Measure Shear Stress in Microfluidics Systems Efficiently

SEP 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microfluidic Shear Stress Measurement Background and Objectives

Microfluidic systems have revolutionized numerous fields including biomedical research, pharmaceutical development, and chemical analysis since their emergence in the early 1990s. The ability to manipulate fluids at the microscale has enabled unprecedented control over experimental conditions, reduced reagent consumption, and accelerated analytical processes. Within this domain, shear stress measurement represents a critical parameter that directly impacts cell behavior, protein interactions, and fluid dynamics in microfluidic devices.

Historically, shear stress quantification in microfluidics evolved from macroscale fluid mechanics principles adapted to microscale environments. Early approaches relied primarily on theoretical calculations based on channel geometry and flow rates, often neglecting the complex interactions occurring at microscale interfaces. The field has progressively moved toward more sophisticated measurement techniques as applications demanding precise shear stress control have expanded.

The technological evolution of microfluidic shear stress measurement has followed three distinct phases. The initial phase (1990s-2000s) focused on theoretical modeling and indirect measurement approaches. The second phase (2000s-2010s) saw the integration of microfabricated sensors and optical techniques. The current phase (2010s-present) is characterized by advanced real-time monitoring systems and computational fluid dynamics integration.

Current research objectives in this field center on developing measurement techniques that combine high spatial resolution, temporal sensitivity, and non-invasive characteristics. There is particular emphasis on creating methods that can measure shear stress in three-dimensional microfluidic structures and in the presence of complex biological samples without disrupting the microenvironment.

The clinical significance of accurate shear stress measurement cannot be overstated, particularly in applications such as organ-on-chip platforms, where physiologically relevant mechanical forces are essential for creating valid disease models. Similarly, in drug development, understanding shear effects on drug carriers and cellular uptake mechanisms requires precise measurement capabilities.

From an industrial perspective, efficient shear stress measurement enables optimization of manufacturing processes involving microfluidic systems, particularly in point-of-care diagnostics and continuous flow chemistry applications. The ability to rapidly characterize and control shear forces translates directly to improved product quality and manufacturing efficiency.

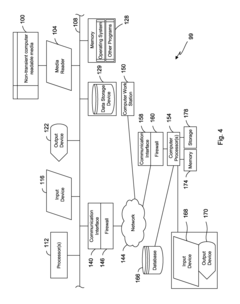

Looking forward, the field is trending toward integrated measurement solutions that combine multiple sensing modalities, wireless capabilities, and artificial intelligence for real-time data interpretation. These developments align with broader industry trends toward automation, miniaturization, and increased analytical capabilities in microfluidic systems.

Historically, shear stress quantification in microfluidics evolved from macroscale fluid mechanics principles adapted to microscale environments. Early approaches relied primarily on theoretical calculations based on channel geometry and flow rates, often neglecting the complex interactions occurring at microscale interfaces. The field has progressively moved toward more sophisticated measurement techniques as applications demanding precise shear stress control have expanded.

The technological evolution of microfluidic shear stress measurement has followed three distinct phases. The initial phase (1990s-2000s) focused on theoretical modeling and indirect measurement approaches. The second phase (2000s-2010s) saw the integration of microfabricated sensors and optical techniques. The current phase (2010s-present) is characterized by advanced real-time monitoring systems and computational fluid dynamics integration.

Current research objectives in this field center on developing measurement techniques that combine high spatial resolution, temporal sensitivity, and non-invasive characteristics. There is particular emphasis on creating methods that can measure shear stress in three-dimensional microfluidic structures and in the presence of complex biological samples without disrupting the microenvironment.

The clinical significance of accurate shear stress measurement cannot be overstated, particularly in applications such as organ-on-chip platforms, where physiologically relevant mechanical forces are essential for creating valid disease models. Similarly, in drug development, understanding shear effects on drug carriers and cellular uptake mechanisms requires precise measurement capabilities.

From an industrial perspective, efficient shear stress measurement enables optimization of manufacturing processes involving microfluidic systems, particularly in point-of-care diagnostics and continuous flow chemistry applications. The ability to rapidly characterize and control shear forces translates directly to improved product quality and manufacturing efficiency.

Looking forward, the field is trending toward integrated measurement solutions that combine multiple sensing modalities, wireless capabilities, and artificial intelligence for real-time data interpretation. These developments align with broader industry trends toward automation, miniaturization, and increased analytical capabilities in microfluidic systems.

Market Applications and Demand Analysis for Microfluidic Shear Stress Measurement

The microfluidic shear stress measurement market is experiencing significant growth driven by expanding applications in biomedical research, pharmaceutical development, and industrial process optimization. Current market estimates value the global microfluidics market at approximately $20 billion, with the analytical instruments segment, which includes shear stress measurement technologies, growing at a compound annual rate of 12-15%.

Healthcare and biomedical research represent the largest demand sector, accounting for nearly 40% of the market. Within this sector, cardiovascular research applications dominate, as researchers seek to understand how blood vessel cells respond to varying shear stress conditions. This knowledge is critical for developing treatments for atherosclerosis, thrombosis, and other vascular diseases that affect millions globally.

Pharmaceutical companies constitute the second-largest market segment, with increasing adoption of microfluidic technologies for drug development and testing. These companies require precise shear stress measurements to evaluate drug delivery systems, particularly for injectable formulations and targeted therapies. The ability to accurately simulate in vivo conditions using microfluidic platforms has reduced development costs by up to 30% in early-stage testing.

Industrial applications, particularly in chemical processing and materials science, represent a rapidly growing segment with projected annual growth of 18%. Companies in these sectors utilize shear stress measurements to optimize fluid handling processes, develop specialized coatings, and engineer advanced materials with specific rheological properties.

Academic research institutions continue to drive innovation in the field, with over 2,500 published studies annually involving microfluidic shear stress analysis. This research ecosystem creates consistent demand for increasingly sophisticated measurement technologies and serves as an incubator for commercial applications.

Geographically, North America leads market consumption (38%), followed by Europe (29%) and Asia-Pacific (25%). However, the Asia-Pacific region shows the highest growth rate at 17% annually, driven by expanding research infrastructure in China, Japan, and South Korea.

Key market drivers include miniaturization trends in analytical instruments, increasing focus on personalized medicine, and growing adoption of lab-on-a-chip technologies. The demand for real-time, high-resolution shear stress measurements has intensified as researchers seek to understand cellular mechanotransduction pathways and their implications for disease progression and treatment.

Market challenges include high initial equipment costs, technical complexity requiring specialized expertise, and integration difficulties with existing laboratory workflows. These factors have limited adoption in smaller research facilities and emerging markets, representing significant opportunities for companies that can develop more accessible solutions.

Healthcare and biomedical research represent the largest demand sector, accounting for nearly 40% of the market. Within this sector, cardiovascular research applications dominate, as researchers seek to understand how blood vessel cells respond to varying shear stress conditions. This knowledge is critical for developing treatments for atherosclerosis, thrombosis, and other vascular diseases that affect millions globally.

Pharmaceutical companies constitute the second-largest market segment, with increasing adoption of microfluidic technologies for drug development and testing. These companies require precise shear stress measurements to evaluate drug delivery systems, particularly for injectable formulations and targeted therapies. The ability to accurately simulate in vivo conditions using microfluidic platforms has reduced development costs by up to 30% in early-stage testing.

Industrial applications, particularly in chemical processing and materials science, represent a rapidly growing segment with projected annual growth of 18%. Companies in these sectors utilize shear stress measurements to optimize fluid handling processes, develop specialized coatings, and engineer advanced materials with specific rheological properties.

Academic research institutions continue to drive innovation in the field, with over 2,500 published studies annually involving microfluidic shear stress analysis. This research ecosystem creates consistent demand for increasingly sophisticated measurement technologies and serves as an incubator for commercial applications.

Geographically, North America leads market consumption (38%), followed by Europe (29%) and Asia-Pacific (25%). However, the Asia-Pacific region shows the highest growth rate at 17% annually, driven by expanding research infrastructure in China, Japan, and South Korea.

Key market drivers include miniaturization trends in analytical instruments, increasing focus on personalized medicine, and growing adoption of lab-on-a-chip technologies. The demand for real-time, high-resolution shear stress measurements has intensified as researchers seek to understand cellular mechanotransduction pathways and their implications for disease progression and treatment.

Market challenges include high initial equipment costs, technical complexity requiring specialized expertise, and integration difficulties with existing laboratory workflows. These factors have limited adoption in smaller research facilities and emerging markets, representing significant opportunities for companies that can develop more accessible solutions.

Current Challenges in Microfluidic Shear Stress Quantification

Despite significant advancements in microfluidic technologies, quantifying shear stress in these systems remains a persistent challenge for researchers and engineers. The microscale dimensions of microfluidic channels create unique fluid dynamics that complicate accurate measurement of wall shear stress, which is crucial for numerous biomedical and industrial applications. Current measurement techniques often suffer from spatial resolution limitations, making it difficult to capture the high-gradient stress distributions characteristic of microfluidic environments.

Traditional computational fluid dynamics (CFD) approaches, while theoretically comprehensive, frequently encounter difficulties when modeling complex geometries or multiphase flows common in practical microfluidic systems. The computational resources required for high-fidelity simulations can be prohibitive, especially when rapid iterative design is needed. Additionally, CFD models often rely on assumptions that may not hold true at the microscale, where surface forces dominate over volume forces.

Experimental measurement techniques face their own set of challenges. Optical methods such as micro-particle image velocimetry (μPIV) provide valuable velocity field data but require sophisticated equipment and transparent materials. Converting these velocity measurements to accurate shear stress values introduces additional uncertainties, particularly near channel walls where measurements are most critical but also most difficult to obtain.

Sensor-based approaches for direct measurement of shear stress in microfluidics have been developed, but miniaturization of these sensors presents significant fabrication challenges. Current microelectromechanical systems (MEMS) sensors often disrupt the flow they are meant to measure, altering the very parameter they aim to quantify. Furthermore, the integration of these sensors into existing microfluidic platforms without compromising functionality remains problematic.

The dynamic nature of many microfluidic applications introduces additional complexity. Biological samples, for instance, may change their rheological properties in response to shear stress, creating a feedback loop that is difficult to characterize with current methodologies. Time-dependent flows and transient phenomena further complicate measurement efforts, as most techniques provide only time-averaged data or have insufficient temporal resolution.

Calibration and validation of measurement techniques present another significant hurdle. The lack of standardized reference systems for microfluidic shear stress measurement makes it difficult to compare results across different studies or methodologies. This absence of standardization impedes progress in the field and complicates the translation of research findings into practical applications.

Cost considerations also limit widespread adoption of advanced measurement techniques. High-precision equipment required for accurate shear stress quantification is often prohibitively expensive for many research laboratories and industrial settings, creating a barrier to entry that slows innovation in this critical area of microfluidic research.

Traditional computational fluid dynamics (CFD) approaches, while theoretically comprehensive, frequently encounter difficulties when modeling complex geometries or multiphase flows common in practical microfluidic systems. The computational resources required for high-fidelity simulations can be prohibitive, especially when rapid iterative design is needed. Additionally, CFD models often rely on assumptions that may not hold true at the microscale, where surface forces dominate over volume forces.

Experimental measurement techniques face their own set of challenges. Optical methods such as micro-particle image velocimetry (μPIV) provide valuable velocity field data but require sophisticated equipment and transparent materials. Converting these velocity measurements to accurate shear stress values introduces additional uncertainties, particularly near channel walls where measurements are most critical but also most difficult to obtain.

Sensor-based approaches for direct measurement of shear stress in microfluidics have been developed, but miniaturization of these sensors presents significant fabrication challenges. Current microelectromechanical systems (MEMS) sensors often disrupt the flow they are meant to measure, altering the very parameter they aim to quantify. Furthermore, the integration of these sensors into existing microfluidic platforms without compromising functionality remains problematic.

The dynamic nature of many microfluidic applications introduces additional complexity. Biological samples, for instance, may change their rheological properties in response to shear stress, creating a feedback loop that is difficult to characterize with current methodologies. Time-dependent flows and transient phenomena further complicate measurement efforts, as most techniques provide only time-averaged data or have insufficient temporal resolution.

Calibration and validation of measurement techniques present another significant hurdle. The lack of standardized reference systems for microfluidic shear stress measurement makes it difficult to compare results across different studies or methodologies. This absence of standardization impedes progress in the field and complicates the translation of research findings into practical applications.

Cost considerations also limit widespread adoption of advanced measurement techniques. High-precision equipment required for accurate shear stress quantification is often prohibitively expensive for many research laboratories and industrial settings, creating a barrier to entry that slows innovation in this critical area of microfluidic research.

State-of-the-Art Shear Stress Measurement Methods in Microfluidics

01 Microfluidic devices for measuring shear stress

Microfluidic systems can be designed specifically to measure shear stress in various fluid environments. These devices typically incorporate sensors or detection mechanisms that can quantify the forces exerted by flowing fluids on surfaces or particles within the microchannels. Such systems enable precise control over flow conditions and can be used to study biological responses to shear stress or fluid mechanical properties in controlled environments.- Microfluidic devices for measuring shear stress: Microfluidic systems designed specifically for measuring shear stress in fluid flows. These devices incorporate sensors and specialized channels to accurately quantify shear forces at microscale levels. The technology enables precise measurement of fluid behavior under various flow conditions, which is critical for biomedical applications, material testing, and fluid dynamics research.

- Cell culture systems with controlled shear stress: Microfluidic platforms designed for cell culture applications where precise control of shear stress is critical. These systems allow researchers to study cellular responses to mechanical forces that mimic physiological conditions. The technology incorporates flow control mechanisms to create defined shear environments for investigating cell adhesion, differentiation, and mechanotransduction pathways under controlled conditions.

- Shear stress sensors in microfluidic applications: Advanced sensor technologies integrated into microfluidic systems for real-time monitoring of shear stress. These sensors utilize various physical principles including optical, electrical, and mechanical methods to detect and quantify shear forces with high sensitivity. The integration of these sensors enables continuous monitoring of flow conditions and provides feedback for precise control of microfluidic experiments.

- Flow control mechanisms for shear stress regulation: Engineering solutions for controlling and modulating shear stress in microfluidic systems. These mechanisms include specialized channel geometries, programmable pumps, and valve systems that enable precise manipulation of flow rates and patterns. The technology allows researchers to create complex flow profiles and gradients of shear stress for applications in drug testing, organ-on-chip models, and fluid dynamics studies.

- Biomedical applications of shear stress in microfluidics: Microfluidic systems that leverage controlled shear stress for specific biomedical applications. These include platforms for blood cell analysis, thrombosis studies, vascular disease modeling, and drug screening under physiologically relevant flow conditions. The technology enables researchers to recreate the mechanical microenvironment of various tissues and study pathological processes in vitro with improved clinical relevance.

02 Biological applications of shear stress in microfluidics

Microfluidic systems are used to study the effects of shear stress on biological samples such as cells, tissues, and blood. These platforms can simulate physiological flow conditions found in blood vessels or other biological systems, allowing researchers to investigate cellular responses to mechanical forces. Applications include studying endothelial cell behavior, platelet activation, blood rheology, and developing organ-on-chip models that incorporate physiologically relevant shear stress conditions.Expand Specific Solutions03 Shear stress sensors in microfluidic systems

Various sensor technologies are integrated into microfluidic systems to measure shear stress directly. These include MEMS-based sensors, piezoelectric elements, optical detection methods, and electrical impedance measurements. These sensors can provide real-time data on shear forces within microchannels, enabling precise characterization of flow behavior and fluid-structure interactions at the microscale. The integration of these sensors allows for feedback control of flow conditions in advanced microfluidic applications.Expand Specific Solutions04 Flow control and manipulation of shear stress

Microfluidic systems incorporate various mechanisms to control and manipulate shear stress levels within channels. These include specialized channel geometries, flow restrictors, programmable pumps, and active flow control elements. By precisely controlling the flow parameters, researchers can generate defined shear stress gradients or patterns for experimental purposes. These control mechanisms are essential for applications requiring specific shear conditions, such as particle separation, mixing enhancement, or mimicking physiological flow environments.Expand Specific Solutions05 Computational modeling of shear stress in microfluidics

Computational fluid dynamics (CFD) and other numerical modeling approaches are used to predict, analyze, and optimize shear stress distributions in microfluidic systems. These computational tools help in designing microfluidic channels with specific shear characteristics, understanding complex flow phenomena at microscale, and interpreting experimental results. The integration of modeling with experimental validation enables the development of more sophisticated microfluidic platforms with precisely controlled shear stress environments for various applications in biomedical research and diagnostics.Expand Specific Solutions

Leading Research Groups and Companies in Microfluidic Sensing

The microfluidic shear stress measurement market is currently in a growth phase, with increasing applications in biomedical research, pharmaceutical development, and industrial process optimization. The global market size is estimated to reach $500-700 million by 2025, driven by demand for precise fluid dynamics analysis in lab-on-chip devices. Technology maturity varies significantly among key players: established companies like Lenterra and Formulaction offer commercial solutions with proven reliability, while academic institutions (University of Florida, USC, Tianjin University) focus on fundamental research innovations. Novartis and Samsung Electro-Mechanics represent industrial end-users integrating these technologies into their R&D processes. Emerging players like Flusso and MedTrain Technologies are developing miniaturized sensors with enhanced sensitivity, potentially disrupting the current market landscape dominated by optical and MEMS-based measurement approaches.

University of Florida

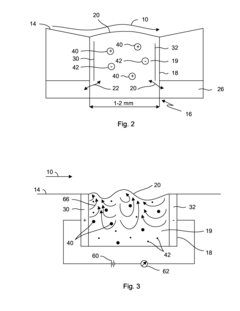

Technical Solution: The University of Florida has developed a novel electrochemical sensing platform for measuring shear stress in microfluidic systems. Their approach utilizes microelectrode arrays fabricated on glass or polymer substrates that detect changes in the diffusion-limited current of redox-active species in solution, which is directly influenced by local shear forces. The technology employs a three-electrode configuration with working electrodes as small as 10 μm in diameter, allowing for high spatial resolution measurements. The system includes a potentiostat circuit that maintains precise potential control while measuring the resulting current with nano-ampere sensitivity. UF researchers have developed specialized algorithms that convert the measured current signals into shear stress values based on established electrochemical principles and empirical calibrations. The technology has been demonstrated in various microfluidic geometries, including straight channels, contractions, and bifurcations, showing excellent correlation with computational fluid dynamics predictions. Recent advancements include multiplexed sensing arrays that can simultaneously measure shear stress at multiple locations within a microfluidic network.

Strengths: Label-free detection without the need for tracer particles; high sensitivity to local flow conditions; compatible with transparent and opaque channel materials; relatively low cost implementation. Weaknesses: Requires presence of electroactive species in the fluid; electrode fouling may occur with certain biological samples; measurement accuracy depends on careful calibration procedures.

Lenterra, Inc.

Technical Solution: Lenterra has developed a proprietary Drag Force Flow (DFF) sensor technology specifically designed for measuring shear stress in microfluidic systems. Their approach utilizes miniaturized cantilever-based sensors that directly interact with the fluid flow, providing real-time measurements of drag forces which are then converted to shear stress values. The technology employs fiber optic-based sensing elements that are minimally invasive to the flow field, with diameters as small as 200 microns, allowing for high spatial resolution measurements. Lenterra's sensors can detect forces in the micro-Newton range with response times in milliseconds, making them suitable for dynamic flow conditions. The system includes proprietary signal processing algorithms that filter noise and compensate for temperature variations, ensuring accurate measurements across a wide range of operating conditions.

Strengths: Non-intrusive measurement capability with minimal flow disturbance; high sensitivity to micro-Newton forces; real-time monitoring capability; temperature compensation for accurate readings across varying conditions. Weaknesses: Relatively higher cost compared to some alternative methods; requires specialized calibration; potential challenges in extremely small microchannels below certain dimensions.

Key Patents and Scientific Breakthroughs in Microfluidic Sensing

Shear Stress Sensor

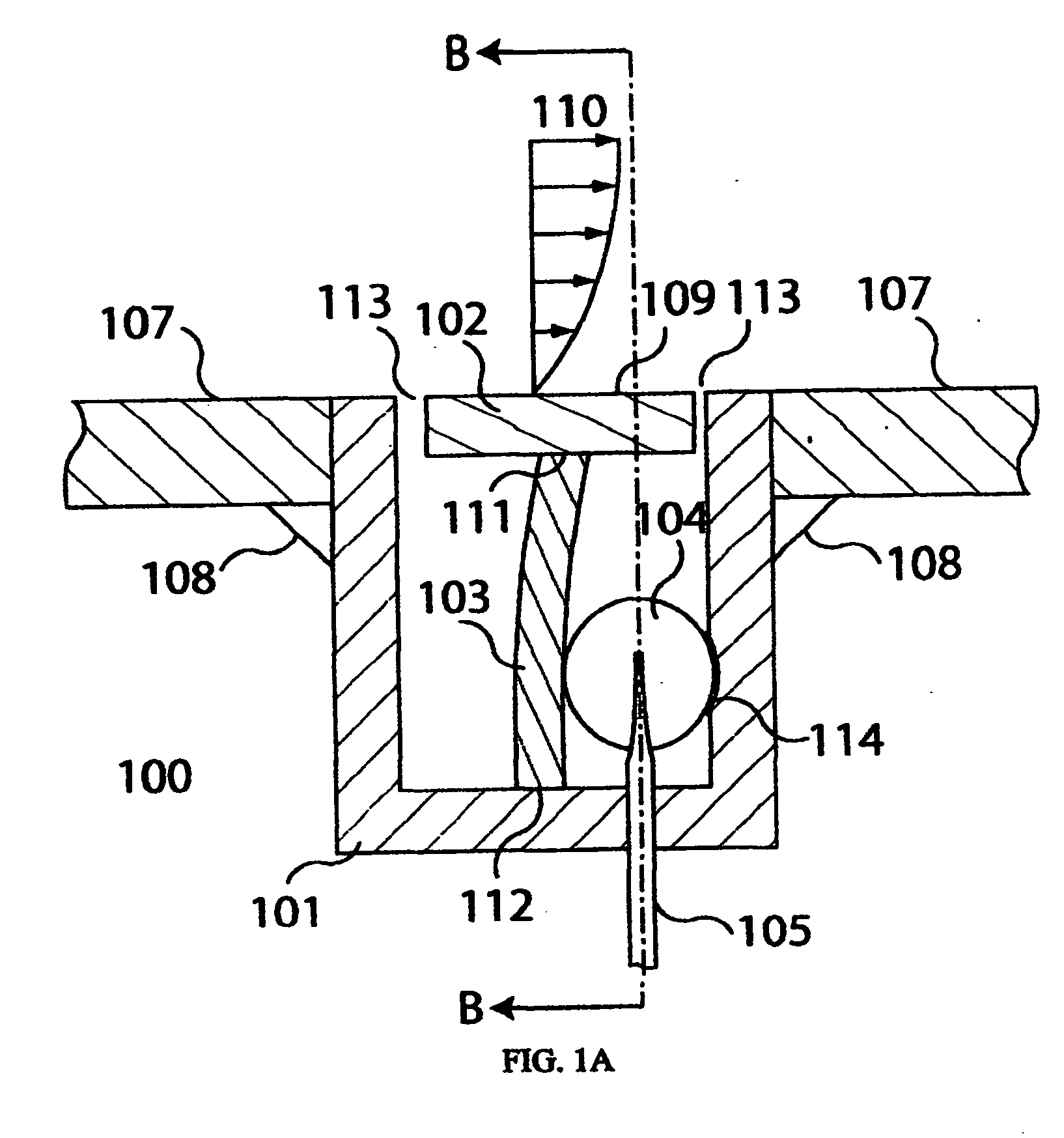

PatentInactiveUS20150211972A1

Innovation

- A microfluidics-based shear stress sensor utilizing a well with electrolyte fluid and an amperometric system to detect changes in ionic current, which correlates with convective flux and shear stress, providing a more sensitive and scalable solution that overcomes the limitations of existing MEMS sensors.

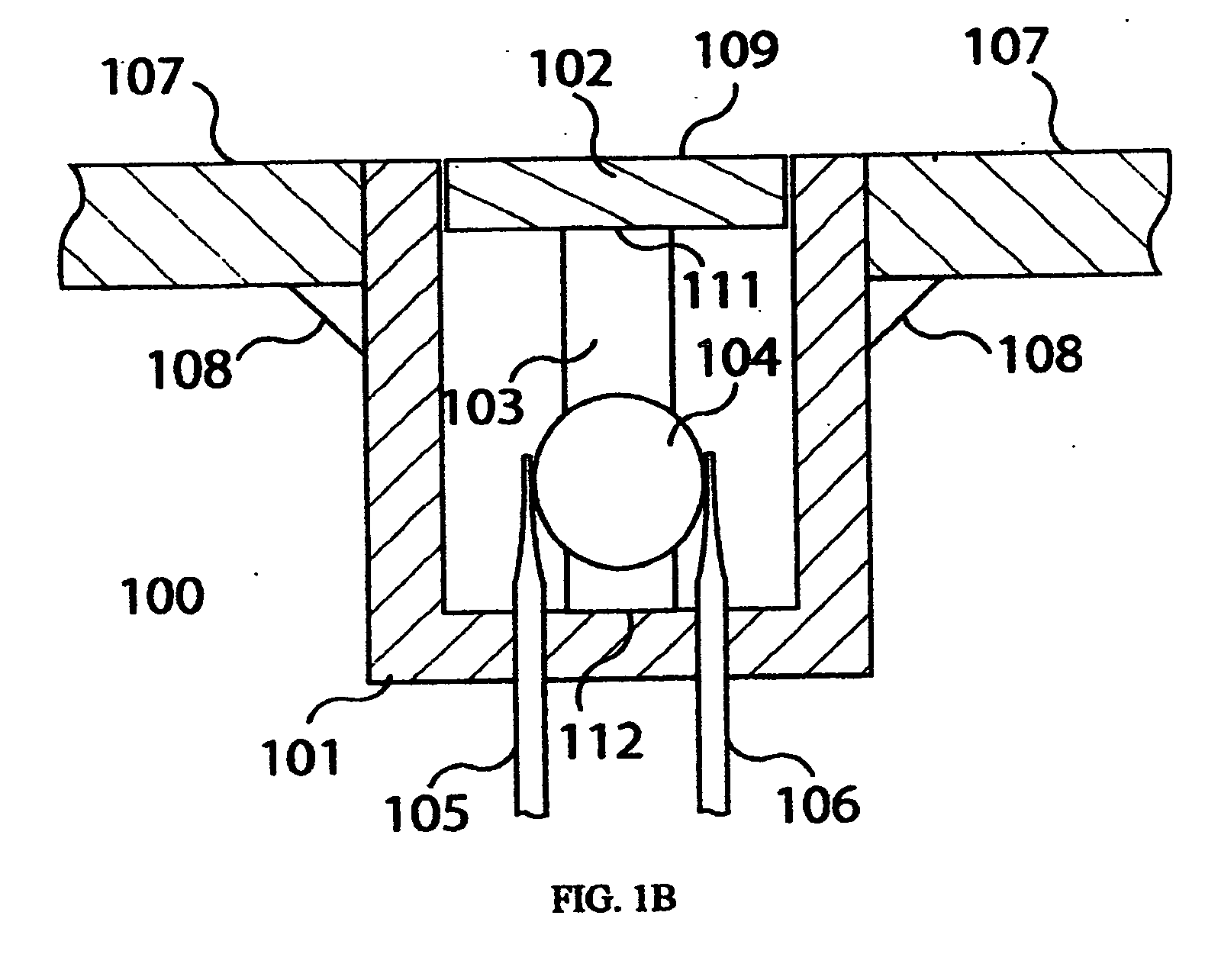

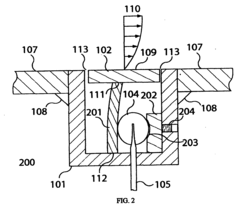

Shear stress measurement apparatus

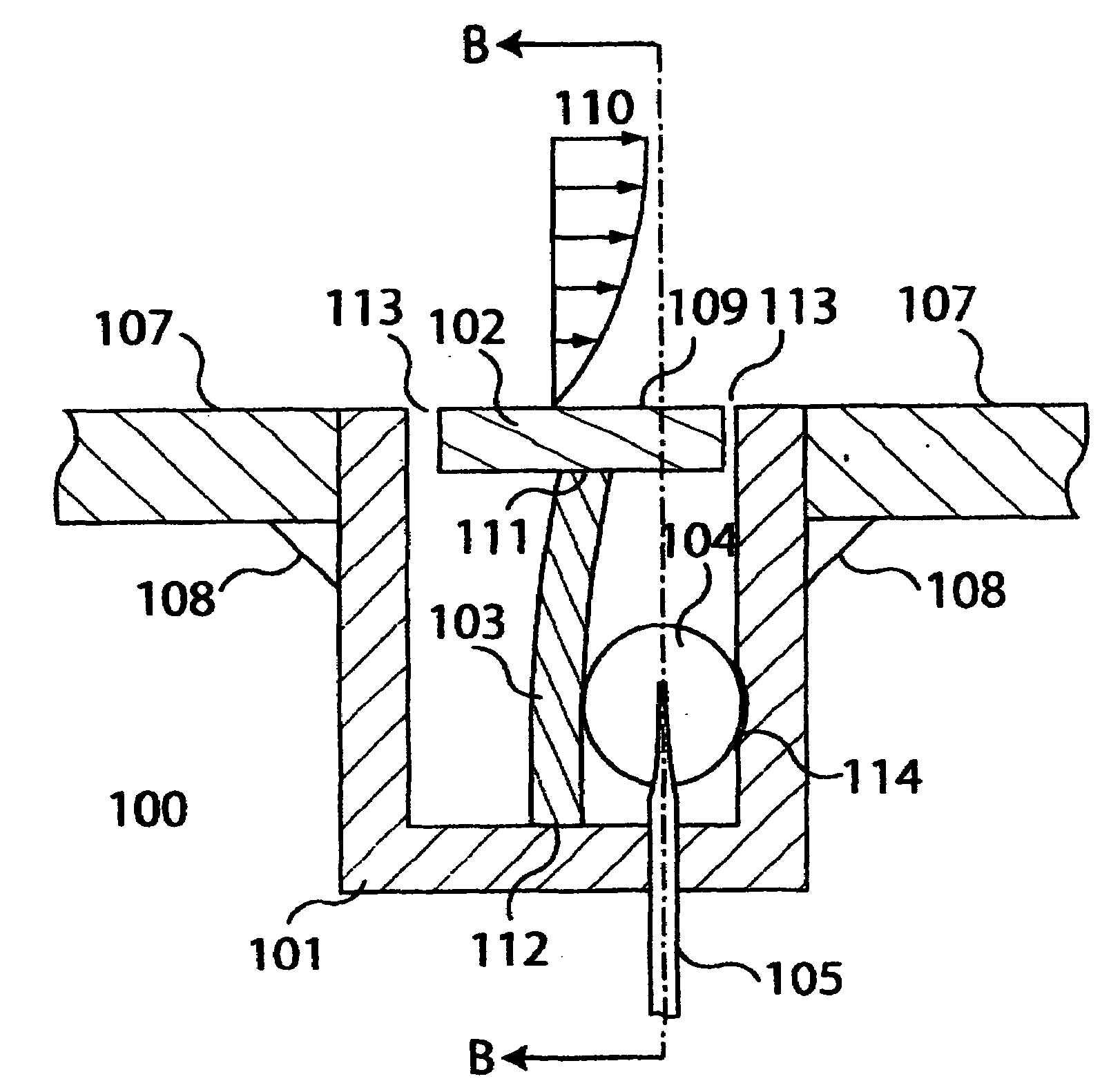

PatentInactiveUS20090133505A1

Innovation

- A shear stress sensor utilizing a micro-resonator that changes shape and refractive index in response to applied forces, allowing for precise measurement of shear stress with minimal detectable gap size through whispering gallery mode (WGM) optical resonance shifts, where the micro-resonator is positioned between a floating element and the wall, amplifying the force and increasing sensitivity.

Standardization and Calibration Protocols for Microfluidic Measurements

Standardization and calibration protocols are essential for ensuring the reliability, reproducibility, and comparability of shear stress measurements in microfluidic systems. The current landscape reveals significant variability in measurement methodologies, making it difficult to compare results across different research groups and applications.

The establishment of standardized protocols begins with reference materials and calibration standards. Currently, certified reference materials specifically designed for microfluidic shear stress calibration are limited. Several research institutions, including NIST (National Institute of Standards and Technology) and PTB (Physikalisch-Technische Bundesanstalt), are developing reference microchannels with well-characterized flow properties that can serve as calibration standards.

Calibration methodologies for shear stress sensors in microfluidics typically involve multi-step procedures. These include zero-point calibration under no-flow conditions, followed by calibration against known reference flows. Advanced protocols incorporate temperature compensation mechanisms, as thermal fluctuations significantly impact measurement accuracy in microfluidic environments. Recent developments have introduced automated calibration systems that can perform in-situ calibration without disassembling the microfluidic setup.

Measurement traceability represents another critical aspect of standardization. The traceability chain for microfluidic shear stress measurements typically links to fundamental SI units through intermediate standards. This chain ensures that measurements can be traced back to internationally recognized standards, facilitating global comparability of research results.

Interlaboratory comparison studies have emerged as valuable tools for validating measurement protocols. Recent initiatives, such as the International Microfluidics Metrology Consortium, coordinate round-robin testing where identical samples are measured across multiple laboratories using standardized protocols. These studies have revealed measurement variations of up to 30% between laboratories, highlighting the urgent need for improved standardization.

Quality assurance frameworks specific to microfluidic measurements are being developed by organizations like ISO Technical Committee 48 (Biotechnology). These frameworks include guidelines for uncertainty estimation, which account for systematic and random errors in microfluidic shear stress measurements. Typical uncertainty budgets consider contributions from calibration standards, sensor response, temperature effects, and flow stability.

Documentation requirements constitute the final component of standardization protocols. Comprehensive documentation should include detailed descriptions of calibration procedures, traceability information, uncertainty calculations, and environmental conditions during measurement. This documentation enables reproducibility and facilitates troubleshooting when measurement discrepancies arise.

The establishment of standardized protocols begins with reference materials and calibration standards. Currently, certified reference materials specifically designed for microfluidic shear stress calibration are limited. Several research institutions, including NIST (National Institute of Standards and Technology) and PTB (Physikalisch-Technische Bundesanstalt), are developing reference microchannels with well-characterized flow properties that can serve as calibration standards.

Calibration methodologies for shear stress sensors in microfluidics typically involve multi-step procedures. These include zero-point calibration under no-flow conditions, followed by calibration against known reference flows. Advanced protocols incorporate temperature compensation mechanisms, as thermal fluctuations significantly impact measurement accuracy in microfluidic environments. Recent developments have introduced automated calibration systems that can perform in-situ calibration without disassembling the microfluidic setup.

Measurement traceability represents another critical aspect of standardization. The traceability chain for microfluidic shear stress measurements typically links to fundamental SI units through intermediate standards. This chain ensures that measurements can be traced back to internationally recognized standards, facilitating global comparability of research results.

Interlaboratory comparison studies have emerged as valuable tools for validating measurement protocols. Recent initiatives, such as the International Microfluidics Metrology Consortium, coordinate round-robin testing where identical samples are measured across multiple laboratories using standardized protocols. These studies have revealed measurement variations of up to 30% between laboratories, highlighting the urgent need for improved standardization.

Quality assurance frameworks specific to microfluidic measurements are being developed by organizations like ISO Technical Committee 48 (Biotechnology). These frameworks include guidelines for uncertainty estimation, which account for systematic and random errors in microfluidic shear stress measurements. Typical uncertainty budgets consider contributions from calibration standards, sensor response, temperature effects, and flow stability.

Documentation requirements constitute the final component of standardization protocols. Comprehensive documentation should include detailed descriptions of calibration procedures, traceability information, uncertainty calculations, and environmental conditions during measurement. This documentation enables reproducibility and facilitates troubleshooting when measurement discrepancies arise.

Integration with Lab-on-a-Chip and Point-of-Care Diagnostics

The integration of shear stress measurement technologies with Lab-on-a-Chip (LOC) and Point-of-Care (POC) diagnostic systems represents a significant advancement in microfluidic applications. This convergence enables real-time monitoring of fluid dynamics in compact, portable diagnostic platforms, enhancing both research capabilities and clinical applications.

Lab-on-a-Chip systems, which miniaturize laboratory processes onto small chips, benefit substantially from integrated shear stress measurement. These integrated sensors allow for continuous monitoring of flow conditions, ensuring optimal performance of diagnostic assays that depend on precise fluid dynamics. The ability to detect anomalies in shear stress patterns can serve as an early warning system for potential device malfunctions or sample irregularities.

Point-of-Care diagnostics particularly benefit from this integration as they operate in diverse, often resource-limited settings where traditional laboratory equipment is unavailable. Embedded shear stress sensors can verify proper sample flow through microchannels, confirming test validity without requiring additional validation steps or equipment. This capability is crucial for ensuring diagnostic accuracy in field conditions.

Recent technological developments have focused on creating non-invasive shear stress measurement systems that maintain the compact form factor essential for POC applications. Optical methods utilizing fluorescent microparticles and miniaturized micro-PIV (Particle Image Velocimetry) systems have been successfully integrated into diagnostic chips without significantly increasing device complexity or cost.

The integration also enables advanced functionalities such as adaptive flow control in diagnostic systems. By continuously monitoring shear stress, microfluidic pumps and valves can automatically adjust to maintain optimal conditions for biological sample processing, cell sorting, or chemical reactions. This feedback mechanism significantly improves the reliability of diagnostic results across varying environmental conditions.

Commercially, several emerging startups are developing integrated platforms that combine shear stress measurement with multiplexed diagnostic capabilities. These systems can simultaneously perform multiple assays while monitoring flow conditions, maximizing diagnostic efficiency in clinical settings. The market potential for such integrated systems is substantial, particularly in applications requiring rapid, reliable results with minimal operator intervention.

Challenges remain in further miniaturizing sensor components while maintaining measurement accuracy. Current research focuses on developing MEMS-based sensors with reduced power requirements and enhanced sensitivity. Additionally, data processing algorithms are being refined to extract meaningful diagnostic information from shear stress patterns, potentially enabling new biomarker detection methodologies based on fluid dynamic signatures.

The convergence of these technologies promises to revolutionize portable diagnostics by enhancing reliability, expanding functional capabilities, and enabling new diagnostic approaches based on fluid behavior analysis rather than solely chemical or biological markers.

Lab-on-a-Chip systems, which miniaturize laboratory processes onto small chips, benefit substantially from integrated shear stress measurement. These integrated sensors allow for continuous monitoring of flow conditions, ensuring optimal performance of diagnostic assays that depend on precise fluid dynamics. The ability to detect anomalies in shear stress patterns can serve as an early warning system for potential device malfunctions or sample irregularities.

Point-of-Care diagnostics particularly benefit from this integration as they operate in diverse, often resource-limited settings where traditional laboratory equipment is unavailable. Embedded shear stress sensors can verify proper sample flow through microchannels, confirming test validity without requiring additional validation steps or equipment. This capability is crucial for ensuring diagnostic accuracy in field conditions.

Recent technological developments have focused on creating non-invasive shear stress measurement systems that maintain the compact form factor essential for POC applications. Optical methods utilizing fluorescent microparticles and miniaturized micro-PIV (Particle Image Velocimetry) systems have been successfully integrated into diagnostic chips without significantly increasing device complexity or cost.

The integration also enables advanced functionalities such as adaptive flow control in diagnostic systems. By continuously monitoring shear stress, microfluidic pumps and valves can automatically adjust to maintain optimal conditions for biological sample processing, cell sorting, or chemical reactions. This feedback mechanism significantly improves the reliability of diagnostic results across varying environmental conditions.

Commercially, several emerging startups are developing integrated platforms that combine shear stress measurement with multiplexed diagnostic capabilities. These systems can simultaneously perform multiple assays while monitoring flow conditions, maximizing diagnostic efficiency in clinical settings. The market potential for such integrated systems is substantial, particularly in applications requiring rapid, reliable results with minimal operator intervention.

Challenges remain in further miniaturizing sensor components while maintaining measurement accuracy. Current research focuses on developing MEMS-based sensors with reduced power requirements and enhanced sensitivity. Additionally, data processing algorithms are being refined to extract meaningful diagnostic information from shear stress patterns, potentially enabling new biomarker detection methodologies based on fluid dynamic signatures.

The convergence of these technologies promises to revolutionize portable diagnostics by enhancing reliability, expanding functional capabilities, and enabling new diagnostic approaches based on fluid behavior analysis rather than solely chemical or biological markers.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!