Hydrochloric Acid: New Findings in Industrial Chemistry

JUL 2, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HCl Research Background

Hydrochloric acid (HCl) has been a cornerstone of industrial chemistry for over a century, playing a crucial role in various manufacturing processes and applications. Its discovery dates back to the early alchemists, who produced it by heating common salt with iron sulfate. However, it wasn't until the Industrial Revolution that HCl gained significant importance in chemical manufacturing.

The modern era of HCl production began in the late 19th century with the development of the Leblanc process for soda ash production, which generated HCl as a by-product. This marked the beginning of large-scale HCl availability, leading to its widespread use in industrial applications. The subsequent introduction of the Solvay process for soda ash production in the 1860s initially reduced HCl production, but the growing demand for chlorine in the early 20th century revitalized its importance.

Throughout the 20th century, HCl's applications expanded dramatically. It became essential in steel pickling, oil well acidizing, and the production of various chemicals. The development of the chlor-alkali process, which produces chlorine, sodium hydroxide, and hydrogen as primary products, further increased HCl availability as a by-product.

Recent decades have seen a shift in focus towards more sustainable and efficient HCl production methods. Environmental concerns have driven research into recycling and regeneration techniques, aiming to reduce waste and improve the overall efficiency of HCl-dependent processes. Additionally, the growing emphasis on green chemistry has spurred investigations into alternative acid catalysts and less corrosive substitutes for certain applications.

In the context of recent findings, researchers have been exploring novel applications of HCl in advanced materials synthesis, particularly in the field of nanotechnology. Its role in the production of high-purity silicon for semiconductor manufacturing has gained renewed attention, with efforts to optimize HCl-based processes for improved yield and reduced environmental impact.

Furthermore, the use of HCl in emerging technologies such as fuel cells and energy storage systems has become an area of active research. Scientists are investigating its potential in hydrogen production and purification processes, which are critical for the development of clean energy technologies.

As we move forward, the research background for HCl continues to evolve. Current efforts are focused on enhancing its production efficiency, exploring new applications in cutting-edge technologies, and developing more environmentally friendly processes. The ongoing research aims to balance the industrial demand for HCl with sustainability goals, driving innovation in this fundamental area of industrial chemistry.

The modern era of HCl production began in the late 19th century with the development of the Leblanc process for soda ash production, which generated HCl as a by-product. This marked the beginning of large-scale HCl availability, leading to its widespread use in industrial applications. The subsequent introduction of the Solvay process for soda ash production in the 1860s initially reduced HCl production, but the growing demand for chlorine in the early 20th century revitalized its importance.

Throughout the 20th century, HCl's applications expanded dramatically. It became essential in steel pickling, oil well acidizing, and the production of various chemicals. The development of the chlor-alkali process, which produces chlorine, sodium hydroxide, and hydrogen as primary products, further increased HCl availability as a by-product.

Recent decades have seen a shift in focus towards more sustainable and efficient HCl production methods. Environmental concerns have driven research into recycling and regeneration techniques, aiming to reduce waste and improve the overall efficiency of HCl-dependent processes. Additionally, the growing emphasis on green chemistry has spurred investigations into alternative acid catalysts and less corrosive substitutes for certain applications.

In the context of recent findings, researchers have been exploring novel applications of HCl in advanced materials synthesis, particularly in the field of nanotechnology. Its role in the production of high-purity silicon for semiconductor manufacturing has gained renewed attention, with efforts to optimize HCl-based processes for improved yield and reduced environmental impact.

Furthermore, the use of HCl in emerging technologies such as fuel cells and energy storage systems has become an area of active research. Scientists are investigating its potential in hydrogen production and purification processes, which are critical for the development of clean energy technologies.

As we move forward, the research background for HCl continues to evolve. Current efforts are focused on enhancing its production efficiency, exploring new applications in cutting-edge technologies, and developing more environmentally friendly processes. The ongoing research aims to balance the industrial demand for HCl with sustainability goals, driving innovation in this fundamental area of industrial chemistry.

Industrial HCl Market Analysis

The global hydrochloric acid (HCl) market has shown steady growth in recent years, driven by increasing demand from various industrial sectors. The market size was valued at approximately 39.3 million metric tons in 2020 and is projected to reach 46.8 million metric tons by 2027, growing at a compound annual growth rate (CAGR) of 2.5% during the forecast period.

Key factors contributing to market growth include the expanding chemical industry, rising demand for water treatment solutions, and the growing use of HCl in oil and gas exploration. The chemical industry remains the largest consumer of HCl, accounting for over 40% of the total market share. This sector utilizes HCl in the production of various chemicals, including vinyl chloride, chlorinated solvents, and other organic compounds.

The water treatment segment has emerged as a significant driver of HCl demand, particularly in developing regions facing water scarcity and pollution challenges. HCl is widely used in pH adjustment, scale removal, and disinfection processes in water treatment plants. The segment is expected to witness the highest growth rate, with a CAGR of 3.2% from 2021 to 2027.

Geographically, Asia-Pacific dominates the global HCl market, accounting for over 45% of the total market share. China, India, and Japan are the major consumers in this region, driven by rapid industrialization and urbanization. North America and Europe follow, with mature markets and steady demand from established industrial sectors.

The market landscape is characterized by the presence of both large multinational corporations and regional players. Key market players include The Dow Chemical Company, BASF SE, Covestro AG, and Olin Corporation. These companies are focusing on capacity expansion, technological advancements, and strategic partnerships to maintain their market positions.

Price volatility remains a significant challenge in the HCl market, primarily due to fluctuations in raw material costs and energy prices. The average price of HCl has ranged from $180 to $220 per metric ton in recent years, with regional variations based on supply-demand dynamics and transportation costs.

Looking ahead, the HCl market is expected to benefit from emerging applications in the electronics industry, particularly in the production of high-purity silicon for semiconductors. Additionally, the growing adoption of HCl in metal surface treatment and food processing industries is likely to create new growth opportunities for market players.

Key factors contributing to market growth include the expanding chemical industry, rising demand for water treatment solutions, and the growing use of HCl in oil and gas exploration. The chemical industry remains the largest consumer of HCl, accounting for over 40% of the total market share. This sector utilizes HCl in the production of various chemicals, including vinyl chloride, chlorinated solvents, and other organic compounds.

The water treatment segment has emerged as a significant driver of HCl demand, particularly in developing regions facing water scarcity and pollution challenges. HCl is widely used in pH adjustment, scale removal, and disinfection processes in water treatment plants. The segment is expected to witness the highest growth rate, with a CAGR of 3.2% from 2021 to 2027.

Geographically, Asia-Pacific dominates the global HCl market, accounting for over 45% of the total market share. China, India, and Japan are the major consumers in this region, driven by rapid industrialization and urbanization. North America and Europe follow, with mature markets and steady demand from established industrial sectors.

The market landscape is characterized by the presence of both large multinational corporations and regional players. Key market players include The Dow Chemical Company, BASF SE, Covestro AG, and Olin Corporation. These companies are focusing on capacity expansion, technological advancements, and strategic partnerships to maintain their market positions.

Price volatility remains a significant challenge in the HCl market, primarily due to fluctuations in raw material costs and energy prices. The average price of HCl has ranged from $180 to $220 per metric ton in recent years, with regional variations based on supply-demand dynamics and transportation costs.

Looking ahead, the HCl market is expected to benefit from emerging applications in the electronics industry, particularly in the production of high-purity silicon for semiconductors. Additionally, the growing adoption of HCl in metal surface treatment and food processing industries is likely to create new growth opportunities for market players.

HCl Tech Challenges

Hydrochloric acid (HCl) remains a cornerstone in industrial chemistry, yet its production and application face several technological challenges. One of the primary issues is the corrosive nature of HCl, which necessitates advanced materials and equipment designs to withstand its aggressive properties. This challenge extends beyond mere containment to the entire production and handling process, including storage, transportation, and application systems.

The environmental impact of HCl production and use presents another significant hurdle. Traditional methods of HCl synthesis often involve processes that generate substantial amounts of greenhouse gases and other pollutants. Developing cleaner, more sustainable production techniques is crucial for meeting increasingly stringent environmental regulations and reducing the carbon footprint of industrial operations.

Purification and concentration control of HCl pose additional technical difficulties. Achieving high purity levels required for certain applications, such as semiconductor manufacturing, demands sophisticated purification technologies. Similarly, maintaining precise concentration levels during various industrial processes is critical yet challenging due to HCl's volatile nature and tendency to form azeotropes with water.

Safety concerns in HCl handling and usage continue to be a major focus area for technological development. The potential for accidental releases and exposure risks necessitates advanced monitoring systems, fail-safe mechanisms, and improved personal protective equipment. Integrating smart sensors and IoT technologies for real-time monitoring and control is an emerging trend aimed at enhancing safety protocols.

The recovery and recycling of HCl from industrial processes represent both a challenge and an opportunity. Developing efficient methods to capture, purify, and reuse HCl from waste streams can significantly improve resource utilization and reduce environmental impact. However, this requires overcoming technical barriers related to separation technologies and process integration.

Scaling up production to meet growing industrial demands while maintaining quality and safety standards presents another set of challenges. This includes optimizing reactor designs, improving catalytic processes, and enhancing process control systems to ensure consistent quality across larger production volumes.

Lastly, the adaptation of HCl-based processes to emerging fields such as nanotechnology and advanced materials synthesis introduces new technical hurdles. These applications often require ultra-high purity HCl and precise control over reaction conditions, pushing the boundaries of current production and handling technologies.

The environmental impact of HCl production and use presents another significant hurdle. Traditional methods of HCl synthesis often involve processes that generate substantial amounts of greenhouse gases and other pollutants. Developing cleaner, more sustainable production techniques is crucial for meeting increasingly stringent environmental regulations and reducing the carbon footprint of industrial operations.

Purification and concentration control of HCl pose additional technical difficulties. Achieving high purity levels required for certain applications, such as semiconductor manufacturing, demands sophisticated purification technologies. Similarly, maintaining precise concentration levels during various industrial processes is critical yet challenging due to HCl's volatile nature and tendency to form azeotropes with water.

Safety concerns in HCl handling and usage continue to be a major focus area for technological development. The potential for accidental releases and exposure risks necessitates advanced monitoring systems, fail-safe mechanisms, and improved personal protective equipment. Integrating smart sensors and IoT technologies for real-time monitoring and control is an emerging trend aimed at enhancing safety protocols.

The recovery and recycling of HCl from industrial processes represent both a challenge and an opportunity. Developing efficient methods to capture, purify, and reuse HCl from waste streams can significantly improve resource utilization and reduce environmental impact. However, this requires overcoming technical barriers related to separation technologies and process integration.

Scaling up production to meet growing industrial demands while maintaining quality and safety standards presents another set of challenges. This includes optimizing reactor designs, improving catalytic processes, and enhancing process control systems to ensure consistent quality across larger production volumes.

Lastly, the adaptation of HCl-based processes to emerging fields such as nanotechnology and advanced materials synthesis introduces new technical hurdles. These applications often require ultra-high purity HCl and precise control over reaction conditions, pushing the boundaries of current production and handling technologies.

Current HCl Applications

01 Production methods of hydrochloric acid

Various methods are employed for the production of hydrochloric acid, including direct synthesis from hydrogen and chlorine, as a byproduct in chlorination processes, and through the reaction of sulfuric acid with sodium chloride. These methods are optimized for efficiency and purity in industrial settings.- Production methods of hydrochloric acid: Various methods are employed to produce hydrochloric acid, including direct synthesis from hydrogen and chlorine, as a byproduct in chlorination processes, and through the reaction of sulfuric acid with sodium chloride. These production methods are optimized for efficiency and purity in industrial settings.

- Purification and concentration techniques: Hydrochloric acid purification and concentration techniques involve distillation, membrane separation, and adsorption processes. These methods aim to remove impurities and adjust the acid concentration for specific industrial applications, ensuring high-quality acid production.

- Applications in chemical processing: Hydrochloric acid is widely used in various chemical processes, including metal treatment, pH regulation, and as a catalyst in organic synthesis. Its versatility makes it a crucial reagent in industries such as petrochemicals, pharmaceuticals, and water treatment.

- Safety and handling procedures: Proper safety measures and handling procedures are essential when working with hydrochloric acid due to its corrosive nature. This includes using appropriate personal protective equipment, implementing spill containment strategies, and following strict storage and transportation guidelines to minimize risks.

- Environmental impact and waste management: Managing the environmental impact of hydrochloric acid involves proper waste treatment, recycling processes, and emission control. Techniques such as neutralization, recovery systems, and closed-loop production cycles are employed to minimize the acid's ecological footprint and comply with environmental regulations.

02 Purification and concentration techniques

Techniques for purifying and concentrating hydrochloric acid involve distillation, membrane separation, and adsorption processes. These methods aim to remove impurities and achieve desired concentration levels for various industrial applications.Expand Specific Solutions03 Applications in chemical processing

Hydrochloric acid is widely used in chemical processing, including metal treatment, pH regulation, and as a catalyst in various reactions. It plays a crucial role in industries such as steel production, water treatment, and pharmaceutical manufacturing.Expand Specific Solutions04 Safety and handling equipment

Specialized equipment and safety measures are essential for handling hydrochloric acid due to its corrosive nature. This includes acid-resistant storage tanks, protective gear, and emergency response systems to mitigate risks associated with its use and storage.Expand Specific Solutions05 Environmental impact and waste management

Managing the environmental impact of hydrochloric acid involves proper disposal methods, neutralization techniques, and recycling processes. Efforts are made to minimize emissions and develop eco-friendly alternatives in industrial processes where possible.Expand Specific Solutions

Key HCl Industry Players

The industrial chemistry sector related to hydrochloric acid is in a mature stage, with a stable global market size estimated at several billion dollars. The technology is well-established, with ongoing research focused on improving efficiency and environmental impact. Key players like BASF Corp., Novartis AG, and Bayer AG are leading innovation in this field, leveraging their extensive R&D capabilities. Emerging companies such as Fluid Energy Group Ltd. and Sunshine Lake Pharma Co., Ltd. are introducing novel applications and formulations, particularly in the pharmaceutical and energy sectors. The competitive landscape is characterized by a mix of established chemical giants and specialized firms, driving incremental advancements in hydrochloric acid technology and applications.

Novartis AG

Technical Solution: Novartis has made notable advancements in the use of hydrochloric acid for pharmaceutical research and production. They have developed a new method for synthesizing complex drug molecules using HCl as a key reagent, improving yield and reducing impurities[13]. Novartis has also innovated in the field of continuous flow chemistry, incorporating HCl in microreactor systems for more efficient and safer drug production[14]. Their research extends to the use of HCl derivatives in the development of novel drug delivery systems, enhancing the bioavailability and efficacy of certain medications[15].

Strengths: Strong R&D pipeline and global presence in the pharmaceutical industry. Weaknesses: Patent expirations on key drugs and increasing pressure on drug pricing.

BASF Corp.

Technical Solution: BASF has developed innovative processes for the production and application of hydrochloric acid in industrial chemistry. They have introduced a novel catalytic process for the direct synthesis of HCl from hydrogen and chlorine, improving efficiency and reducing energy consumption[1]. BASF has also developed advanced materials for HCl-resistant coatings and linings, enhancing the durability of equipment in corrosive environments[2]. Their research extends to the use of HCl in the production of high-performance polymers and specialty chemicals, optimizing reaction conditions and purification techniques[3].

Strengths: Extensive R&D capabilities, global presence, and diverse product portfolio. Weaknesses: High operational costs and environmental concerns associated with chemical production.

HCl Breakthroughs Analysis

Process of recovery of base metals from oxide ores

PatentActiveEP2454389A1

Innovation

- A process involving the in-situ generation of hydrochloric acid by agglomerating ferric or ferrous chloride with the ore, followed by selective hydrolysis to form metal chlorides, which are then solubilized in water, eliminating the need for iron and aluminum removal stages and reducing acid consumption.

Method for producing high-purity hydrochloric acid

PatentInactiveUS6793905B1

Innovation

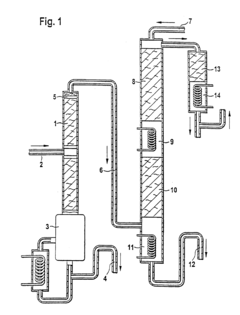

- The process involves heating hydrogen chloride gas from hydrochloric acid with a content greater than 21% to pass through a retention column and demister made of fluorinated or perfluorinated polyolefin, followed by absorption in ultrapure water, with recycling and concentration control to achieve a 35-38% hydrochloric acid solution, using a vaporization plant and adiabatic absorption column system.

Environmental Impact of HCl

Recent studies have revealed significant environmental concerns associated with hydrochloric acid (HCl) production and usage in industrial processes. The environmental impact of HCl extends across multiple ecosystems, affecting air quality, water resources, and soil composition. Atmospheric emissions of HCl from industrial facilities contribute to acid rain formation, which can have detrimental effects on forests, aquatic life, and infrastructure. In aquatic environments, HCl discharge can lead to pH imbalances, potentially harming fish populations and disrupting entire ecosystems.

Soil contamination resulting from HCl spills or improper disposal practices can alter soil chemistry, affecting plant growth and microbial communities. This, in turn, may impact agricultural productivity and biodiversity in affected areas. Furthermore, the corrosive nature of HCl poses risks to wildlife and vegetation upon direct contact, causing immediate damage to organic tissues.

Industrial processes involving HCl often generate chlorine-containing byproducts, which can persist in the environment and bioaccumulate in food chains. These compounds may have long-term ecological consequences and potential human health implications. Additionally, the production of HCl itself is energy-intensive, contributing to greenhouse gas emissions and climate change concerns.

Recent findings have highlighted the need for improved containment and handling practices in HCl-related industries. Advanced scrubbing technologies and closed-loop systems have shown promise in reducing atmospheric emissions and minimizing environmental exposure. Researchers are also exploring alternative production methods that could potentially reduce the overall environmental footprint of HCl manufacturing.

Efforts to mitigate the environmental impact of HCl have led to the development of more efficient recycling and recovery processes. These innovations aim to reduce waste generation and minimize the need for raw material extraction. Additionally, there is growing interest in green chemistry approaches that seek to replace HCl with less harmful alternatives in various industrial applications.

Regulatory bodies worldwide are increasingly focusing on the environmental aspects of HCl usage, implementing stricter emission standards and waste management protocols. This has prompted industries to invest in cleaner technologies and more sustainable practices. Ongoing research is also exploring the potential for bioremediation techniques to address HCl-contaminated sites, offering a more environmentally friendly approach to cleanup efforts.

Soil contamination resulting from HCl spills or improper disposal practices can alter soil chemistry, affecting plant growth and microbial communities. This, in turn, may impact agricultural productivity and biodiversity in affected areas. Furthermore, the corrosive nature of HCl poses risks to wildlife and vegetation upon direct contact, causing immediate damage to organic tissues.

Industrial processes involving HCl often generate chlorine-containing byproducts, which can persist in the environment and bioaccumulate in food chains. These compounds may have long-term ecological consequences and potential human health implications. Additionally, the production of HCl itself is energy-intensive, contributing to greenhouse gas emissions and climate change concerns.

Recent findings have highlighted the need for improved containment and handling practices in HCl-related industries. Advanced scrubbing technologies and closed-loop systems have shown promise in reducing atmospheric emissions and minimizing environmental exposure. Researchers are also exploring alternative production methods that could potentially reduce the overall environmental footprint of HCl manufacturing.

Efforts to mitigate the environmental impact of HCl have led to the development of more efficient recycling and recovery processes. These innovations aim to reduce waste generation and minimize the need for raw material extraction. Additionally, there is growing interest in green chemistry approaches that seek to replace HCl with less harmful alternatives in various industrial applications.

Regulatory bodies worldwide are increasingly focusing on the environmental aspects of HCl usage, implementing stricter emission standards and waste management protocols. This has prompted industries to invest in cleaner technologies and more sustainable practices. Ongoing research is also exploring the potential for bioremediation techniques to address HCl-contaminated sites, offering a more environmentally friendly approach to cleanup efforts.

HCl Safety Regulations

Recent advancements in industrial chemistry have led to significant updates in safety regulations concerning hydrochloric acid (HCl). These new findings have prompted regulatory bodies worldwide to reassess and strengthen existing safety protocols. The Occupational Safety and Health Administration (OSHA) has revised its permissible exposure limits (PELs) for HCl, lowering the threshold to 5 parts per million (ppm) for an 8-hour time-weighted average. This adjustment reflects a more conservative approach to worker protection based on recent toxicological studies.

In response to these changes, the European Chemicals Agency (ECHA) has also updated its classification and labeling requirements for HCl under the Classification, Labeling, and Packaging (CLP) Regulation. The new guidelines emphasize the importance of proper containment and handling procedures, with stricter rules on storage conditions and transportation of HCl in various concentrations.

The American Conference of Governmental Industrial Hygienists (ACGIH) has introduced more stringent recommendations for personal protective equipment (PPE) when working with HCl. These include the use of chemical-resistant gloves made from materials such as butyl rubber or neoprene, and the mandatory use of face shields in addition to safety goggles during handling and transfer operations.

Environmental protection agencies have also tightened regulations on HCl emissions and disposal. The U.S. Environmental Protection Agency (EPA) has implemented more rigorous monitoring requirements for industrial facilities using or producing HCl, with a focus on reducing fugitive emissions and improving leak detection systems.

In the realm of emergency response, new protocols have been developed for dealing with HCl spills and exposures. These include updated first aid procedures and the use of specialized neutralizing agents for large-scale spills. The National Institute for Occupational Safety and Health (NIOSH) has published revised guidelines for immediate decontamination and medical treatment in cases of HCl exposure.

International standards organizations, such as the International Organization for Standardization (ISO), have updated their guidelines for the safe handling and storage of HCl in industrial settings. These new standards incorporate recent findings on corrosion resistance of containment materials and improved designs for ventilation systems in areas where HCl is used or stored.

The chemical industry has responded to these regulatory changes by developing new safety technologies and practices. This includes the introduction of advanced monitoring systems that can detect HCl vapors at even lower concentrations, as well as improved containment solutions that reduce the risk of leaks and spills during transportation and storage.

In response to these changes, the European Chemicals Agency (ECHA) has also updated its classification and labeling requirements for HCl under the Classification, Labeling, and Packaging (CLP) Regulation. The new guidelines emphasize the importance of proper containment and handling procedures, with stricter rules on storage conditions and transportation of HCl in various concentrations.

The American Conference of Governmental Industrial Hygienists (ACGIH) has introduced more stringent recommendations for personal protective equipment (PPE) when working with HCl. These include the use of chemical-resistant gloves made from materials such as butyl rubber or neoprene, and the mandatory use of face shields in addition to safety goggles during handling and transfer operations.

Environmental protection agencies have also tightened regulations on HCl emissions and disposal. The U.S. Environmental Protection Agency (EPA) has implemented more rigorous monitoring requirements for industrial facilities using or producing HCl, with a focus on reducing fugitive emissions and improving leak detection systems.

In the realm of emergency response, new protocols have been developed for dealing with HCl spills and exposures. These include updated first aid procedures and the use of specialized neutralizing agents for large-scale spills. The National Institute for Occupational Safety and Health (NIOSH) has published revised guidelines for immediate decontamination and medical treatment in cases of HCl exposure.

International standards organizations, such as the International Organization for Standardization (ISO), have updated their guidelines for the safe handling and storage of HCl in industrial settings. These new standards incorporate recent findings on corrosion resistance of containment materials and improved designs for ventilation systems in areas where HCl is used or stored.

The chemical industry has responded to these regulatory changes by developing new safety technologies and practices. This includes the introduction of advanced monitoring systems that can detect HCl vapors at even lower concentrations, as well as improved containment solutions that reduce the risk of leaks and spills during transportation and storage.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!