New induction motor technologies for high-altitude operations

AUG 18, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

High-Altitude Motor Tech Evolution and Objectives

Induction motors have been a cornerstone of industrial applications for over a century, but their performance in high-altitude environments has long been a challenge. The evolution of high-altitude motor technology has been driven by the increasing demand for reliable and efficient power systems in aerospace, mountainous regions, and other elevated locations where atmospheric conditions significantly differ from sea level.

The development of induction motors for high-altitude operations can be traced back to the mid-20th century when the aerospace industry began to expand rapidly. Early attempts to use standard motors at high altitudes resulted in reduced efficiency, overheating, and premature failure due to the lower air density and reduced cooling capacity. This led to the recognition that specialized motor designs were necessary for these extreme environments.

Throughout the 1960s and 1970s, researchers focused on improving insulation materials and cooling systems to address the thermal management issues prevalent in high-altitude operations. The introduction of advanced synthetic insulation materials and the development of forced-air and liquid cooling systems marked significant milestones in this period.

The 1980s and 1990s saw a shift towards optimizing motor designs specifically for high-altitude performance. This included the development of new rotor and stator configurations that could maintain efficiency and torque output despite the reduced air density. Computational fluid dynamics and thermal modeling techniques became instrumental in predicting motor behavior under various atmospheric conditions.

In recent years, the focus has shifted towards integrating smart technologies and advanced materials into high-altitude motor designs. The use of rare-earth magnets, superconducting materials, and advanced power electronics has pushed the boundaries of motor performance in extreme environments. Additionally, the incorporation of sensors and real-time monitoring systems has enhanced the reliability and adaptability of these motors.

The current technological objectives for high-altitude induction motors are multifaceted. Researchers and engineers are striving to further improve energy efficiency, reduce weight, and enhance power density to meet the demanding requirements of modern applications. There is also a growing emphasis on developing motors that can operate across a wider range of altitudes without significant performance degradation.

Another key objective is the integration of these motors with renewable energy systems, particularly in remote high-altitude locations where traditional power infrastructure is limited. This includes developing hybrid systems that can seamlessly switch between different power sources and operate efficiently under variable load conditions.

Looking ahead, the future of high-altitude motor technology is likely to be shaped by advancements in materials science, thermal management techniques, and intelligent control systems. The ultimate goal is to create induction motors that can deliver consistent, high-performance operation regardless of altitude, while also meeting increasingly stringent environmental and efficiency standards.

The development of induction motors for high-altitude operations can be traced back to the mid-20th century when the aerospace industry began to expand rapidly. Early attempts to use standard motors at high altitudes resulted in reduced efficiency, overheating, and premature failure due to the lower air density and reduced cooling capacity. This led to the recognition that specialized motor designs were necessary for these extreme environments.

Throughout the 1960s and 1970s, researchers focused on improving insulation materials and cooling systems to address the thermal management issues prevalent in high-altitude operations. The introduction of advanced synthetic insulation materials and the development of forced-air and liquid cooling systems marked significant milestones in this period.

The 1980s and 1990s saw a shift towards optimizing motor designs specifically for high-altitude performance. This included the development of new rotor and stator configurations that could maintain efficiency and torque output despite the reduced air density. Computational fluid dynamics and thermal modeling techniques became instrumental in predicting motor behavior under various atmospheric conditions.

In recent years, the focus has shifted towards integrating smart technologies and advanced materials into high-altitude motor designs. The use of rare-earth magnets, superconducting materials, and advanced power electronics has pushed the boundaries of motor performance in extreme environments. Additionally, the incorporation of sensors and real-time monitoring systems has enhanced the reliability and adaptability of these motors.

The current technological objectives for high-altitude induction motors are multifaceted. Researchers and engineers are striving to further improve energy efficiency, reduce weight, and enhance power density to meet the demanding requirements of modern applications. There is also a growing emphasis on developing motors that can operate across a wider range of altitudes without significant performance degradation.

Another key objective is the integration of these motors with renewable energy systems, particularly in remote high-altitude locations where traditional power infrastructure is limited. This includes developing hybrid systems that can seamlessly switch between different power sources and operate efficiently under variable load conditions.

Looking ahead, the future of high-altitude motor technology is likely to be shaped by advancements in materials science, thermal management techniques, and intelligent control systems. The ultimate goal is to create induction motors that can deliver consistent, high-performance operation regardless of altitude, while also meeting increasingly stringent environmental and efficiency standards.

Market Analysis for High-Altitude Motors

The market for high-altitude induction motors is experiencing significant growth, driven by the increasing demand for reliable and efficient power systems in aerospace, aviation, and high-altitude applications. As industries expand their operations to more challenging environments, the need for motors capable of performing optimally at high altitudes has become crucial.

The aerospace sector represents a substantial portion of the market, with applications ranging from commercial aircraft to military planes and unmanned aerial vehicles (UAVs). These vehicles require motors that can maintain performance and efficiency at altitudes where air density is significantly lower. The aviation industry's continuous expansion, particularly in regions with high-altitude airports, further fuels the demand for specialized motor technologies.

Another key market segment is high-altitude industrial applications, including mining operations in mountainous regions, high-altitude observatories, and telecommunications infrastructure. These sectors require robust motor systems that can withstand the harsh conditions associated with high-altitude environments, such as extreme temperature fluctuations and reduced cooling efficiency.

The renewable energy sector, particularly wind power generation in high-altitude locations, presents a growing opportunity for specialized induction motor technologies. As wind farms are increasingly established in mountainous terrains to harness stronger and more consistent wind patterns, the demand for motors capable of operating efficiently in these conditions is rising.

Market trends indicate a shift towards more compact, lightweight, and energy-efficient motor designs. This is particularly important for aerospace applications where weight reduction directly translates to fuel savings and increased payload capacity. Additionally, there is a growing emphasis on motors with enhanced thermal management capabilities to address the cooling challenges at high altitudes.

The global market for high-altitude induction motors is geographically diverse, with North America and Europe leading in terms of technological advancements and market share. However, emerging economies in Asia-Pacific and South America are showing rapid growth, driven by increasing industrialization in high-altitude regions and expanding aerospace sectors.

Key factors influencing market growth include ongoing technological advancements in motor design, materials science, and power electronics. These innovations are enabling the development of more efficient and reliable high-altitude motor solutions. Additionally, stringent environmental regulations and the push for reduced carbon emissions are driving the adoption of more energy-efficient motor technologies across various industries.

The aerospace sector represents a substantial portion of the market, with applications ranging from commercial aircraft to military planes and unmanned aerial vehicles (UAVs). These vehicles require motors that can maintain performance and efficiency at altitudes where air density is significantly lower. The aviation industry's continuous expansion, particularly in regions with high-altitude airports, further fuels the demand for specialized motor technologies.

Another key market segment is high-altitude industrial applications, including mining operations in mountainous regions, high-altitude observatories, and telecommunications infrastructure. These sectors require robust motor systems that can withstand the harsh conditions associated with high-altitude environments, such as extreme temperature fluctuations and reduced cooling efficiency.

The renewable energy sector, particularly wind power generation in high-altitude locations, presents a growing opportunity for specialized induction motor technologies. As wind farms are increasingly established in mountainous terrains to harness stronger and more consistent wind patterns, the demand for motors capable of operating efficiently in these conditions is rising.

Market trends indicate a shift towards more compact, lightweight, and energy-efficient motor designs. This is particularly important for aerospace applications where weight reduction directly translates to fuel savings and increased payload capacity. Additionally, there is a growing emphasis on motors with enhanced thermal management capabilities to address the cooling challenges at high altitudes.

The global market for high-altitude induction motors is geographically diverse, with North America and Europe leading in terms of technological advancements and market share. However, emerging economies in Asia-Pacific and South America are showing rapid growth, driven by increasing industrialization in high-altitude regions and expanding aerospace sectors.

Key factors influencing market growth include ongoing technological advancements in motor design, materials science, and power electronics. These innovations are enabling the development of more efficient and reliable high-altitude motor solutions. Additionally, stringent environmental regulations and the push for reduced carbon emissions are driving the adoption of more energy-efficient motor technologies across various industries.

Current Challenges in High-Altitude Motor Design

The design of induction motors for high-altitude operations presents several unique challenges that engineers must overcome to ensure optimal performance and reliability. One of the primary issues is the reduced air density at high altitudes, which significantly impacts the motor's cooling capabilities. As the air becomes thinner, its ability to dissipate heat decreases, leading to potential overheating problems in the motor. This necessitates innovative cooling solutions or the development of motors that can operate efficiently at higher temperatures.

Another critical challenge is the reduced dielectric strength of air at high altitudes. The lower air pressure can lead to increased risk of electrical breakdown and arcing between motor components. This phenomenon, known as corona discharge, can cause insulation degradation and ultimately lead to motor failure. Engineers must carefully consider insulation materials and designs that can withstand these harsh conditions.

The extreme temperature variations encountered in high-altitude environments also pose significant challenges. Motors must be designed to operate reliably in both extremely cold conditions during ascent and potentially high temperatures due to reduced cooling efficiency. This wide temperature range puts stress on motor components, particularly bearings and lubricants, which may require special formulations or designs to maintain proper function.

Moisture condensation is another issue that becomes more pronounced at high altitudes. As aircraft ascend and descend through different atmospheric layers, rapid temperature changes can cause condensation to form inside the motor. This moisture can lead to corrosion, electrical shorts, and insulation breakdown. Effective sealing and moisture management strategies are essential to mitigate these risks.

The reduced atmospheric pressure at high altitudes also affects the motor's ability to dissipate ozone, which is generated by electrical discharges. Ozone accumulation can accelerate the degradation of insulation materials and other motor components. Engineers must consider materials and designs that are resistant to ozone damage or implement strategies to minimize ozone generation and accumulation.

Furthermore, the mechanical stresses induced by rapid pressure changes during ascent and descent can impact motor performance and longevity. These pressure variations can affect the structural integrity of motor components and may require special considerations in the design of seals, gaskets, and enclosures to prevent deformation or failure.

Lastly, the weight constraints inherent in aerospace applications add another layer of complexity to high-altitude motor design. Engineers must balance the need for robust, high-performance motors with the imperative to minimize overall weight. This often necessitates the use of advanced materials and innovative design techniques to achieve the required power output and reliability while keeping the motor as lightweight as possible.

Another critical challenge is the reduced dielectric strength of air at high altitudes. The lower air pressure can lead to increased risk of electrical breakdown and arcing between motor components. This phenomenon, known as corona discharge, can cause insulation degradation and ultimately lead to motor failure. Engineers must carefully consider insulation materials and designs that can withstand these harsh conditions.

The extreme temperature variations encountered in high-altitude environments also pose significant challenges. Motors must be designed to operate reliably in both extremely cold conditions during ascent and potentially high temperatures due to reduced cooling efficiency. This wide temperature range puts stress on motor components, particularly bearings and lubricants, which may require special formulations or designs to maintain proper function.

Moisture condensation is another issue that becomes more pronounced at high altitudes. As aircraft ascend and descend through different atmospheric layers, rapid temperature changes can cause condensation to form inside the motor. This moisture can lead to corrosion, electrical shorts, and insulation breakdown. Effective sealing and moisture management strategies are essential to mitigate these risks.

The reduced atmospheric pressure at high altitudes also affects the motor's ability to dissipate ozone, which is generated by electrical discharges. Ozone accumulation can accelerate the degradation of insulation materials and other motor components. Engineers must consider materials and designs that are resistant to ozone damage or implement strategies to minimize ozone generation and accumulation.

Furthermore, the mechanical stresses induced by rapid pressure changes during ascent and descent can impact motor performance and longevity. These pressure variations can affect the structural integrity of motor components and may require special considerations in the design of seals, gaskets, and enclosures to prevent deformation or failure.

Lastly, the weight constraints inherent in aerospace applications add another layer of complexity to high-altitude motor design. Engineers must balance the need for robust, high-performance motors with the imperative to minimize overall weight. This often necessitates the use of advanced materials and innovative design techniques to achieve the required power output and reliability while keeping the motor as lightweight as possible.

Existing High-Altitude Motor Solutions

01 Design and construction of induction motors

This category covers the fundamental design and construction aspects of induction motors, including rotor and stator configurations, winding arrangements, and core materials. Innovations in these areas aim to improve efficiency, power output, and overall performance of the motors.- Design and construction of induction motors: This category covers the fundamental design and construction aspects of induction motors, including rotor and stator configurations, winding arrangements, and core materials. Innovations in these areas aim to improve motor efficiency, power output, and overall performance.

- Control systems for induction motors: Control systems play a crucial role in regulating the speed, torque, and efficiency of induction motors. This category encompasses various control strategies, including vector control, direct torque control, and sensorless control techniques, as well as the implementation of advanced microcontrollers and power electronics for motor control.

- Energy efficiency improvements in induction motors: This category focuses on techniques and technologies aimed at enhancing the energy efficiency of induction motors. This includes the use of high-efficiency materials, optimized designs, and advanced control algorithms to reduce power losses and improve overall motor performance.

- Specialized applications of induction motors: Induction motors are used in various specialized applications, each with unique requirements. This category covers modifications and adaptations of induction motors for specific industries or purposes, such as high-speed motors, submersible motors, or motors designed for harsh environments.

- Diagnostics and condition monitoring of induction motors: This category encompasses methods and systems for monitoring the health and performance of induction motors. It includes techniques for fault detection, predictive maintenance, and real-time performance analysis to ensure optimal motor operation and prevent unexpected failures.

02 Control systems for induction motors

Control systems play a crucial role in regulating the speed, torque, and efficiency of induction motors. This category encompasses various control strategies, including vector control, direct torque control, and advanced algorithms for optimizing motor performance under different operating conditions.Expand Specific Solutions03 Energy efficiency improvements in induction motors

This category focuses on techniques and technologies aimed at enhancing the energy efficiency of induction motors. This includes the use of advanced materials, improved cooling systems, and innovative designs to reduce losses and increase overall efficiency.Expand Specific Solutions04 Specialized applications of induction motors

Induction motors are used in a wide range of specialized applications, each with unique requirements. This category covers adaptations and modifications of induction motors for specific industries or purposes, such as high-speed operations, harsh environments, or integration with renewable energy systems.Expand Specific Solutions05 Maintenance and diagnostics of induction motors

Effective maintenance and diagnostics are essential for ensuring the longevity and reliability of induction motors. This category includes methods for condition monitoring, fault detection, and predictive maintenance techniques to minimize downtime and extend the operational life of induction motors.Expand Specific Solutions

Key Players in High-Altitude Motor Industry

The development of new induction motor technologies for high-altitude operations is in a nascent stage, with significant potential for growth as aerospace and defense industries expand their high-altitude capabilities. The market size is relatively small but expected to increase as demand for specialized motors in extreme environments grows. Technologically, the field is still evolving, with companies like Cummins, Inc., Hitachi Ltd., and The Boeing Co. leading research efforts. These firms are leveraging their expertise in power systems and aerospace engineering to develop more efficient and reliable motors for high-altitude applications. While progress has been made, further advancements are needed to fully address the challenges of operating in low-pressure, low-temperature environments at high altitudes.

The Boeing Co.

Technical Solution: Boeing has developed advanced induction motor technologies for high-altitude operations, focusing on improving efficiency and reliability in low-pressure environments. Their approach includes the use of specialized insulation materials and cooling systems to prevent overheating and electrical breakdown at high altitudes[1]. Boeing's motors incorporate advanced rotor designs with high-strength alloys to withstand the increased stresses of high-speed operation in thin air[2]. They have also implemented sophisticated control algorithms that adjust motor parameters in real-time based on altitude and atmospheric conditions, ensuring optimal performance across a wide range of operating environments[3].

Strengths: Extensive aerospace experience, advanced materials expertise, and sophisticated control systems. Weaknesses: High development costs and potential over-engineering for some applications.

World View Enterprises, Inc.

Technical Solution: World View Enterprises has pioneered induction motor technologies specifically designed for stratospheric balloon operations. Their motors feature ultra-lightweight construction using advanced composite materials to minimize payload weight[4]. The company has developed a unique cooling system that leverages the extreme cold of high altitudes to maintain optimal motor temperatures without adding significant weight[5]. World View's motors also incorporate specialized bearings and lubricants designed to function in near-vacuum conditions, ensuring long-term reliability during extended high-altitude missions[6].

Strengths: Specialized in high-altitude applications, innovative lightweight designs. Weaknesses: Limited applicability to other industries, potentially higher unit costs due to specialized components.

Innovations in High-Altitude Motor Design

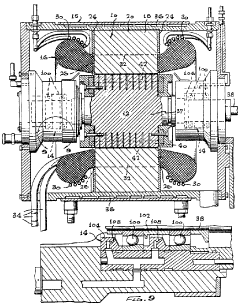

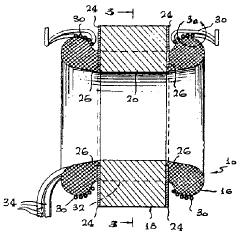

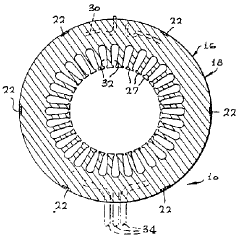

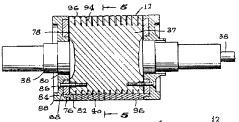

High speed induction motor

PatentInactiveJP1987141945A

Innovation

- The design incorporates a water-cooled single-stage rotor assembly with a hard alloy steel rotor and copper conductors, titanium end caps, and an oil jet lubricated bearing system, along with a laminated core assembly for heat dissipation and a unique rotor construction that includes semi-closed slots and radial restraints to manage centrifugal forces.

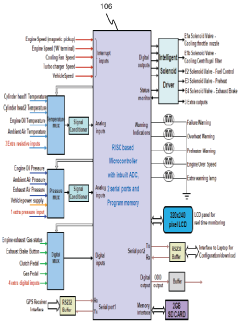

ECU with high altitude kit (HAK)

PatentActiveIN201941007630A

Innovation

- An electronically controlled valve system between the air intake manifold and pressure corrector, controlled by an electronic control unit, regulates intake air flow to manage fuel injection and reduce heat generation in internal combustion engines, preventing overheating and turbocharger over-speeding.

Environmental Impact of High-Altitude Motors

The environmental impact of high-altitude motors, particularly induction motors designed for operation in elevated regions, is a critical consideration in their development and deployment. These motors, while essential for various applications in high-altitude environments, can have significant ecological implications that must be carefully evaluated and mitigated.

One of the primary environmental concerns associated with high-altitude motors is their energy consumption. Operating in thin air and extreme conditions often requires motors to work harder, potentially leading to increased power usage. This heightened energy demand can indirectly contribute to greater greenhouse gas emissions if the electricity source is not renewable. Consequently, the development of more efficient motor technologies for high-altitude operations is crucial to minimize the carbon footprint of these systems.

Noise pollution is another environmental factor to consider. High-altitude motors may produce higher levels of noise due to the need for increased power and the challenges of heat dissipation in rarified air. This can have detrimental effects on local wildlife, particularly in sensitive mountain ecosystems where many species rely on acoustic communication for survival and reproduction.

The materials used in high-altitude motors also play a role in their environmental impact. These motors often require specialized materials to withstand extreme temperatures and low air pressure, which may involve the use of rare earth elements or other resources with significant extraction and processing footprints. The lifecycle assessment of these materials, from mining to disposal, is an important aspect of evaluating the overall environmental sustainability of high-altitude motor technologies.

Thermal management in high-altitude environments presents unique challenges that can affect local microclimates. The heat generated by these motors, if not properly managed, can contribute to localized warming effects, potentially disrupting delicate alpine or high-altitude ecosystems. Innovative cooling solutions that are both effective and environmentally friendly are essential for mitigating these thermal impacts.

The installation and maintenance of high-altitude motors can also have environmental consequences. The construction of infrastructure to support these motors in remote, high-altitude locations may lead to habitat disruption and fragmentation. Regular maintenance activities can further stress these sensitive environments if not conducted with proper care and environmental safeguards.

As the demand for high-altitude operations grows, particularly in sectors such as renewable energy (e.g., wind turbines in mountainous regions), telecommunications, and scientific research, the cumulative environmental impact of these motors becomes increasingly significant. This underscores the importance of developing and implementing sustainable practices in the design, manufacture, operation, and end-of-life management of high-altitude induction motors.

One of the primary environmental concerns associated with high-altitude motors is their energy consumption. Operating in thin air and extreme conditions often requires motors to work harder, potentially leading to increased power usage. This heightened energy demand can indirectly contribute to greater greenhouse gas emissions if the electricity source is not renewable. Consequently, the development of more efficient motor technologies for high-altitude operations is crucial to minimize the carbon footprint of these systems.

Noise pollution is another environmental factor to consider. High-altitude motors may produce higher levels of noise due to the need for increased power and the challenges of heat dissipation in rarified air. This can have detrimental effects on local wildlife, particularly in sensitive mountain ecosystems where many species rely on acoustic communication for survival and reproduction.

The materials used in high-altitude motors also play a role in their environmental impact. These motors often require specialized materials to withstand extreme temperatures and low air pressure, which may involve the use of rare earth elements or other resources with significant extraction and processing footprints. The lifecycle assessment of these materials, from mining to disposal, is an important aspect of evaluating the overall environmental sustainability of high-altitude motor technologies.

Thermal management in high-altitude environments presents unique challenges that can affect local microclimates. The heat generated by these motors, if not properly managed, can contribute to localized warming effects, potentially disrupting delicate alpine or high-altitude ecosystems. Innovative cooling solutions that are both effective and environmentally friendly are essential for mitigating these thermal impacts.

The installation and maintenance of high-altitude motors can also have environmental consequences. The construction of infrastructure to support these motors in remote, high-altitude locations may lead to habitat disruption and fragmentation. Regular maintenance activities can further stress these sensitive environments if not conducted with proper care and environmental safeguards.

As the demand for high-altitude operations grows, particularly in sectors such as renewable energy (e.g., wind turbines in mountainous regions), telecommunications, and scientific research, the cumulative environmental impact of these motors becomes increasingly significant. This underscores the importance of developing and implementing sustainable practices in the design, manufacture, operation, and end-of-life management of high-altitude induction motors.

Reliability and Safety Standards for High-Altitude Motors

The reliability and safety standards for high-altitude motors are crucial considerations in the development and implementation of new induction motor technologies for high-altitude operations. These standards are designed to ensure the consistent performance and longevity of motors operating in challenging environmental conditions, while also prioritizing the safety of personnel and equipment.

One of the primary concerns for high-altitude motors is the reduced air density, which affects cooling efficiency and insulation properties. To address this, standards often require enhanced thermal management systems and specialized insulation materials that can withstand the extreme temperature fluctuations common at high altitudes. These standards may specify the use of advanced cooling techniques, such as forced-air cooling or liquid cooling systems, to maintain optimal operating temperatures.

Electrical insulation standards for high-altitude motors are particularly stringent due to the increased risk of partial discharge and electrical breakdown in low-pressure environments. Standards typically mandate the use of corona-resistant insulation materials and designs that minimize air gaps within the motor structure. Additionally, they may require extensive testing procedures to verify the insulation system's performance under simulated high-altitude conditions.

Mechanical reliability standards focus on the structural integrity of motor components subjected to extreme environmental stresses. These standards often specify the use of materials with high strength-to-weight ratios and resistance to thermal cycling. Vibration and shock resistance requirements are also typically more demanding for high-altitude motors, necessitating robust mounting systems and reinforced internal components.

Safety standards for high-altitude motors emphasize protection against electrical faults and overheating. These may include requirements for advanced monitoring systems that can detect anomalies in motor performance and trigger automatic shutdown procedures. Standards often mandate the integration of multiple layers of protection, such as thermal overload relays, current-limiting devices, and emergency stop mechanisms.

Electromagnetic compatibility (EMC) standards are another critical aspect of high-altitude motor regulations. These standards ensure that motors do not generate excessive electromagnetic interference that could affect other sensitive equipment operating in the same environment. Conversely, they also require motors to be resistant to external electromagnetic disturbances.

Certification and testing procedures for high-altitude motors are typically more rigorous than those for standard motors. Standards may require extensive environmental testing, including operation in hypobaric chambers to simulate high-altitude conditions. Accelerated life testing and stress testing under extreme conditions are often mandated to verify long-term reliability and performance.

As technology advances, these standards are continually evolving to incorporate new materials, design techniques, and safety features. Regulatory bodies and industry associations work closely with manufacturers to update standards, ensuring they remain relevant and effective in promoting the reliability and safety of high-altitude motor technologies.

One of the primary concerns for high-altitude motors is the reduced air density, which affects cooling efficiency and insulation properties. To address this, standards often require enhanced thermal management systems and specialized insulation materials that can withstand the extreme temperature fluctuations common at high altitudes. These standards may specify the use of advanced cooling techniques, such as forced-air cooling or liquid cooling systems, to maintain optimal operating temperatures.

Electrical insulation standards for high-altitude motors are particularly stringent due to the increased risk of partial discharge and electrical breakdown in low-pressure environments. Standards typically mandate the use of corona-resistant insulation materials and designs that minimize air gaps within the motor structure. Additionally, they may require extensive testing procedures to verify the insulation system's performance under simulated high-altitude conditions.

Mechanical reliability standards focus on the structural integrity of motor components subjected to extreme environmental stresses. These standards often specify the use of materials with high strength-to-weight ratios and resistance to thermal cycling. Vibration and shock resistance requirements are also typically more demanding for high-altitude motors, necessitating robust mounting systems and reinforced internal components.

Safety standards for high-altitude motors emphasize protection against electrical faults and overheating. These may include requirements for advanced monitoring systems that can detect anomalies in motor performance and trigger automatic shutdown procedures. Standards often mandate the integration of multiple layers of protection, such as thermal overload relays, current-limiting devices, and emergency stop mechanisms.

Electromagnetic compatibility (EMC) standards are another critical aspect of high-altitude motor regulations. These standards ensure that motors do not generate excessive electromagnetic interference that could affect other sensitive equipment operating in the same environment. Conversely, they also require motors to be resistant to external electromagnetic disturbances.

Certification and testing procedures for high-altitude motors are typically more rigorous than those for standard motors. Standards may require extensive environmental testing, including operation in hypobaric chambers to simulate high-altitude conditions. Accelerated life testing and stress testing under extreme conditions are often mandated to verify long-term reliability and performance.

As technology advances, these standards are continually evolving to incorporate new materials, design techniques, and safety features. Regulatory bodies and industry associations work closely with manufacturers to update standards, ensuring they remain relevant and effective in promoting the reliability and safety of high-altitude motor technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!