Material Innovations in Carbon Capture Technology Advancements

OCT 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbon Capture Materials Background and Objectives

Carbon capture technology has evolved significantly over the past several decades, transitioning from theoretical concepts to practical applications in response to growing climate change concerns. Initially developed in the 1970s for enhanced oil recovery purposes, carbon capture technologies have since expanded in scope and sophistication, particularly as global awareness of greenhouse gas emissions has intensified. The fundamental objective of modern carbon capture materials research is to develop efficient, cost-effective solutions that can significantly reduce carbon dioxide emissions from industrial sources and potentially from the atmosphere directly.

The evolution of carbon capture materials has progressed through several distinct phases. First-generation technologies primarily utilized liquid amine-based absorbents, which while effective, presented challenges related to energy consumption and corrosion. Second-generation approaches introduced solid adsorbents and membrane technologies, offering improved efficiency but still facing scalability issues. Current third-generation research focuses on novel materials including metal-organic frameworks (MOFs), covalent organic frameworks (COFs), and advanced polymer membranes that promise unprecedented capture capacity and selectivity.

The technical objectives in this field are multifaceted and ambitious. Primary goals include developing materials that can achieve at least 90% capture efficiency while reducing the energy penalty below 30% of current levels. Additionally, researchers aim to create materials that maintain stability over thousands of capture-release cycles, operate effectively under variable conditions found in industrial settings, and can be manufactured at scale using sustainable processes.

Material innovation in carbon capture represents a critical pathway toward meeting international climate agreements, including the Paris Accord targets. The Intergovernmental Panel on Climate Change (IPCC) has identified carbon capture as an essential technology for limiting global warming to 1.5°C above pre-industrial levels. This creates significant urgency for breakthrough materials that can transform theoretical carbon reduction models into practical reality.

Recent technological trajectories indicate promising directions, including biomimetic approaches that emulate natural carbon fixation processes, hybrid materials that combine the advantages of different capture mechanisms, and stimuli-responsive materials that can be precisely controlled during capture and release cycles. The integration of nanotechnology and advanced manufacturing techniques has further accelerated innovation in this space, enabling precise control over material properties at the molecular level.

The ultimate objective remains developing carbon capture materials that not only perform technically but also create economically viable pathways for widespread industrial adoption, potentially transforming carbon dioxide from an environmental liability into a valuable feedstock for various industrial processes.

The evolution of carbon capture materials has progressed through several distinct phases. First-generation technologies primarily utilized liquid amine-based absorbents, which while effective, presented challenges related to energy consumption and corrosion. Second-generation approaches introduced solid adsorbents and membrane technologies, offering improved efficiency but still facing scalability issues. Current third-generation research focuses on novel materials including metal-organic frameworks (MOFs), covalent organic frameworks (COFs), and advanced polymer membranes that promise unprecedented capture capacity and selectivity.

The technical objectives in this field are multifaceted and ambitious. Primary goals include developing materials that can achieve at least 90% capture efficiency while reducing the energy penalty below 30% of current levels. Additionally, researchers aim to create materials that maintain stability over thousands of capture-release cycles, operate effectively under variable conditions found in industrial settings, and can be manufactured at scale using sustainable processes.

Material innovation in carbon capture represents a critical pathway toward meeting international climate agreements, including the Paris Accord targets. The Intergovernmental Panel on Climate Change (IPCC) has identified carbon capture as an essential technology for limiting global warming to 1.5°C above pre-industrial levels. This creates significant urgency for breakthrough materials that can transform theoretical carbon reduction models into practical reality.

Recent technological trajectories indicate promising directions, including biomimetic approaches that emulate natural carbon fixation processes, hybrid materials that combine the advantages of different capture mechanisms, and stimuli-responsive materials that can be precisely controlled during capture and release cycles. The integration of nanotechnology and advanced manufacturing techniques has further accelerated innovation in this space, enabling precise control over material properties at the molecular level.

The ultimate objective remains developing carbon capture materials that not only perform technically but also create economically viable pathways for widespread industrial adoption, potentially transforming carbon dioxide from an environmental liability into a valuable feedstock for various industrial processes.

Market Analysis for Carbon Capture Solutions

The global carbon capture market is experiencing significant growth, driven by increasing environmental regulations and corporate sustainability commitments. Current market valuations place the carbon capture, utilization, and storage (CCUS) sector at approximately $2.5 billion in 2023, with projections indicating expansion to reach $7.0 billion by 2030, representing a compound annual growth rate (CAGR) of 15.8%.

Regional analysis reveals North America currently dominates the market with roughly 40% share, attributed to favorable government policies and substantial industrial emissions. Europe follows closely at 30% market share, with the European Union's aggressive carbon neutrality targets accelerating adoption. The Asia-Pacific region, particularly China and Japan, demonstrates the fastest growth trajectory with projected CAGR exceeding 20% through 2028.

By application segment, the power generation sector constitutes the largest market share at 35%, followed by industrial processes (25%), natural gas processing (20%), and other applications (20%). Material innovations are creating new market opportunities, with advanced sorbent materials showing particular promise for cost reduction.

Investment patterns indicate a surge in venture capital funding, with over $1.2 billion invested in carbon capture startups in 2022 alone, tripling the amount from 2020. Major corporations are increasingly forming strategic partnerships and joint ventures to accelerate technology commercialization and market penetration.

Customer segmentation reveals three primary buyer categories: large industrial emitters seeking compliance solutions, energy companies pursuing enhanced oil recovery applications, and forward-thinking corporations implementing voluntary carbon reduction initiatives. Price sensitivity varies significantly across these segments, with compliance-driven customers demonstrating less elasticity than voluntary adopters.

Market barriers include high capital expenditure requirements, uncertain regulatory frameworks in developing markets, and competition from alternative carbon reduction strategies. The levelized cost of carbon capture currently ranges from $40-120 per ton depending on the application and technology, with material innovations potentially reducing this to $25-80 per ton by 2030.

Growth opportunities exist particularly in developing economies where industrialization continues to accelerate carbon emissions. The integration of carbon capture with renewable energy systems represents another expanding market segment, as does the utilization of captured carbon in value-added products such as construction materials, chemicals, and synthetic fuels.

Regional analysis reveals North America currently dominates the market with roughly 40% share, attributed to favorable government policies and substantial industrial emissions. Europe follows closely at 30% market share, with the European Union's aggressive carbon neutrality targets accelerating adoption. The Asia-Pacific region, particularly China and Japan, demonstrates the fastest growth trajectory with projected CAGR exceeding 20% through 2028.

By application segment, the power generation sector constitutes the largest market share at 35%, followed by industrial processes (25%), natural gas processing (20%), and other applications (20%). Material innovations are creating new market opportunities, with advanced sorbent materials showing particular promise for cost reduction.

Investment patterns indicate a surge in venture capital funding, with over $1.2 billion invested in carbon capture startups in 2022 alone, tripling the amount from 2020. Major corporations are increasingly forming strategic partnerships and joint ventures to accelerate technology commercialization and market penetration.

Customer segmentation reveals three primary buyer categories: large industrial emitters seeking compliance solutions, energy companies pursuing enhanced oil recovery applications, and forward-thinking corporations implementing voluntary carbon reduction initiatives. Price sensitivity varies significantly across these segments, with compliance-driven customers demonstrating less elasticity than voluntary adopters.

Market barriers include high capital expenditure requirements, uncertain regulatory frameworks in developing markets, and competition from alternative carbon reduction strategies. The levelized cost of carbon capture currently ranges from $40-120 per ton depending on the application and technology, with material innovations potentially reducing this to $25-80 per ton by 2030.

Growth opportunities exist particularly in developing economies where industrialization continues to accelerate carbon emissions. The integration of carbon capture with renewable energy systems represents another expanding market segment, as does the utilization of captured carbon in value-added products such as construction materials, chemicals, and synthetic fuels.

Current State and Technical Barriers in Carbon Capture Materials

Carbon capture materials have evolved significantly over the past decade, with current technologies primarily categorized into three generations. First-generation materials include aqueous amines such as monoethanolamine (MEA), which remain the commercial standard despite high regeneration energy requirements (3.5-4.2 GJ/tCO2). Second-generation materials encompass solid sorbents like metal-organic frameworks (MOFs), zeolites, and activated carbons, offering improved energy efficiency but facing stability challenges. Third-generation materials feature advanced membranes and enzyme-based systems that show promising selectivity but remain largely in laboratory stages.

The global landscape of carbon capture materials research shows distinct regional focuses. North America leads in amine-based technologies and membrane development, while Europe excels in MOF research and pilot implementations. Asia, particularly China and Japan, demonstrates strength in zeolite development and industrial-scale applications of carbon capture systems.

Despite progress, significant technical barriers persist across all material categories. For amine-based systems, degradation through oxidation and thermal cycling remains problematic, with current materials losing 2-5% capacity per cycle in industrial settings. Corrosion of equipment and high regeneration energy requirements further limit widespread adoption. Solid sorbents face challenges in maintaining structural integrity during repeated adsorption-desorption cycles, with many promising MOFs showing 15-30% capacity reduction after just 50 cycles.

Membrane technologies struggle with the fundamental trade-off between permeability and selectivity, known as Robeson's upper bound. Current membranes achieving high CO2 selectivity (>50) typically demonstrate low permeance (<1000 GPU), making large-scale implementation economically challenging. Additionally, membrane fouling in real flue gas conditions significantly reduces operational lifetimes.

Scale-up represents perhaps the most significant barrier across all material types. Laboratory-developed materials often show dramatically reduced performance in industrial settings due to contaminants, variable gas compositions, and mechanical stress. The cost of novel materials presents another obstacle, with advanced MOFs and specialized membranes currently priced at $200-1000/kg compared to conventional amine solutions at $2-5/kg.

Water tolerance remains a critical challenge, as most flue gases contain 5-15% water vapor. Many promising materials, particularly zeolites and certain MOFs, show significant performance degradation in humid conditions, with some losing over 50% capacity at relative humidity above 40%. This necessitates either costly pre-treatment systems or development of water-tolerant materials, both of which impact overall system economics and efficiency.

The global landscape of carbon capture materials research shows distinct regional focuses. North America leads in amine-based technologies and membrane development, while Europe excels in MOF research and pilot implementations. Asia, particularly China and Japan, demonstrates strength in zeolite development and industrial-scale applications of carbon capture systems.

Despite progress, significant technical barriers persist across all material categories. For amine-based systems, degradation through oxidation and thermal cycling remains problematic, with current materials losing 2-5% capacity per cycle in industrial settings. Corrosion of equipment and high regeneration energy requirements further limit widespread adoption. Solid sorbents face challenges in maintaining structural integrity during repeated adsorption-desorption cycles, with many promising MOFs showing 15-30% capacity reduction after just 50 cycles.

Membrane technologies struggle with the fundamental trade-off between permeability and selectivity, known as Robeson's upper bound. Current membranes achieving high CO2 selectivity (>50) typically demonstrate low permeance (<1000 GPU), making large-scale implementation economically challenging. Additionally, membrane fouling in real flue gas conditions significantly reduces operational lifetimes.

Scale-up represents perhaps the most significant barrier across all material types. Laboratory-developed materials often show dramatically reduced performance in industrial settings due to contaminants, variable gas compositions, and mechanical stress. The cost of novel materials presents another obstacle, with advanced MOFs and specialized membranes currently priced at $200-1000/kg compared to conventional amine solutions at $2-5/kg.

Water tolerance remains a critical challenge, as most flue gases contain 5-15% water vapor. Many promising materials, particularly zeolites and certain MOFs, show significant performance degradation in humid conditions, with some losing over 50% capacity at relative humidity above 40%. This necessitates either costly pre-treatment systems or development of water-tolerant materials, both of which impact overall system economics and efficiency.

Current Material Solutions for Carbon Capture

01 Metal-organic frameworks (MOFs) for carbon capture

Metal-organic frameworks represent a significant innovation in carbon capture materials due to their highly porous structure and customizable properties. These crystalline compounds consist of metal ions coordinated to organic ligands, creating a framework with exceptional surface area for CO2 adsorption. Their tunable pore sizes and chemical functionality allow for selective capture of carbon dioxide from various gas streams, including industrial emissions and ambient air. Recent innovations have focused on improving MOFs' stability, selectivity, and regeneration capabilities under real-world conditions.- Metal-organic frameworks (MOFs) for carbon capture: Metal-organic frameworks represent a significant innovation in carbon capture materials due to their highly porous structure and customizable properties. These crystalline compounds consist of metal ions coordinated to organic ligands, creating a framework with exceptional surface area for CO2 adsorption. Their tunable pore sizes and chemical functionality allow for selective capture of carbon dioxide from various gas streams, including industrial emissions and ambient air. Recent innovations have focused on improving MOFs' stability, selectivity, and regeneration capabilities under real-world conditions.

- Amine-functionalized adsorbents: Amine-functionalized materials have emerged as effective carbon capture solutions by leveraging the chemical affinity between amine groups and CO2 molecules. These materials typically consist of a porous support structure (such as silica, polymers, or carbon) modified with various amine compounds that can chemically bind carbon dioxide. The innovation lies in developing materials with higher amine loading, improved stability during multiple adsorption-desorption cycles, and reduced energy requirements for regeneration. These adsorbents can operate effectively at lower temperatures compared to traditional capture methods.

- Integrated carbon capture and utilization systems: Innovative materials and systems that not only capture carbon dioxide but also convert it into valuable products represent a significant advancement in carbon capture technology. These integrated systems incorporate catalytic materials that can transform captured CO2 into fuels, chemicals, or building materials. The materials innovation focuses on developing efficient catalysts that can operate at ambient conditions with minimal energy input. By creating economic value from captured carbon, these systems offer a sustainable approach to reducing atmospheric CO2 while producing useful commodities.

- Membrane-based carbon capture materials: Advanced membrane materials represent a promising approach for selective carbon dioxide separation from gas mixtures. These membranes utilize innovative polymers, mixed matrix materials, or facilitated transport mechanisms to achieve high CO2 permeability and selectivity. The material innovations focus on enhancing membrane stability under harsh conditions, improving separation efficiency, and reducing the energy requirements for the separation process. Membrane-based systems offer advantages including continuous operation, compact design, and scalability for various industrial applications.

- Direct air capture (DAC) materials: Materials specifically designed for direct air capture represent a cutting-edge approach to removing carbon dioxide directly from ambient air. These innovative materials must overcome the challenge of capturing CO2 at very low atmospheric concentrations (approximately 400 ppm). The innovations include highly selective sorbents with strong CO2 affinity, novel structured materials that maximize air contact while minimizing pressure drop, and materials engineered for efficient regeneration using renewable energy sources. These materials typically incorporate advanced functionalities such as specialized amine groups, alkali metal compounds, or engineered porous structures.

02 Amine-functionalized sorbents and membranes

Amine-functionalized materials have emerged as effective carbon capture solutions by leveraging the chemical affinity between amine groups and CO2 molecules. These materials include modified silica, polymers, and porous substrates impregnated with various amine compounds. The amine functional groups form carbamates or bicarbonates when reacting with CO2, enabling efficient capture even at low concentrations. Recent innovations focus on optimizing amine loading, minimizing degradation during regeneration cycles, and developing novel support structures to enhance CO2 adsorption capacity and selectivity.Expand Specific Solutions03 Integrated carbon capture and utilization systems

Integrated systems combine carbon capture with utilization technologies to transform captured CO2 into valuable products. These systems incorporate novel materials that not only capture carbon dioxide but also catalyze its conversion into chemicals, fuels, or building materials. Recent innovations include electrochemical reduction catalysts, photocatalytic materials, and biocatalytic systems that can operate at ambient conditions. By creating economic value from captured carbon, these integrated approaches help offset the costs of carbon capture while reducing net emissions and promoting circular carbon economy principles.Expand Specific Solutions04 Cryogenic carbon capture materials

Cryogenic carbon capture technologies utilize specialized materials designed to function at extremely low temperatures where CO2 can be separated through phase changes. These materials include advanced heat exchangers, thermal insulators, and specialized refrigerants that enable efficient cooling and phase separation. Innovations in this field focus on materials that can withstand thermal cycling while maintaining structural integrity and performance. Recent developments include composite materials with enhanced thermal properties, novel refrigeration cycles, and specialized separation media that can operate with reduced energy requirements compared to conventional cryogenic processes.Expand Specific Solutions05 Biomimetic and nature-inspired carbon capture materials

Biomimetic approaches draw inspiration from natural carbon fixation processes to develop innovative capture materials. These include synthetic enzymes that mimic carbonic anhydrase, artificial leaf structures that combine capture with photosynthetic principles, and bio-derived materials with optimized CO2 binding sites. Recent innovations focus on enhancing the stability and efficiency of these biomimetic systems under industrial conditions. By emulating nature's carbon processing mechanisms, these materials often achieve higher selectivity and lower energy requirements than conventional approaches, while potentially offering more environmentally compatible solutions for large-scale carbon capture applications.Expand Specific Solutions

Leading Organizations in Carbon Capture Material Development

Carbon capture technology is evolving rapidly, currently transitioning from early commercial deployment to growth phase, with the global market expected to reach $7-10 billion by 2030. The competitive landscape features diverse players across the value chain, with varying technological maturity. Established energy companies like China Petroleum & Chemical Corp. and PETRONAS Energy Canada are investing heavily in industrial-scale implementation, while specialized innovators such as Climeworks AG lead in direct air capture technologies. Academic institutions including MIT, Columbia University, and Tianjin University are advancing novel materials research, particularly in sorbent development and membrane technologies. Research organizations like CSIRO and Korea Institute of Energy Research bridge the gap between laboratory breakthroughs and commercial applications, focusing on cost reduction and efficiency improvements critical for widespread adoption.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed an integrated carbon capture, utilization, and storage (CCUS) technology platform focused on post-combustion capture from industrial sources. Their proprietary amine-based solvent systems demonstrate 90%+ capture efficiency with reduced energy penalties compared to first-generation solvents. Sinopec's approach includes specialized absorption columns with structured packing that increases contact efficiency while reducing pressure drop, resulting in approximately 15% lower energy consumption. Their Qilu-Shengli CCUS project, operational since 2021, captures over 1 million tons of CO2 annually from petrochemical operations for enhanced oil recovery (EOR) applications. Sinopec has also pioneered solid adsorbent materials based on modified activated carbon and metal-organic frameworks that show promising performance in cyclic operations, with adsorption capacities exceeding 3 mmol/g under typical flue gas conditions and good stability over 1000+ cycles. Their integrated approach includes proprietary heat integration systems that recover waste heat from industrial processes to power the carbon capture operations.

Strengths: Extensive industrial implementation experience; integrated approach combining capture with utilization pathways; proprietary materials with improved performance metrics; ability to leverage existing infrastructure. Weaknesses: Heavy focus on EOR applications which ultimately release some CO2; technologies primarily designed for high-concentration point sources rather than ambient air capture; continued reliance on fossil fuel business model.

Climeworks AG

Technical Solution: Climeworks has pioneered Direct Air Capture (DAC) technology that extracts CO2 directly from ambient air through a two-step process. Their modular collectors use a patented filter material that selectively captures CO2 when air passes through it. Once saturated, the filters are heated to approximately 100°C, releasing concentrated CO2 that can be permanently stored underground through mineralization in basaltic rock formations. Their Orca plant in Iceland, launched in 2021, captures 4,000 tons of CO2 annually, while their upcoming Mammoth plant aims to scale to 36,000 tons per year. Climeworks' technology integrates with geothermal energy sources to power their operations, creating a carbon-negative solution. Their approach allows for flexible deployment in various locations regardless of emission sources, with demonstrated 90% efficiency in CO2 capture from ambient air.

Strengths: Modular design allows for scalable implementation; integration with renewable energy sources; permanent storage solution through mineralization; location-independent deployment. Weaknesses: Currently high cost per ton of CO2 captured (estimated $600-800/ton); energy-intensive process requiring significant heat for regeneration; limited scale compared to global emissions.

Key Innovations in Carbon Capture Material Science

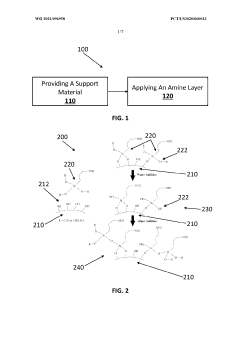

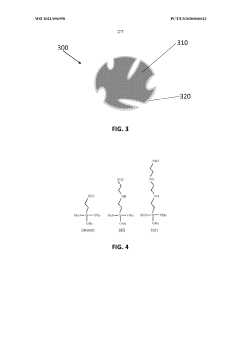

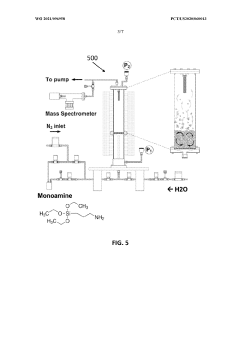

Synthesis process for solid carbon capture materials

PatentWO2021096958A1

Innovation

- The use of molecular layer deposition (MLD) to create amine-functionalized solid CO2 sorbents, which allows for precise angstrom-level thickness control and covalent anchoring of amine layers on a wide range of substrate materials, including nano-powders, enhancing surface area functionalization and maintaining active sites during regeneration without specialized substrates or costly preparation.

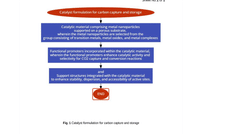

Novel catalyst formulation for efficient carbon capture and storage

PatentPendingIN202441035402A

Innovation

- A novel catalyst formulation incorporating advanced materials with high surface area, tailored pore structures, and functional groups for enhanced CO2 adsorption and conversion, along with support structures and functional promoters to improve stability and selectivity, is designed to address these challenges.

Environmental Impact Assessment of Carbon Capture Materials

The environmental implications of carbon capture materials extend far beyond their primary function of reducing atmospheric CO2. When evaluating these materials, lifecycle assessment reveals significant environmental considerations across production, deployment, and disposal phases. Most advanced carbon capture materials, including metal-organic frameworks (MOFs), amine-functionalized sorbents, and novel membrane technologies, require energy-intensive manufacturing processes that can generate substantial carbon footprints before deployment.

Water consumption presents another critical concern, particularly for solvent-based capture systems which typically require 0.7-2.0 cubic meters of water per ton of CO2 captured. This water intensity creates potential conflicts in water-stressed regions where carbon capture facilities might compete with agricultural and municipal needs. Additionally, the chemical degradation of capture materials, especially amine-based solvents, can release compounds such as nitrosamines and ammonia that pose ecological risks to surrounding ecosystems.

Land use impacts vary significantly between capture technologies. Direct air capture installations require approximately 0.5-1.5 hectares per kiloton of annual CO2 capture capacity, while post-combustion systems integrated with existing facilities have substantially smaller footprints. The environmental justice implications cannot be overlooked, as carbon capture facilities are frequently sited near industrial zones that may already experience disproportionate pollution burdens.

Toxicity profiles of novel carbon capture materials remain incompletely characterized, particularly for nanomaterials and metal-organic composites. Recent studies indicate potential aquatic toxicity from degradation products of certain ionic liquids used in carbon capture, with EC50 values for freshwater organisms ranging from 25-150 mg/L depending on the specific compound structure.

The energy penalty associated with material regeneration represents perhaps the most significant environmental trade-off. Current technologies require 0.7-1.1 GJ of energy per ton of CO2 captured, which can increase the host facility's fuel consumption by 15-30% if not powered by renewable sources. This creates a complex environmental calculus where the benefits of carbon reduction must be weighed against increased resource consumption and potential pollutant emissions.

Encouragingly, recent innovations in biologically-derived capture materials show promise for reducing environmental impacts. Cellulose-based sorbents and algae-derived membranes demonstrate 40-60% lower embodied energy compared to synthetic alternatives, while maintaining comparable capture performance under optimized conditions.

Water consumption presents another critical concern, particularly for solvent-based capture systems which typically require 0.7-2.0 cubic meters of water per ton of CO2 captured. This water intensity creates potential conflicts in water-stressed regions where carbon capture facilities might compete with agricultural and municipal needs. Additionally, the chemical degradation of capture materials, especially amine-based solvents, can release compounds such as nitrosamines and ammonia that pose ecological risks to surrounding ecosystems.

Land use impacts vary significantly between capture technologies. Direct air capture installations require approximately 0.5-1.5 hectares per kiloton of annual CO2 capture capacity, while post-combustion systems integrated with existing facilities have substantially smaller footprints. The environmental justice implications cannot be overlooked, as carbon capture facilities are frequently sited near industrial zones that may already experience disproportionate pollution burdens.

Toxicity profiles of novel carbon capture materials remain incompletely characterized, particularly for nanomaterials and metal-organic composites. Recent studies indicate potential aquatic toxicity from degradation products of certain ionic liquids used in carbon capture, with EC50 values for freshwater organisms ranging from 25-150 mg/L depending on the specific compound structure.

The energy penalty associated with material regeneration represents perhaps the most significant environmental trade-off. Current technologies require 0.7-1.1 GJ of energy per ton of CO2 captured, which can increase the host facility's fuel consumption by 15-30% if not powered by renewable sources. This creates a complex environmental calculus where the benefits of carbon reduction must be weighed against increased resource consumption and potential pollutant emissions.

Encouragingly, recent innovations in biologically-derived capture materials show promise for reducing environmental impacts. Cellulose-based sorbents and algae-derived membranes demonstrate 40-60% lower embodied energy compared to synthetic alternatives, while maintaining comparable capture performance under optimized conditions.

Cost-Efficiency Analysis of Material-Based Capture Technologies

The economic viability of carbon capture technologies is fundamentally tied to the materials used in their implementation. Current cost analyses indicate that traditional carbon capture methods using amine-based solvents typically range from $40-80 per ton of CO2 captured, representing a significant economic barrier to widespread adoption. Material innovations are rapidly changing this landscape, with novel adsorbents showing potential to reduce costs by 30-45% compared to first-generation technologies.

Metal-Organic Frameworks (MOFs) demonstrate particularly promising cost-efficiency metrics, with recent advancements reducing synthesis costs from approximately $200/kg to under $50/kg in laboratory settings. When scaled to industrial production, projections suggest costs could fall below $10/kg, making MOF-based capture systems economically competitive with conventional approaches while offering superior capture capacity and selectivity.

Membrane-based capture technologies present another cost-efficient alternative, with thin-film composite membranes showing operational costs approximately 25% lower than amine scrubbing systems. The primary economic advantage stems from reduced energy requirements during the regeneration phase, which typically accounts for 60-70% of operational expenses in traditional capture systems.

Solid sorbents, particularly those based on modified carbon materials, exhibit favorable economic profiles when lifecycle costs are considered. While initial material costs may be 15-20% higher than conventional sorbents, their extended operational lifespan (3-5 times longer) and reduced regeneration energy requirements (30-40% lower) result in significantly improved long-term cost-efficiency metrics.

Economic modeling of direct air capture (DAC) technologies reveals that material selection dramatically impacts overall system economics. Current DAC costs using conventional materials range from $250-600 per ton of CO2, but advanced material systems incorporating engineered porous structures and surface-modified adsorbents show potential to reduce these costs to $100-150 per ton within the next decade.

Return on investment calculations for various material-based capture technologies indicate that porous polymer networks and functionalized silica materials offer the most favorable economic profiles for near-term implementation, with payback periods of 5-7 years when carbon pricing mechanisms are considered. These materials strike an optimal balance between manufacturing complexity, operational durability, and capture performance.

The economic landscape for material-based capture technologies is further influenced by regional factors, with manufacturing capabilities, energy costs, and regulatory frameworks creating significant variations in cost-efficiency profiles across different markets. Materials that can be produced using locally available resources and existing manufacturing infrastructure demonstrate 15-25% better economic performance than those requiring specialized production facilities.

Metal-Organic Frameworks (MOFs) demonstrate particularly promising cost-efficiency metrics, with recent advancements reducing synthesis costs from approximately $200/kg to under $50/kg in laboratory settings. When scaled to industrial production, projections suggest costs could fall below $10/kg, making MOF-based capture systems economically competitive with conventional approaches while offering superior capture capacity and selectivity.

Membrane-based capture technologies present another cost-efficient alternative, with thin-film composite membranes showing operational costs approximately 25% lower than amine scrubbing systems. The primary economic advantage stems from reduced energy requirements during the regeneration phase, which typically accounts for 60-70% of operational expenses in traditional capture systems.

Solid sorbents, particularly those based on modified carbon materials, exhibit favorable economic profiles when lifecycle costs are considered. While initial material costs may be 15-20% higher than conventional sorbents, their extended operational lifespan (3-5 times longer) and reduced regeneration energy requirements (30-40% lower) result in significantly improved long-term cost-efficiency metrics.

Economic modeling of direct air capture (DAC) technologies reveals that material selection dramatically impacts overall system economics. Current DAC costs using conventional materials range from $250-600 per ton of CO2, but advanced material systems incorporating engineered porous structures and surface-modified adsorbents show potential to reduce these costs to $100-150 per ton within the next decade.

Return on investment calculations for various material-based capture technologies indicate that porous polymer networks and functionalized silica materials offer the most favorable economic profiles for near-term implementation, with payback periods of 5-7 years when carbon pricing mechanisms are considered. These materials strike an optimal balance between manufacturing complexity, operational durability, and capture performance.

The economic landscape for material-based capture technologies is further influenced by regional factors, with manufacturing capabilities, energy costs, and regulatory frameworks creating significant variations in cost-efficiency profiles across different markets. Materials that can be produced using locally available resources and existing manufacturing infrastructure demonstrate 15-25% better economic performance than those requiring specialized production facilities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!