Lifecycle Assessment For PCM Versus Other Emerging NVMs

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PCM and NVM Technology Evolution Background

Non-volatile memory (NVM) technologies have undergone significant evolution over the past decades, with Phase Change Memory (PCM) emerging as a promising contender among next-generation solutions. The journey of memory technologies began with magnetic core memory in the 1950s, followed by semiconductor-based memories like DRAM and SRAM in the 1970s, and eventually Flash memory in the 1980s. These conventional technologies have faced increasing challenges in scaling beyond certain physical limitations, prompting research into alternative NVM technologies.

PCM specifically emerged in the early 2000s as a viable technology based on the unique properties of chalcogenide materials, particularly Ge2Sb2Te5 (GST). These materials exhibit rapid and reversible transitions between amorphous and crystalline states when subjected to electrical pulses, allowing binary data storage. The fundamental principle of PCM operation involves the significant difference in electrical resistivity between these two states, with the high-resistance amorphous state representing one binary value and the low-resistance crystalline state representing another.

The evolution of PCM has been marked by several technological breakthroughs, including improvements in material composition, cell architecture, and manufacturing processes. Early PCM devices suffered from high programming currents, limited endurance, and thermal disturbance issues. However, continuous research has led to significant advancements in addressing these challenges, making PCM increasingly viable for commercial applications.

Parallel to PCM development, other emerging NVM technologies have also progressed significantly. Resistive RAM (ReRAM) utilizes the formation and dissolution of conductive filaments in a dielectric material. Magnetoresistive RAM (MRAM) and Spin-Transfer Torque MRAM (STT-MRAM) leverage magnetic properties for data storage. Ferroelectric RAM (FeRAM) employs ferroelectric materials that can maintain polarization states. Each technology presents unique advantages and challenges in terms of performance metrics such as speed, endurance, power consumption, and scalability.

The technological landscape has been further shaped by industry consolidation and strategic investments. Major semiconductor companies including Intel, Samsung, Micron, and IBM have made significant contributions to NVM research and development. The introduction of 3D XPoint technology by Intel and Micron in 2015 represented a major milestone in PCM commercialization, although the exact architecture remains proprietary.

Current trends indicate a shift toward hybrid memory systems that leverage the complementary strengths of different memory technologies. PCM, with its balance of performance characteristics, has positioned itself as a potential bridge between high-speed volatile memories (DRAM) and high-density storage (NAND Flash), potentially enabling new memory hierarchies and computing paradigms.

PCM specifically emerged in the early 2000s as a viable technology based on the unique properties of chalcogenide materials, particularly Ge2Sb2Te5 (GST). These materials exhibit rapid and reversible transitions between amorphous and crystalline states when subjected to electrical pulses, allowing binary data storage. The fundamental principle of PCM operation involves the significant difference in electrical resistivity between these two states, with the high-resistance amorphous state representing one binary value and the low-resistance crystalline state representing another.

The evolution of PCM has been marked by several technological breakthroughs, including improvements in material composition, cell architecture, and manufacturing processes. Early PCM devices suffered from high programming currents, limited endurance, and thermal disturbance issues. However, continuous research has led to significant advancements in addressing these challenges, making PCM increasingly viable for commercial applications.

Parallel to PCM development, other emerging NVM technologies have also progressed significantly. Resistive RAM (ReRAM) utilizes the formation and dissolution of conductive filaments in a dielectric material. Magnetoresistive RAM (MRAM) and Spin-Transfer Torque MRAM (STT-MRAM) leverage magnetic properties for data storage. Ferroelectric RAM (FeRAM) employs ferroelectric materials that can maintain polarization states. Each technology presents unique advantages and challenges in terms of performance metrics such as speed, endurance, power consumption, and scalability.

The technological landscape has been further shaped by industry consolidation and strategic investments. Major semiconductor companies including Intel, Samsung, Micron, and IBM have made significant contributions to NVM research and development. The introduction of 3D XPoint technology by Intel and Micron in 2015 represented a major milestone in PCM commercialization, although the exact architecture remains proprietary.

Current trends indicate a shift toward hybrid memory systems that leverage the complementary strengths of different memory technologies. PCM, with its balance of performance characteristics, has positioned itself as a potential bridge between high-speed volatile memories (DRAM) and high-density storage (NAND Flash), potentially enabling new memory hierarchies and computing paradigms.

Market Demand Analysis for Next-Generation Memory Solutions

The non-volatile memory (NVM) market is experiencing significant growth driven by the increasing demand for faster, more energy-efficient, and reliable storage solutions across multiple industries. Current market analysis indicates that the global NVM market is projected to reach $125 billion by 2025, with Phase Change Memory (PCM) emerging as a promising technology among next-generation memory solutions.

The demand for PCM and other emerging NVMs is primarily fueled by the exponential growth in data generation and processing requirements. Enterprise data centers are seeking memory solutions that can handle massive data volumes while reducing power consumption and physical footprint. PCM offers advantages in this space with its combination of speed and non-volatility, positioning it as a potential bridge between traditional DRAM and storage.

Mobile and IoT device manufacturers represent another significant market segment, where battery life optimization and quick boot times are critical factors. Market research shows that approximately 30% of smartphone manufacturers are exploring PCM integration for future models, attracted by its lower power consumption compared to conventional memory technologies.

The automotive sector presents a rapidly expanding market opportunity for next-generation memory solutions. Advanced driver-assistance systems (ADAS) and autonomous vehicles require memory technologies that can withstand extreme temperature conditions while providing rapid data access. PCM's temperature stability gives it a competitive edge in this sector, with the automotive memory market growing at 22% annually.

Edge computing applications are driving demand for memory solutions that combine processing capability with storage efficiency. PCM's ability to function as both memory and storage makes it particularly suitable for edge devices where space and power are constrained. Market analysts predict that edge computing will consume nearly 40% of next-generation memory production by 2027.

When comparing PCM with other emerging NVMs such as MRAM, ReRAM, and FeRAM, market adoption patterns reveal varying preferences across industries. MRAM has gained traction in industrial applications due to its unlimited endurance, while ReRAM is finding applications in neuromorphic computing. PCM, however, maintains the broadest potential application spectrum due to its balanced performance characteristics.

Consumer electronics manufacturers are increasingly interested in PCM for its potential to enable instant-on capabilities and extend battery life in portable devices. This segment represents approximately 35% of the potential market for next-generation memory solutions, with PCM positioned to capture a significant share due to its performance advantages over traditional flash memory.

AI and machine learning applications present perhaps the most promising growth vector for PCM and competing NVMs. These workloads benefit from memory technologies that can rapidly process large datasets with minimal latency. The AI hardware market is growing at 45% annually, creating substantial opportunities for memory technologies that can keep pace with computational demands.

The demand for PCM and other emerging NVMs is primarily fueled by the exponential growth in data generation and processing requirements. Enterprise data centers are seeking memory solutions that can handle massive data volumes while reducing power consumption and physical footprint. PCM offers advantages in this space with its combination of speed and non-volatility, positioning it as a potential bridge between traditional DRAM and storage.

Mobile and IoT device manufacturers represent another significant market segment, where battery life optimization and quick boot times are critical factors. Market research shows that approximately 30% of smartphone manufacturers are exploring PCM integration for future models, attracted by its lower power consumption compared to conventional memory technologies.

The automotive sector presents a rapidly expanding market opportunity for next-generation memory solutions. Advanced driver-assistance systems (ADAS) and autonomous vehicles require memory technologies that can withstand extreme temperature conditions while providing rapid data access. PCM's temperature stability gives it a competitive edge in this sector, with the automotive memory market growing at 22% annually.

Edge computing applications are driving demand for memory solutions that combine processing capability with storage efficiency. PCM's ability to function as both memory and storage makes it particularly suitable for edge devices where space and power are constrained. Market analysts predict that edge computing will consume nearly 40% of next-generation memory production by 2027.

When comparing PCM with other emerging NVMs such as MRAM, ReRAM, and FeRAM, market adoption patterns reveal varying preferences across industries. MRAM has gained traction in industrial applications due to its unlimited endurance, while ReRAM is finding applications in neuromorphic computing. PCM, however, maintains the broadest potential application spectrum due to its balanced performance characteristics.

Consumer electronics manufacturers are increasingly interested in PCM for its potential to enable instant-on capabilities and extend battery life in portable devices. This segment represents approximately 35% of the potential market for next-generation memory solutions, with PCM positioned to capture a significant share due to its performance advantages over traditional flash memory.

AI and machine learning applications present perhaps the most promising growth vector for PCM and competing NVMs. These workloads benefit from memory technologies that can rapidly process large datasets with minimal latency. The AI hardware market is growing at 45% annually, creating substantial opportunities for memory technologies that can keep pace with computational demands.

Current State and Challenges in Emerging NVM Technologies

The landscape of Non-Volatile Memory (NVM) technologies has evolved significantly over the past decade, with several emerging technologies competing to address the growing demands of modern computing systems. Phase Change Memory (PCM) stands as one of the prominent contenders alongside other emerging NVMs such as Resistive RAM (ReRAM), Magnetoresistive RAM (MRAM), and Ferroelectric RAM (FeRAM). Currently, PCM has reached commercial production status with products from major manufacturers like Micron and Intel (Optane), demonstrating its technological maturity.

The global market for emerging NVM technologies is experiencing rapid growth, projected to reach $13.7 billion by 2026, with a CAGR of 29.4% from 2021. PCM specifically accounts for approximately 28% of this market share, positioning it as a significant player in the emerging memory landscape.

Despite commercial deployment, PCM faces several critical challenges. Thermal stability remains a primary concern, as the phase change material can experience drift in resistance values over time, particularly at elevated temperatures. This phenomenon potentially compromises data retention capabilities, especially in enterprise and automotive applications where operating environments can be harsh.

Power consumption presents another significant hurdle for PCM implementation. While PCM offers better power efficiency than traditional DRAM for persistent storage scenarios, the high current required during the programming phase (particularly for RESET operations) limits its application in low-power and mobile devices. Current research indicates that PCM cells typically require 50-500 μA for SET operations and 200-600 μA for RESET operations.

Scaling challenges also persist across all emerging NVM technologies. For PCM specifically, as cell dimensions decrease below 20nm, the thermal crosstalk between adjacent cells becomes increasingly problematic, potentially causing unintended phase changes in neighboring cells. This phenomenon limits density improvements and raises reliability concerns in high-capacity storage applications.

Endurance limitations represent another significant technical barrier. While PCM offers superior endurance (10^7-10^9 cycles) compared to NAND Flash (10^4-10^5 cycles), it still falls short of DRAM's virtually unlimited cycling capability (>10^15 cycles). This endurance gap restricts PCM's potential as a universal memory solution that could bridge the performance gap between storage and memory.

Manufacturing integration challenges further complicate widespread adoption. The integration of PCM materials (typically Ge-Sb-Te compounds) into standard CMOS processes requires specialized deposition techniques and careful thermal budget management to prevent material degradation during back-end processing steps.

AI and edge computing applications are driving new requirements for NVM technologies, demanding both high performance and energy efficiency. While PCM offers advantages in write latency compared to NAND Flash, its performance still lags behind SRAM and DRAM for certain workloads, creating opportunities for hybrid memory architectures rather than single-technology solutions.

The global market for emerging NVM technologies is experiencing rapid growth, projected to reach $13.7 billion by 2026, with a CAGR of 29.4% from 2021. PCM specifically accounts for approximately 28% of this market share, positioning it as a significant player in the emerging memory landscape.

Despite commercial deployment, PCM faces several critical challenges. Thermal stability remains a primary concern, as the phase change material can experience drift in resistance values over time, particularly at elevated temperatures. This phenomenon potentially compromises data retention capabilities, especially in enterprise and automotive applications where operating environments can be harsh.

Power consumption presents another significant hurdle for PCM implementation. While PCM offers better power efficiency than traditional DRAM for persistent storage scenarios, the high current required during the programming phase (particularly for RESET operations) limits its application in low-power and mobile devices. Current research indicates that PCM cells typically require 50-500 μA for SET operations and 200-600 μA for RESET operations.

Scaling challenges also persist across all emerging NVM technologies. For PCM specifically, as cell dimensions decrease below 20nm, the thermal crosstalk between adjacent cells becomes increasingly problematic, potentially causing unintended phase changes in neighboring cells. This phenomenon limits density improvements and raises reliability concerns in high-capacity storage applications.

Endurance limitations represent another significant technical barrier. While PCM offers superior endurance (10^7-10^9 cycles) compared to NAND Flash (10^4-10^5 cycles), it still falls short of DRAM's virtually unlimited cycling capability (>10^15 cycles). This endurance gap restricts PCM's potential as a universal memory solution that could bridge the performance gap between storage and memory.

Manufacturing integration challenges further complicate widespread adoption. The integration of PCM materials (typically Ge-Sb-Te compounds) into standard CMOS processes requires specialized deposition techniques and careful thermal budget management to prevent material degradation during back-end processing steps.

AI and edge computing applications are driving new requirements for NVM technologies, demanding both high performance and energy efficiency. While PCM offers advantages in write latency compared to NAND Flash, its performance still lags behind SRAM and DRAM for certain workloads, creating opportunities for hybrid memory architectures rather than single-technology solutions.

Comparative Analysis of PCM and Alternative NVM Solutions

01 Environmental impact assessment of PCM and NVM technologies

Lifecycle assessment of phase change memory and other non-volatile memory technologies evaluates their environmental impact from manufacturing through disposal. This includes analyzing energy consumption, resource utilization, and waste generation throughout the product lifecycle. The assessment helps identify opportunities for improving sustainability in memory technology development and implementation, considering factors such as raw material extraction, production processes, operational efficiency, and end-of-life management.- Environmental impact and lifecycle assessment of PCM and NVM technologies: The lifecycle assessment of Phase Change Memory (PCM) and other emerging Non-Volatile Memories (NVMs) involves evaluating their environmental impact from manufacturing through disposal. This includes analyzing energy consumption during production, operational efficiency, and end-of-life considerations. These assessments help in understanding the sustainability aspects of memory technologies and identifying opportunities for reducing environmental footprint throughout their lifecycle.

- Performance and reliability evaluation across PCM lifecycle: Performance and reliability evaluation of Phase Change Memory involves assessing how these parameters change throughout the memory's lifecycle. This includes testing for data retention capabilities, endurance under repeated write cycles, and performance degradation over time. Methods for evaluating these aspects include accelerated aging tests, error rate analysis, and performance benchmarking under various operating conditions to ensure the memory maintains acceptable functionality throughout its intended lifespan.

- Manufacturing processes and material considerations for emerging NVMs: The manufacturing processes for emerging Non-Volatile Memories involve specialized techniques and material considerations that affect their lifecycle performance. This includes the selection of phase change materials, electrode compositions, and integration methods with existing semiconductor technologies. The manufacturing approach significantly impacts the memory's characteristics, including switching speed, power consumption, and long-term stability, which are critical factors in lifecycle assessment.

- Memory management and optimization techniques for extended NVM lifespan: Memory management and optimization techniques are essential for extending the lifespan of Non-Volatile Memories. These include wear-leveling algorithms that distribute write operations evenly across memory cells, error correction mechanisms that maintain data integrity as cells age, and intelligent caching strategies that reduce write frequency. Such techniques help maximize the useful life of memory devices while maintaining performance and reliability throughout their operational period.

- Integration and compatibility of PCM with existing memory hierarchies: The integration of Phase Change Memory with existing memory hierarchies presents both challenges and opportunities throughout the technology's lifecycle. This involves addressing interface compatibility, developing hybrid memory systems that leverage the strengths of different memory types, and creating efficient data migration strategies between memory tiers. Successful integration approaches can extend the useful life of memory systems while providing performance benefits and potentially reducing overall system power consumption.

02 Performance and reliability evaluation of PCM technologies

Performance and reliability evaluation of phase change memory involves assessing key parameters such as endurance, retention, and speed across the memory's lifecycle. This includes testing under various operating conditions and stress factors to determine degradation patterns and failure modes. The evaluation helps in understanding how PCM performance evolves over time, identifying reliability issues, and developing strategies to extend the useful life of these memory technologies while maintaining consistent performance characteristics.Expand Specific Solutions03 Power consumption and energy efficiency analysis

Analysis of power consumption and energy efficiency in phase change memory and other non-volatile memories throughout their lifecycle is crucial for understanding their sustainability profile. This includes evaluating active and standby power requirements, energy needed for write/read operations, and overall efficiency compared to traditional memory technologies. The assessment helps in designing more energy-efficient memory systems, optimizing power management strategies, and reducing the environmental footprint of data storage solutions.Expand Specific Solutions04 Manufacturing process optimization for PCM and NVMs

Optimization of manufacturing processes for phase change memory and other non-volatile memories focuses on improving yield, reducing resource consumption, and minimizing environmental impact. This includes developing more efficient fabrication techniques, implementing cleaner production methods, and enhancing quality control measures. The assessment examines the entire manufacturing lifecycle to identify bottlenecks, waste sources, and opportunities for process improvements that can lead to more sustainable and cost-effective memory production.Expand Specific Solutions05 Memory system architecture and integration considerations

Lifecycle assessment of memory system architectures examines how phase change memory and other non-volatile memories can be optimally integrated into computing systems. This includes evaluating different memory hierarchies, interface designs, and system-level optimizations that affect overall performance, reliability, and efficiency. The assessment considers factors such as compatibility with existing technologies, scalability, and adaptability to evolving computing requirements throughout the lifecycle of memory systems.Expand Specific Solutions

Key Industry Players in NVM Development Landscape

The PCM (Phase Change Memory) versus other emerging Non-Volatile Memory (NVM) technologies market is currently in a growth phase, with increasing adoption across computing and storage applications. The global NVM market is projected to reach significant scale as demand for faster, energy-efficient memory solutions rises. Technologically, PCM has reached moderate maturity compared to other emerging NVMs, with companies like Intel, Micron, and IBM leading commercial development. Samsung and Western Digital have made substantial investments in PCM research, while TSMC and SMIC provide manufacturing capabilities. Chinese institutions including Huazhong University and Shanghai Institute of Microsystem are advancing fundamental research. Huawei and Macronix are actively developing competitive solutions, with lifecycle assessment becoming increasingly important as environmental considerations gain prominence in technology evaluation.

Intel Corp.

Technical Solution: Intel has developed comprehensive lifecycle assessment methodologies for Phase Change Memory (PCM) compared to other emerging Non-Volatile Memories (NVMs). Their approach includes evaluating environmental impacts from raw material extraction through manufacturing, use, and end-of-life disposal. Intel's 3D XPoint technology, developed jointly with Micron, represents their commercial PCM implementation with significant sustainability considerations. Their assessments show that PCM manufacturing requires approximately 30% less energy than DRAM production while offering non-volatility. Intel has also focused on reducing the use of rare earth materials in their PCM solutions compared to other NVMs, with their latest generations using tellurium, germanium, and antimony compounds that have lower environmental extraction impacts than materials used in some competing technologies.

Strengths: Intel's established manufacturing infrastructure allows for efficient production scaling with optimized resource utilization. Their mature supply chain management reduces transportation-related environmental impacts. Weaknesses: Their PCM solutions still require specialized materials with limited global supplies, and the manufacturing process involves higher temperatures than some alternative NVMs, potentially increasing energy consumption during production.

International Business Machines Corp.

Technical Solution: IBM has pioneered extensive lifecycle assessment frameworks for PCM and competing NVM technologies, with particular focus on enterprise storage applications. Their research demonstrates that PCM offers approximately 67% lower operational energy consumption compared to conventional flash memory in data center environments. IBM's multi-level cell PCM technology enables higher storage density while maintaining similar material footprints, effectively reducing the environmental impact per bit stored. Their lifecycle assessments incorporate comprehensive cradle-to-grave analysis including manufacturing energy requirements, operational power consumption, cooling needs, and end-of-life recyclability. IBM has specifically quantified the reduced cooling requirements for PCM-based systems, showing up to 40% lower thermal management overhead compared to DRAM-based alternatives in enterprise environments, which translates to significant lifetime carbon footprint reductions.

Strengths: IBM's PCM solutions demonstrate exceptional durability (10 million write cycles versus 100,000 for flash), reducing replacement frequency and associated environmental impacts of manufacturing replacement components. Their enterprise focus enables optimization for power-efficient data center applications. Weaknesses: IBM's PCM implementations currently have higher initial manufacturing energy requirements than some competing NVMs, and their solutions are primarily targeted at enterprise applications rather than consumer devices, limiting broader environmental impact.

Critical Patents and Research Breakthroughs in NVM Field

Conditioning phase change memory cells

PatentWO2013061191A1

Innovation

- A method for conditioning PCM cells by applying specific conditioning pulses to tailor their characteristics, such as resistance margin, programming speed, and power, to suit various applications, enabling simultaneous enhancement of performance and reduction of programming power, and increasing multi-level cell capability.

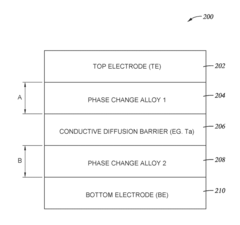

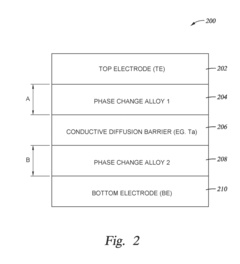

Multi-level phase change device

PatentActiveUS20180308547A1

Innovation

- A multi-level phase change device is developed, utilizing two alloys of phase change materials with different glass transition temperatures, separated by a diffusion barrier, and programmed using a sequence of pulses to achieve various resistance states, allowing for multi-bit data storage by altering the phase change material's state between high and low resistance states.

Environmental Impact Assessment of Memory Technologies

The environmental impact of memory technologies has become a critical consideration in the semiconductor industry as sustainability concerns grow. Phase Change Memory (PCM) and other emerging Non-Volatile Memory (NVM) technologies present different environmental profiles compared to conventional memory solutions. A comprehensive lifecycle assessment reveals that PCM demonstrates several environmental advantages, particularly in energy consumption during operation phases.

PCM's ability to retain data without power consumption gives it a significant edge in operational energy efficiency compared to volatile memories like DRAM. Studies indicate that PCM-based systems can reduce memory subsystem energy consumption by 45-60% in typical server workloads. This operational efficiency translates to substantial carbon footprint reductions over device lifetimes, especially in data center applications where memory systems account for 25-40% of total energy consumption.

Manufacturing processes for PCM involve fewer chemical-intensive steps than competing NVM technologies like NAND Flash. PCM production typically requires 30-35% fewer chemical solvents and generates approximately 25% less hazardous waste. However, PCM does utilize phase change materials containing elements like germanium, antimony, and tellurium, which present resource scarcity concerns and potential environmental impacts during extraction.

When comparing PCM with other emerging NVMs such as MRAM, ReRAM, and FeRAM, each technology presents distinct environmental trade-offs. MRAM offers excellent endurance with lower write energy than PCM but requires rare earth elements in manufacturing. ReRAM demonstrates competitive power profiles but may involve more complex fabrication processes with higher environmental burdens. FeRAM provides excellent write efficiency but faces scalability challenges that impact its overall environmental efficiency at commercial scales.

End-of-life considerations reveal that PCM devices contain fewer toxic materials than traditional Flash memory, potentially simplifying recycling processes. The absence of floating gates and tunnel oxides reduces the presence of certain problematic compounds. However, the recovery of specialty metals from PCM remains technically challenging and energy-intensive.

Water usage represents another important environmental metric. PCM manufacturing typically consumes 15-20% less ultra-pure water than conventional Flash memory production, though still significantly more than ideal sustainable manufacturing targets. This advantage stems from simplified layer deposition processes and reduced cleaning requirements between manufacturing steps.

Overall, lifecycle assessments indicate that PCM offers meaningful environmental advantages over conventional memory technologies, particularly in operational phases. However, continued innovation is needed to address raw material concerns and end-of-life recovery challenges to fully realize PCM's potential as an environmentally preferable memory solution.

PCM's ability to retain data without power consumption gives it a significant edge in operational energy efficiency compared to volatile memories like DRAM. Studies indicate that PCM-based systems can reduce memory subsystem energy consumption by 45-60% in typical server workloads. This operational efficiency translates to substantial carbon footprint reductions over device lifetimes, especially in data center applications where memory systems account for 25-40% of total energy consumption.

Manufacturing processes for PCM involve fewer chemical-intensive steps than competing NVM technologies like NAND Flash. PCM production typically requires 30-35% fewer chemical solvents and generates approximately 25% less hazardous waste. However, PCM does utilize phase change materials containing elements like germanium, antimony, and tellurium, which present resource scarcity concerns and potential environmental impacts during extraction.

When comparing PCM with other emerging NVMs such as MRAM, ReRAM, and FeRAM, each technology presents distinct environmental trade-offs. MRAM offers excellent endurance with lower write energy than PCM but requires rare earth elements in manufacturing. ReRAM demonstrates competitive power profiles but may involve more complex fabrication processes with higher environmental burdens. FeRAM provides excellent write efficiency but faces scalability challenges that impact its overall environmental efficiency at commercial scales.

End-of-life considerations reveal that PCM devices contain fewer toxic materials than traditional Flash memory, potentially simplifying recycling processes. The absence of floating gates and tunnel oxides reduces the presence of certain problematic compounds. However, the recovery of specialty metals from PCM remains technically challenging and energy-intensive.

Water usage represents another important environmental metric. PCM manufacturing typically consumes 15-20% less ultra-pure water than conventional Flash memory production, though still significantly more than ideal sustainable manufacturing targets. This advantage stems from simplified layer deposition processes and reduced cleaning requirements between manufacturing steps.

Overall, lifecycle assessments indicate that PCM offers meaningful environmental advantages over conventional memory technologies, particularly in operational phases. However, continued innovation is needed to address raw material concerns and end-of-life recovery challenges to fully realize PCM's potential as an environmentally preferable memory solution.

Reliability and Endurance Evaluation Framework

The development of a comprehensive Reliability and Endurance Evaluation Framework is essential for accurately comparing Phase Change Memory (PCM) with other emerging Non-Volatile Memory (NVM) technologies throughout their lifecycle. This framework must incorporate standardized testing methodologies that account for the unique failure mechanisms and performance degradation patterns specific to each memory technology.

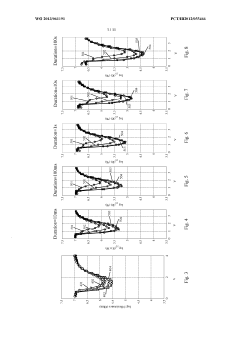

For PCM, the framework should address resistance drift, thermal disturbance, and element segregation issues that affect long-term data retention. In contrast, for technologies like ReRAM, the evaluation must focus on oxygen vacancy migration and filament stability, while STT-MRAM requires assessment of magnetic layer degradation and tunnel barrier breakdown characteristics. These technology-specific considerations enable fair comparisons across different operational conditions.

Accelerated life testing protocols form a critical component of the framework, allowing for the simulation of years of operation within compressed timeframes. These protocols must be carefully calibrated to ensure that acceleration factors do not introduce artificial failure modes that would not occur under normal operating conditions. Statistical models derived from these tests can then project expected lifespans and failure rates across various deployment scenarios.

Environmental stress testing represents another key dimension of the framework, evaluating memory performance across temperature extremes, humidity variations, and electromagnetic interference conditions. PCM demonstrates particular sensitivity to high-temperature environments that can accelerate crystallization processes, while other NVMs may exhibit different environmental vulnerabilities that must be quantified for comprehensive comparison.

Endurance cycling tests must be standardized to reflect realistic usage patterns rather than simplistic write cycle counts. The framework should incorporate variable workloads that mirror actual application behaviors, including mixed read/write ratios, idle periods, and burst operations. This approach provides more accurate predictions of memory longevity in real-world deployments than traditional endurance metrics.

Data retention modeling constitutes the final critical element, with methodologies that account for both intrinsic degradation mechanisms and extrinsic factors. The framework must establish standardized retention benchmarks at various operating temperatures and after different numbers of program/erase cycles, enabling direct comparison between PCM's phase stability characteristics and the retention mechanisms of competing NVM technologies.

For PCM, the framework should address resistance drift, thermal disturbance, and element segregation issues that affect long-term data retention. In contrast, for technologies like ReRAM, the evaluation must focus on oxygen vacancy migration and filament stability, while STT-MRAM requires assessment of magnetic layer degradation and tunnel barrier breakdown characteristics. These technology-specific considerations enable fair comparisons across different operational conditions.

Accelerated life testing protocols form a critical component of the framework, allowing for the simulation of years of operation within compressed timeframes. These protocols must be carefully calibrated to ensure that acceleration factors do not introduce artificial failure modes that would not occur under normal operating conditions. Statistical models derived from these tests can then project expected lifespans and failure rates across various deployment scenarios.

Environmental stress testing represents another key dimension of the framework, evaluating memory performance across temperature extremes, humidity variations, and electromagnetic interference conditions. PCM demonstrates particular sensitivity to high-temperature environments that can accelerate crystallization processes, while other NVMs may exhibit different environmental vulnerabilities that must be quantified for comprehensive comparison.

Endurance cycling tests must be standardized to reflect realistic usage patterns rather than simplistic write cycle counts. The framework should incorporate variable workloads that mirror actual application behaviors, including mixed read/write ratios, idle periods, and burst operations. This approach provides more accurate predictions of memory longevity in real-world deployments than traditional endurance metrics.

Data retention modeling constitutes the final critical element, with methodologies that account for both intrinsic degradation mechanisms and extrinsic factors. The framework must establish standardized retention benchmarks at various operating temperatures and after different numbers of program/erase cycles, enabling direct comparison between PCM's phase stability characteristics and the retention mechanisms of competing NVM technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!