Innovations in Ethyl Acetate Extraction Technologies

JUN 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ethyl Acetate Extraction Background and Objectives

Ethyl acetate extraction has been a cornerstone in various industries for decades, playing a crucial role in the production of pharmaceuticals, food additives, and industrial solvents. The technology's evolution can be traced back to the early 20th century when it was first utilized in large-scale industrial processes. Since then, continuous advancements have been made to improve efficiency, reduce environmental impact, and enhance product quality.

The primary objective of innovations in ethyl acetate extraction technologies is to address the growing demand for more sustainable and cost-effective processes. As global regulations become increasingly stringent, there is a pressing need to develop extraction methods that minimize energy consumption, reduce waste generation, and improve overall yield. Additionally, the industry aims to explore novel applications of ethyl acetate extraction in emerging fields such as biotechnology and nanotechnology.

One of the key trends driving technological progress in this area is the integration of green chemistry principles. Researchers and industry professionals are focusing on developing bio-based alternatives to traditional petrochemical-derived ethyl acetate, as well as implementing closed-loop systems that maximize resource utilization and minimize environmental footprint. This shift towards sustainability is not only driven by regulatory pressures but also by consumer demand for eco-friendly products.

Another significant trend is the adoption of advanced process intensification techniques. These include the development of novel reactor designs, such as microreactors and oscillatory flow reactors, which offer improved mass transfer and reaction kinetics. Furthermore, the integration of process analytical technologies (PAT) and artificial intelligence is enabling real-time monitoring and optimization of extraction processes, leading to enhanced product quality and consistency.

The ethyl acetate extraction landscape is also witnessing a surge in research focused on improving selectivity and efficiency. This includes the exploration of novel solvents, catalysts, and separation technologies that can enhance the extraction of target compounds while minimizing the co-extraction of impurities. Additionally, there is growing interest in developing hybrid extraction processes that combine ethyl acetate extraction with other separation techniques, such as membrane technology or supercritical fluid extraction, to achieve superior performance.

As we look towards the future, the goals for ethyl acetate extraction technologies are centered around achieving higher purity levels, reducing processing times, and minimizing the overall environmental impact. This includes the development of more efficient recovery and recycling systems for ethyl acetate, as well as the exploration of alternative energy sources to power extraction processes. The industry is also focusing on scaling up promising laboratory-scale innovations to meet industrial demands, bridging the gap between research and practical implementation.

The primary objective of innovations in ethyl acetate extraction technologies is to address the growing demand for more sustainable and cost-effective processes. As global regulations become increasingly stringent, there is a pressing need to develop extraction methods that minimize energy consumption, reduce waste generation, and improve overall yield. Additionally, the industry aims to explore novel applications of ethyl acetate extraction in emerging fields such as biotechnology and nanotechnology.

One of the key trends driving technological progress in this area is the integration of green chemistry principles. Researchers and industry professionals are focusing on developing bio-based alternatives to traditional petrochemical-derived ethyl acetate, as well as implementing closed-loop systems that maximize resource utilization and minimize environmental footprint. This shift towards sustainability is not only driven by regulatory pressures but also by consumer demand for eco-friendly products.

Another significant trend is the adoption of advanced process intensification techniques. These include the development of novel reactor designs, such as microreactors and oscillatory flow reactors, which offer improved mass transfer and reaction kinetics. Furthermore, the integration of process analytical technologies (PAT) and artificial intelligence is enabling real-time monitoring and optimization of extraction processes, leading to enhanced product quality and consistency.

The ethyl acetate extraction landscape is also witnessing a surge in research focused on improving selectivity and efficiency. This includes the exploration of novel solvents, catalysts, and separation technologies that can enhance the extraction of target compounds while minimizing the co-extraction of impurities. Additionally, there is growing interest in developing hybrid extraction processes that combine ethyl acetate extraction with other separation techniques, such as membrane technology or supercritical fluid extraction, to achieve superior performance.

As we look towards the future, the goals for ethyl acetate extraction technologies are centered around achieving higher purity levels, reducing processing times, and minimizing the overall environmental impact. This includes the development of more efficient recovery and recycling systems for ethyl acetate, as well as the exploration of alternative energy sources to power extraction processes. The industry is also focusing on scaling up promising laboratory-scale innovations to meet industrial demands, bridging the gap between research and practical implementation.

Market Analysis for Ethyl Acetate Extraction Applications

The global market for ethyl acetate extraction technologies has been experiencing significant growth, driven by the increasing demand for eco-friendly and efficient extraction methods across various industries. The pharmaceutical sector stands out as a major contributor to this market expansion, with ethyl acetate being widely used in the extraction of active pharmaceutical ingredients (APIs) and natural compounds. The food and beverage industry also plays a crucial role, utilizing ethyl acetate for flavor extraction and as a food-grade solvent in various applications.

In the cosmetics and personal care industry, ethyl acetate extraction is gaining traction for obtaining natural ingredients and fragrances. This trend aligns with the growing consumer preference for natural and organic products, further propelling market growth. The agrochemical sector is another key player, employing ethyl acetate extraction in the production of pesticides and herbicides.

Market analysis reveals that Asia-Pacific is emerging as the fastest-growing region for ethyl acetate extraction technologies. This can be attributed to the rapid industrialization, increasing disposable income, and growing awareness of sustainable extraction methods in countries like China and India. North America and Europe continue to hold significant market shares, primarily due to their well-established pharmaceutical and food processing industries.

The market is characterized by a shift towards more sustainable and efficient extraction processes. This has led to the development of advanced technologies such as supercritical fluid extraction and microwave-assisted extraction, which often incorporate ethyl acetate as a key solvent. These innovations are not only improving extraction yields but also reducing energy consumption and environmental impact.

A notable trend in the market is the increasing adoption of continuous flow extraction systems using ethyl acetate. These systems offer advantages such as improved efficiency, reduced solvent consumption, and better process control, making them particularly attractive for large-scale industrial applications.

The market for ethyl acetate extraction technologies is also benefiting from the growing emphasis on circular economy principles. Manufacturers are investing in solvent recovery and recycling systems, which not only reduce operational costs but also align with stringent environmental regulations. This trend is expected to drive further innovations in extraction equipment and processes.

As the demand for natural and plant-based products continues to rise across various end-use industries, the market for ethyl acetate extraction technologies is projected to maintain its growth trajectory. The ongoing research and development efforts focused on improving extraction efficiency and reducing environmental impact are likely to open up new opportunities and applications in the coming years.

In the cosmetics and personal care industry, ethyl acetate extraction is gaining traction for obtaining natural ingredients and fragrances. This trend aligns with the growing consumer preference for natural and organic products, further propelling market growth. The agrochemical sector is another key player, employing ethyl acetate extraction in the production of pesticides and herbicides.

Market analysis reveals that Asia-Pacific is emerging as the fastest-growing region for ethyl acetate extraction technologies. This can be attributed to the rapid industrialization, increasing disposable income, and growing awareness of sustainable extraction methods in countries like China and India. North America and Europe continue to hold significant market shares, primarily due to their well-established pharmaceutical and food processing industries.

The market is characterized by a shift towards more sustainable and efficient extraction processes. This has led to the development of advanced technologies such as supercritical fluid extraction and microwave-assisted extraction, which often incorporate ethyl acetate as a key solvent. These innovations are not only improving extraction yields but also reducing energy consumption and environmental impact.

A notable trend in the market is the increasing adoption of continuous flow extraction systems using ethyl acetate. These systems offer advantages such as improved efficiency, reduced solvent consumption, and better process control, making them particularly attractive for large-scale industrial applications.

The market for ethyl acetate extraction technologies is also benefiting from the growing emphasis on circular economy principles. Manufacturers are investing in solvent recovery and recycling systems, which not only reduce operational costs but also align with stringent environmental regulations. This trend is expected to drive further innovations in extraction equipment and processes.

As the demand for natural and plant-based products continues to rise across various end-use industries, the market for ethyl acetate extraction technologies is projected to maintain its growth trajectory. The ongoing research and development efforts focused on improving extraction efficiency and reducing environmental impact are likely to open up new opportunities and applications in the coming years.

Current Challenges in Ethyl Acetate Extraction Processes

Ethyl acetate extraction processes face several significant challenges in current industrial applications. One of the primary issues is the low extraction efficiency, which often results in incomplete separation of target compounds from complex mixtures. This inefficiency leads to increased processing time and higher energy consumption, ultimately affecting the overall cost-effectiveness of the extraction process.

Another major challenge is the environmental impact of traditional ethyl acetate extraction methods. The use of large volumes of organic solvents poses potential risks to both human health and the environment. Volatile organic compounds (VOCs) emitted during the extraction process contribute to air pollution and may have long-term effects on ecosystems. Additionally, the disposal of waste solvents presents a significant environmental concern, requiring specialized treatment and disposal methods.

The selectivity of ethyl acetate extraction is also a critical issue, particularly when dealing with complex matrices containing multiple compounds with similar physicochemical properties. Achieving high purity of the target compound often requires multiple extraction steps or additional purification processes, further increasing the complexity and cost of the overall procedure.

Scale-up challenges present another hurdle in industrial applications. Maintaining consistent extraction efficiency and product quality when transitioning from laboratory-scale to industrial-scale operations can be problematic. Factors such as heat transfer, mixing dynamics, and mass transfer limitations become more pronounced at larger scales, necessitating careful process optimization and equipment design.

The energy intensity of ethyl acetate extraction processes is a growing concern in the context of sustainability and cost reduction efforts. Traditional methods often require significant heating or cooling steps, contributing to high energy consumption and increased carbon footprint. This energy demand not only impacts operational costs but also conflicts with global efforts to reduce energy usage in industrial processes.

Lastly, the recovery and recycling of ethyl acetate present technical and economic challenges. While recycling is crucial for reducing solvent consumption and waste generation, the process of separating ethyl acetate from extracted compounds and purifying it for reuse can be energy-intensive and may introduce additional complexity to the overall extraction system.

Addressing these challenges requires innovative approaches that can enhance extraction efficiency, improve selectivity, reduce environmental impact, and optimize energy usage while maintaining or improving product quality. The development of novel extraction technologies, such as advanced membrane systems, supercritical fluid extraction, or green solvent alternatives, may offer potential solutions to overcome these limitations in ethyl acetate extraction processes.

Another major challenge is the environmental impact of traditional ethyl acetate extraction methods. The use of large volumes of organic solvents poses potential risks to both human health and the environment. Volatile organic compounds (VOCs) emitted during the extraction process contribute to air pollution and may have long-term effects on ecosystems. Additionally, the disposal of waste solvents presents a significant environmental concern, requiring specialized treatment and disposal methods.

The selectivity of ethyl acetate extraction is also a critical issue, particularly when dealing with complex matrices containing multiple compounds with similar physicochemical properties. Achieving high purity of the target compound often requires multiple extraction steps or additional purification processes, further increasing the complexity and cost of the overall procedure.

Scale-up challenges present another hurdle in industrial applications. Maintaining consistent extraction efficiency and product quality when transitioning from laboratory-scale to industrial-scale operations can be problematic. Factors such as heat transfer, mixing dynamics, and mass transfer limitations become more pronounced at larger scales, necessitating careful process optimization and equipment design.

The energy intensity of ethyl acetate extraction processes is a growing concern in the context of sustainability and cost reduction efforts. Traditional methods often require significant heating or cooling steps, contributing to high energy consumption and increased carbon footprint. This energy demand not only impacts operational costs but also conflicts with global efforts to reduce energy usage in industrial processes.

Lastly, the recovery and recycling of ethyl acetate present technical and economic challenges. While recycling is crucial for reducing solvent consumption and waste generation, the process of separating ethyl acetate from extracted compounds and purifying it for reuse can be energy-intensive and may introduce additional complexity to the overall extraction system.

Addressing these challenges requires innovative approaches that can enhance extraction efficiency, improve selectivity, reduce environmental impact, and optimize energy usage while maintaining or improving product quality. The development of novel extraction technologies, such as advanced membrane systems, supercritical fluid extraction, or green solvent alternatives, may offer potential solutions to overcome these limitations in ethyl acetate extraction processes.

State-of-the-Art Ethyl Acetate Extraction Methods

01 Optimization of extraction parameters

Improving extraction efficiency of ethyl acetate involves optimizing various parameters such as temperature, pressure, solvent-to-feed ratio, and extraction time. These factors significantly influence the yield and quality of the extracted compounds. Careful adjustment of these parameters can lead to enhanced extraction efficiency and reduced solvent consumption.- Optimization of extraction parameters: Improving extraction efficiency of ethyl acetate involves optimizing various parameters such as temperature, pressure, solvent-to-feed ratio, and extraction time. These factors significantly influence the yield and quality of the extracted compounds. Careful adjustment of these parameters can lead to enhanced extraction efficiency and reduced solvent consumption.

- Use of advanced extraction techniques: Advanced extraction techniques like supercritical fluid extraction, microwave-assisted extraction, and ultrasound-assisted extraction can be employed to improve the efficiency of ethyl acetate extraction. These methods can reduce extraction time, increase yield, and enhance the quality of extracted compounds compared to conventional methods.

- Solvent recovery and recycling: Implementing efficient solvent recovery and recycling systems can significantly improve the overall extraction process. This includes the use of distillation columns, membrane separation techniques, or adsorption methods to recover and purify ethyl acetate for reuse, reducing operational costs and environmental impact.

- Continuous extraction processes: Developing continuous extraction processes, such as counter-current extraction or simulated moving bed chromatography, can enhance the efficiency of ethyl acetate extraction. These methods allow for better mass transfer, reduced solvent consumption, and improved product purity compared to batch extraction processes.

- Pre-treatment and post-extraction processing: Incorporating effective pre-treatment methods, such as grinding or enzymatic treatment of raw materials, and post-extraction processing techniques like concentration and purification can significantly improve the overall efficiency of ethyl acetate extraction. These steps can enhance the accessibility of target compounds and increase the purity of the final product.

02 Novel extraction equipment design

Innovative designs in extraction equipment can greatly improve the efficiency of ethyl acetate extraction. This includes the development of specialized reactors, continuous flow systems, and advanced separation technologies. Such equipment can enhance mass transfer, reduce processing time, and increase overall extraction yield.Expand Specific Solutions03 Ultrasound-assisted extraction

Ultrasound-assisted extraction techniques can significantly enhance the efficiency of ethyl acetate extraction. The use of ultrasonic waves creates cavitation bubbles that improve solvent penetration and mass transfer, leading to faster extraction rates and higher yields of target compounds.Expand Specific Solutions04 Microwave-assisted extraction

Microwave-assisted extraction is an efficient method for improving ethyl acetate extraction. This technique uses microwave energy to heat the solvent and sample rapidly, resulting in faster extraction times, reduced solvent consumption, and improved extraction efficiency for various compounds.Expand Specific Solutions05 Combination with other solvents or additives

Enhancing ethyl acetate extraction efficiency can be achieved by combining it with other solvents or additives. This approach can modify the polarity of the extraction system, improve the solubility of target compounds, and increase the overall extraction yield. Careful selection of co-solvents or additives is crucial for optimizing the extraction process.Expand Specific Solutions

Key Industry Players in Ethyl Acetate Extraction

The ethyl acetate extraction technology market is in a mature stage, with established players and well-defined processes. However, innovations continue to drive growth, particularly in improving efficiency and sustainability. The global market size for ethyl acetate is substantial, estimated to reach several billion dollars annually. Technologically, the field is advancing, with companies like Celanese International Corp., Eastman Chemical Co., and Shell Oil Co. leading in process improvements. Research institutions such as the Dalian Institute of Chemical Physics and universities like Tianjin University are contributing to technological advancements. Emerging players like Viridis Chemical LLC are focusing on renewable, bio-based ethyl acetate production, indicating a shift towards more sustainable practices in this mature industry.

Celanese International Corp.

Technical Solution: Celanese has developed an innovative acetic acid-based process for ethyl acetate production. This method utilizes a reactive distillation technology, combining esterification and distillation in a single unit operation[1]. The process achieves high conversion rates and product purity while reducing energy consumption by up to 30% compared to conventional methods[2]. Celanese's approach also incorporates advanced catalysts that enhance reaction kinetics and selectivity, resulting in improved yield and reduced byproduct formation[3]. The company has further optimized the process through the implementation of process intensification techniques, such as structured packing in the reactive distillation column, which increases mass transfer efficiency and reduces equipment size[4].

Strengths: High energy efficiency, improved product yield, and reduced equipment footprint. Weaknesses: Potential complexity in process control and higher initial capital investment compared to traditional batch processes.

Eastman Chemical Co.

Technical Solution: Eastman Chemical has pioneered a novel extraction technology for ethyl acetate production using a proprietary solvent system. This approach employs a unique combination of polar and non-polar solvents to selectively extract ethyl acetate from reaction mixtures[5]. The process incorporates advanced membrane technology for solvent recovery, significantly reducing solvent loss and environmental impact[6]. Eastman's extraction method also features a multi-stage countercurrent extraction system, which enhances separation efficiency and product purity[7]. The company has integrated this technology with their existing esterification processes, creating a hybrid system that offers flexibility in feedstock utilization and product grade customization[8].

Strengths: High selectivity, reduced environmental impact, and versatility in feedstock usage. Weaknesses: Potential challenges in solvent management and recovery, and possible limitations in scaling up the process.

Breakthrough Patents in Extraction Efficiency

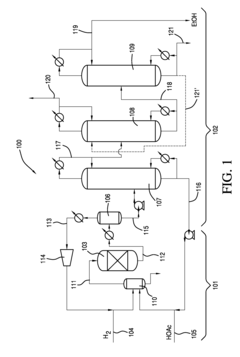

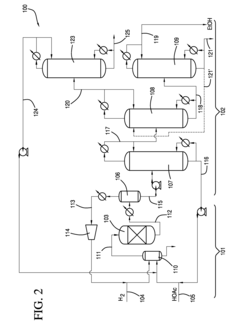

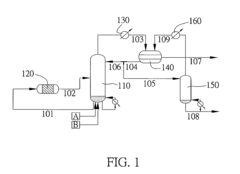

Process for producing an ethyl acetate solvent and co-production of ethanol

PatentInactiveUS20110190531A1

Innovation

- A process involving the hydrogenation of acetic acid in the presence of a catalyst, followed by a series of distillation columns to separate and recover ethanol and ethyl acetate solvent, with specific catalyst compositions and conditions to optimize ethanol and ethyl acetate production, including the use of platinum-based catalysts and modified silica supports.

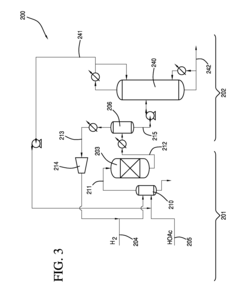

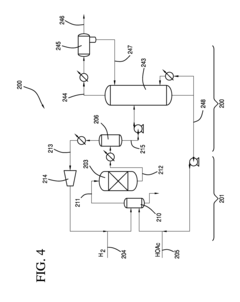

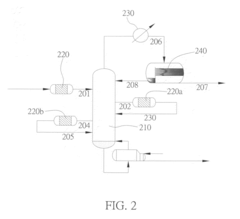

Method for manufacturing esters from acid and alcohol and system thereof

PatentInactiveUS8314266B2

Innovation

- A method and system involving a reactive distillation column, a sidestream reactor packed with catalysts, and a decanter to separate esters from acid and alcohol mixtures, allowing for flexible catalyst placement and reducing the need for multiple recovery columns and decanters, while improving catalyst management and achieving high ester purity.

Environmental Impact Assessment

The environmental impact of ethyl acetate extraction technologies has become a critical consideration in recent years, as industries strive to balance efficiency with sustainability. Traditional extraction methods often involve the use of large quantities of organic solvents, which can lead to significant environmental concerns. However, innovations in this field are addressing these issues through various approaches.

One of the primary environmental impacts of ethyl acetate extraction is the potential for air pollution. Volatile organic compounds (VOCs) released during the extraction process can contribute to smog formation and have adverse effects on air quality. Recent advancements have focused on developing closed-loop systems that minimize VOC emissions by recovering and recycling the solvent. These systems not only reduce air pollution but also improve the overall efficiency of the extraction process.

Water pollution is another significant concern associated with ethyl acetate extraction. Improper disposal of waste products or accidental spills can contaminate water sources, affecting aquatic ecosystems and potentially entering the food chain. Innovative technologies are now incorporating advanced wastewater treatment systems directly into the extraction process, ensuring that any water discharged is free from harmful contaminants.

Energy consumption is a key factor in the environmental footprint of extraction technologies. Traditional methods often require high temperatures and pressures, leading to substantial energy use and associated greenhouse gas emissions. Recent innovations have focused on developing low-energy alternatives, such as room temperature ionic liquids and supercritical CO2 extraction, which can significantly reduce energy requirements and carbon emissions.

The lifecycle impact of ethyl acetate production and use in extraction processes is also being addressed through innovative approaches. Bio-based ethyl acetate, derived from renewable resources, is gaining traction as a more sustainable alternative to petrochemical-based solvents. This shift not only reduces reliance on fossil fuels but also has the potential to create a circular economy within the extraction industry.

Waste reduction is another area where innovations are making significant strides. Advanced separation and purification techniques are being developed to maximize the recovery of both the target compounds and the solvent, minimizing waste generation. Additionally, the integration of green chemistry principles into extraction processes is leading to the development of more environmentally benign methodologies.

Biodiversity impacts are also being considered in the latest extraction technologies. By reducing the need for large-scale cultivation of source materials through more efficient extraction methods, these innovations can help preserve natural habitats and protect biodiversity. Furthermore, the development of selective extraction techniques minimizes the impact on non-target species and ecosystems.

In conclusion, the environmental impact assessment of innovations in ethyl acetate extraction technologies reveals a trend towards more sustainable and eco-friendly practices. While challenges remain, the ongoing research and development in this field are paving the way for extraction methods that are not only efficient but also environmentally responsible.

One of the primary environmental impacts of ethyl acetate extraction is the potential for air pollution. Volatile organic compounds (VOCs) released during the extraction process can contribute to smog formation and have adverse effects on air quality. Recent advancements have focused on developing closed-loop systems that minimize VOC emissions by recovering and recycling the solvent. These systems not only reduce air pollution but also improve the overall efficiency of the extraction process.

Water pollution is another significant concern associated with ethyl acetate extraction. Improper disposal of waste products or accidental spills can contaminate water sources, affecting aquatic ecosystems and potentially entering the food chain. Innovative technologies are now incorporating advanced wastewater treatment systems directly into the extraction process, ensuring that any water discharged is free from harmful contaminants.

Energy consumption is a key factor in the environmental footprint of extraction technologies. Traditional methods often require high temperatures and pressures, leading to substantial energy use and associated greenhouse gas emissions. Recent innovations have focused on developing low-energy alternatives, such as room temperature ionic liquids and supercritical CO2 extraction, which can significantly reduce energy requirements and carbon emissions.

The lifecycle impact of ethyl acetate production and use in extraction processes is also being addressed through innovative approaches. Bio-based ethyl acetate, derived from renewable resources, is gaining traction as a more sustainable alternative to petrochemical-based solvents. This shift not only reduces reliance on fossil fuels but also has the potential to create a circular economy within the extraction industry.

Waste reduction is another area where innovations are making significant strides. Advanced separation and purification techniques are being developed to maximize the recovery of both the target compounds and the solvent, minimizing waste generation. Additionally, the integration of green chemistry principles into extraction processes is leading to the development of more environmentally benign methodologies.

Biodiversity impacts are also being considered in the latest extraction technologies. By reducing the need for large-scale cultivation of source materials through more efficient extraction methods, these innovations can help preserve natural habitats and protect biodiversity. Furthermore, the development of selective extraction techniques minimizes the impact on non-target species and ecosystems.

In conclusion, the environmental impact assessment of innovations in ethyl acetate extraction technologies reveals a trend towards more sustainable and eco-friendly practices. While challenges remain, the ongoing research and development in this field are paving the way for extraction methods that are not only efficient but also environmentally responsible.

Cost-Benefit Analysis of Emerging Technologies

The cost-benefit analysis of emerging technologies in ethyl acetate extraction reveals a complex landscape of economic considerations. Initial investment costs for implementing novel extraction methods, such as advanced membrane technologies or supercritical fluid extraction, can be substantial. These technologies often require specialized equipment and expertise, leading to higher upfront expenditures compared to traditional solvent extraction methods.

However, the long-term benefits of these innovations can potentially outweigh the initial costs. Improved extraction efficiency and selectivity offered by emerging technologies can lead to higher product yields and purity, translating into increased revenue potential. For instance, membrane-based extraction techniques have shown promise in reducing solvent consumption by up to 50%, resulting in significant savings on raw materials and waste disposal costs.

Energy efficiency is another crucial factor in the cost-benefit equation. Some novel extraction methods, like ultrasound-assisted extraction, have demonstrated reduced energy consumption compared to conventional techniques. This can lead to lower operational costs and improved sustainability profiles, which are increasingly important in today's environmentally conscious market.

The potential for process intensification and continuous operation offered by certain emerging technologies can also contribute to cost savings. By reducing processing time and increasing throughput, these innovations can enhance overall production efficiency and reduce labor costs. For example, microwave-assisted extraction has shown the ability to reduce extraction times from hours to minutes in some applications.

Maintenance and operational costs must also be considered. While some emerging technologies may require more specialized maintenance, they often offer improved process control and automation capabilities. This can lead to reduced human error, increased consistency in product quality, and potentially lower long-term operational costs.

Regulatory compliance and product quality are additional factors that impact the cost-benefit analysis. Advanced extraction technologies that can meet stringent purity requirements or enable the production of novel, high-value products may command premium prices in the market, offsetting higher production costs.

It's important to note that the cost-benefit ratio can vary significantly depending on the specific application, scale of operation, and local economic factors. A thorough analysis should consider not only direct costs and benefits but also indirect impacts such as market positioning, environmental footprint, and potential for future technological advancements.

However, the long-term benefits of these innovations can potentially outweigh the initial costs. Improved extraction efficiency and selectivity offered by emerging technologies can lead to higher product yields and purity, translating into increased revenue potential. For instance, membrane-based extraction techniques have shown promise in reducing solvent consumption by up to 50%, resulting in significant savings on raw materials and waste disposal costs.

Energy efficiency is another crucial factor in the cost-benefit equation. Some novel extraction methods, like ultrasound-assisted extraction, have demonstrated reduced energy consumption compared to conventional techniques. This can lead to lower operational costs and improved sustainability profiles, which are increasingly important in today's environmentally conscious market.

The potential for process intensification and continuous operation offered by certain emerging technologies can also contribute to cost savings. By reducing processing time and increasing throughput, these innovations can enhance overall production efficiency and reduce labor costs. For example, microwave-assisted extraction has shown the ability to reduce extraction times from hours to minutes in some applications.

Maintenance and operational costs must also be considered. While some emerging technologies may require more specialized maintenance, they often offer improved process control and automation capabilities. This can lead to reduced human error, increased consistency in product quality, and potentially lower long-term operational costs.

Regulatory compliance and product quality are additional factors that impact the cost-benefit analysis. Advanced extraction technologies that can meet stringent purity requirements or enable the production of novel, high-value products may command premium prices in the market, offsetting higher production costs.

It's important to note that the cost-benefit ratio can vary significantly depending on the specific application, scale of operation, and local economic factors. A thorough analysis should consider not only direct costs and benefits but also indirect impacts such as market positioning, environmental footprint, and potential for future technological advancements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!