New Horizons: UHMWPE in the 3D Printing Industry

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

UHMWPE 3D Printing Evolution and Objectives

Ultra-high-molecular-weight polyethylene (UHMWPE) has emerged as a promising material in the 3D printing industry, offering unique properties that have the potential to revolutionize various applications. The evolution of UHMWPE in 3D printing can be traced back to the early 2010s when researchers began exploring its potential for additive manufacturing.

Initially, the use of UHMWPE in 3D printing was limited due to its high molecular weight and viscosity, which made it challenging to process using conventional 3D printing techniques. However, as technology advanced, new methods were developed to overcome these obstacles, paving the way for UHMWPE's integration into the 3D printing landscape.

One of the key milestones in UHMWPE 3D printing was the development of specialized extrusion techniques that could handle the material's unique properties. These innovations allowed for the creation of UHMWPE filaments suitable for fused deposition modeling (FDM) printers, opening up new possibilities for producing high-performance parts with exceptional wear resistance and impact strength.

The objectives of incorporating UHMWPE into 3D printing are multifaceted. Primarily, researchers and industry professionals aim to leverage the material's outstanding mechanical properties, including its high tensile strength, low coefficient of friction, and excellent chemical resistance. These characteristics make UHMWPE an ideal candidate for applications in industries such as aerospace, automotive, and medical devices.

Another key objective is to expand the range of printable materials available to manufacturers, enabling the production of complex geometries and customized parts that were previously difficult or impossible to create using traditional manufacturing methods. By integrating UHMWPE into 3D printing processes, engineers can design and fabricate components with enhanced durability and performance characteristics.

Furthermore, the development of UHMWPE 3D printing technologies aims to address the growing demand for sustainable and recyclable materials in additive manufacturing. As a thermoplastic, UHMWPE offers the potential for recycling and reuse, aligning with the industry's push towards more environmentally friendly production methods.

Looking ahead, the evolution of UHMWPE in 3D printing is expected to focus on improving print quality, increasing printing speeds, and developing new composite materials that combine UHMWPE with other high-performance polymers or reinforcing agents. These advancements will likely lead to broader adoption of UHMWPE in various industrial applications, further solidifying its position as a valuable material in the 3D printing industry.

Initially, the use of UHMWPE in 3D printing was limited due to its high molecular weight and viscosity, which made it challenging to process using conventional 3D printing techniques. However, as technology advanced, new methods were developed to overcome these obstacles, paving the way for UHMWPE's integration into the 3D printing landscape.

One of the key milestones in UHMWPE 3D printing was the development of specialized extrusion techniques that could handle the material's unique properties. These innovations allowed for the creation of UHMWPE filaments suitable for fused deposition modeling (FDM) printers, opening up new possibilities for producing high-performance parts with exceptional wear resistance and impact strength.

The objectives of incorporating UHMWPE into 3D printing are multifaceted. Primarily, researchers and industry professionals aim to leverage the material's outstanding mechanical properties, including its high tensile strength, low coefficient of friction, and excellent chemical resistance. These characteristics make UHMWPE an ideal candidate for applications in industries such as aerospace, automotive, and medical devices.

Another key objective is to expand the range of printable materials available to manufacturers, enabling the production of complex geometries and customized parts that were previously difficult or impossible to create using traditional manufacturing methods. By integrating UHMWPE into 3D printing processes, engineers can design and fabricate components with enhanced durability and performance characteristics.

Furthermore, the development of UHMWPE 3D printing technologies aims to address the growing demand for sustainable and recyclable materials in additive manufacturing. As a thermoplastic, UHMWPE offers the potential for recycling and reuse, aligning with the industry's push towards more environmentally friendly production methods.

Looking ahead, the evolution of UHMWPE in 3D printing is expected to focus on improving print quality, increasing printing speeds, and developing new composite materials that combine UHMWPE with other high-performance polymers or reinforcing agents. These advancements will likely lead to broader adoption of UHMWPE in various industrial applications, further solidifying its position as a valuable material in the 3D printing industry.

Market Analysis for UHMWPE 3D Printed Products

The market for UHMWPE 3D printed products is experiencing significant growth, driven by the material's unique properties and the expanding applications of additive manufacturing. UHMWPE, known for its exceptional strength-to-weight ratio, chemical resistance, and low friction coefficient, is finding increasing adoption in various industries.

In the medical sector, UHMWPE 3D printed products are gaining traction for orthopedic implants and prosthetics. The ability to create custom-fit, patient-specific devices is a key driver, with the market expected to see substantial growth in the coming years. The aerospace industry is another major adopter, utilizing UHMWPE for lightweight components that offer high strength and durability.

The automotive sector is exploring UHMWPE 3D printed products for interior components and under-the-hood applications, leveraging the material's resistance to chemicals and abrasion. Additionally, the sports and recreation industry is incorporating UHMWPE into protective gear and high-performance equipment, capitalizing on its impact resistance and low weight.

Market analysts predict a compound annual growth rate (CAGR) for UHMWPE 3D printed products that outpaces the overall 3D printing materials market. This growth is attributed to increasing awareness of the material's benefits and advancements in 3D printing technologies that enable more efficient processing of UHMWPE.

Geographically, North America and Europe are currently the largest markets for UHMWPE 3D printed products, with established manufacturing bases and high adoption rates of advanced materials. However, the Asia-Pacific region is expected to show the fastest growth, driven by rapid industrialization and increasing investments in additive manufacturing technologies.

Challenges in the market include the relatively high cost of UHMWPE compared to traditional 3D printing materials and the need for specialized equipment to process the material effectively. However, ongoing research and development efforts are focused on addressing these issues, which is expected to further drive market growth.

The demand for sustainable and recyclable materials is also influencing the UHMWPE 3D printing market. Manufacturers are increasingly focusing on developing eco-friendly variants and recycling processes for UHMWPE, aligning with global sustainability trends and potentially opening new market segments.

In the medical sector, UHMWPE 3D printed products are gaining traction for orthopedic implants and prosthetics. The ability to create custom-fit, patient-specific devices is a key driver, with the market expected to see substantial growth in the coming years. The aerospace industry is another major adopter, utilizing UHMWPE for lightweight components that offer high strength and durability.

The automotive sector is exploring UHMWPE 3D printed products for interior components and under-the-hood applications, leveraging the material's resistance to chemicals and abrasion. Additionally, the sports and recreation industry is incorporating UHMWPE into protective gear and high-performance equipment, capitalizing on its impact resistance and low weight.

Market analysts predict a compound annual growth rate (CAGR) for UHMWPE 3D printed products that outpaces the overall 3D printing materials market. This growth is attributed to increasing awareness of the material's benefits and advancements in 3D printing technologies that enable more efficient processing of UHMWPE.

Geographically, North America and Europe are currently the largest markets for UHMWPE 3D printed products, with established manufacturing bases and high adoption rates of advanced materials. However, the Asia-Pacific region is expected to show the fastest growth, driven by rapid industrialization and increasing investments in additive manufacturing technologies.

Challenges in the market include the relatively high cost of UHMWPE compared to traditional 3D printing materials and the need for specialized equipment to process the material effectively. However, ongoing research and development efforts are focused on addressing these issues, which is expected to further drive market growth.

The demand for sustainable and recyclable materials is also influencing the UHMWPE 3D printing market. Manufacturers are increasingly focusing on developing eco-friendly variants and recycling processes for UHMWPE, aligning with global sustainability trends and potentially opening new market segments.

UHMWPE 3D Printing: Current State and Challenges

Ultra-high-molecular-weight polyethylene (UHMWPE) has emerged as a promising material in the 3D printing industry, offering unique properties that make it attractive for various applications. However, the integration of UHMWPE into 3D printing processes faces several challenges that need to be addressed for widespread adoption.

The current state of UHMWPE 3D printing is characterized by limited commercial availability and specialized equipment requirements. Only a handful of companies offer UHMWPE filaments or powders specifically designed for 3D printing, which restricts accessibility for many potential users. The high melting point and viscosity of UHMWPE necessitate modified printing hardware capable of reaching and maintaining elevated temperatures, often exceeding 200°C.

One of the primary challenges in UHMWPE 3D printing is achieving consistent layer adhesion and part density. The material's low surface energy and high crystallinity can lead to poor interlayer bonding, resulting in weak mechanical properties in the Z-axis. Researchers and manufacturers are exploring various strategies to overcome this issue, including the use of plasma treatments, specialized bed materials, and optimized printing parameters.

Another significant challenge is controlling the thermal behavior of UHMWPE during the printing process. The material's high thermal expansion coefficient can cause warping and dimensional inaccuracies in printed parts. This necessitates careful temperature management throughout the printing process, including heated build chambers and gradual cooling strategies.

The high molecular weight of UHMWPE, while beneficial for its mechanical properties, poses challenges in terms of processability. The material's high melt viscosity can lead to nozzle clogging and inconsistent extrusion, requiring specialized extruder designs and carefully tuned printing parameters. Some researchers are investigating the use of diluents or plasticizers to improve flowability without significantly compromising the material's desirable properties.

Post-processing of UHMWPE 3D printed parts presents another set of challenges. The material's chemical resistance makes it difficult to bond or paint, limiting certain applications. Additionally, achieving a smooth surface finish can be challenging due to the material's properties, often requiring mechanical post-processing techniques.

Despite these challenges, ongoing research and development efforts are making progress in addressing these issues. Advanced printing techniques, such as selective laser sintering (SLS) for UHMWPE powders, are being explored to overcome some of the limitations associated with fused deposition modeling (FDM). Additionally, the development of composite UHMWPE materials, incorporating additives or reinforcing fibers, shows promise in enhancing printability and expanding the range of achievable properties.

The current state of UHMWPE 3D printing is characterized by limited commercial availability and specialized equipment requirements. Only a handful of companies offer UHMWPE filaments or powders specifically designed for 3D printing, which restricts accessibility for many potential users. The high melting point and viscosity of UHMWPE necessitate modified printing hardware capable of reaching and maintaining elevated temperatures, often exceeding 200°C.

One of the primary challenges in UHMWPE 3D printing is achieving consistent layer adhesion and part density. The material's low surface energy and high crystallinity can lead to poor interlayer bonding, resulting in weak mechanical properties in the Z-axis. Researchers and manufacturers are exploring various strategies to overcome this issue, including the use of plasma treatments, specialized bed materials, and optimized printing parameters.

Another significant challenge is controlling the thermal behavior of UHMWPE during the printing process. The material's high thermal expansion coefficient can cause warping and dimensional inaccuracies in printed parts. This necessitates careful temperature management throughout the printing process, including heated build chambers and gradual cooling strategies.

The high molecular weight of UHMWPE, while beneficial for its mechanical properties, poses challenges in terms of processability. The material's high melt viscosity can lead to nozzle clogging and inconsistent extrusion, requiring specialized extruder designs and carefully tuned printing parameters. Some researchers are investigating the use of diluents or plasticizers to improve flowability without significantly compromising the material's desirable properties.

Post-processing of UHMWPE 3D printed parts presents another set of challenges. The material's chemical resistance makes it difficult to bond or paint, limiting certain applications. Additionally, achieving a smooth surface finish can be challenging due to the material's properties, often requiring mechanical post-processing techniques.

Despite these challenges, ongoing research and development efforts are making progress in addressing these issues. Advanced printing techniques, such as selective laser sintering (SLS) for UHMWPE powders, are being explored to overcome some of the limitations associated with fused deposition modeling (FDM). Additionally, the development of composite UHMWPE materials, incorporating additives or reinforcing fibers, shows promise in enhancing printability and expanding the range of achievable properties.

Existing UHMWPE 3D Printing Solutions

01 Composition and properties of UHMWPE

Ultra-High Molecular Weight Polyethylene (UHMWPE) is a type of polyethylene with extremely long chains, resulting in a material with very high molecular weight. This unique structure gives UHMWPE exceptional properties, including high impact strength, low friction coefficient, and excellent wear resistance. These characteristics make it suitable for various applications in industries such as medical, aerospace, and manufacturing.- Composition and properties of UHMWPE: Ultra-High Molecular Weight Polyethylene (UHMWPE) is a type of polyethylene with extremely long chains, resulting in a very high molecular weight. This unique structure gives UHMWPE exceptional properties, including high impact strength, excellent abrasion resistance, low friction coefficient, and chemical inertness. These characteristics make it suitable for various applications in industries such as medical, aerospace, and manufacturing.

- Processing methods for UHMWPE: Various processing methods are employed to manufacture UHMWPE products, including compression molding, ram extrusion, and gel spinning. These techniques aim to overcome the challenges associated with the material's high viscosity and molecular weight. Advanced processing methods may involve the use of additives, controlled cooling rates, or specialized equipment to enhance the material's properties and processability.

- UHMWPE fiber and composite applications: UHMWPE fibers and composites are widely used in high-performance applications due to their exceptional strength-to-weight ratio and durability. These materials find use in ballistic protection, cut-resistant gloves, marine ropes, and sports equipment. Research focuses on improving fiber production techniques, enhancing interfacial adhesion in composites, and developing novel applications for these advanced materials.

- Modifications and enhancements of UHMWPE: Ongoing research aims to further improve the properties of UHMWPE through various modifications. These include crosslinking techniques to enhance wear resistance, incorporation of nanoparticles or reinforcing agents to improve mechanical properties, and surface treatments to modify friction characteristics or biocompatibility. Such enhancements expand the potential applications of UHMWPE in fields like orthopedic implants and industrial machinery.

- UHMWPE in medical applications: UHMWPE plays a crucial role in medical applications, particularly in orthopedic implants such as artificial joints. Its biocompatibility, low wear rate, and high impact resistance make it an ideal material for load-bearing implants. Research in this area focuses on improving wear resistance through crosslinking, enhancing longevity of implants, and developing new grades of UHMWPE with superior performance in the human body.

02 Processing methods for UHMWPE

Various processing methods are employed to manufacture UHMWPE products, including compression molding, ram extrusion, and gel spinning. These techniques aim to overcome the challenges associated with processing high molecular weight polymers while maintaining their desirable properties. Advanced processing methods may involve the use of additives or specialized equipment to enhance the material's performance or tailor it for specific applications.Expand Specific Solutions03 UHMWPE fiber and composite applications

UHMWPE fibers and composites are widely used in high-performance applications due to their exceptional strength-to-weight ratio and durability. These materials find use in ballistic protection, cut-resistant gloves, high-strength ropes, and sports equipment. The development of UHMWPE composites often involves combining the polymer with other materials to create products with enhanced properties for specific end-uses.Expand Specific Solutions04 Medical applications of UHMWPE

UHMWPE is extensively used in medical applications, particularly in orthopedic implants such as artificial joints. Its biocompatibility, low wear rate, and high impact resistance make it an ideal material for long-term implants. Ongoing research focuses on improving the wear resistance and longevity of UHMWPE implants through techniques such as cross-linking and the incorporation of antioxidants.Expand Specific Solutions05 Modifications and enhancements of UHMWPE

Researchers and manufacturers continually work on modifying and enhancing UHMWPE to improve its properties or add new functionalities. This includes the development of nanocomposites, surface treatments, and the incorporation of additives to enhance specific characteristics such as wear resistance, thermal stability, or electrical conductivity. These modifications aim to expand the range of applications for UHMWPE in various industries.Expand Specific Solutions

Key Players in UHMWPE 3D Printing Industry

The 3D printing industry's adoption of UHMWPE is in its early stages, with significant growth potential as the market for high-performance materials expands. The global UHMWPE market size is projected to increase substantially, driven by demand in various sectors including aerospace, defense, and medical applications. Technologically, UHMWPE in 3D printing is still evolving, with companies like DuPont, SABIC, and Braskem leading research and development efforts. These firms are focusing on improving processability and enhancing material properties for additive manufacturing applications. Academic institutions such as Sichuan University and the Chinese Academy of Sciences are also contributing to advancements in UHMWPE 3D printing technology, indicating a collaborative approach to innovation in this field.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed a proprietary UHMWPE filament for 3D printing called Surlyn. This filament combines the high strength and durability of UHMWPE with improved processability for additive manufacturing. The company has optimized the molecular weight and particle morphology to enhance flowability during extrusion while maintaining the desirable mechanical properties of UHMWPE[1]. DuPont's approach involves a specialized thermal treatment process to partially align the polymer chains, resulting in improved interlayer adhesion in 3D printed parts[2]. Additionally, they have incorporated nano-additives to further enhance the material's printability and final part performance[3].

Strengths: Expertise in polymer science, established manufacturing capabilities, and brand recognition. Weaknesses: Higher material costs compared to standard filaments, may require specialized printing equipment.

SABIC Global Technologies BV

Technical Solution: SABIC has introduced UHMWPE powder specifically designed for selective laser sintering (SLS) 3D printing. Their approach focuses on achieving a fine particle size distribution and optimized flow characteristics to ensure uniform layer deposition during the printing process[4]. SABIC's UHMWPE powder incorporates proprietary additives that enhance laser absorption and thermal conductivity, leading to improved part density and mechanical properties[5]. The company has also developed a post-processing technique involving controlled cooling and annealing to maximize crystallinity and reduce internal stresses in printed parts[6].

Strengths: Advanced material formulation expertise, global distribution network. Weaknesses: Limited to SLS technology, potentially higher equipment costs for end-users.

Core Innovations in UHMWPE 3D Printing

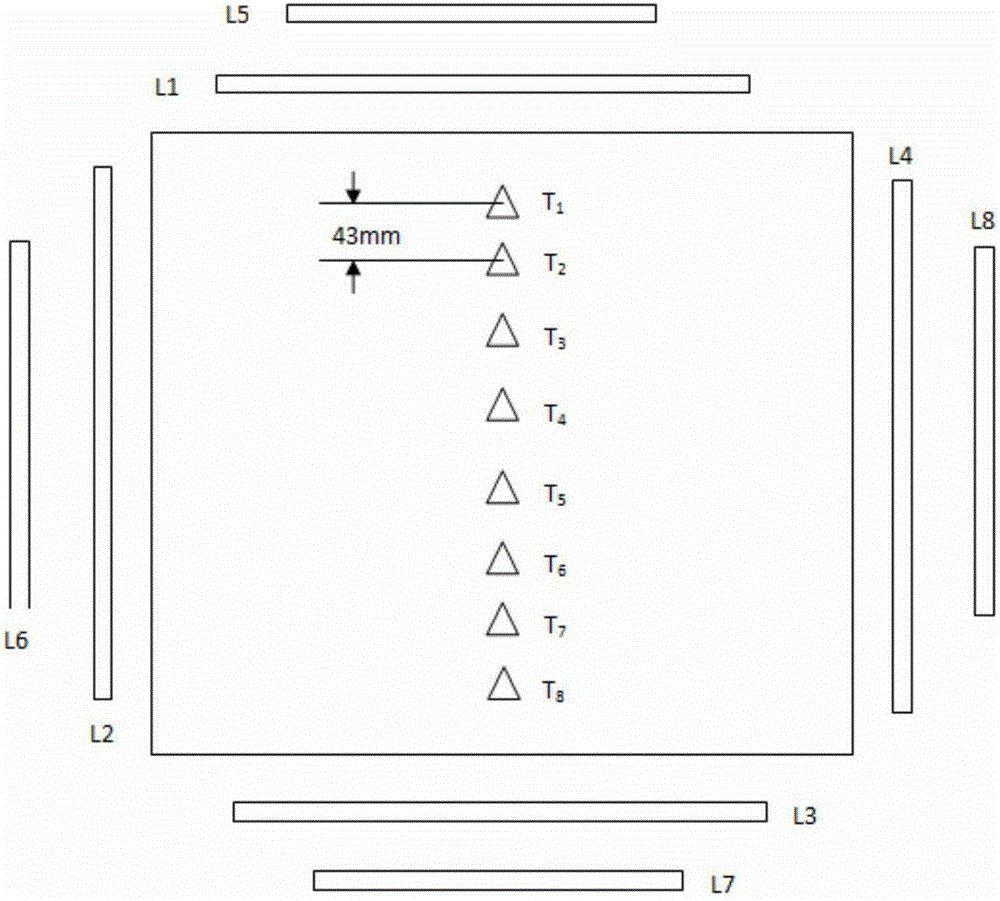

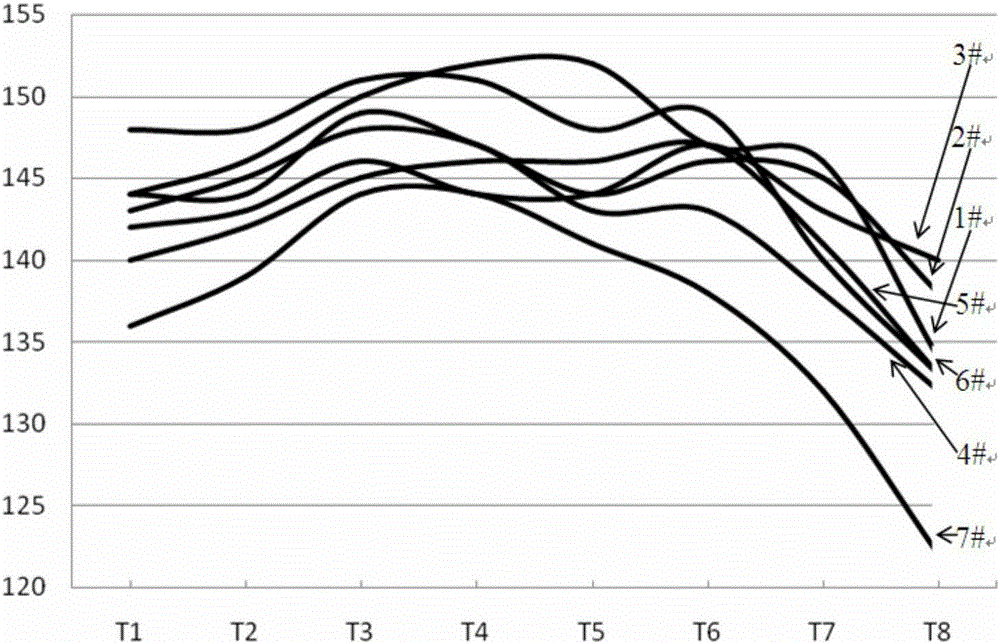

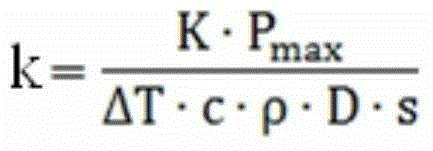

Selected region laser sintering and molding method of ultrahigh molecular weight polyethylene

PatentActiveCN105172154A

Innovation

- The selective laser sintering molding method of ultra-high molecular weight polyethylene is adopted. By heating to the preheating temperature in the selective laser sintering equipment, combined with the optimized laser scanning speed and output power, a double-layer heating lamp is used to ensure the uniformity of the temperature field, and the Insulation and cooling are carried out at a specific temperature to produce molded parts with high mechanical properties and dimensional accuracy.

Ultra-high molecular weight polyethylene

PatentWO2011089017A1

Innovation

- The use of a blend of two metallocene-type catalysts, with Hafnium (Hf) and Chromium (Cr) as catalyst residues, to produce UHMW-PE with medium density and enhanced Charpy impact resistance, achieving a synergistic effect that improves both abrasion and impact resistance, and maintaining a suitable average grain size.

Material Properties and Characterization

Ultra-high-molecular-weight polyethylene (UHMWPE) is a unique thermoplastic polymer with exceptional properties that make it an attractive material for various applications, including 3D printing. The characterization of UHMWPE is crucial for understanding its behavior and optimizing its use in additive manufacturing processes.

UHMWPE exhibits remarkable mechanical properties, including high tensile strength, excellent wear resistance, and low friction coefficient. Its molecular structure, consisting of extremely long chains of polyethylene, contributes to its superior performance. The material's high molecular weight, typically ranging from 3.5 to 7.5 million g/mol, results in a high degree of entanglement between polymer chains, leading to enhanced mechanical properties.

One of the key characteristics of UHMWPE is its exceptional abrasion resistance, which surpasses that of carbon steel. This property makes it ideal for applications requiring durability and longevity. Additionally, UHMWPE demonstrates excellent impact strength, even at low temperatures, making it suitable for use in harsh environments.

The thermal properties of UHMWPE are also noteworthy. It has a relatively low melting point of around 130-135°C, which is advantageous for 3D printing processes. However, its high melt viscosity poses challenges in traditional extrusion-based printing methods. The material's low coefficient of thermal expansion contributes to dimensional stability in printed parts.

Chemical resistance is another significant attribute of UHMWPE. It exhibits excellent resistance to a wide range of chemicals, including acids, bases, and organic solvents. This property makes it suitable for applications in corrosive environments and enhances the longevity of printed parts.

In terms of surface properties, UHMWPE has a low coefficient of friction, which contributes to its self-lubricating characteristics. This property is particularly beneficial in applications where reduced wear and improved sliding behavior are required. The material's hydrophobicity also makes it resistant to moisture absorption, enhancing its stability in various environmental conditions.

Characterization techniques for UHMWPE in 3D printing applications include differential scanning calorimetry (DSC) for thermal analysis, rheological measurements for understanding flow behavior, and mechanical testing to assess strength and durability. X-ray diffraction (XRD) and Fourier-transform infrared spectroscopy (FTIR) are employed to analyze the material's crystallinity and chemical structure, respectively.

Understanding these material properties and employing appropriate characterization methods are essential for optimizing UHMWPE's performance in 3D printing processes. By leveraging its unique characteristics, researchers and manufacturers can develop innovative applications and improve the quality of printed parts, opening new horizons in the additive manufacturing industry.

UHMWPE exhibits remarkable mechanical properties, including high tensile strength, excellent wear resistance, and low friction coefficient. Its molecular structure, consisting of extremely long chains of polyethylene, contributes to its superior performance. The material's high molecular weight, typically ranging from 3.5 to 7.5 million g/mol, results in a high degree of entanglement between polymer chains, leading to enhanced mechanical properties.

One of the key characteristics of UHMWPE is its exceptional abrasion resistance, which surpasses that of carbon steel. This property makes it ideal for applications requiring durability and longevity. Additionally, UHMWPE demonstrates excellent impact strength, even at low temperatures, making it suitable for use in harsh environments.

The thermal properties of UHMWPE are also noteworthy. It has a relatively low melting point of around 130-135°C, which is advantageous for 3D printing processes. However, its high melt viscosity poses challenges in traditional extrusion-based printing methods. The material's low coefficient of thermal expansion contributes to dimensional stability in printed parts.

Chemical resistance is another significant attribute of UHMWPE. It exhibits excellent resistance to a wide range of chemicals, including acids, bases, and organic solvents. This property makes it suitable for applications in corrosive environments and enhances the longevity of printed parts.

In terms of surface properties, UHMWPE has a low coefficient of friction, which contributes to its self-lubricating characteristics. This property is particularly beneficial in applications where reduced wear and improved sliding behavior are required. The material's hydrophobicity also makes it resistant to moisture absorption, enhancing its stability in various environmental conditions.

Characterization techniques for UHMWPE in 3D printing applications include differential scanning calorimetry (DSC) for thermal analysis, rheological measurements for understanding flow behavior, and mechanical testing to assess strength and durability. X-ray diffraction (XRD) and Fourier-transform infrared spectroscopy (FTIR) are employed to analyze the material's crystallinity and chemical structure, respectively.

Understanding these material properties and employing appropriate characterization methods are essential for optimizing UHMWPE's performance in 3D printing processes. By leveraging its unique characteristics, researchers and manufacturers can develop innovative applications and improve the quality of printed parts, opening new horizons in the additive manufacturing industry.

Sustainability and Recycling Considerations

The integration of Ultra-High Molecular Weight Polyethylene (UHMWPE) into the 3D printing industry brings forth significant considerations regarding sustainability and recycling. UHMWPE, known for its exceptional strength and durability, presents both opportunities and challenges in the context of environmental responsibility.

One of the primary advantages of UHMWPE in 3D printing is its potential for extended product lifecycles. The material's resistance to wear, chemicals, and impact means that products manufactured using UHMWPE are likely to last longer, reducing the need for frequent replacements and thereby minimizing waste generation. This longevity aligns well with sustainability goals by reducing the overall consumption of resources over time.

However, the very properties that make UHMWPE desirable also pose recycling challenges. The high molecular weight and strong intermolecular bonds that contribute to its durability also make it difficult to break down and reprocess. Traditional recycling methods may prove ineffective, necessitating the development of specialized recycling techniques tailored to UHMWPE.

Efforts are underway to address these recycling challenges. Research is focusing on advanced mechanical recycling processes that can maintain the material's properties through multiple cycles. Chemical recycling methods, which break down the polymer into its base components, are also being explored as a potential solution for UHMWPE waste.

The 3D printing industry's adoption of UHMWPE also opens up possibilities for more efficient material use. Additive manufacturing techniques can significantly reduce material waste compared to traditional subtractive manufacturing methods. This efficiency can contribute to a more sustainable production process, minimizing the environmental impact of manufacturing.

Furthermore, the ability to 3D print with UHMWPE allows for on-demand production and localized manufacturing. This can lead to reduced transportation needs and associated carbon emissions, as products can be produced closer to the point of use. It also enables easier customization and repair of products, potentially extending their useful life and reducing waste.

As the industry moves forward, there is a growing emphasis on developing circular economy models for UHMWPE in 3D printing. This involves designing products with end-of-life considerations in mind, creating closed-loop systems for material recovery, and investing in recycling infrastructure capable of handling UHMWPE waste effectively.

In conclusion, while UHMWPE offers significant benefits in terms of product durability and manufacturing efficiency, its integration into the 3D printing industry must be accompanied by concerted efforts to address recycling challenges. The development of innovative recycling technologies and the implementation of sustainable design practices will be crucial in realizing the full potential of UHMWPE while minimizing its environmental impact.

One of the primary advantages of UHMWPE in 3D printing is its potential for extended product lifecycles. The material's resistance to wear, chemicals, and impact means that products manufactured using UHMWPE are likely to last longer, reducing the need for frequent replacements and thereby minimizing waste generation. This longevity aligns well with sustainability goals by reducing the overall consumption of resources over time.

However, the very properties that make UHMWPE desirable also pose recycling challenges. The high molecular weight and strong intermolecular bonds that contribute to its durability also make it difficult to break down and reprocess. Traditional recycling methods may prove ineffective, necessitating the development of specialized recycling techniques tailored to UHMWPE.

Efforts are underway to address these recycling challenges. Research is focusing on advanced mechanical recycling processes that can maintain the material's properties through multiple cycles. Chemical recycling methods, which break down the polymer into its base components, are also being explored as a potential solution for UHMWPE waste.

The 3D printing industry's adoption of UHMWPE also opens up possibilities for more efficient material use. Additive manufacturing techniques can significantly reduce material waste compared to traditional subtractive manufacturing methods. This efficiency can contribute to a more sustainable production process, minimizing the environmental impact of manufacturing.

Furthermore, the ability to 3D print with UHMWPE allows for on-demand production and localized manufacturing. This can lead to reduced transportation needs and associated carbon emissions, as products can be produced closer to the point of use. It also enables easier customization and repair of products, potentially extending their useful life and reducing waste.

As the industry moves forward, there is a growing emphasis on developing circular economy models for UHMWPE in 3D printing. This involves designing products with end-of-life considerations in mind, creating closed-loop systems for material recovery, and investing in recycling infrastructure capable of handling UHMWPE waste effectively.

In conclusion, while UHMWPE offers significant benefits in terms of product durability and manufacturing efficiency, its integration into the 3D printing industry must be accompanied by concerted efforts to address recycling challenges. The development of innovative recycling technologies and the implementation of sustainable design practices will be crucial in realizing the full potential of UHMWPE while minimizing its environmental impact.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!