Market Dynamics of Cold Plasma Treatment in Food Industry Applications

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cold Plasma Technology Evolution and Objectives

Cold plasma technology has evolved significantly over the past several decades, transitioning from primarily industrial applications to emerging food safety solutions. Initially developed in the early 20th century for material surface modifications, cold plasma technology remained largely confined to semiconductor manufacturing, medical sterilization, and polymer treatment until the early 2000s. The fundamental breakthrough enabling its application in food processing came with the development of atmospheric pressure cold plasma systems, eliminating the need for vacuum chambers that made earlier plasma technologies impractical for food applications.

The evolution accelerated around 2010-2015 when researchers demonstrated cold plasma's efficacy in microbial inactivation without thermal damage to heat-sensitive food products. This represented a critical turning point, as conventional food preservation methods typically involve heat treatments that can compromise nutritional value and sensory qualities. The non-thermal nature of cold plasma offered a promising alternative that aligned with growing consumer demand for minimally processed foods.

Technical advancements in plasma generation methods have been pivotal in this evolution. Early systems relied primarily on dielectric barrier discharge (DBD) technology, while recent innovations have expanded to include atmospheric pressure plasma jets, microwave-induced plasma, and surface micro-discharge systems. Each generation has improved energy efficiency, treatment uniformity, and operational flexibility, making the technology increasingly viable for commercial food applications.

The regulatory landscape has also shaped the technology's trajectory. Initially facing significant hurdles due to limited safety data and regulatory frameworks, cold plasma treatments have gradually gained recognition from food safety authorities. The European Food Safety Authority and the FDA have begun establishing guidelines for plasma applications, though comprehensive regulatory approval remains an ongoing process in many regions.

The primary objectives driving cold plasma technology development in the food industry include: achieving consistent microbial reduction across diverse food matrices; minimizing impacts on nutritional and sensory properties; developing cost-effective and scalable systems suitable for industrial implementation; establishing standardized treatment protocols; and addressing regulatory requirements for novel food processing technologies.

Current research focuses on optimizing plasma chemistry for specific food applications, understanding interaction mechanisms between reactive species and food components, and developing in-line monitoring systems to ensure treatment efficacy. The technology aims to provide the food industry with a versatile tool that can address emerging food safety challenges while meeting consumer expectations for minimally processed products with extended shelf life and preserved nutritional qualities.

The evolution accelerated around 2010-2015 when researchers demonstrated cold plasma's efficacy in microbial inactivation without thermal damage to heat-sensitive food products. This represented a critical turning point, as conventional food preservation methods typically involve heat treatments that can compromise nutritional value and sensory qualities. The non-thermal nature of cold plasma offered a promising alternative that aligned with growing consumer demand for minimally processed foods.

Technical advancements in plasma generation methods have been pivotal in this evolution. Early systems relied primarily on dielectric barrier discharge (DBD) technology, while recent innovations have expanded to include atmospheric pressure plasma jets, microwave-induced plasma, and surface micro-discharge systems. Each generation has improved energy efficiency, treatment uniformity, and operational flexibility, making the technology increasingly viable for commercial food applications.

The regulatory landscape has also shaped the technology's trajectory. Initially facing significant hurdles due to limited safety data and regulatory frameworks, cold plasma treatments have gradually gained recognition from food safety authorities. The European Food Safety Authority and the FDA have begun establishing guidelines for plasma applications, though comprehensive regulatory approval remains an ongoing process in many regions.

The primary objectives driving cold plasma technology development in the food industry include: achieving consistent microbial reduction across diverse food matrices; minimizing impacts on nutritional and sensory properties; developing cost-effective and scalable systems suitable for industrial implementation; establishing standardized treatment protocols; and addressing regulatory requirements for novel food processing technologies.

Current research focuses on optimizing plasma chemistry for specific food applications, understanding interaction mechanisms between reactive species and food components, and developing in-line monitoring systems to ensure treatment efficacy. The technology aims to provide the food industry with a versatile tool that can address emerging food safety challenges while meeting consumer expectations for minimally processed products with extended shelf life and preserved nutritional qualities.

Food Industry Market Demand Analysis

The global food industry is experiencing a significant shift towards advanced preservation technologies, with cold plasma treatment emerging as a promising solution. Market research indicates that the global food safety testing market, which includes novel preservation technologies, is projected to reach $24.6 billion by 2025, growing at a CAGR of 7.7%. Within this broader market, cold plasma technology for food applications is gaining substantial traction due to its non-thermal nature and minimal impact on nutritional and sensory properties.

Consumer demand for minimally processed foods with extended shelf life has created a substantial market opportunity for cold plasma technology. Recent surveys reveal that approximately 68% of consumers globally prefer food products with fewer chemical preservatives, creating a direct market pull for physical preservation methods like cold plasma treatment. This consumer preference is particularly pronounced in developed markets across North America and Europe, where willingness to pay premium prices for "clean label" products is highest.

The fresh produce segment represents the largest potential application area, with market analysts estimating that cold plasma solutions could address preservation needs for approximately 40% of the global fresh fruit and vegetable market. Meat and poultry processors are also showing increased interest, with industry reports indicating that around 35% of processors are actively exploring non-thermal preservation technologies including cold plasma.

Regulatory developments are further driving market demand, with stricter food safety standards being implemented globally. The FDA's Food Safety Modernization Act in the US and similar regulations in the EU have created a regulatory environment that favors adoption of innovative preservation technologies. This regulatory push is expected to accelerate market adoption of cold plasma technology over the next five years.

Regional analysis shows varying levels of market readiness. North America currently leads in terms of cold plasma technology adoption in food applications, followed by Europe. The Asia-Pacific region, particularly China, Japan, and South Korea, is projected to witness the fastest growth rate in adoption, driven by rapid modernization of food processing infrastructure and increasing consumer awareness about food safety.

Economic factors also support market growth, with cold plasma systems offering potential operational cost savings of 15-25% compared to conventional thermal processing when considering energy consumption, processing time, and reduced product loss. These economic benefits are particularly attractive to medium and large-scale food processors seeking to optimize operational efficiency while meeting evolving consumer demands.

Consumer demand for minimally processed foods with extended shelf life has created a substantial market opportunity for cold plasma technology. Recent surveys reveal that approximately 68% of consumers globally prefer food products with fewer chemical preservatives, creating a direct market pull for physical preservation methods like cold plasma treatment. This consumer preference is particularly pronounced in developed markets across North America and Europe, where willingness to pay premium prices for "clean label" products is highest.

The fresh produce segment represents the largest potential application area, with market analysts estimating that cold plasma solutions could address preservation needs for approximately 40% of the global fresh fruit and vegetable market. Meat and poultry processors are also showing increased interest, with industry reports indicating that around 35% of processors are actively exploring non-thermal preservation technologies including cold plasma.

Regulatory developments are further driving market demand, with stricter food safety standards being implemented globally. The FDA's Food Safety Modernization Act in the US and similar regulations in the EU have created a regulatory environment that favors adoption of innovative preservation technologies. This regulatory push is expected to accelerate market adoption of cold plasma technology over the next five years.

Regional analysis shows varying levels of market readiness. North America currently leads in terms of cold plasma technology adoption in food applications, followed by Europe. The Asia-Pacific region, particularly China, Japan, and South Korea, is projected to witness the fastest growth rate in adoption, driven by rapid modernization of food processing infrastructure and increasing consumer awareness about food safety.

Economic factors also support market growth, with cold plasma systems offering potential operational cost savings of 15-25% compared to conventional thermal processing when considering energy consumption, processing time, and reduced product loss. These economic benefits are particularly attractive to medium and large-scale food processors seeking to optimize operational efficiency while meeting evolving consumer demands.

Global Cold Plasma Technology Landscape

Cold plasma technology has emerged as a revolutionary approach in food processing, with global adoption accelerating over the past decade. The technology landscape spans across North America, Europe, and Asia-Pacific regions, with each contributing unique advancements to the field. North America leads in research and commercial applications, particularly in the United States where regulatory frameworks have evolved to accommodate this novel technology. Europe follows closely, with countries like Germany and the Netherlands pioneering specialized applications for dairy and meat processing industries.

The global cold plasma technology ecosystem encompasses various technical approaches, primarily divided into atmospheric pressure plasma and low-pressure plasma systems. Atmospheric pressure systems dominate the food industry applications due to their operational flexibility and lower implementation costs. Within this category, dielectric barrier discharge (DBD) and plasma jet systems represent the most widely adopted configurations, accounting for approximately 65% of current installations worldwide.

From a technological maturity perspective, cold plasma applications in food safety have reached commercial viability, while applications in shelf-life extension and functional modification of food properties remain in advanced development stages. The technology readiness level (TRL) varies significantly across applications, with decontamination solutions reaching TRL 8-9, while nutrient preservation applications typically fall within TRL 5-6.

Key technological hubs have emerged globally, with notable research clusters in California (USA), Eindhoven (Netherlands), Munich (Germany), and Osaka (Japan). These hubs have developed specialized expertise in different aspects of cold plasma technology, from equipment miniaturization to plasma chemistry optimization for specific food matrices. Cross-border collaboration between these hubs has accelerated in recent years, particularly in standardizing measurement protocols and safety parameters.

The intellectual property landscape reveals concentrated patent activity, with over 1,200 active patents related to cold plasma food applications filed in the last five years. Patent density analysis shows a significant focus on electrode design innovations (32%), process control systems (27%), and application-specific configurations (25%). The remaining patents cover novel power supply systems and integration technologies for existing production lines.

Global investment in cold plasma food technology has seen a compound annual growth rate of 22% since 2018, reaching approximately $450 million in 2022. This investment has primarily targeted scaling challenges and cost reduction initiatives, with significant progress in reducing both capital expenditure and operational costs by an average of 35% compared to first-generation systems.

The global cold plasma technology ecosystem encompasses various technical approaches, primarily divided into atmospheric pressure plasma and low-pressure plasma systems. Atmospheric pressure systems dominate the food industry applications due to their operational flexibility and lower implementation costs. Within this category, dielectric barrier discharge (DBD) and plasma jet systems represent the most widely adopted configurations, accounting for approximately 65% of current installations worldwide.

From a technological maturity perspective, cold plasma applications in food safety have reached commercial viability, while applications in shelf-life extension and functional modification of food properties remain in advanced development stages. The technology readiness level (TRL) varies significantly across applications, with decontamination solutions reaching TRL 8-9, while nutrient preservation applications typically fall within TRL 5-6.

Key technological hubs have emerged globally, with notable research clusters in California (USA), Eindhoven (Netherlands), Munich (Germany), and Osaka (Japan). These hubs have developed specialized expertise in different aspects of cold plasma technology, from equipment miniaturization to plasma chemistry optimization for specific food matrices. Cross-border collaboration between these hubs has accelerated in recent years, particularly in standardizing measurement protocols and safety parameters.

The intellectual property landscape reveals concentrated patent activity, with over 1,200 active patents related to cold plasma food applications filed in the last five years. Patent density analysis shows a significant focus on electrode design innovations (32%), process control systems (27%), and application-specific configurations (25%). The remaining patents cover novel power supply systems and integration technologies for existing production lines.

Global investment in cold plasma food technology has seen a compound annual growth rate of 22% since 2018, reaching approximately $450 million in 2022. This investment has primarily targeted scaling challenges and cost reduction initiatives, with significant progress in reducing both capital expenditure and operational costs by an average of 35% compared to first-generation systems.

Current Cold Plasma Food Treatment Solutions

01 Medical applications of cold plasma treatment

Cold plasma technology is being utilized in various medical applications for treatment of tissues and wounds. The non-thermal plasma can effectively kill bacteria and promote healing without damaging surrounding healthy tissue. This technology is particularly useful for treating chronic wounds, infections, and certain skin conditions. The controlled application of cold plasma can stimulate tissue regeneration while simultaneously providing antimicrobial effects.- Medical applications of cold plasma treatment: Cold plasma technology is being utilized in various medical applications for treatment of tissues and wounds. The non-thermal plasma can effectively kill bacteria and promote healing without damaging surrounding healthy tissue. These treatments can be applied to chronic wounds, dermatological conditions, and even in dental procedures. The controlled application of cold plasma allows for targeted therapy with minimal side effects compared to traditional treatments.

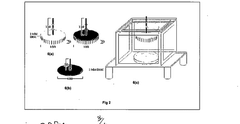

- Cold plasma devices and delivery systems: Various devices and systems have been developed for the generation and delivery of cold plasma for therapeutic and industrial applications. These include handheld devices, plasma jets, and integrated treatment systems that can produce controlled plasma discharge. The designs focus on safety, precision, and ease of use, with some incorporating specialized electrodes, gas delivery mechanisms, and power control systems to ensure consistent plasma generation and application.

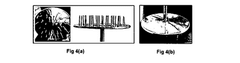

- Surface modification and sterilization using cold plasma: Cold plasma treatment is effective for modifying surface properties of materials and sterilizing various objects. The technology can alter surface chemistry, improve adhesion properties, and enhance biocompatibility of materials. In sterilization applications, cold plasma can inactivate microorganisms on heat-sensitive materials without causing thermal damage. This makes it particularly valuable in medical device manufacturing, food processing, and pharmaceutical industries where traditional heat sterilization methods may be unsuitable.

- Agricultural and food processing applications: Cold plasma technology is being applied in agriculture and food processing for decontamination, seed treatment, and shelf-life extension. The treatment can effectively eliminate pathogens and fungi on food surfaces without affecting nutritional quality or taste. In agricultural applications, cold plasma can enhance seed germination rates and plant growth by modifying seed surfaces and eliminating harmful microorganisms. These applications offer environmentally friendly alternatives to chemical treatments in food safety and agricultural production.

- Industrial and environmental applications: Cold plasma treatment has significant applications in industrial processes and environmental remediation. It can be used for wastewater treatment, air purification, and degradation of pollutants through advanced oxidation processes. In manufacturing, cold plasma enables surface activation for improved coating adhesion, printing, and bonding of materials that are otherwise difficult to join. The technology offers energy-efficient alternatives to conventional chemical processes, reducing environmental impact while improving process efficiency.

02 Cold plasma devices for therapeutic use

Specialized devices have been developed for delivering cold plasma treatment in therapeutic settings. These devices are designed to generate and apply non-thermal plasma safely to biological tissues. They include handheld applicators, plasma jets, and integrated systems with precise control mechanisms for treatment parameters. The devices incorporate various electrode configurations and gas delivery systems to produce specific plasma characteristics suitable for different medical applications.Expand Specific Solutions03 Cold plasma for surface modification and sterilization

Cold plasma treatment is effective for modifying surface properties of materials and sterilizing various objects. The technology can alter surface chemistry, improve wettability, and enhance adhesion properties without affecting bulk material characteristics. In sterilization applications, cold plasma can inactivate microorganisms on heat-sensitive materials that cannot withstand traditional high-temperature sterilization methods. This makes it particularly valuable for medical devices, packaging materials, and sensitive equipment.Expand Specific Solutions04 Agricultural and food processing applications

Cold plasma technology is being applied in agriculture and food processing for decontamination, seed treatment, and shelf-life extension. The treatment can effectively eliminate pathogens and spoilage microorganisms on food surfaces without altering nutritional content or sensory qualities. In agricultural applications, cold plasma can improve seed germination rates and plant growth by modifying seed surface properties and eliminating harmful microorganisms. This technology offers an environmentally friendly alternative to chemical treatments.Expand Specific Solutions05 Industrial and environmental applications

Cold plasma treatment has diverse industrial and environmental applications including wastewater treatment, air purification, and surface cleaning. The technology can break down pollutants and contaminants through oxidation processes without requiring high temperatures or harmful chemicals. In manufacturing, cold plasma is used for surface preparation before coating or bonding, improving adhesion properties and product quality. The versatility of cold plasma systems allows for integration into various industrial processes with minimal disruption to existing workflows.Expand Specific Solutions

Key Industry Players and Competitive Analysis

The cold plasma treatment market in the food industry is in an early growth phase, characterized by increasing adoption but still evolving technological maturity. The global market size is expanding rapidly, driven by growing demand for non-thermal food preservation methods and extended shelf-life solutions. From a technological standpoint, companies like Air Liquide, Plasmapp, and US Medical Innovations are leading commercial applications, while research institutions such as Purdue Research Foundation, Zhejiang University, and China Agricultural University are advancing fundamental science. The competitive landscape features a mix of specialized plasma technology firms (Plasmapp, CAPS Medical), large industrial gas companies (Air Liquide), and academic-industry partnerships developing novel food safety applications, indicating significant potential for market expansion as the technology matures.

Plasmology4, Inc.

Technical Solution: Plasmology4 has developed a patented cold plasma technology called Symphion™ that utilizes a unique combination of noble gases and electromagnetic field generators to create stable, controlled plasma environments for food treatment. Their system features a proprietary electrode design that enables uniform plasma distribution across varying food surfaces and geometries. The technology incorporates advanced feedback control systems that continuously monitor and adjust plasma parameters based on food characteristics, ensuring consistent treatment efficacy. Plasmology4's innovation includes specialized plasma delivery mechanisms for different food applications, including direct surface treatment for solid foods and bubble-based plasma diffusion for liquid products. Their research has demonstrated significant reductions in microbial load while preserving nutritional content, with minimal impact on sensory attributes across various food categories.

Strengths: Highly adaptable system design accommodates diverse food products; sophisticated control systems ensure treatment consistency; demonstrated efficacy against biofilms and hard-to-reach surface contaminants. Weaknesses: Technology requires specialized training for operators; higher energy consumption compared to some conventional methods.

Air Liquide SA

Technical Solution: Air Liquide has developed an advanced cold plasma technology platform called ACXYS specifically tailored for food industry applications. Their system utilizes a proprietary gas mixture optimization approach that enhances antimicrobial efficacy while minimizing treatment time. The technology employs atmospheric pressure plasma jets (APPJ) with precisely controlled gas composition to generate specific reactive species targeted at different food contaminants. Air Liquide's innovation includes a modular design that can be configured for in-line processing of various food products, from fresh produce to packaged goods. Their system features advanced gas flow control mechanisms that ensure uniform plasma distribution across treatment surfaces, addressing a key challenge in industrial-scale applications. The company has successfully implemented this technology in commercial settings, demonstrating 3-5 log reductions in pathogenic bacteria while maintaining organoleptic properties of treated foods.

Strengths: Extensive gas expertise allows for optimized plasma chemistry; established global infrastructure supports rapid deployment and service; demonstrated compatibility with high-throughput industrial processing. Weaknesses: Requires continuous supply of specialized gas mixtures; higher operational costs compared to some competing technologies.

Critical Patents and Technical Innovations

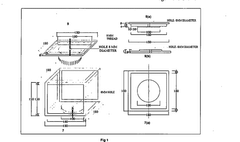

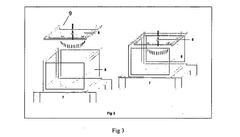

A cold plasma system and its method for preservation of food

PatentPendingIN202441030833A

Innovation

- A cost-effective cold plasma system using a dielectric barrier discharge (DBD) configuration with a flyback transformer, zero voltage switching (ZVS) circuit, and Cockcroft Walton Voltage Multiplier (CWVM) to generate atmospheric pressure cold plasma, effectively decontaminating food surfaces and extending shelf life without compromising quality.

Patent

Innovation

- Development of non-thermal cold plasma treatment systems that effectively decontaminate food surfaces while preserving nutritional and sensory qualities.

- Design of specialized cold plasma delivery mechanisms tailored for different food matrices (solid, liquid, powdered) that ensure uniform treatment and maximum efficacy.

- Creation of sustainable cold plasma systems with reduced energy consumption and environmentally friendly working gases that maintain antimicrobial efficacy while improving cost-effectiveness for industrial applications.

Regulatory Framework for Novel Food Technologies

The regulatory landscape for cold plasma technology in food processing represents a complex and evolving framework that significantly impacts market adoption and commercialization pathways. Currently, cold plasma applications in the food industry operate within regulatory structures that were not specifically designed for this novel technology, creating challenges for manufacturers and technology providers.

In the United States, the Food and Drug Administration (FDA) evaluates cold plasma technology primarily under existing frameworks for food additives and food contact substances. The FDA has not yet established specific guidelines for cold plasma applications, requiring companies to demonstrate safety through extensive scientific documentation. The Generally Recognized as Safe (GRAS) pathway offers one potential route for approval, though the burden of proof remains substantial.

The European Union approaches novel food technologies through the European Food Safety Authority (EFSA), which implements a more precautionary regulatory stance. Cold plasma applications must undergo rigorous safety assessments under Regulation (EC) No 1935/2004 for food contact materials and Regulation (EC) No 852/2004 for food hygiene. The Novel Food Regulation (EU) 2015/2283 may also apply depending on specific applications, creating additional regulatory hurdles.

Asian markets present varying regulatory approaches, with Japan's Food Sanitation Law requiring approval for new food processing technologies, while China's National Food Safety Standard system continues to evolve its position on novel technologies like cold plasma. These regional differences create significant challenges for global technology deployment and market harmonization.

Labeling requirements represent another critical regulatory consideration. In most jurisdictions, food products treated with cold plasma technology may require specific labeling to inform consumers, potentially affecting market perception and consumer acceptance. The lack of standardized terminology for cold plasma treatment further complicates compliance with these requirements.

Industry stakeholders are actively engaging with regulatory bodies to develop more appropriate frameworks for cold plasma technology. The International Plasma Food Safety Consortium, comprising industry leaders and academic institutions, is working to establish standardized testing protocols and safety parameters that could inform future regulatory guidelines. These collaborative efforts aim to create more predictable and streamlined approval pathways.

The regulatory environment is expected to evolve significantly over the next five years as scientific evidence accumulates and regulatory familiarity with cold plasma technology increases. Early adopters who engage proactively with regulatory authorities and contribute to the development of standards may gain competitive advantages in this emerging market space.

In the United States, the Food and Drug Administration (FDA) evaluates cold plasma technology primarily under existing frameworks for food additives and food contact substances. The FDA has not yet established specific guidelines for cold plasma applications, requiring companies to demonstrate safety through extensive scientific documentation. The Generally Recognized as Safe (GRAS) pathway offers one potential route for approval, though the burden of proof remains substantial.

The European Union approaches novel food technologies through the European Food Safety Authority (EFSA), which implements a more precautionary regulatory stance. Cold plasma applications must undergo rigorous safety assessments under Regulation (EC) No 1935/2004 for food contact materials and Regulation (EC) No 852/2004 for food hygiene. The Novel Food Regulation (EU) 2015/2283 may also apply depending on specific applications, creating additional regulatory hurdles.

Asian markets present varying regulatory approaches, with Japan's Food Sanitation Law requiring approval for new food processing technologies, while China's National Food Safety Standard system continues to evolve its position on novel technologies like cold plasma. These regional differences create significant challenges for global technology deployment and market harmonization.

Labeling requirements represent another critical regulatory consideration. In most jurisdictions, food products treated with cold plasma technology may require specific labeling to inform consumers, potentially affecting market perception and consumer acceptance. The lack of standardized terminology for cold plasma treatment further complicates compliance with these requirements.

Industry stakeholders are actively engaging with regulatory bodies to develop more appropriate frameworks for cold plasma technology. The International Plasma Food Safety Consortium, comprising industry leaders and academic institutions, is working to establish standardized testing protocols and safety parameters that could inform future regulatory guidelines. These collaborative efforts aim to create more predictable and streamlined approval pathways.

The regulatory environment is expected to evolve significantly over the next five years as scientific evidence accumulates and regulatory familiarity with cold plasma technology increases. Early adopters who engage proactively with regulatory authorities and contribute to the development of standards may gain competitive advantages in this emerging market space.

Environmental Impact and Sustainability Assessment

Cold plasma treatment in the food industry represents a significant advancement in sustainable food processing technologies. When evaluating its environmental impact, it becomes evident that this technology offers substantial advantages over conventional thermal and chemical treatments. Cold plasma systems typically consume less energy than traditional heat-based processing methods, with studies indicating energy reductions of 20-40% depending on the specific application and scale of implementation. This reduced energy footprint translates directly to lower greenhouse gas emissions throughout the food processing chain.

Water conservation represents another critical environmental benefit of cold plasma technology. Unlike conventional washing and sanitizing processes that may require large volumes of water and chemical sanitizers, cold plasma treatments operate in dry or semi-dry conditions. Research conducted across multiple food processing facilities demonstrates water usage reductions of up to 80% when implementing cold plasma systems as replacements for traditional washing lines.

The chemical-free nature of cold plasma technology further enhances its sustainability profile. By generating reactive species directly from ambient air or other gases, cold plasma eliminates the need for chemical preservatives, sanitizers, and fumigants that can leave residues and create disposal challenges. This reduction in chemical usage minimizes environmental contamination risks and reduces the chemical burden in wastewater streams from food processing facilities.

Waste reduction capabilities represent another significant environmental advantage. Cold plasma treatments can extend product shelf life by 30-200% depending on the food commodity, substantially reducing food waste throughout the supply chain. This extension of usable product life addresses one of the food industry's most pressing sustainability challenges, as food waste accounts for approximately 8-10% of global greenhouse gas emissions.

Life cycle assessments of cold plasma implementation in various food processing scenarios reveal favorable environmental profiles compared to conventional technologies. These assessments typically show reduced carbon footprints, water usage, and overall environmental impact scores. However, certain plasma generation methods may require rare gases or specialized components with their own environmental considerations during manufacturing and disposal phases.

Regulatory frameworks are increasingly recognizing cold plasma's environmental benefits, with several countries developing specific sustainability incentives for food processors adopting this technology. These incentives acknowledge cold plasma's potential contribution to meeting industry-wide sustainability targets and reducing the environmental footprint of food production systems globally.

Water conservation represents another critical environmental benefit of cold plasma technology. Unlike conventional washing and sanitizing processes that may require large volumes of water and chemical sanitizers, cold plasma treatments operate in dry or semi-dry conditions. Research conducted across multiple food processing facilities demonstrates water usage reductions of up to 80% when implementing cold plasma systems as replacements for traditional washing lines.

The chemical-free nature of cold plasma technology further enhances its sustainability profile. By generating reactive species directly from ambient air or other gases, cold plasma eliminates the need for chemical preservatives, sanitizers, and fumigants that can leave residues and create disposal challenges. This reduction in chemical usage minimizes environmental contamination risks and reduces the chemical burden in wastewater streams from food processing facilities.

Waste reduction capabilities represent another significant environmental advantage. Cold plasma treatments can extend product shelf life by 30-200% depending on the food commodity, substantially reducing food waste throughout the supply chain. This extension of usable product life addresses one of the food industry's most pressing sustainability challenges, as food waste accounts for approximately 8-10% of global greenhouse gas emissions.

Life cycle assessments of cold plasma implementation in various food processing scenarios reveal favorable environmental profiles compared to conventional technologies. These assessments typically show reduced carbon footprints, water usage, and overall environmental impact scores. However, certain plasma generation methods may require rare gases or specialized components with their own environmental considerations during manufacturing and disposal phases.

Regulatory frameworks are increasingly recognizing cold plasma's environmental benefits, with several countries developing specific sustainability incentives for food processors adopting this technology. These incentives acknowledge cold plasma's potential contribution to meeting industry-wide sustainability targets and reducing the environmental footprint of food production systems globally.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!