, and the use of specific catalysts to improve yield and efficiency. The processes aim to obtain high-purity ethyl acetate while minimizing energy consumption and waste production.

- Applications of ethyl acetate in industrial processes: Ethyl acetate finds diverse applications in industrial processes. It is used as a solvent in various industries, including pharmaceuticals, coatings, and electronics. The compound is also utilized in extraction processes, as a reaction medium, and in the production of other chemicals.

- Ethyl acetate in polymer and material science: Ethyl acetate plays a role in polymer and material science applications. It is used in the preparation of various polymers, as a solvent for resins, and in the development of novel materials with specific properties. The compound's solvent properties make it valuable in processing and modifying polymeric materials.

- Environmental and safety considerations for ethyl acetate: Research and development efforts focus on improving the environmental profile and safety aspects of ethyl acetate production and use. This includes developing greener production methods, exploring bio-based sources, and implementing safety measures for handling and storage of the compound in industrial settings.

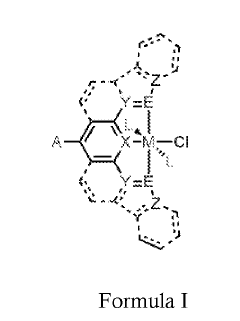

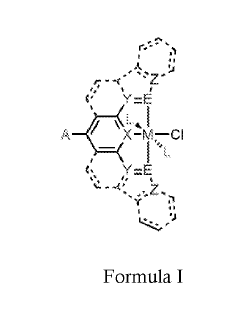

- Novel synthesis routes and catalysts for ethyl acetate: Innovative approaches to synthesizing ethyl acetate are being explored, including the development of new catalysts and reaction pathways. These methods aim to improve yield, selectivity, and sustainability of ethyl acetate production, potentially offering advantages over traditional manufacturing processes.

02 Applications of ethyl acetate in chemical processes

Ethyl acetate is utilized in various chemical processes, including as a solvent, reagent, or intermediate in the production of other compounds. Its applications span across different industries such as pharmaceuticals, coatings, and adhesives.Expand Specific Solutions03 Ethyl acetate in extraction and separation processes

Ethyl acetate is employed in extraction and separation processes for various substances, including natural products, pharmaceuticals, and other organic compounds. Its properties make it suitable for liquid-liquid extraction and chromatographic techniques.Expand Specific Solutions04 Synthesis and modification of ethyl acetate derivatives

Research focuses on the synthesis and modification of ethyl acetate derivatives for various applications. These derivatives may possess enhanced properties or specific functionalities for use in different fields such as pharmaceuticals or materials science.Expand Specific Solutions05 Environmental and safety considerations for ethyl acetate

Studies and innovations address environmental and safety aspects related to ethyl acetate production, handling, and use. This includes developing greener production methods, improving storage and transportation safety, and assessing its environmental impact.Expand Specific Solutions

Key Players in Green Solvent Industry

The implementation of ethyl acetate in novel green processes is gaining traction in the chemical industry, with the market currently in a growth phase. The global ethyl acetate market size is projected to expand significantly, driven by increasing demand in various applications. Technologically, the field is advancing rapidly, with companies like Celanese International Corp., BASF Corp., and Shell Oil Co. leading innovation efforts. Research institutions such as the Council of Scientific & Industrial Research and universities like IIT Guwahati are contributing to technological advancements. The involvement of major players like China Petroleum & Chemical Corp. and Saudi Basic Industries Corp. indicates the industry's commitment to developing sustainable processes for ethyl acetate production.

BASF Corp.

Technical Solution: BASF has developed a novel green process for ethyl acetate production using reactive distillation technology. This process combines reaction and separation in a single unit operation, significantly reducing energy consumption and equipment costs[1]. The company utilizes bio-based feedstocks, such as ethanol derived from renewable resources, to produce ethyl acetate. BASF's process achieves high conversion rates and selectivity, resulting in a purity of over 99.5% ethyl acetate[2]. The company has also implemented advanced catalysts that enhance reaction efficiency and minimize by-product formation, further improving the sustainability of the process[3].

Strengths: High purity product, energy-efficient process, use of renewable feedstocks. Weaknesses: Potential higher initial investment costs, dependence on bio-based ethanol availability.

Shell Oil Co.

Technical Solution: Shell has pioneered a green process for ethyl acetate production using a novel heterogeneous catalyst system. The process employs a fixed-bed reactor with a highly selective zeolite-based catalyst, which promotes the direct esterification of ethanol and acetic acid[4]. Shell's approach eliminates the need for homogeneous catalysts, reducing waste and simplifying product separation. The company has optimized reaction conditions to operate at lower temperatures (around 150°C) compared to conventional processes, resulting in significant energy savings[5]. Additionally, Shell has integrated heat recovery systems and utilized process intensification techniques to further enhance the overall efficiency of the ethyl acetate production[6].

Strengths: Improved catalyst selectivity, reduced energy consumption, simplified separation process. Weaknesses: Potential catalyst deactivation over time, may require specialized equipment for catalyst handling.

Innovative Green Synthesis Methods

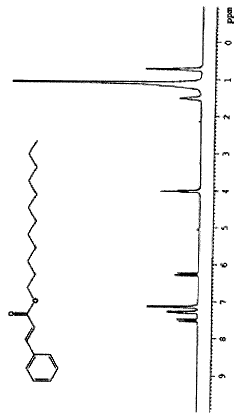

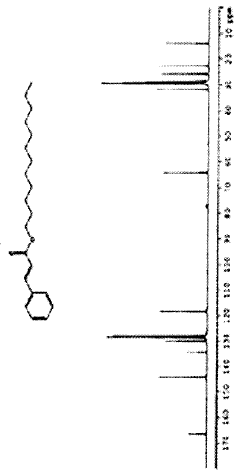

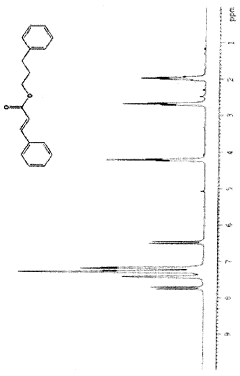

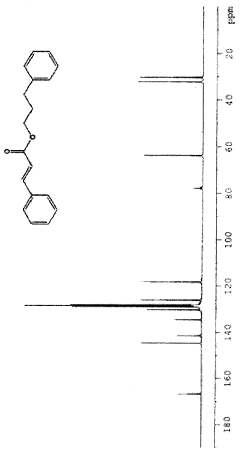

A green process for the preparation of substituted cinnamic esters with trans-selectivity

PatentInactiveIN892DEL2006A

Innovation

- A single-step green process involving the direct conversion of cinnamaldehydes or cinnamyl alcohols into cinnamic esters using an oxidizing agent and a recyclable catalyst, such as 2,3-dichloro-5,6-dicyano-p-benzoquinone (DDQ) or chloranil, with alcohols like methanol or ethanol, under conventional, microwave, or ultrasound conditions, without the need for organic solvents.

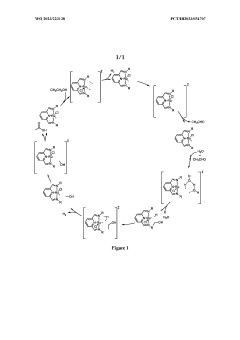

Group (VIII) catalysts for generation of green hydrogen and acetic acid from ethanol and its mechanism thereof

PatentWO2023223138A1

Innovation

- Development of a process using pincer group (VIII) complexes, specifically ruthenium-based catalysts with various ligands, to catalyze the dehydrogenation of ethanol, involving a reaction with a base and water under controlled temperature and atmosphere to produce green hydrogen and acetic acid efficiently.

Environmental Impact Assessment

The implementation of ethyl acetate in novel green processes necessitates a comprehensive environmental impact assessment to ensure sustainability and regulatory compliance. This assessment evaluates the potential effects of ethyl acetate production and utilization on various environmental components, including air, water, soil, and ecosystems.

Air quality is a primary concern in ethyl acetate processes. The volatile nature of ethyl acetate can lead to emissions of volatile organic compounds (VOCs) during production, storage, and application. These emissions contribute to the formation of ground-level ozone and photochemical smog, potentially impacting human health and vegetation. However, compared to traditional solvents, ethyl acetate's lower toxicity and reactivity present a reduced environmental burden.

Water resources are another critical aspect of the assessment. The production of ethyl acetate involves aqueous processes, and potential contamination of water bodies through effluent discharge must be carefully monitored. Advanced wastewater treatment technologies, such as membrane filtration and advanced oxidation processes, can effectively mitigate the risk of water pollution. Additionally, the biodegradability of ethyl acetate in aquatic environments is relatively high, reducing long-term impacts on aquatic ecosystems.

Soil contamination risks associated with ethyl acetate are generally lower compared to many other industrial solvents. Its rapid evaporation and biodegradability limit the potential for soil accumulation. However, proper handling and storage practices are essential to prevent accidental spills that could lead to localized soil contamination.

The lifecycle analysis of ethyl acetate in green processes reveals potential benefits in terms of reduced carbon footprint. When derived from renewable resources, such as bioethanol, the production of ethyl acetate can contribute to a circular economy model, reducing reliance on fossil-based raw materials. This shift towards bio-based feedstocks can significantly lower greenhouse gas emissions associated with the solvent's lifecycle.

Biodiversity impacts of ethyl acetate implementation are generally minimal when proper environmental management practices are in place. The compound's low persistence in the environment and limited bioaccumulation potential reduce the risk of long-term ecological effects. However, the cultivation of crops for bio-based ethyl acetate production requires careful land-use planning to avoid negative impacts on local ecosystems and biodiversity.

Energy consumption and efficiency in ethyl acetate processes are crucial considerations in the environmental impact assessment. Novel green processes often incorporate energy-efficient technologies, such as process intensification and heat integration, which can substantially reduce the overall energy footprint of ethyl acetate production and utilization.

In conclusion, the environmental impact assessment of implementing ethyl acetate in novel green processes reveals a generally favorable profile compared to conventional solvent systems. The key to maximizing environmental benefits lies in adopting best practices in production, handling, and end-of-life management, coupled with continuous innovation in process technologies and renewable feedstock utilization.

Air quality is a primary concern in ethyl acetate processes. The volatile nature of ethyl acetate can lead to emissions of volatile organic compounds (VOCs) during production, storage, and application. These emissions contribute to the formation of ground-level ozone and photochemical smog, potentially impacting human health and vegetation. However, compared to traditional solvents, ethyl acetate's lower toxicity and reactivity present a reduced environmental burden.

Water resources are another critical aspect of the assessment. The production of ethyl acetate involves aqueous processes, and potential contamination of water bodies through effluent discharge must be carefully monitored. Advanced wastewater treatment technologies, such as membrane filtration and advanced oxidation processes, can effectively mitigate the risk of water pollution. Additionally, the biodegradability of ethyl acetate in aquatic environments is relatively high, reducing long-term impacts on aquatic ecosystems.

Soil contamination risks associated with ethyl acetate are generally lower compared to many other industrial solvents. Its rapid evaporation and biodegradability limit the potential for soil accumulation. However, proper handling and storage practices are essential to prevent accidental spills that could lead to localized soil contamination.

The lifecycle analysis of ethyl acetate in green processes reveals potential benefits in terms of reduced carbon footprint. When derived from renewable resources, such as bioethanol, the production of ethyl acetate can contribute to a circular economy model, reducing reliance on fossil-based raw materials. This shift towards bio-based feedstocks can significantly lower greenhouse gas emissions associated with the solvent's lifecycle.

Biodiversity impacts of ethyl acetate implementation are generally minimal when proper environmental management practices are in place. The compound's low persistence in the environment and limited bioaccumulation potential reduce the risk of long-term ecological effects. However, the cultivation of crops for bio-based ethyl acetate production requires careful land-use planning to avoid negative impacts on local ecosystems and biodiversity.

Energy consumption and efficiency in ethyl acetate processes are crucial considerations in the environmental impact assessment. Novel green processes often incorporate energy-efficient technologies, such as process intensification and heat integration, which can substantially reduce the overall energy footprint of ethyl acetate production and utilization.

In conclusion, the environmental impact assessment of implementing ethyl acetate in novel green processes reveals a generally favorable profile compared to conventional solvent systems. The key to maximizing environmental benefits lies in adopting best practices in production, handling, and end-of-life management, coupled with continuous innovation in process technologies and renewable feedstock utilization.

Regulatory Framework for Green Solvents

The regulatory framework for green solvents plays a crucial role in the implementation of ethyl acetate in novel green processes. As environmental concerns continue to drive policy changes, governments and international organizations have established comprehensive guidelines and regulations to promote the use of sustainable solvents in various industries.

In the United States, the Environmental Protection Agency (EPA) has implemented the Toxic Substances Control Act (TSCA) and the Pollution Prevention Act, which encourage the development and adoption of green chemistry principles. These regulations provide incentives for companies to utilize environmentally friendly solvents like ethyl acetate in their processes. Additionally, the EPA's Safer Choice program recognizes products that meet stringent human health and environmental criteria, further promoting the use of green solvents.

The European Union has taken significant steps in regulating green solvents through the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation. REACH aims to improve the protection of human health and the environment by requiring manufacturers and importers to assess and manage the risks associated with chemicals. Ethyl acetate, being a more environmentally friendly alternative to traditional solvents, aligns well with REACH objectives and is likely to face fewer restrictions in its use and application.

In Asia, countries like Japan and South Korea have implemented their own chemical management systems, such as Japan's Chemical Substances Control Law (CSCL) and South Korea's Act on Registration and Evaluation of Chemicals (K-REACH). These regulations emphasize the importance of using safer alternatives and promote the adoption of green solvents in industrial processes.

International organizations also play a significant role in shaping the regulatory landscape for green solvents. The United Nations Environment Programme (UNEP) has developed the Strategic Approach to International Chemicals Management (SAICM), which aims to achieve the sound management of chemicals throughout their lifecycle. This global policy framework encourages the use of safer alternatives and supports the transition towards more sustainable chemical practices.

The International Organization for Standardization (ISO) has developed standards related to environmental management and life cycle assessment, which indirectly influence the adoption of green solvents. ISO 14001, for example, provides a framework for organizations to implement effective environmental management systems, encouraging the use of environmentally friendly materials and processes.

As the regulatory landscape continues to evolve, it is expected that more stringent regulations will be implemented to promote the use of green solvents like ethyl acetate. This trend is likely to drive innovation in novel green processes and create new opportunities for sustainable chemical manufacturing. Companies that proactively adopt green solvents and align their processes with these regulatory frameworks will be better positioned to meet future compliance requirements and gain a competitive advantage in the market.

In the United States, the Environmental Protection Agency (EPA) has implemented the Toxic Substances Control Act (TSCA) and the Pollution Prevention Act, which encourage the development and adoption of green chemistry principles. These regulations provide incentives for companies to utilize environmentally friendly solvents like ethyl acetate in their processes. Additionally, the EPA's Safer Choice program recognizes products that meet stringent human health and environmental criteria, further promoting the use of green solvents.

The European Union has taken significant steps in regulating green solvents through the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation. REACH aims to improve the protection of human health and the environment by requiring manufacturers and importers to assess and manage the risks associated with chemicals. Ethyl acetate, being a more environmentally friendly alternative to traditional solvents, aligns well with REACH objectives and is likely to face fewer restrictions in its use and application.

In Asia, countries like Japan and South Korea have implemented their own chemical management systems, such as Japan's Chemical Substances Control Law (CSCL) and South Korea's Act on Registration and Evaluation of Chemicals (K-REACH). These regulations emphasize the importance of using safer alternatives and promote the adoption of green solvents in industrial processes.

International organizations also play a significant role in shaping the regulatory landscape for green solvents. The United Nations Environment Programme (UNEP) has developed the Strategic Approach to International Chemicals Management (SAICM), which aims to achieve the sound management of chemicals throughout their lifecycle. This global policy framework encourages the use of safer alternatives and supports the transition towards more sustainable chemical practices.

The International Organization for Standardization (ISO) has developed standards related to environmental management and life cycle assessment, which indirectly influence the adoption of green solvents. ISO 14001, for example, provides a framework for organizations to implement effective environmental management systems, encouraging the use of environmentally friendly materials and processes.

As the regulatory landscape continues to evolve, it is expected that more stringent regulations will be implemented to promote the use of green solvents like ethyl acetate. This trend is likely to drive innovation in novel green processes and create new opportunities for sustainable chemical manufacturing. Companies that proactively adopt green solvents and align their processes with these regulatory frameworks will be better positioned to meet future compliance requirements and gain a competitive advantage in the market.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!