Incorporate AI for Turbine Engine Control System Improvements

SEP 23, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AI-Turbine Engine Control Background and Objectives

The integration of artificial intelligence into turbine engine control systems represents a significant evolution in aerospace and power generation technologies. Historically, engine control systems have progressed from mechanical governors to hydromechanical systems, then to digital electronic controls (FADEC - Full Authority Digital Engine Control), and now stand at the threshold of AI-enhanced intelligent control systems. This technological progression has consistently aimed at improving engine efficiency, reliability, and performance while reducing maintenance costs and environmental impact.

The current technological landscape shows increasing computational capabilities and decreasing costs of implementing AI solutions, creating an opportune moment for this integration. Machine learning algorithms, particularly deep learning and reinforcement learning techniques, have demonstrated remarkable capabilities in pattern recognition, predictive analytics, and adaptive control—all critical for advanced engine management.

The primary objectives of incorporating AI into turbine engine control systems include achieving real-time adaptive control that can optimize engine performance across varying operational conditions. This involves developing systems capable of predictive maintenance through continuous monitoring and analysis of engine parameters, potentially preventing failures before they occur and extending component life cycles.

Another key goal is to enhance fuel efficiency and reduce emissions through more precise combustion control and operational optimization. AI systems can continuously analyze vast amounts of operational data to identify efficiency improvements that would be impossible to detect through traditional methods. This aligns with global sustainability initiatives and increasingly stringent environmental regulations.

Furthermore, the integration aims to develop self-learning systems that improve over time, adapting to specific engine characteristics and operational patterns. Such systems would move beyond pre-programmed responses to develop truly intelligent control strategies based on accumulated operational experience.

The technological trajectory suggests a phased approach, beginning with AI-assisted monitoring and diagnostics, progressing to hybrid systems where AI augments traditional control algorithms, and ultimately moving toward fully autonomous AI-driven control systems. This evolution is expected to parallel advancements in computational hardware, sensor technology, and algorithm development.

Industry stakeholders anticipate that successful implementation will result in significant competitive advantages, including reduced operational costs, extended maintenance intervals, improved safety margins, and enhanced overall performance. The technology also promises to enable more flexible power generation and propulsion solutions, adapting to changing energy demands and environmental considerations.

The current technological landscape shows increasing computational capabilities and decreasing costs of implementing AI solutions, creating an opportune moment for this integration. Machine learning algorithms, particularly deep learning and reinforcement learning techniques, have demonstrated remarkable capabilities in pattern recognition, predictive analytics, and adaptive control—all critical for advanced engine management.

The primary objectives of incorporating AI into turbine engine control systems include achieving real-time adaptive control that can optimize engine performance across varying operational conditions. This involves developing systems capable of predictive maintenance through continuous monitoring and analysis of engine parameters, potentially preventing failures before they occur and extending component life cycles.

Another key goal is to enhance fuel efficiency and reduce emissions through more precise combustion control and operational optimization. AI systems can continuously analyze vast amounts of operational data to identify efficiency improvements that would be impossible to detect through traditional methods. This aligns with global sustainability initiatives and increasingly stringent environmental regulations.

Furthermore, the integration aims to develop self-learning systems that improve over time, adapting to specific engine characteristics and operational patterns. Such systems would move beyond pre-programmed responses to develop truly intelligent control strategies based on accumulated operational experience.

The technological trajectory suggests a phased approach, beginning with AI-assisted monitoring and diagnostics, progressing to hybrid systems where AI augments traditional control algorithms, and ultimately moving toward fully autonomous AI-driven control systems. This evolution is expected to parallel advancements in computational hardware, sensor technology, and algorithm development.

Industry stakeholders anticipate that successful implementation will result in significant competitive advantages, including reduced operational costs, extended maintenance intervals, improved safety margins, and enhanced overall performance. The technology also promises to enable more flexible power generation and propulsion solutions, adapting to changing energy demands and environmental considerations.

Market Demand Analysis for AI-Enhanced Turbine Systems

The global market for AI-enhanced turbine systems is experiencing significant growth, driven by increasing demands for energy efficiency, operational reliability, and reduced maintenance costs. Current market analysis indicates that the power generation sector is actively seeking advanced control systems that can optimize turbine performance while minimizing environmental impact. This demand is particularly pronounced in regions with aging power infrastructure, where retrofitting existing turbines with AI-based control systems presents a cost-effective alternative to complete system replacement.

Energy companies worldwide are facing mounting pressure to improve operational efficiency while reducing carbon emissions. This dual challenge has created a substantial market opportunity for AI-enhanced turbine control systems that can optimize combustion processes, predict maintenance needs, and adapt to varying operational conditions in real-time. The market size for intelligent control systems in the power generation sector is projected to grow substantially over the next five years, with particularly strong demand in North America, Europe, and parts of Asia.

Industrial sectors beyond power generation are also showing increased interest in AI-enhanced turbine systems. Aviation, marine propulsion, and industrial manufacturing all utilize turbines that could benefit from advanced control systems. These sectors value solutions that can provide fuel efficiency improvements, extended equipment lifespan, and reduced downtime—all benefits that AI-enhanced control systems can deliver.

Market research reveals that end-users are particularly interested in AI solutions that offer predictive maintenance capabilities. The ability to forecast potential failures before they occur represents significant value in terms of avoided downtime costs, which can amount to millions of dollars per day in large power plants or industrial facilities. This specific application of AI in turbine systems has shown the highest return on investment in early adopter case studies.

Regulatory trends are further driving market demand, as emissions standards become increasingly stringent worldwide. AI-enhanced control systems that can optimize combustion processes to reduce NOx, CO2, and other emissions while maintaining performance are seeing accelerated adoption in regions with strict environmental regulations.

Customer feedback indicates a preference for modular AI solutions that can be integrated with existing SCADA and control systems, rather than requiring complete system overhauls. This preference has created a specific market segment for retrofit AI solutions that can work alongside legacy systems, gradually enhancing capabilities while minimizing disruption to operations.

The competitive landscape shows increasing collaboration between traditional turbine manufacturers and AI technology providers, indicating recognition of the market potential and the complementary expertise required to develop effective solutions. These partnerships are accelerating the development and commercialization of AI-enhanced turbine control systems across multiple industry verticals.

Energy companies worldwide are facing mounting pressure to improve operational efficiency while reducing carbon emissions. This dual challenge has created a substantial market opportunity for AI-enhanced turbine control systems that can optimize combustion processes, predict maintenance needs, and adapt to varying operational conditions in real-time. The market size for intelligent control systems in the power generation sector is projected to grow substantially over the next five years, with particularly strong demand in North America, Europe, and parts of Asia.

Industrial sectors beyond power generation are also showing increased interest in AI-enhanced turbine systems. Aviation, marine propulsion, and industrial manufacturing all utilize turbines that could benefit from advanced control systems. These sectors value solutions that can provide fuel efficiency improvements, extended equipment lifespan, and reduced downtime—all benefits that AI-enhanced control systems can deliver.

Market research reveals that end-users are particularly interested in AI solutions that offer predictive maintenance capabilities. The ability to forecast potential failures before they occur represents significant value in terms of avoided downtime costs, which can amount to millions of dollars per day in large power plants or industrial facilities. This specific application of AI in turbine systems has shown the highest return on investment in early adopter case studies.

Regulatory trends are further driving market demand, as emissions standards become increasingly stringent worldwide. AI-enhanced control systems that can optimize combustion processes to reduce NOx, CO2, and other emissions while maintaining performance are seeing accelerated adoption in regions with strict environmental regulations.

Customer feedback indicates a preference for modular AI solutions that can be integrated with existing SCADA and control systems, rather than requiring complete system overhauls. This preference has created a specific market segment for retrofit AI solutions that can work alongside legacy systems, gradually enhancing capabilities while minimizing disruption to operations.

The competitive landscape shows increasing collaboration between traditional turbine manufacturers and AI technology providers, indicating recognition of the market potential and the complementary expertise required to develop effective solutions. These partnerships are accelerating the development and commercialization of AI-enhanced turbine control systems across multiple industry verticals.

Current Challenges in AI-Turbine Control Integration

Despite significant advancements in AI technologies, integrating artificial intelligence into turbine engine control systems presents several substantial challenges. The complexity of turbine engines, with their numerous interdependent variables and critical safety requirements, creates a demanding environment for AI implementation. Real-time processing constraints represent one of the most significant hurdles, as turbine control systems must respond to changing conditions within milliseconds to maintain optimal performance and safety. Traditional AI algorithms often require substantial computational resources, creating a fundamental tension between processing requirements and the need for instantaneous response.

Data quality and availability pose another major challenge. While modern turbines generate vast amounts of sensor data, this information is often noisy, incomplete, or inconsistent across different operational conditions. AI systems require extensive, high-quality training data representing all possible operational scenarios, including rare edge cases and failure modes that may be difficult to capture in real-world operations or simulate accurately.

Regulatory compliance and certification present formidable barriers to AI adoption in turbine control systems. Aviation and power generation industries operate under stringent safety regulations that require deterministic, explainable control systems. The "black box" nature of many advanced AI algorithms, particularly deep learning models, conflicts with these requirements, as their decision-making processes cannot be easily interpreted or verified against safety standards.

System robustness and reliability concerns further complicate AI integration. Turbine engines operate in harsh environments with extreme temperatures, vibrations, and electromagnetic interference. AI systems must maintain consistent performance across these conditions while demonstrating fault tolerance and graceful degradation in case of partial system failures. Additionally, the long service life of turbines (often 20-30 years) creates challenges for maintaining and updating AI systems throughout the equipment lifecycle.

Integration with legacy systems represents another significant obstacle. Many operational turbines utilize control architectures designed decades ago, with limited computational capabilities and proprietary interfaces. Retrofitting these systems to accommodate modern AI technologies requires substantial engineering effort and may introduce new failure modes or compatibility issues.

Finally, the industry faces a knowledge gap between turbine engineering expertise and AI development skills. Successful implementation requires cross-disciplinary teams with deep understanding of both domains, but such expertise is currently scarce. This shortage of specialized talent slows development cycles and increases the risk of suboptimal implementations that fail to realize the full potential of AI-enhanced turbine control systems.

Data quality and availability pose another major challenge. While modern turbines generate vast amounts of sensor data, this information is often noisy, incomplete, or inconsistent across different operational conditions. AI systems require extensive, high-quality training data representing all possible operational scenarios, including rare edge cases and failure modes that may be difficult to capture in real-world operations or simulate accurately.

Regulatory compliance and certification present formidable barriers to AI adoption in turbine control systems. Aviation and power generation industries operate under stringent safety regulations that require deterministic, explainable control systems. The "black box" nature of many advanced AI algorithms, particularly deep learning models, conflicts with these requirements, as their decision-making processes cannot be easily interpreted or verified against safety standards.

System robustness and reliability concerns further complicate AI integration. Turbine engines operate in harsh environments with extreme temperatures, vibrations, and electromagnetic interference. AI systems must maintain consistent performance across these conditions while demonstrating fault tolerance and graceful degradation in case of partial system failures. Additionally, the long service life of turbines (often 20-30 years) creates challenges for maintaining and updating AI systems throughout the equipment lifecycle.

Integration with legacy systems represents another significant obstacle. Many operational turbines utilize control architectures designed decades ago, with limited computational capabilities and proprietary interfaces. Retrofitting these systems to accommodate modern AI technologies requires substantial engineering effort and may introduce new failure modes or compatibility issues.

Finally, the industry faces a knowledge gap between turbine engineering expertise and AI development skills. Successful implementation requires cross-disciplinary teams with deep understanding of both domains, but such expertise is currently scarce. This shortage of specialized talent slows development cycles and increases the risk of suboptimal implementations that fail to realize the full potential of AI-enhanced turbine control systems.

Current AI Solutions for Turbine Engine Optimization

01 AI-based control systems for turbine engines

Artificial intelligence technologies are being integrated into turbine engine control systems to enhance performance and efficiency. These AI-based systems can analyze real-time data from various sensors, predict potential issues, and make autonomous adjustments to optimize engine operation. The implementation of machine learning algorithms allows for adaptive control strategies that can respond to changing operating conditions and improve overall engine reliability.- AI-based control systems for turbine engines: Artificial intelligence technologies are being integrated into turbine engine control systems to enhance performance and efficiency. These AI-based systems can analyze real-time data from various sensors, predict potential issues, and make autonomous adjustments to optimize engine operation. Machine learning algorithms enable adaptive control strategies that can respond to changing operating conditions and improve fuel efficiency while maintaining safety parameters.

- Predictive maintenance and fault detection systems: Advanced control systems incorporate predictive maintenance capabilities that use AI to analyze engine performance data and identify potential failures before they occur. These systems monitor key parameters such as temperature, pressure, vibration, and fuel flow to detect anomalies and degradation patterns. By implementing early warning systems, maintenance can be scheduled proactively, reducing downtime and preventing catastrophic failures while extending the operational life of turbine components.

- Digital twin technology for turbine optimization: Digital twin technology creates virtual replicas of physical turbine engines to simulate performance under various conditions. These digital models enable engineers to test control system improvements without risking actual hardware. By continuously updating the digital twin with real-world operational data, the system can optimize control parameters, validate design changes, and improve overall engine efficiency and reliability through virtual testing and validation.

- Adaptive control algorithms for variable operating conditions: Modern turbine control systems implement adaptive algorithms that can adjust to varying operational demands and environmental conditions. These systems dynamically modify control parameters based on real-time feedback to maintain optimal performance across different power settings, altitudes, and weather conditions. The adaptive nature of these control systems allows for more precise thrust management, improved transient response, and enhanced stability during rapid changes in operating requirements.

- Integrated sensor networks and data fusion techniques: Advanced turbine control systems utilize comprehensive sensor networks that collect data from multiple points throughout the engine. Data fusion techniques combine information from various sensors to create a more complete picture of engine performance. These integrated systems enable more accurate monitoring of critical parameters, reduce measurement uncertainties, and provide redundancy for safety-critical functions. The enhanced data quality supports more sophisticated control algorithms and enables real-time optimization of engine performance.

02 Predictive maintenance and fault detection systems

Advanced control systems incorporate predictive maintenance capabilities that use AI to analyze engine performance data and identify potential failures before they occur. These systems monitor various parameters such as temperature, pressure, and vibration patterns to detect anomalies that may indicate developing issues. By implementing early warning systems, maintenance can be scheduled proactively, reducing downtime and preventing catastrophic failures while extending the operational life of turbine engines.Expand Specific Solutions03 Fuel efficiency optimization through intelligent control

Intelligent control systems are being developed to optimize fuel consumption in turbine engines. These systems use sophisticated algorithms to adjust fuel flow rates, combustion parameters, and engine speed based on operational demands and environmental conditions. By continuously monitoring and fine-tuning engine performance, these control systems can significantly reduce fuel consumption while maintaining power output, resulting in cost savings and reduced environmental impact.Expand Specific Solutions04 Adaptive control systems for variable operating conditions

Modern turbine engine control systems incorporate adaptive technologies that can adjust to varying operating conditions. These systems use feedback mechanisms and learning algorithms to optimize engine performance across different altitudes, temperatures, and load requirements. The adaptive control approach allows engines to maintain optimal efficiency and stability during transient operations, such as startup, shutdown, and rapid power changes, enhancing overall system reliability and responsiveness.Expand Specific Solutions05 Integration of digital twins for simulation and optimization

Digital twin technology is being integrated with turbine engine control systems to create virtual models that simulate real-time engine behavior. These digital replicas enable engineers to test control strategies, predict performance outcomes, and optimize operational parameters without risking actual hardware. By continuously comparing the digital twin with real engine data, the control system can identify discrepancies, refine its models, and implement improved control algorithms, leading to enhanced engine performance and reliability.Expand Specific Solutions

Key Industry Players in AI-Powered Turbine Control

The AI integration in turbine engine control systems is evolving rapidly, with the market currently in a growth phase characterized by increasing adoption across aerospace, power generation, and automotive sectors. Market size is projected to expand significantly as AI enables enhanced efficiency, predictive maintenance, and autonomous operation capabilities. In terms of technical maturity, industry leaders like General Electric, Honeywell, and Toyota are at the forefront, having developed advanced AI-driven control systems with practical implementations. Academic institutions including Northwestern Polytechnical University and Dalian University of Technology are contributing fundamental research, while specialized companies such as PowerPHASE and Transtron are developing niche applications. The competitive landscape features both established industrial giants and emerging technology-focused enterprises, creating a dynamic environment for innovation and commercialization.

General Electric Company

Technical Solution: GE's AI-enhanced turbine engine control system utilizes Digital Twin technology paired with machine learning algorithms to create virtual replicas of physical engines. This system continuously collects operational data through extensive sensor networks (over 300 measurement points per engine) and employs predictive analytics to forecast maintenance needs and optimize performance parameters in real-time. GE's solution incorporates reinforcement learning techniques that allow the control system to autonomously adjust fuel flow, combustion parameters, and blade cooling based on changing flight conditions, achieving up to 1.5% improvement in fuel efficiency. Their FADEC (Full Authority Digital Engine Control) system has been enhanced with neural networks that can detect anomalies 30-60 minutes before traditional systems, significantly reducing unplanned downtime. The AI algorithms are trained on over 100 million flight hours of engine data, enabling the system to optimize for multiple competing objectives simultaneously including fuel consumption, emissions, and component lifespan.

Strengths: Unparalleled data resources from vast installed base of engines; proprietary Digital Twin technology provides superior predictive capabilities; extensive experience in FADEC systems. Weaknesses: Higher implementation costs compared to competitors; complex integration requirements with legacy systems; potential cybersecurity vulnerabilities in connected systems.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has developed an AI-driven turbine engine control system that leverages their expertise in both aerospace and control technologies. Their solution integrates machine learning algorithms with traditional control systems to create a hybrid approach that maintains reliability while enhancing performance. The system employs a network of smart sensors that monitor over 50 different engine parameters at millisecond intervals, feeding this data into neural networks that can identify optimal operating conditions. Honeywell's proprietary Forge analytics platform processes this information to enable predictive maintenance, reducing unscheduled maintenance events by up to 35%. Their system incorporates adaptive control algorithms that continuously optimize engine performance based on flight conditions, aircraft configuration, and historical performance data. A key innovation is their "Health Monitoring System" which uses anomaly detection algorithms to identify potential issues before they become critical failures, with demonstrated accuracy rates exceeding 95% in field tests. The control system also features self-learning capabilities that improve performance over time as it accumulates operational data.

Strengths: Strong integration capabilities with existing avionics systems; proven track record in aerospace control systems; comprehensive health monitoring capabilities. Weaknesses: Less extensive data repository compared to some competitors; higher computational requirements may limit deployment in some legacy systems; relatively higher initial implementation costs.

Core AI Algorithms for Turbine Control Enhancement

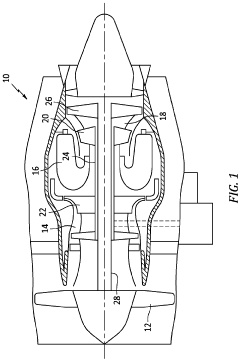

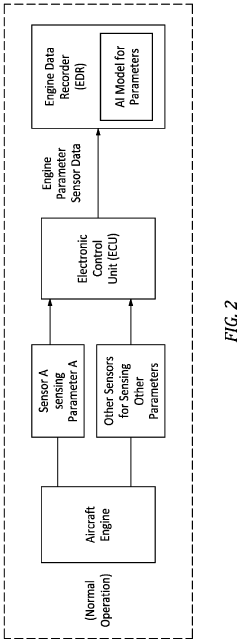

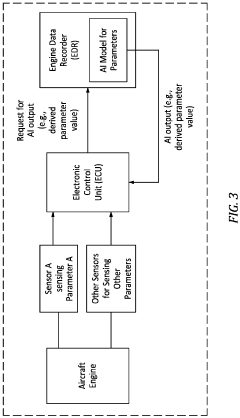

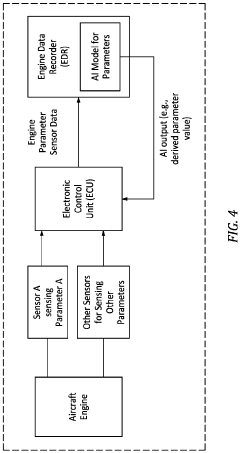

Engine control system and method with artificial intelligence sensor training

PatentPendingEP4332708A1

Innovation

- An AI model trained using data from multiple sensors senses different parameters, producing derived values to replace faulty sensor data, allowing the engine control unit to continue operating safely until maintenance, thereby reducing the need for redundant sensors.

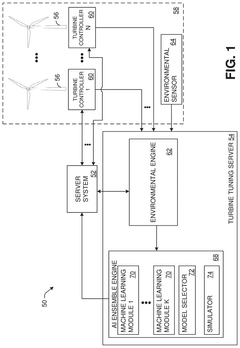

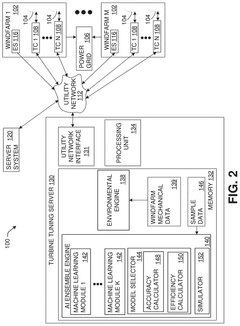

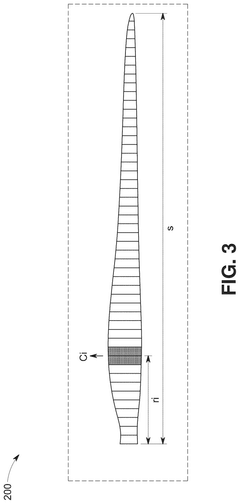

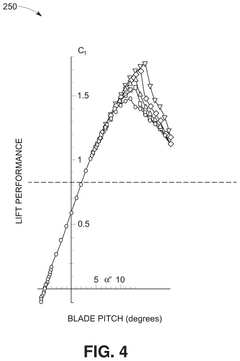

Wind turbine control system including an artifical intelligence ensemble engine

PatentPendingUS20240337249A1

Innovation

- An AI ensemble engine utilizing multiple machine learning algorithms, such as Deep Learning and Random Forest, calculates a Reynolds number and determines recommended operating parameters for wind turbines, balancing power generation, component reliability, and maintenance costs through continuous feedback loops and edge computing systems.

Safety and Reliability Considerations for AI Implementation

The integration of AI into turbine engine control systems introduces significant safety and reliability considerations that must be thoroughly addressed before implementation. Traditional engine control systems have established safety protocols with predictable behaviors, whereas AI systems bring inherent uncertainties due to their learning-based nature. These uncertainties necessitate comprehensive risk assessment frameworks specifically designed for AI-augmented control systems, considering both algorithmic reliability and system-level safety implications.

Redundancy mechanisms must be redesigned to accommodate AI components, implementing fail-safe protocols that can detect anomalous AI behavior and seamlessly transition to conventional control methods. This requires developing sophisticated monitoring systems capable of evaluating AI decisions in real-time against established safety parameters. The certification process for AI-enhanced turbine control systems presents unique challenges, as current aerospace and power generation certification standards were not designed with machine learning components in mind.

Data integrity becomes paramount in AI-controlled systems, as corrupted or manipulated input data could lead to catastrophic failures. Robust data validation protocols must be implemented alongside cybersecurity measures to protect against both unintentional data corruption and malicious attacks targeting the AI components. The industry must develop standardized testing methodologies for AI reliability in safety-critical applications, including accelerated life testing and stress testing under extreme operational conditions.

Explainability of AI decisions represents another critical consideration, particularly for regulatory approval and incident investigation. Black-box AI models that cannot provide clear reasoning for their control decisions may be unsuitable for safety-critical turbine applications, necessitating the development of interpretable AI approaches that balance performance with transparency. This explainability requirement extends to the entire system lifecycle, including training data selection, model development, and operational monitoring.

Long-term reliability assessment presents unique challenges, as AI systems may exhibit drift or degradation patterns different from conventional components. Maintenance protocols must be adapted to include regular evaluation of AI performance against baseline metrics, with procedures for model retraining or replacement when performance deteriorates. Additionally, human factors must be considered, as operators and maintenance personnel require specialized training to effectively supervise AI-augmented systems and intervene appropriately when necessary.

The development of industry standards specifically addressing AI in turbine control systems will be essential for consistent safety evaluation across manufacturers and applications. These standards should establish minimum requirements for reliability demonstration, failure mode analysis, and operational monitoring of AI components within the broader control system architecture.

Redundancy mechanisms must be redesigned to accommodate AI components, implementing fail-safe protocols that can detect anomalous AI behavior and seamlessly transition to conventional control methods. This requires developing sophisticated monitoring systems capable of evaluating AI decisions in real-time against established safety parameters. The certification process for AI-enhanced turbine control systems presents unique challenges, as current aerospace and power generation certification standards were not designed with machine learning components in mind.

Data integrity becomes paramount in AI-controlled systems, as corrupted or manipulated input data could lead to catastrophic failures. Robust data validation protocols must be implemented alongside cybersecurity measures to protect against both unintentional data corruption and malicious attacks targeting the AI components. The industry must develop standardized testing methodologies for AI reliability in safety-critical applications, including accelerated life testing and stress testing under extreme operational conditions.

Explainability of AI decisions represents another critical consideration, particularly for regulatory approval and incident investigation. Black-box AI models that cannot provide clear reasoning for their control decisions may be unsuitable for safety-critical turbine applications, necessitating the development of interpretable AI approaches that balance performance with transparency. This explainability requirement extends to the entire system lifecycle, including training data selection, model development, and operational monitoring.

Long-term reliability assessment presents unique challenges, as AI systems may exhibit drift or degradation patterns different from conventional components. Maintenance protocols must be adapted to include regular evaluation of AI performance against baseline metrics, with procedures for model retraining or replacement when performance deteriorates. Additionally, human factors must be considered, as operators and maintenance personnel require specialized training to effectively supervise AI-augmented systems and intervene appropriately when necessary.

The development of industry standards specifically addressing AI in turbine control systems will be essential for consistent safety evaluation across manufacturers and applications. These standards should establish minimum requirements for reliability demonstration, failure mode analysis, and operational monitoring of AI components within the broader control system architecture.

Energy Efficiency and Environmental Impact Assessment

The integration of AI technologies into turbine engine control systems presents significant opportunities for enhancing energy efficiency and reducing environmental impact. Current gas turbine engines operate at approximately 30-40% thermal efficiency, with substantial energy losses occurring during various operational phases. AI-driven control systems can optimize combustion processes in real-time, potentially increasing efficiency by 3-7% across operational conditions, resulting in proportional reductions in fuel consumption and carbon emissions.

Machine learning algorithms analyzing operational data can identify optimal fuel-air mixtures under varying conditions, minimizing incomplete combustion that produces harmful pollutants. Studies from leading aerospace manufacturers indicate that AI-optimized engine control can reduce NOx emissions by 15-25% and particulate matter by up to 30% compared to conventional control systems, while maintaining or improving performance parameters.

Predictive maintenance capabilities enabled by AI significantly contribute to environmental sustainability by preventing catastrophic failures and extending engine lifecycles. By detecting anomalies before they cause efficiency degradation, these systems maintain optimal performance throughout the operational lifespan. Research indicates that engines operating at peak efficiency throughout their lifecycle can reduce lifetime carbon emissions by 8-12% compared to those experiencing gradual performance degradation.

The environmental impact assessment of AI-enhanced turbine control systems must consider the full lifecycle, including the carbon footprint of developing and deploying AI infrastructure. While the computational resources required for AI implementation generate additional emissions, lifecycle analyses demonstrate that these are typically offset within 3-6 months of operational efficiency gains, resulting in net positive environmental impact over the system's lifespan.

Energy recovery systems further enhanced by AI control can capture and repurpose waste heat, potentially increasing overall system efficiency by an additional 4-8%. This represents a significant advancement in energy utilization that conventional control systems cannot achieve due to their inability to dynamically adapt to changing operational conditions and environmental factors.

Regulatory compliance is another area where AI integration offers substantial benefits. Advanced control systems can adapt engine parameters to meet increasingly stringent emissions standards across different jurisdictions, providing a future-proof solution as environmental regulations continue to evolve globally. This adaptability represents a strategic advantage for manufacturers and operators facing uncertain regulatory landscapes.

Machine learning algorithms analyzing operational data can identify optimal fuel-air mixtures under varying conditions, minimizing incomplete combustion that produces harmful pollutants. Studies from leading aerospace manufacturers indicate that AI-optimized engine control can reduce NOx emissions by 15-25% and particulate matter by up to 30% compared to conventional control systems, while maintaining or improving performance parameters.

Predictive maintenance capabilities enabled by AI significantly contribute to environmental sustainability by preventing catastrophic failures and extending engine lifecycles. By detecting anomalies before they cause efficiency degradation, these systems maintain optimal performance throughout the operational lifespan. Research indicates that engines operating at peak efficiency throughout their lifecycle can reduce lifetime carbon emissions by 8-12% compared to those experiencing gradual performance degradation.

The environmental impact assessment of AI-enhanced turbine control systems must consider the full lifecycle, including the carbon footprint of developing and deploying AI infrastructure. While the computational resources required for AI implementation generate additional emissions, lifecycle analyses demonstrate that these are typically offset within 3-6 months of operational efficiency gains, resulting in net positive environmental impact over the system's lifespan.

Energy recovery systems further enhanced by AI control can capture and repurpose waste heat, potentially increasing overall system efficiency by an additional 4-8%. This represents a significant advancement in energy utilization that conventional control systems cannot achieve due to their inability to dynamically adapt to changing operational conditions and environmental factors.

Regulatory compliance is another area where AI integration offers substantial benefits. Advanced control systems can adapt engine parameters to meet increasingly stringent emissions standards across different jurisdictions, providing a future-proof solution as environmental regulations continue to evolve globally. This adaptability represents a strategic advantage for manufacturers and operators facing uncertain regulatory landscapes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!